Tensile properties evolution of hydrogen-induced TA10 titanium alloy welded joints

-

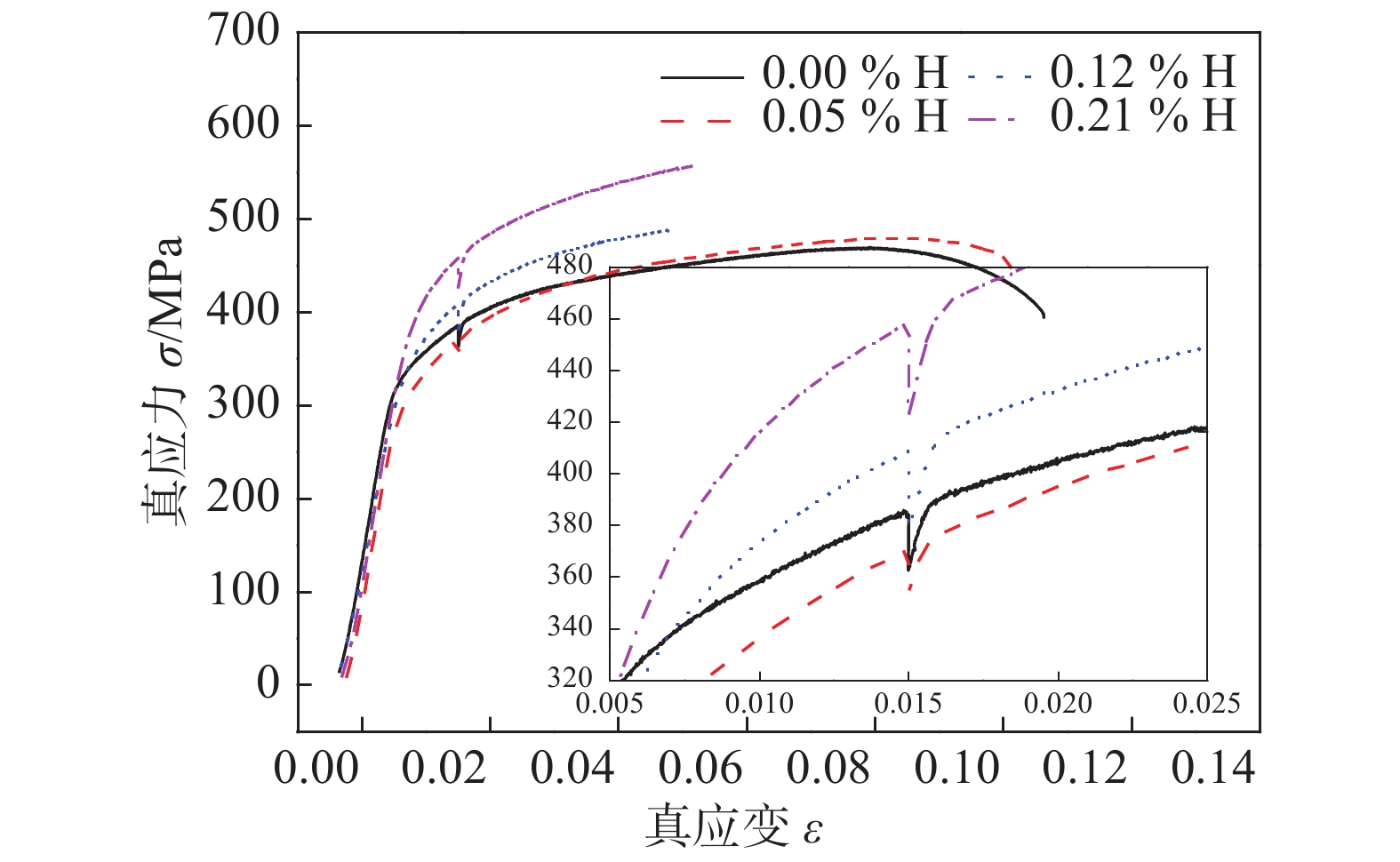

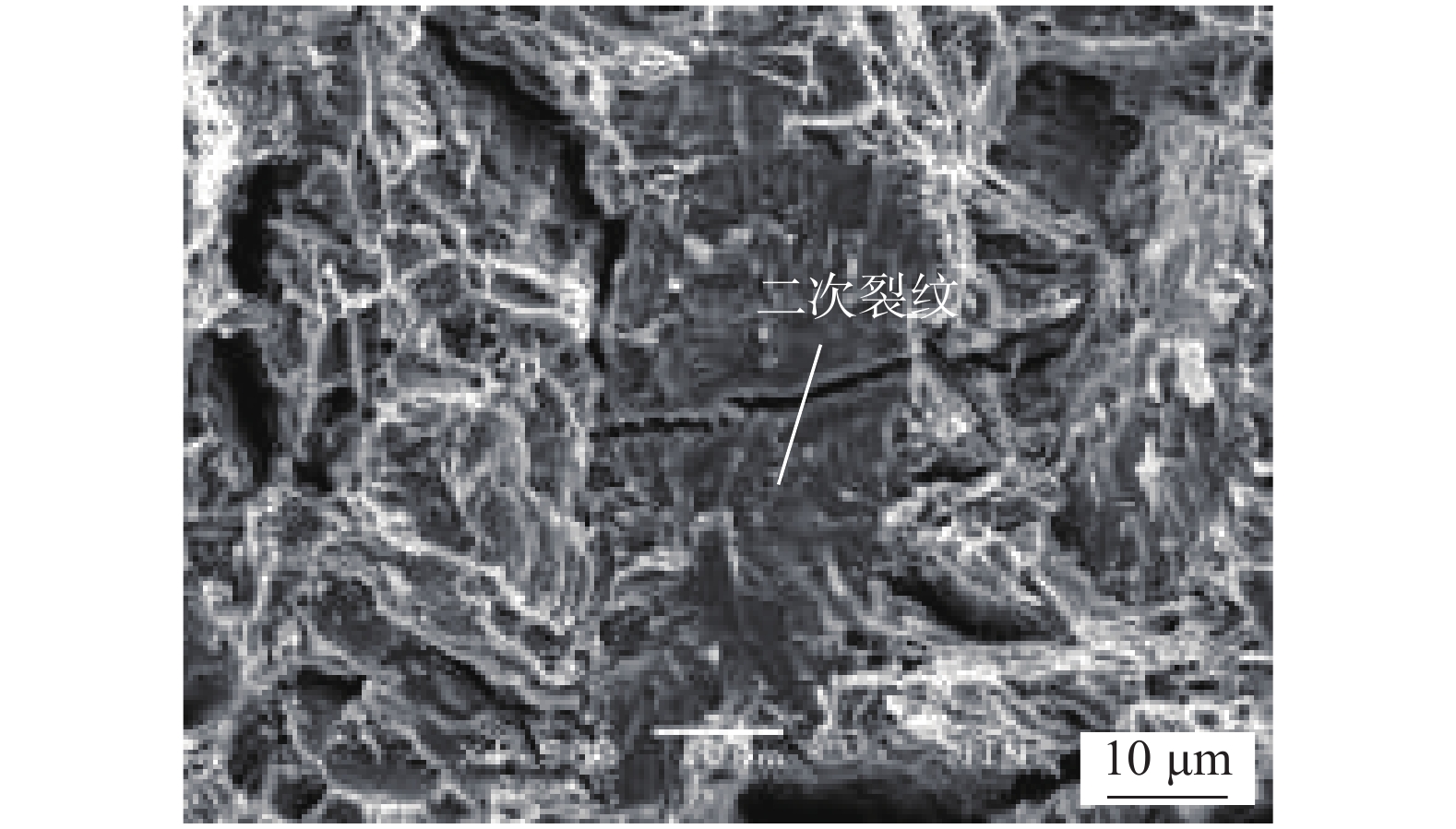

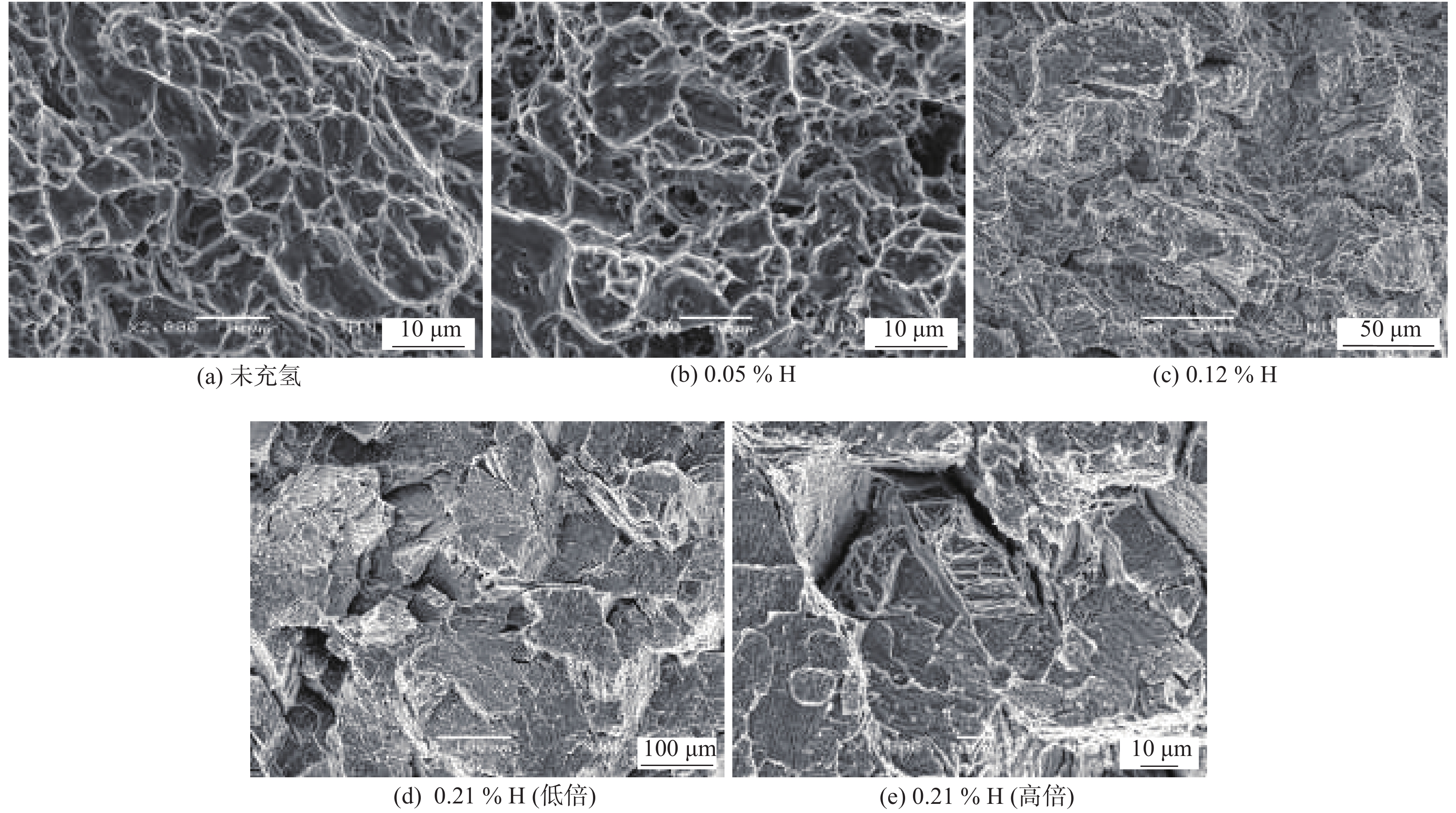

摘要: 钛合金焊接件低氢浓度下常发生氢脆失效,文中研究了充氢量对钛合金焊接接头拉伸性能的影响规律及其作用机制. 结果表明,随充氢量增加,室温强度明显提升,而塑性指标显著恶化. 充氢0.05% (质量分数)时,固溶氢对组织强化效果有限,抗拉强度略有增加;固溶氢降低了溶质原子对位错运动“钉扎”作用,屈服强度下降;固溶氢仅依靠扩散聚集,致局部微区氢浓度增加,其对塑性影响不大. 充氢0.12%后,氢化物“钉扎”作用加强,氢致位错交叉滑移更为困难,室温强度显著增加;脆性氢化物自身断裂、析出特征或加速与基体分离,致塑性显著下降. 未充氢或0.05% H时,焊接接头发生韧性断裂;充氢0.12%后,以脆性断裂为主;固溶氢、氢化物对断裂方式转变产生直接影响.Abstract: Hydrogen embrittlement of titanium alloy weldments often occur at low hydrogen concentrations. The effect of hydrogen content on tensile properties of titanium alloy welded joints and its mechanism were studied. The results show that with the increase of hydrogen content, the room temperature strength was significantly improved, the plasticity was significantly deteriorated. At 0.05 wt.% H, solid solution hydrogen had a limited effect on tissue strengthening and a slight increase in tensile strength; solid solution hydrogen reduced the "pinning" effect of solute atom on dislocation movement, yield strength decreased; solid solution hydrogen only depend on the diffusion and accumulation to cause the local micro-region hydrogen concentration to increase, which had a little effect on the plasticity. After 0.12 wt.% H, the "pinning" effect of the hydride was strengthened, the hydrogen-induced dislocation cross-slip was more difficult, and the strength at room temperature was significantly increased; the brittle hydride itself fractured, precipitated, or accelerated separation from the matrix, resulting in significant plasticity decline. When not charged with hydrogen or 0.05 wt.% H, the ductile fracture occurred in the welded joint; After 0.12 wt.% H, the brittle fracture was the main; solid solution hydrogen and the hydride had a direct effect on fracture mode transformation.

-

-

表 1 TA10合金及TA10焊丝主要化学成分 (质量分数,%)

Table 1 Chemical composition of TA10 alloy and TA10 welding wire

材料 Mo Ni Fe O C N H Ti TA10合金 0.32 0.75 0.08 0.014 0.01 0.03 0.004 余量 TA10焊丝 0.31 0.80 0.05 0.011 0.01 0.02 0.001 余量 -

[1] 张春波, 乌彦全, 朴东光, 等. TA19钛合金惯性摩擦焊接工艺[J]. 焊接学报, 2018, 39(12): 44 − 48. doi: 10.12073/j.hjxb.2018390295 Zhang Chunbo, Wu Yanquan, Piao Dongguang, et al. TA19 titanium alloy inertia friction welding process[J]. Transactions of the China Welding Institution, 2018, 39(12): 44 − 48. doi: 10.12073/j.hjxb.2018390295

[2] Qi Dan, Zhu Ying, Guo Wei, et al. New Ti-Zr-Cu-Ni-La system brazing filler metals for the joining of titanium alloy[J]. China Welding, 2015, 24(2): 6 − 11.

[3] Li Xifeng, Chen Xin, Li Baoyong, et al. Grain refinement mechanism of Ti-55 titanium alloy by hydrogenation and dehydrogenation treatment[J]. Materials Characterization, 2019, 157: 109919. doi: 10.1016/j.matchar.2019.109919

[4] Panin P V, Manokhin S S, Dzunovich D A. Research on submicron-grained structure formation in titanium alloys upon reversible hydrogenation and plastic deformation[J]. Inorganic Materials Applied Research, 2018, 9(6): 1029 − 1034. doi: 10.1134/S2075113318060229

[5] 中国国家标准化管理委员会. GB/T 2651-2008 焊接接头拉伸试验方法[S]. 北京: 中国标准出版社, 2008. Standardization Administration of the People’s Republic of China. GB/T 2651-2008 Tensile test method on welded joints[S]. Beijing: Standards Press of China, 2008.

[6] Liu Quanming, Zhang Zhaohui, Yang Haiying, et al. Hydride precipitation in the hydrogenated 0.12wt.%H weld zone of Ti-0.3Mo-0.8Ni alloy argon-arc-welded joints[J]. The Journal of the Minerals, Metals & Materials Society, 2018, 70(9): 1902 − 1907.

[7] Liu Quanming, Zhang Zhaohui, Liu Shifeng, et al. The hydride precipitation mechanisms in the hydrogenated weld zone of Ti-0.3Mo-0.8Ni alloy argon-arc welded joints[J]. Advanced Engineering Materials, 2018, 20(5): 1700679. doi: 10.1002/adem.201700679

[8] 褚武扬. 氢损伤和滞后断裂[M]. 北京: 冶金工业出版社, 1988. Chu Wuyang. Hydrogen damage and delayed fracture[M]. Beijing: Metallurgical Industry Press, 1988.

[9] 苏娟华, 邵鹏, 任凤章. TA10钛合金高温流变行为及拉伸性能[J]. 材料热处理学报, 2018, 39(6): 14 − 20. Su Juanhua, Shao Peng, Ren Fengzhang. High temperature flow behavior and tensile properties of TA10 titanium alloy[J]. Transactions of Materials and Heat Treatment, 2018, 39(6): 14 − 20.

[10] 施金美. 钛合金环境氢脆的研究[D]. 上海: 上海大学, 2003. Shi Jinmei. Study on environmental hydrogen embrittlement of titanium alloy[D]. Shanghai: Shanghai University, 2003.

[11] Anand L, Mao Y, Talamini B. On modeling fracture of ferritic steels due to hydrogen embrittlement[J]. Journal of the Mechanics and Physics of Solids, 2019, 122: 280 − 314. doi: 10.1016/j.jmps.2018.09.012

[12] 袁宝国. 置氢Ti-6Al-4V合金室温变形行为及改性机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2010. Yuan Baoguo. Deformation behavior and mechanism of hydrogenated Ti-6Al-4V alloy at room temperature[D]. Harbin: Harbin Institute of Technology, 2010.

-

期刊类型引用(4)

1. 许峰,杨莉,熊义峰,刘坡,张尧成. 搅拌摩擦加工Al-Pb表面复合材料的微结构和织构. 稀有金属材料与工程. 2021(03): 957-962 .  百度学术

百度学术

2. 张亚敏,姜永亮. 基于神经网络算法的铝基复合材料搅拌铸造工艺优化. 热加工工艺. 2021(18): 91-94 .  百度学术

百度学术

3. 张孙艺,周爽,朱绍举,高吉成. 基于FSP技术制备CeO_2颗粒增强铝基复合材料. 机械工程与自动化. 2020(02): 151-152 .  百度学术

百度学术

4. 杨绍斌,张旭,谢帅. 高质量分数Al_2O_3/Al复合材料的硬度和耐磨性能. 材料保护. 2018(04): 47-50+140 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: