Thermal-mechanical coupled numerical analysis of laser + GMAW hybrid heat source welding process

-

摘要: 从宏观的焊接热过程出发,根据激光+GMAW复合热源焊接的特点,提出了适用于复合热源焊接的“双椭球体+峰值递增圆柱体”组合式体积热源分布模式;建立了激光+GMAW复合热源焊接过程的有限元模型,数值计算了焊接温度场和焊缝横截面的形状尺寸,计算结果与试验结果吻合良好,证明了组合式体积热源模型的合理性和适用性. 采用焊接温度场的计算结果,进一步对复合热源焊接和GMAW的焊接变形和残余应力进行了数值模拟和对比分析. 结果表明,在焊缝熔深基本相同的情况下,复合热源焊接的焊接热输入、焊缝熔宽、焊接变形和高应力区域范围等均比GMAW小. 研究结果印证了激光+GMAW复合热源焊接工艺的优越性,并为焊接工艺参数的优化提供了基础理论数据.Abstract: From the viewpoint of macroscopic phenomena in heat transfer, a combined “double-ellipsoid + linearly-increased peak value cylinder” volumetric heat source distribution mode was proposed according to the characteristics of laser + GMAW hybrid heat source welding process. A finite element model of laser + GMAW hybrid heat source welding process was established. The temperature distribution, and the size of the weld cross-section were numerically calculated. It can be observed that the calculated results were in good agreement with the experimental results, which proves the rationality and applicability of the combined volumetric heat source model. And then, the calculated temperature field was utilized for the numerical modeling and comparison of the welding deformation and residual stress between GMAW and laser + GMAW hybrid welding process. The results shown that the heat input, weld width, welding deformation and high residual stress region of laser + GMAW hybrid welding were all much smaller than that of GMAW with the identical weld pool depth. The research confirmed the advantages of laser + GMAW hybrid welding, and provided basic theoretical data for the optimization of process parameters.

-

0. 序 言

激光+GMAW(gas metal arc welding, 熔化极气体保护焊)将激光和熔化极电弧这两种物理性质、能量传输机制截然不同的热源复合在一起[1-2],充分利用两种热源各自的优点,并有效地弥补了各自的不足,目前已在工业领域获得了广泛的应用. 近年来,研究者针对激光+GMAW复合焊接工艺和焊接机理进行了大量的研究工作. 研究证实,激光与GMAW复合作用可有效提高焊缝熔深,且对间隙、错边和对中偏离的容忍度均较强[3],电弧能够有效地提高被焊材料对激光能量的吸收能力[4];激光能够稳定电弧,同时能够引导和收缩电弧,且激光和电弧复合能够显著提高焊接速度[5].

近年来,研究者针对激光焊和电弧焊进行了大量的建模计算研究,分析了焊接温度场和应力应变场[6-8]. 虽然也开展了一些针对激光+GMAW复合焊接过程的数值模拟研究[9],但整体来看目前的研究还不够深入,且复合焊接与GMAW在焊接变形和残余应力等方面的对比研究鲜有报道. 在激光+GMAW复合焊接过程中,由于激光与GMAW电弧相互作用的复杂性,难以采用试验测试的方法对激光+GMAW复合焊接过程中电弧和激光的特性进行精确测量. 因此,从宏观传热过程出发,不考虑复杂的激光小孔动力学特性,以复合热源焊接的焊缝横断面形状尺寸为依据,采用SYSWELD软件建立反映复合热源热力作用特点的体积热源模型,并进行焊接温度场的计算;在此基础上,利用工件温度分布数据作为初始温度场进行应力应变的有限元数值计算,为激光+GMAW复合焊接工艺的优化提供基础理论数据.

1. 复合热源温度场的数值计算

1.1 组合式体积热源模型

对于激光+GMAW复合焊接来说,由于焊缝下半部分体积较小且散热较块,因此采用中心热流不变的作用模式很难计算得到理想的熔池轮廓. 考虑到激光与电弧之间的相互作用,以及激光在小孔内壁多次反射所起到的增强效果,采用峰值热流递增的热源,有效地对深度方向上的热流功率进行补偿. 因此,根据激光+GMAW复合热源焊接焊缝横断面几何形状的特点,建立“双椭球体热源+峰值递增圆柱体热源”的组合式体积热源模型.

热源上半部分采用双椭球体热源,即

$$ \begin{split} q(x,y,{\textit{z}}) =& \dfrac{{12\sqrt 3 Q{\chi _1}}}{{{\text{π}} \sqrt {\text{π}} a({b_1} + {b_2})c}}\exp \left( {\dfrac{{ - 3{x^2}}}{{{a^2}}}} \right) \exp \left( {\dfrac{{ - 3{y^2}}}{{b_1^2}}} \right)\\ &\exp \left( {\dfrac{{ - 3{{\textit{z}}^2}}}{{{c^2}}}} \right) (y < 0,{\textit{z}} \leqslant {H_1}) \end{split} $$ (1) $$ \begin{split} q(x,y,{\textit{z}}) =& \dfrac{{12\sqrt 3 Q{\chi _1}}}{{{\text{π}} \sqrt {\text{π}} a({b_1} + {b_2})c}}\exp \left( {\dfrac{{ - 3{x^2}}}{{{a^2}}}} \right)\exp \left( {\dfrac{{ - 3{y^2}}}{{b_2^2}}} \right)\\ &\exp \left( {\dfrac{{ - 3{{\textit{z}}^2}}}{{{c^2}}}} \right) (y \geqslant 0,{\textit{z}} \leqslant {H_1}) \end{split} $$ (2) 式中:Q为总热源;a,b1,b2和c均为半椭球体的分布参数.

热源下半部分采用热流递增的圆柱体热源,即

$$ \begin{split} {q_{V2}}(r,{\textit{z}}) =& \dfrac{{6Q{\chi _2}}}{{{\text{π}} {r_0}H(mH + 2{r_0})}}\exp \left( {\dfrac{{ - 3{r^2}}}{{r_0^2}}} \right)\left( {\dfrac{{m{\rm{{\textit{z}}}} + {r_0}}}{{{r_0}}}} \right)\\ &\qquad\quad \left( {{H_1} < {\textit{z}} \leqslant d} \right) \end{split} $$ (3) 式中:d为板厚;H1为双椭球体热源的作用高度,m为调节系数;H为圆柱体热源的作用高度;r0为圆柱体热源的作用半径;χ1和χ2分别为组合式热源上、下两部分的功率分配系数,有

$$ {\chi _1} + {\chi _2} = 1 $$ (4) χ1和χ2的取值依据电弧和激光的功率占比来确定,即

$${\chi _1} = \dfrac{{{Q_{\rm{A}}}}}{Q}$$ (5) $${\chi _2} = \dfrac{{{Q_{\rm{L}}}}}{Q}$$ (6) 式中:QA和QL分别是电弧和激光的功率.

1.2 材料热物性参数

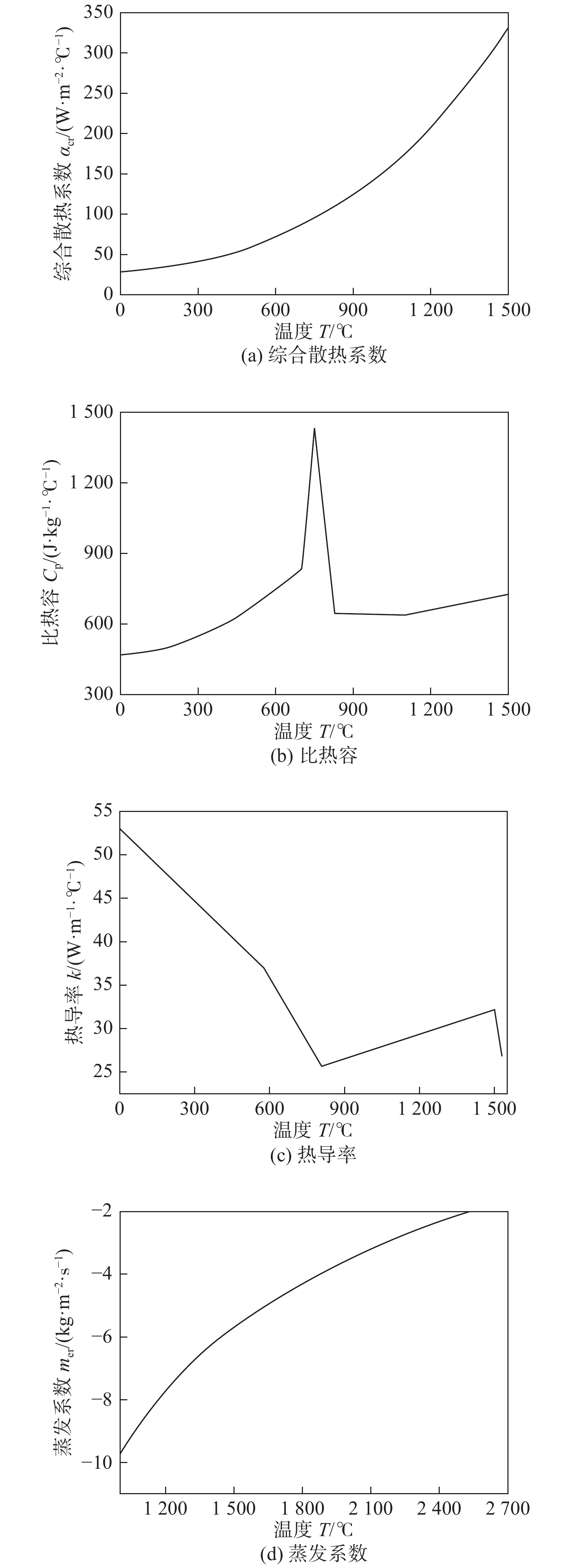

试验中采用的被焊材料为8 mm厚Q235低碳钢板,其热物性参数中的综合散热系数、比热容、热导率和蒸发系数均随温度的变化而变化,如图1所示. 模型中采用的其它参数取值如表1所示.

表 1 模型中的其它参数取值Table 1. Other parameters used in the model环境温度

${T_\infty }$/K熔点

${T_{\rm{m}}}$/K密度

$\;\rho $/(kg·m−3)蒸发潜热

${L_{\rm{b}}}$/(105 J·kg−1)重力加速度

$g$/(m·s−2)293 1773 6900 73.43 9.8 1.3 网格划分

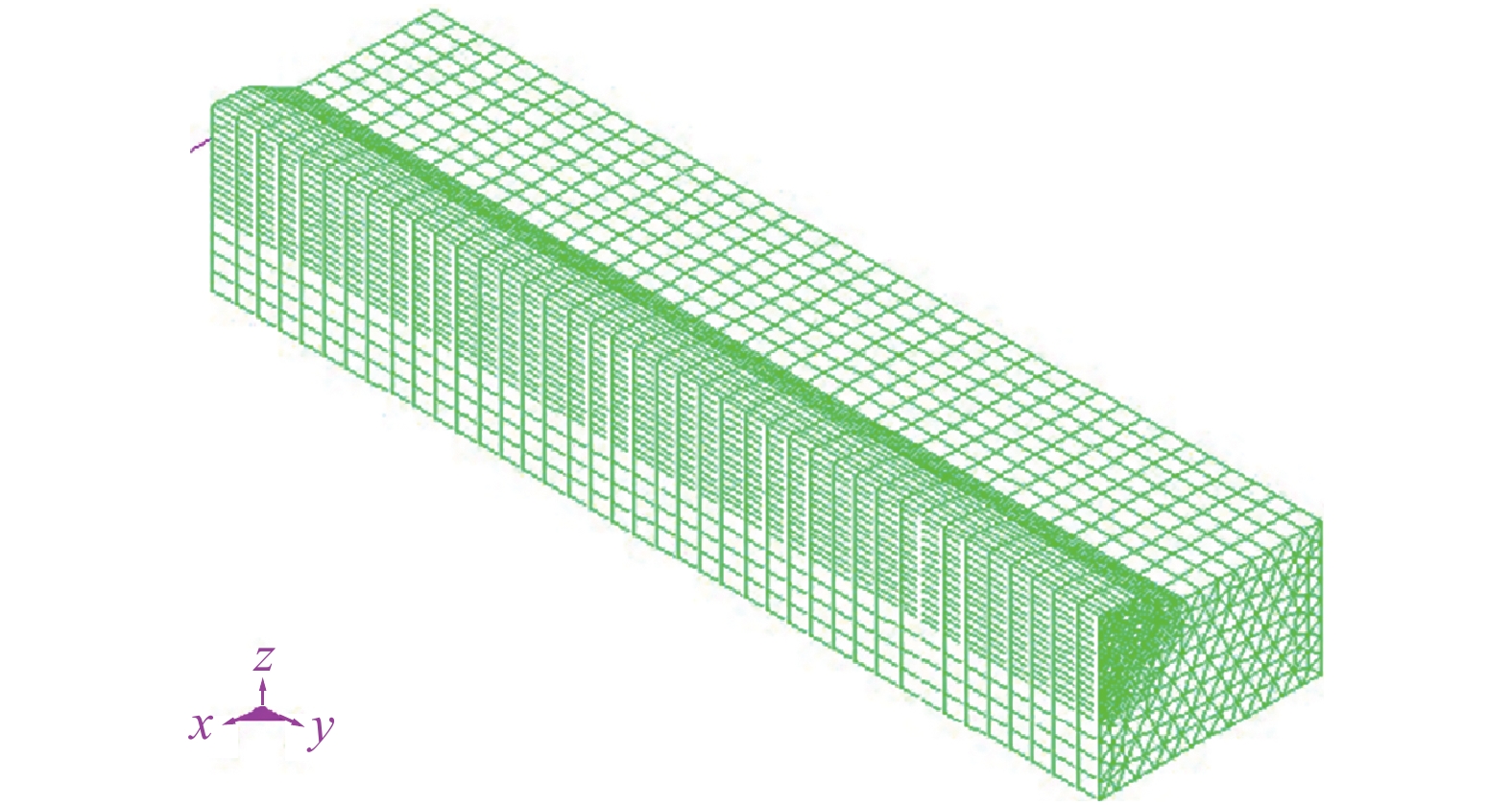

为兼顾计算时间和计算精度,采用6节点的五面体网格. 由于工件左右对称,因此模型在宽度方向上仅取一半进行计算. 在不影响计算精度的前提下,长度方向上也按比例仅选取一部分进行计算. 在温度梯度较大的熔池和热影响区采用较细密的网格,网格尺寸约为0.1 mm;而在温度梯度小的区域采用较稀疏的网格,网格尺寸约为0.8 mm. 这样即保证了工件上关键部位的计算精度,又减少了整体的节点数和计算迭代次数,提高了计算效率. 计算所采用的工件尺寸为40 mm (长) × 10 mm (宽) × 8 mm (高),网格划分如图2所示.

1.4 温度场计算结果与试验验证

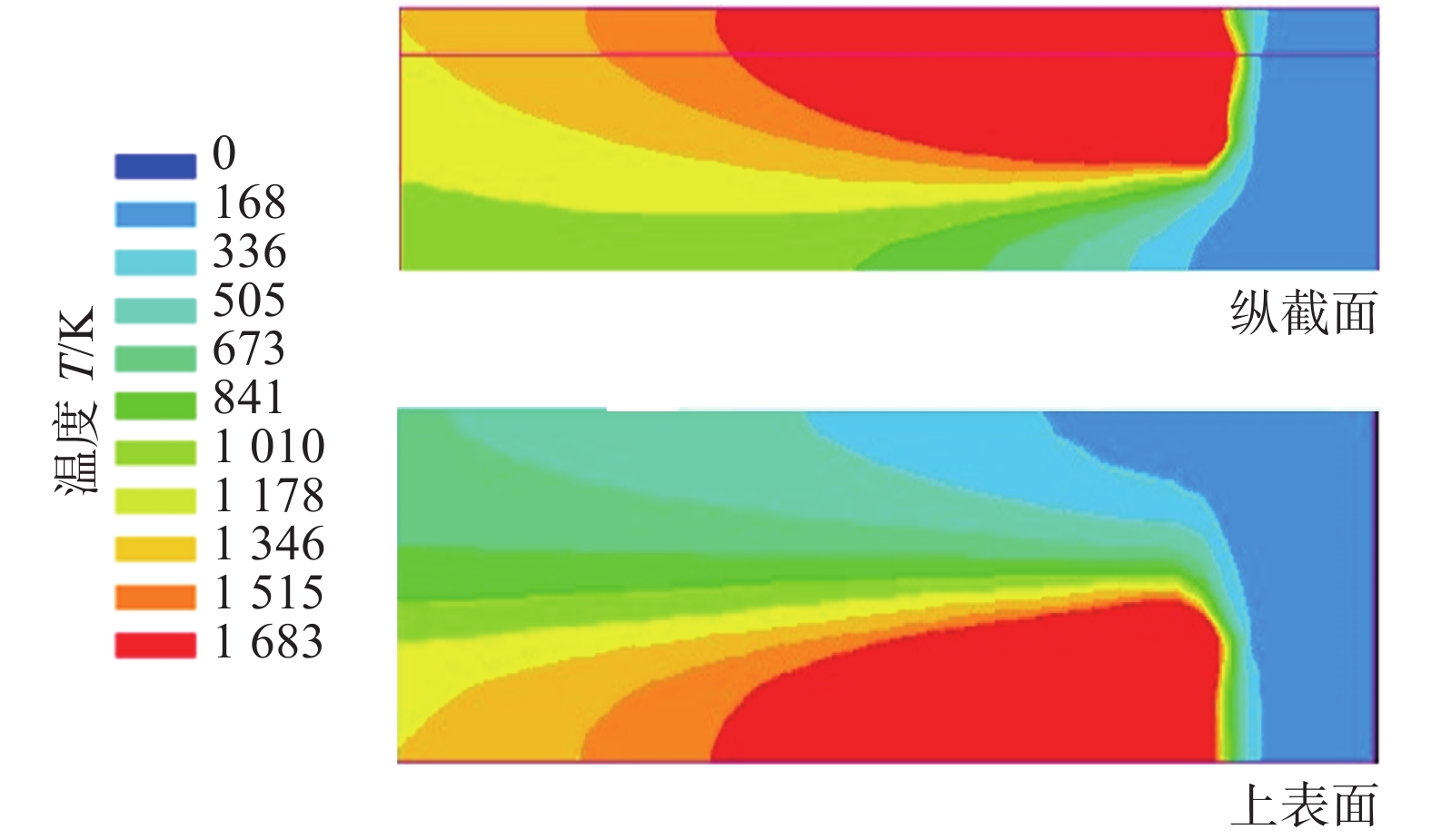

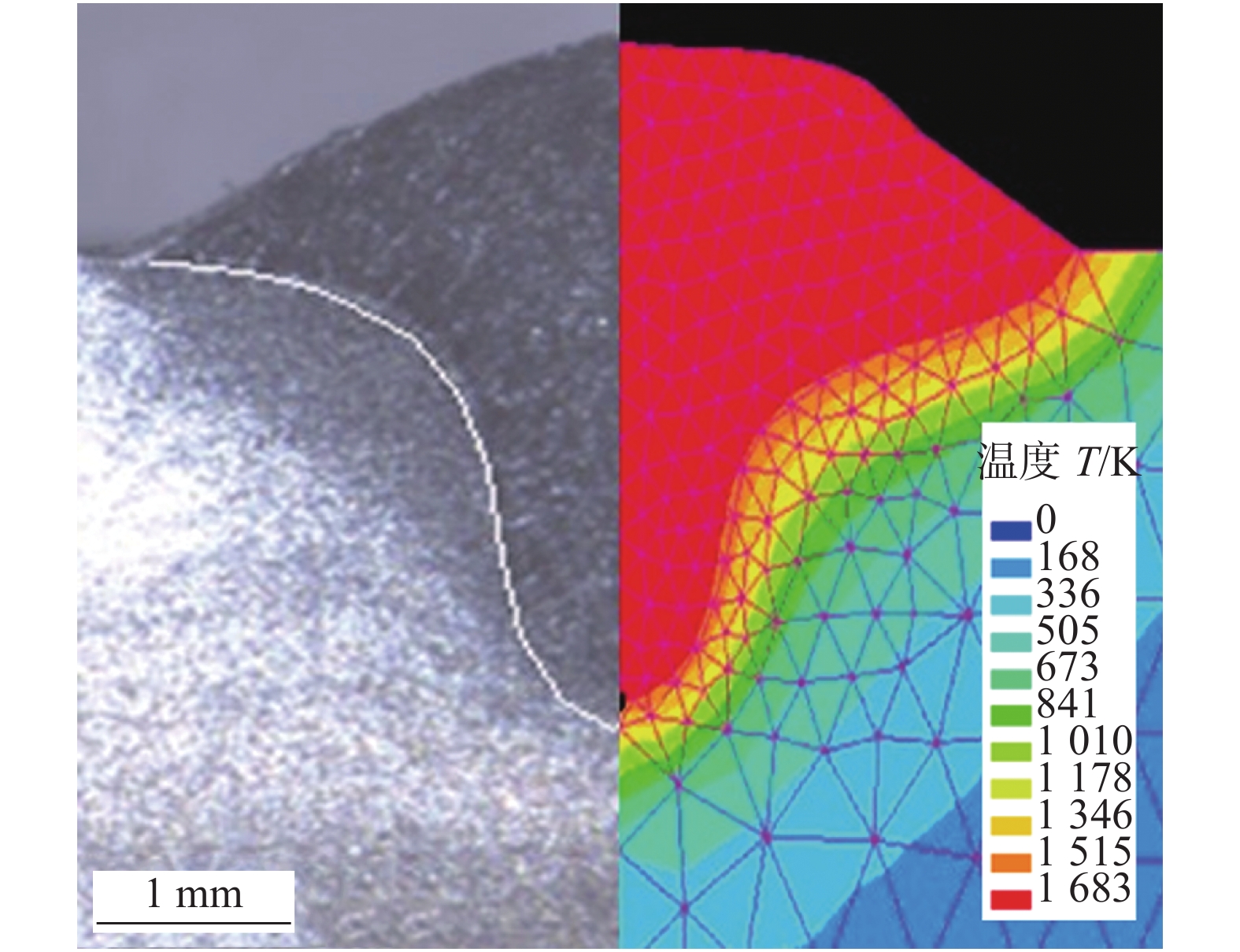

模拟计算所采用的激光功率为2 000 W,离焦量为1 mm;焊丝直径为1.2 mm,焊丝伸出长度为16 mm;光丝夹角为27.7°,光丝间距为1 mm;熔滴过渡频率为1滴/脉冲,送丝速度为6200 mm/min,焊接电流为173.3 A,电弧电压为25.4 V,焊接速度为1.0 m/min. 根据电弧和激光的功率比值确定χ1和χ2的取值分别为0.68和0.32. 图3为计算所得到的温度分布图. 图4为采用组合式体积热源计算得到的焊缝横截面与试验结果的对比,可以看出计算所得的焊缝熔宽、熔深和熔合线走向等均与试验结果接近,模拟结果与试验结果吻合良好.

2. 复合焊接热变形的数值分析

为比较激光+GMAW复合热源焊接与常规GMAW焊接的热变形情况,针对8 mm厚低碳钢板在采用两种方法焊接时所产生的热变形进行比较,如表2所示. 可以看出,在获得基本相同焊缝熔深的情况下,GMAW所需的焊接电流、电弧电压、送丝速度等均比激光+GMAW高很多,而且焊缝熔宽尺寸也比复合热源焊接宽约45.12%.

表 2 相同熔深情况下的GMAW和复合焊接参数Table 2. Welding parameters of GMAW and laser + GMAW with similar weld penetration工艺 电流I/A 电压U /V 送丝速度vf /(m·min−1) 焊接速度v0 /(m·min−1) 熔宽w/mm 熔深h/mm GMAW 427 35.3 14.2 1 11.00 2.90 激光+GMAW 173.3 25.4 6.2 1 7.58 2.91 2.1 力学性能参数

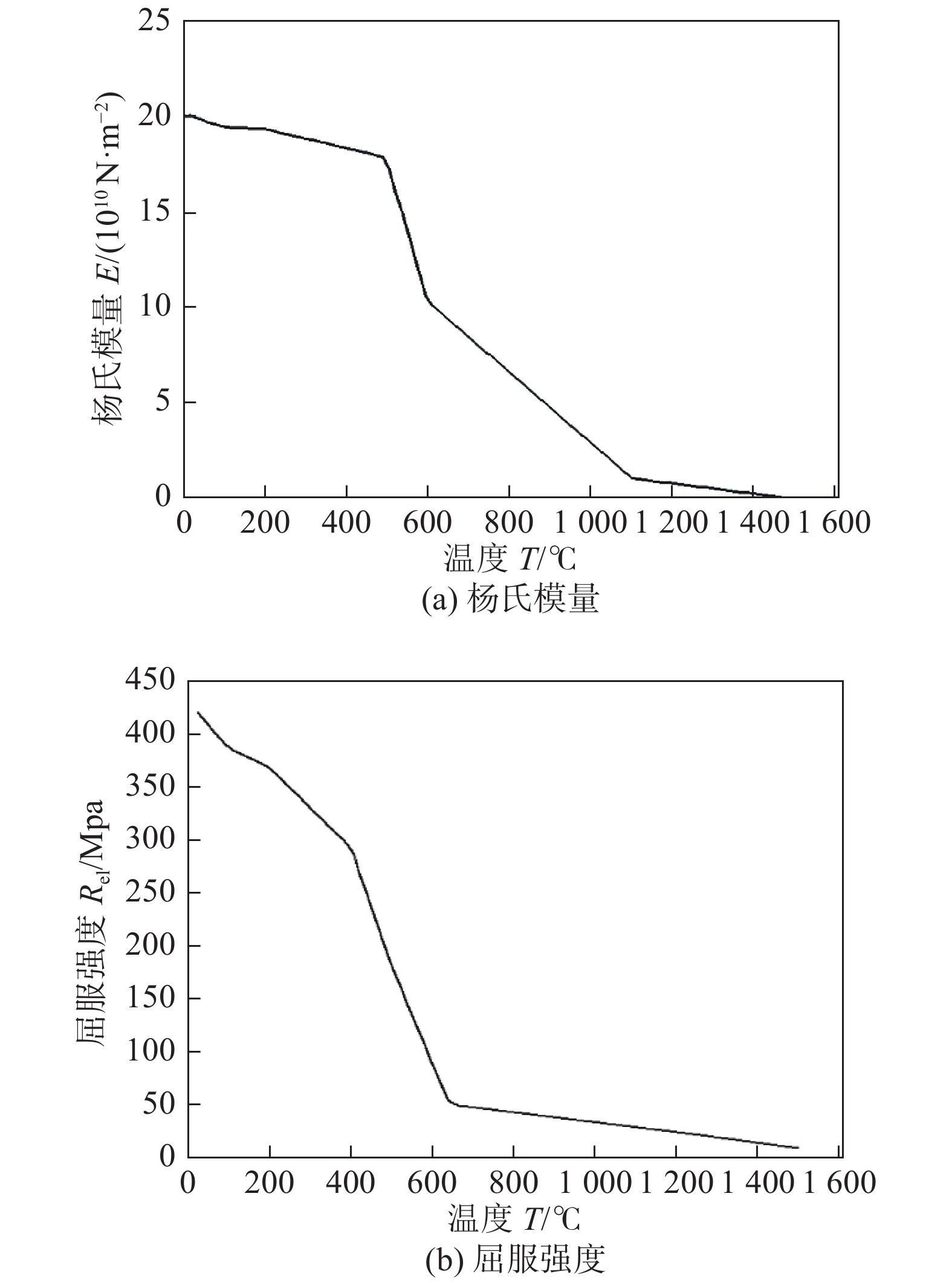

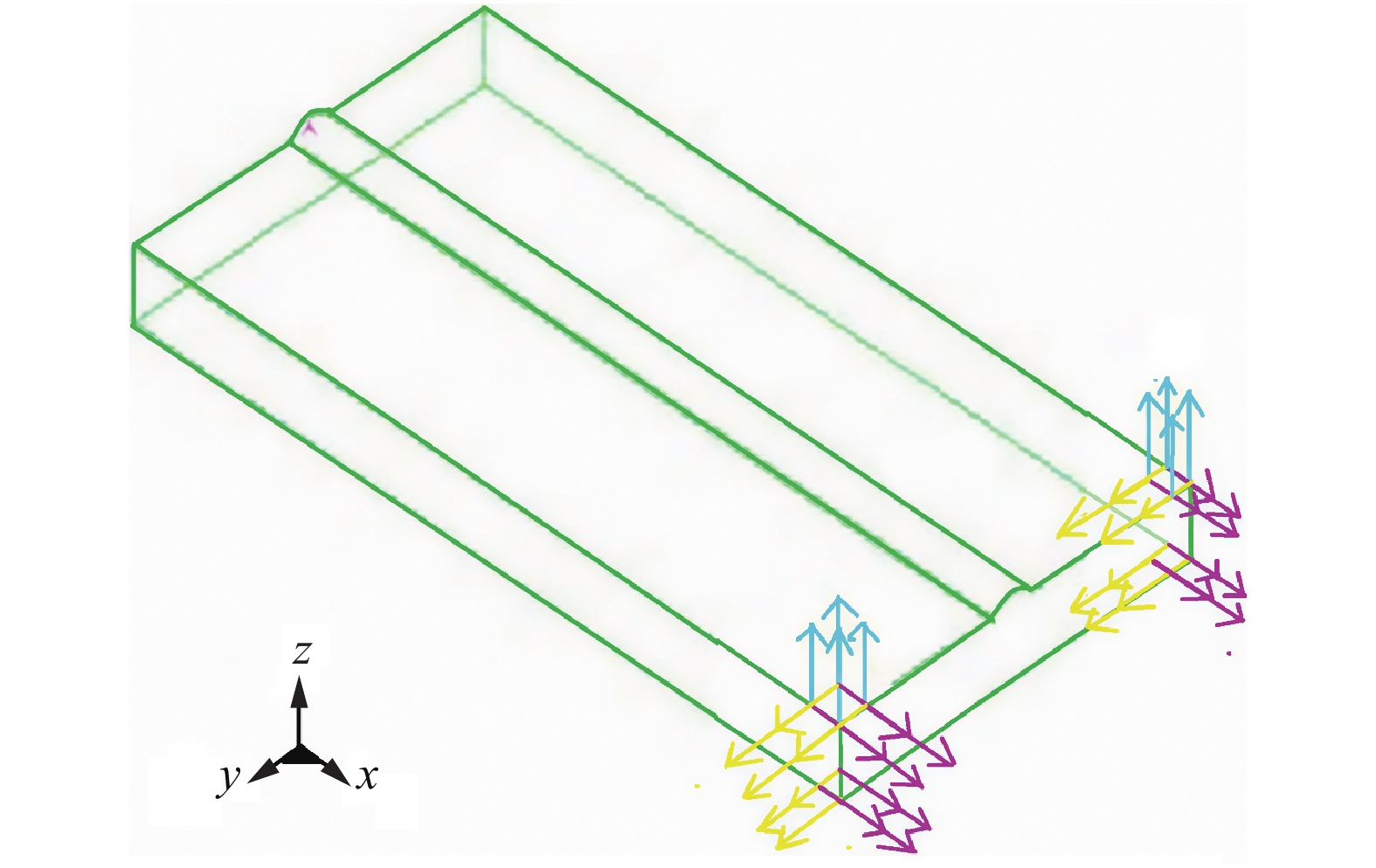

计算所采用材料的泊松比取值为0.33,杨氏模量和屈服强度均随温度变化,取值如图5所示. 工件的夹持情况如图6所示.

2.2 焊接变形

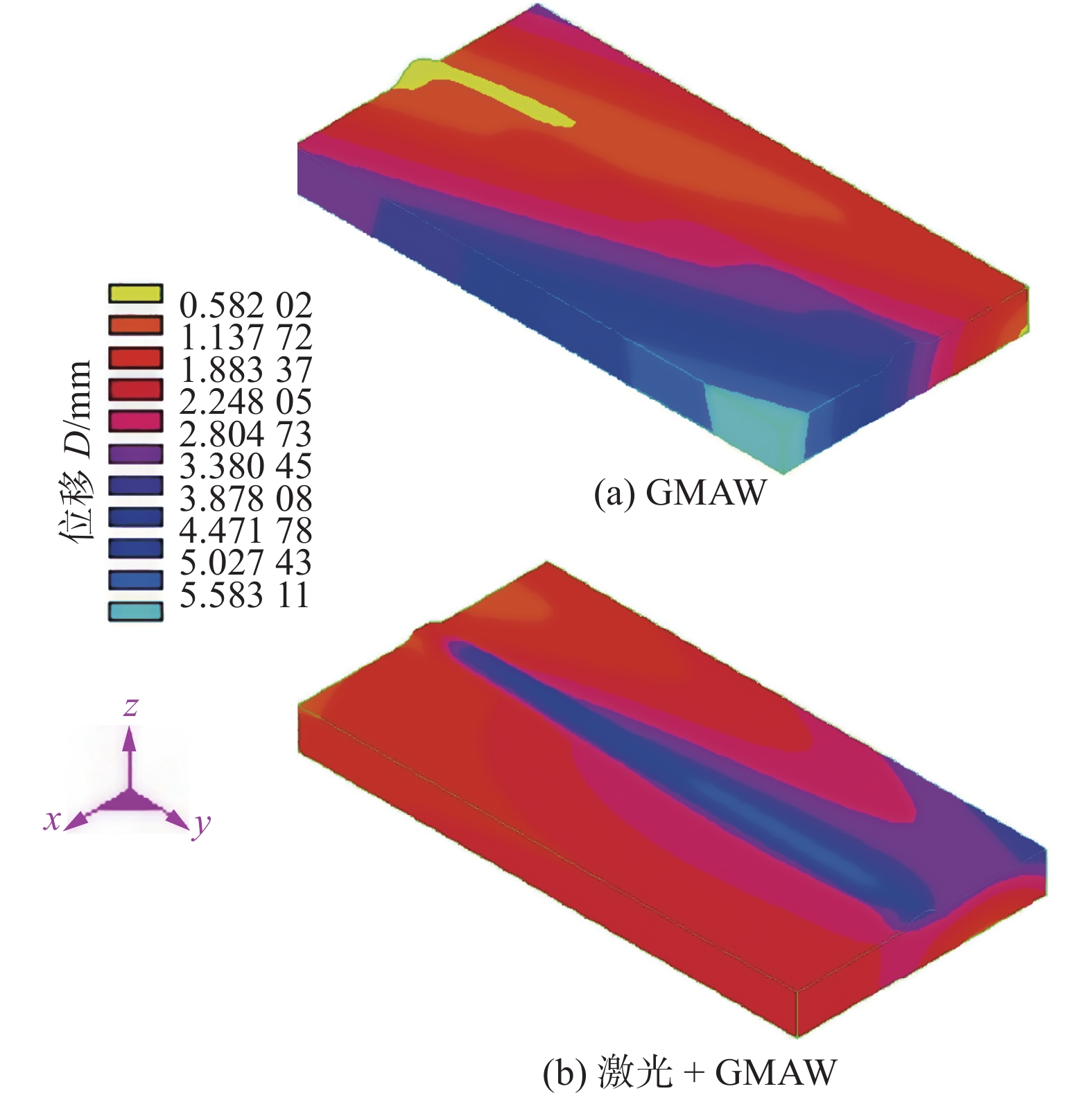

焊接完成后,立即松开夹具,让工件自由变形. 图7所示为焊后300 s工件的整体变形情况. 可以看出,在熔深基本相同的情况下,由于GMAW的焊接热输入比复合焊接高很多,因此GMAW所得到的工件最大变形量是复合焊接的10倍左右,印证了激光+GMAW复合焊接相对GMAW的优越性.

2.3 残余应力

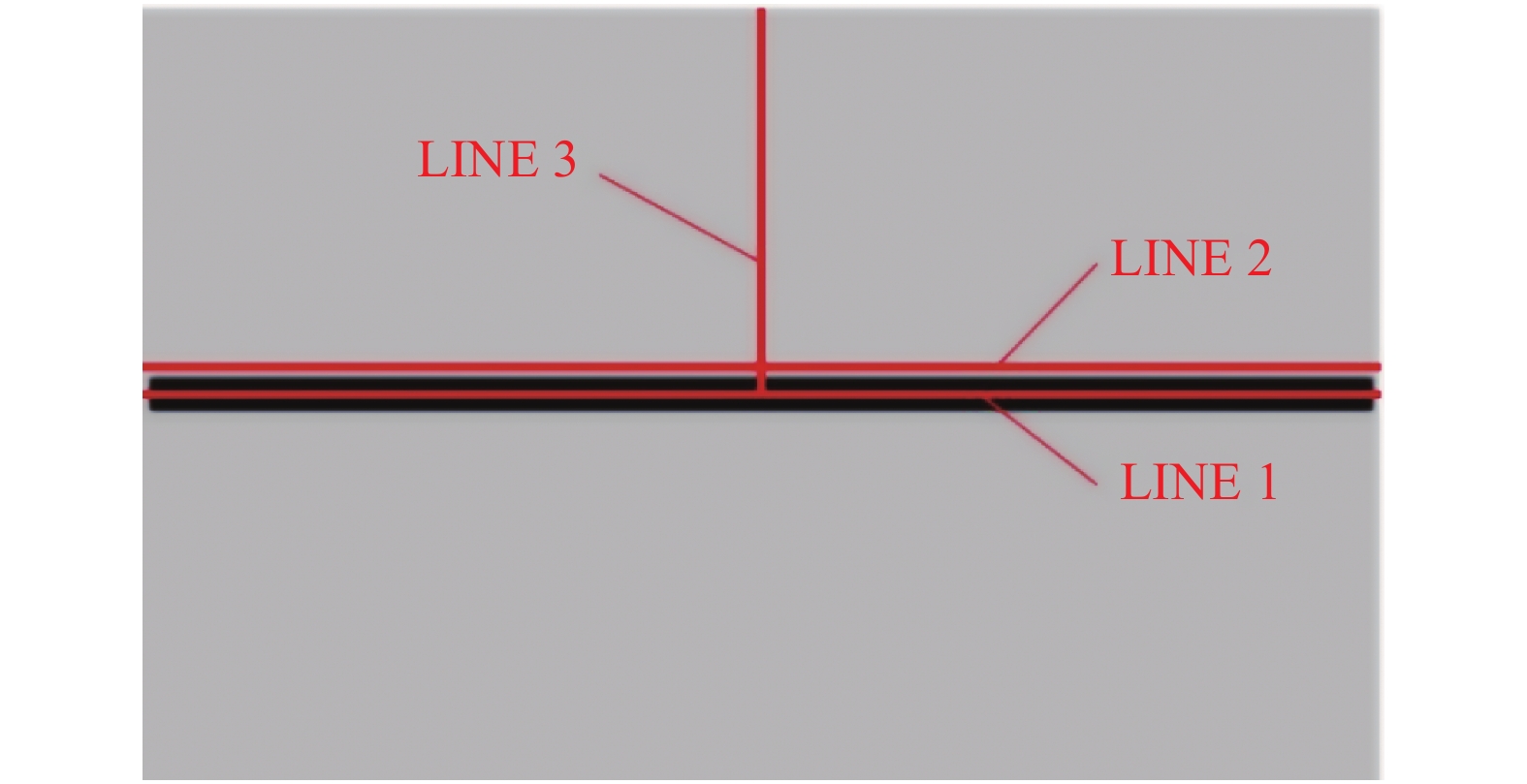

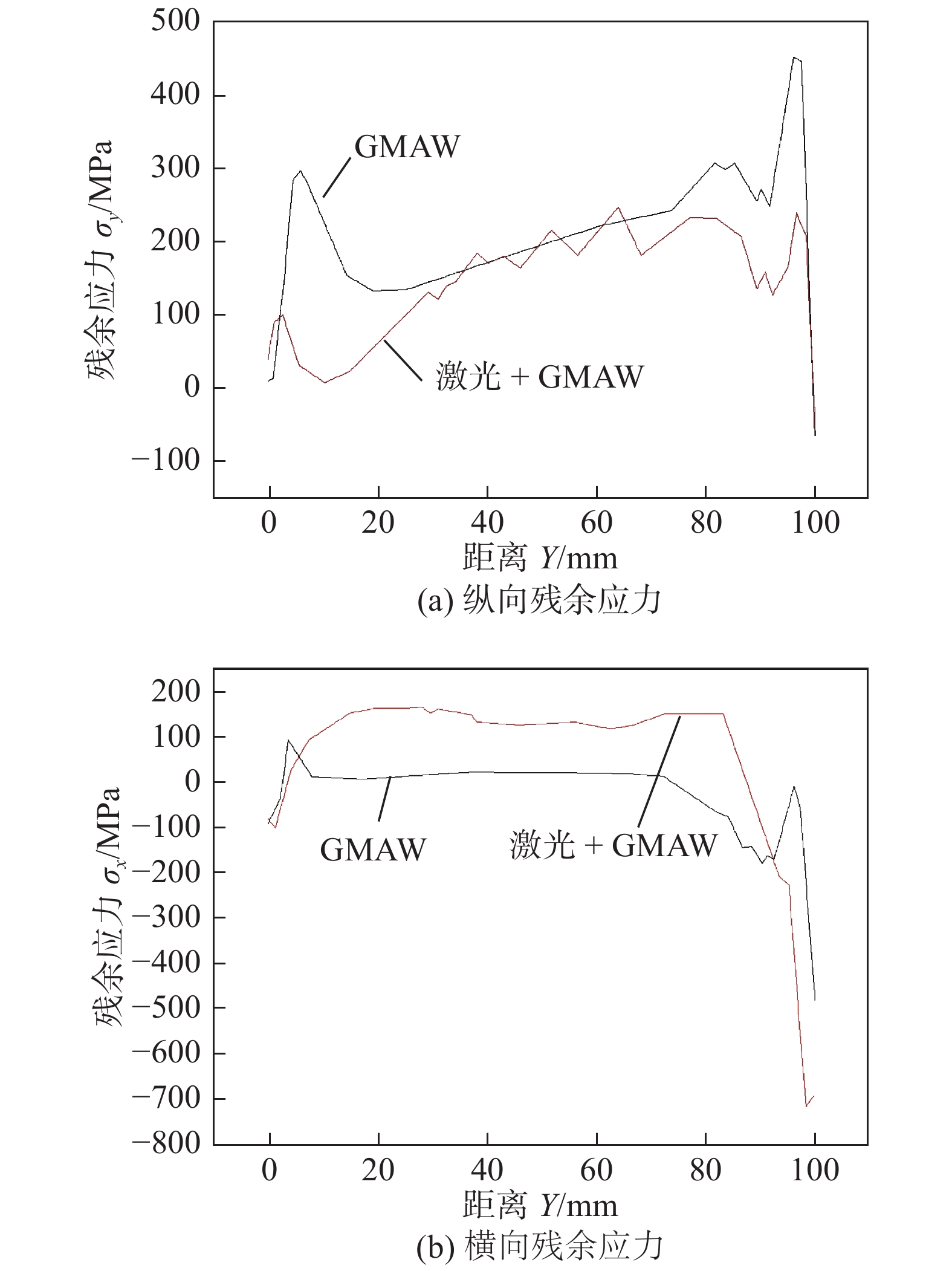

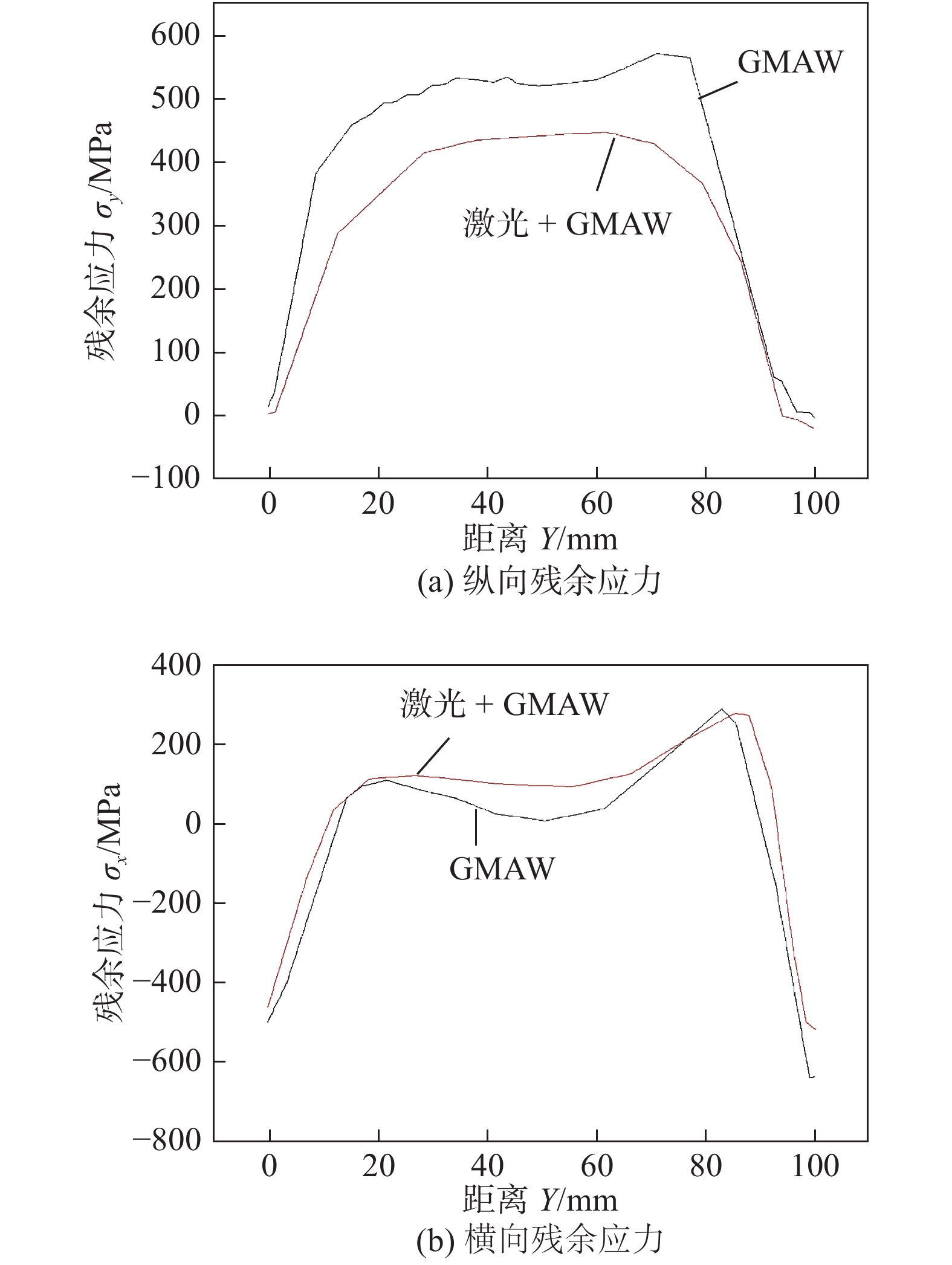

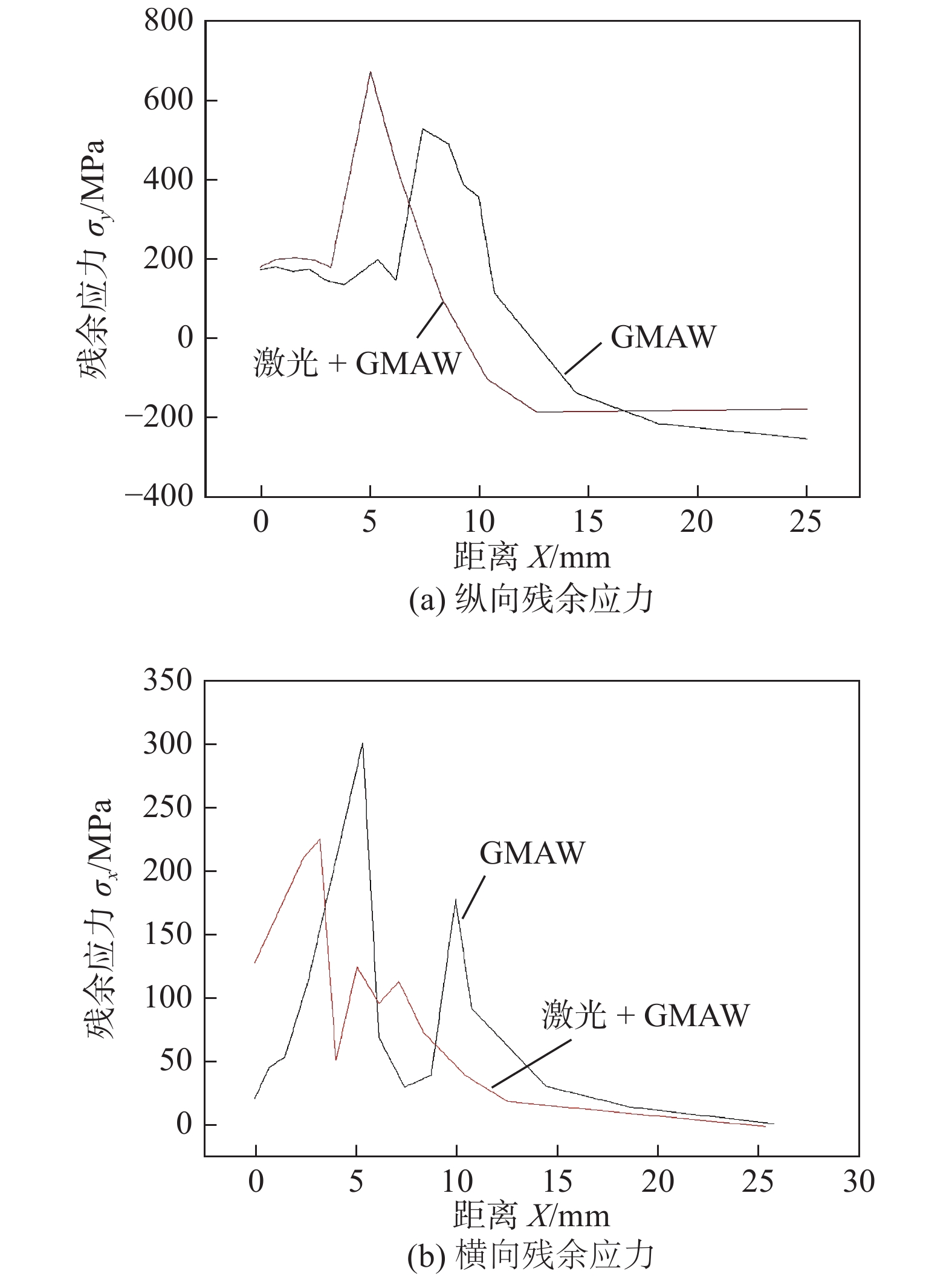

根据焊接应力的分布特点,分别对如图8所示的3条线上的残余应力结果进行提取分析. 其中,LINE 1位于焊缝中心线上,LINE 2位于焊趾处,LINE 3位于焊板中心且垂直于焊缝. 图9~图11分别为这3条线上的残余应力分布曲线. 从图9和图10可知,焊缝中心线LINE 1和焊趾处LINE 2在不同的焊接方法下所得到的残余应力分布规律大体相似. 对于纵向残余应力,由于焊缝两端为自由端,因此其值较小趋近于0;而在焊缝中心位置有较大的纵向拉应力,且由于复合焊的热输入更为集中,在焊趾处GMAW比复合焊的纵向拉应力明显较大,但在焊缝处并不明显. 而对于横向残余应力,在焊缝和焊趾的两端都表现出了较大的压应力. 但由于复合热源焊接的焊缝熔宽较小,故焊缝中间位置所受横向残余应力相比于GMAW焊缝更为显著,而在焊趾处却相差不大. 从图11中可以明显看出,LINE 3上复合焊和GMAW的应力都随着离焊缝的距离增大,应力先增大后减小. 且复合焊比GMAW提前进入应力峰值,这是由于复合焊的焊缝熔宽较窄,焊趾尺寸较小,故复合焊高应力区范围相较于GMAW也较窄. 焊缝及附近区域在高温时塑性变形,焊后受到拉应力的作用;而相对地,两侧远离焊缝的区域在整个热循环过程中未经历塑性变形,焊后受到压应力的作用. 由此可见,对于复合焊与GMAW在相同的熔深条件下,复合焊的高应力区的范围明显的小于GMAW. 这是由于复合焊中,激光热输入较为集中且激光对电弧的收缩作用都更有利于获得较大的熔深. 因此在获得相近熔深时,复合焊的送丝速度明显小于GMAW,且复合焊的热输入仅为GMAW的0.29倍,故产生的应力场也会相应的不同.

3. 结 论

(1) 建立了适用于激光+GMAW复合焊接工艺的“双椭球体热源+峰值递增圆柱体热源”的组合式体积热源,数值计算的结果表明,该热源模型能够准确预测工件的温度分布和焊缝横断面的形状尺寸.

(2) 利用焊接温度场的计算结果对GMAW和激光+GMAW两种焊接工艺的焊接变形和焊后残余应力进行了计算. 结果表明,复合热源焊接的焊接热输入、焊缝熔宽和工件的整体变形量等均比GMAW小. 此外,复合热源焊接情况下的高应力区范围也有所降低.

-

表 1 模型中的其它参数取值

Table 1 Other parameters used in the model

环境温度 ${T_\infty }$ /K熔点 ${T_{\rm{m}}}$ /K密度 $\;\rho $ /(kg·m−3)蒸发潜热

${L_{\rm{b}}}$ /(105 J·kg−1)重力加速度 $g$ /(m·s−2)293 1773 6900 73.43 9.8 表 2 相同熔深情况下的GMAW和复合焊接参数

Table 2 Welding parameters of GMAW and laser + GMAW with similar weld penetration

工艺 电流I/A 电压U /V 送丝速度vf /(m·min−1) 焊接速度v0 /(m·min−1) 熔宽w/mm 熔深h/mm GMAW 427 35.3 14.2 1 11.00 2.90 激光+GMAW 173.3 25.4 6.2 1 7.58 2.91 -

[1] Steen W M, Eboo M. Arc augmented laser welding[J]. Metal Construction, 1979, 11(7): 332 − 335.

[2] Steen W M. Arc augmented laser processing of materials[J]. Applied Physics, 1980, 51(11): 5636 − 5641. doi: 10.1063/1.327560

[3] Dilthey U, Wieschemann A, Lueder F. Technical and economical advantages by synergies in laser arc hybrid welding[J]. Welding in the World, 1999, 43(4): 141 − 152.

[4] Shida T, Hirokawa M, Sato S. CO2 laser welding of aluminum alloys-welding of aluminum alloys using CO2 laser beam in combination with MIG arc[J]. Welding Research Abroad, 1997, 43(5): 36 − 41.

[5] Steen W M. Arc augmented laser welding-process variables, structure and properties[C]//The Joining of Metals, Spring Residential Conference, Coventry, 1981.

[6] Rejc J, Troyanova K, Iorio L, et al. Residual stresses prediction on clad pipeline girth welds through numerical simulation[J]. Procedia Manufacturing, 2019, 37: 605 − 612. doi: 10.1016/j.promfg.2019.12.095

[7] Lu Y, Zhu S, Zhao Z, et al. Numerical simulation of residual stresses in aluminum alloy welded joints[J]. Journal of Manufacturing Processes, 2020, 50: 380 − 393. doi: 10.1016/j.jmapro.2019.12.056

[8] 逯世杰, 郑乔, 张超华, 等. 不同有限元软件对Q390钢厚板T型接头焊接残余应力和变形预测精度与计算效率的比较[J]. 机械工程学报, 2019, 55(6): 11 − 12. doi: 10.3901/JME.2019.06.011 Lu Shijie, Zheng Qiao, Zhang Chaohua, et al. A comparative study on computational accuracy and efficiency of welding residual stresses and deformation in a Q390 steel thick plate T joint among three kinds of different FEM software[J]. Journal of Mechanical Engineering, 2019, 55(6): 11 − 12. doi: 10.3901/JME.2019.06.011

[9] Kong F, Ma J, Kovacevic R. Numerical and experimental study of thermally induced residual stress in the hybrid laser-GMA welding process[J]. Journal of Materials Processing Technology, 2011, 211(6): 1102 − 1111. doi: 10.1016/j.jmatprotec.2011.01.012

-

期刊类型引用(8)

1. 田佳铭,张荣,孔梅. 激光熔覆焊接参数对极细桥丝焊接质量的影响研究. 火工品. 2025(02): 68-74 .  百度学术

百度学术

2. 董军强,陈克选,陈鹏. 基于不同等离子电流的等离子-MIG复合焊数值模拟. 焊接. 2023(05): 1-6 .  百度学术

百度学术

3. 殷琪安,陶武,牟刚,樊雪,任闻杰,杨上陆. 重卡结构件激光-GMAW复合焊接变形数值模拟研究. 电焊机. 2023(07): 16-23 .  百度学术

百度学术

4. 季齐宝,王文焱,张帅锋,吕逸帆,谢敬佩,王爱琴,柳培. TA2工业纯钛激光焊接的数值模拟分析. 激光与光电子学进展. 2022(17): 284-291 .  百度学术

百度学术

5. 杨涛,汪远,庄园,杨瑞欣,曾俊谚,李桓玉. 激光电弧热源复合模式对301L不锈钢焊接接头性能的弱化机制. 焊接学报. 2022(09): 56-61+116 .  本站查看

本站查看

6. 朱东芳,朱加雷,焦向东,苗春雨,周飞鸿,蔡志海,颜秉宇. 921A钢激光-MAG复合焊接头组织及性能. 焊接. 2022(09): 25-29+42 .  百度学术

百度学术

7. 孙家豪,张超勇,吴剑钊,张帅坤,祝磊. 基于神经网络的316L不锈钢激光焊焊缝形貌预测. 焊接学报. 2021(12): 40-47+99 .  本站查看

本站查看

8. 朱梓坤,韩阳,张舟,张义,周龙早. Numerical simulation of residual stress and deformation for submerged arc welding of Q690D high strength low alloy steel thick plate. China Welding. 2021(03): 49-58 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: