Experimental study on deposition rate of high efficiency hot wire GMAW welding process

-

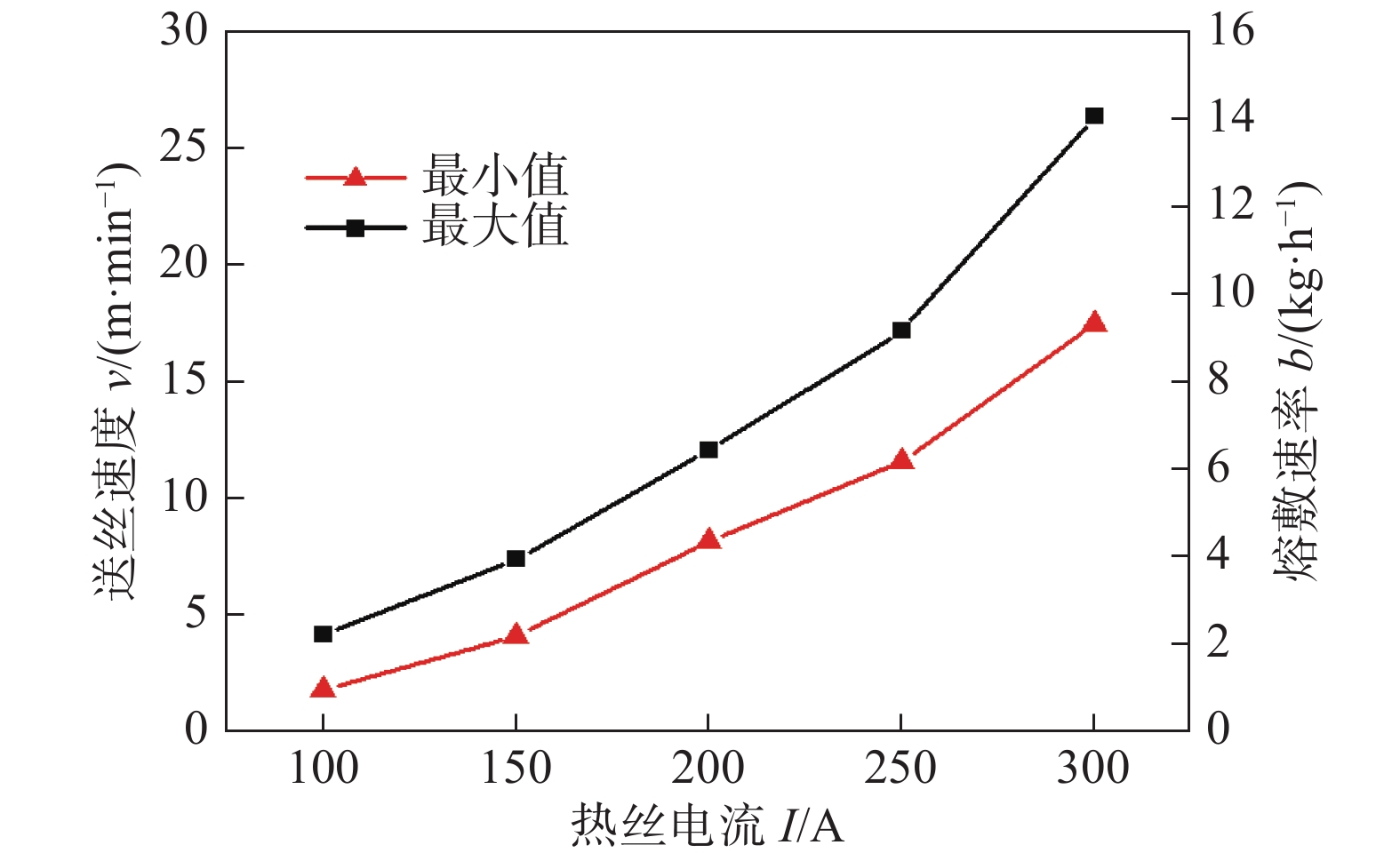

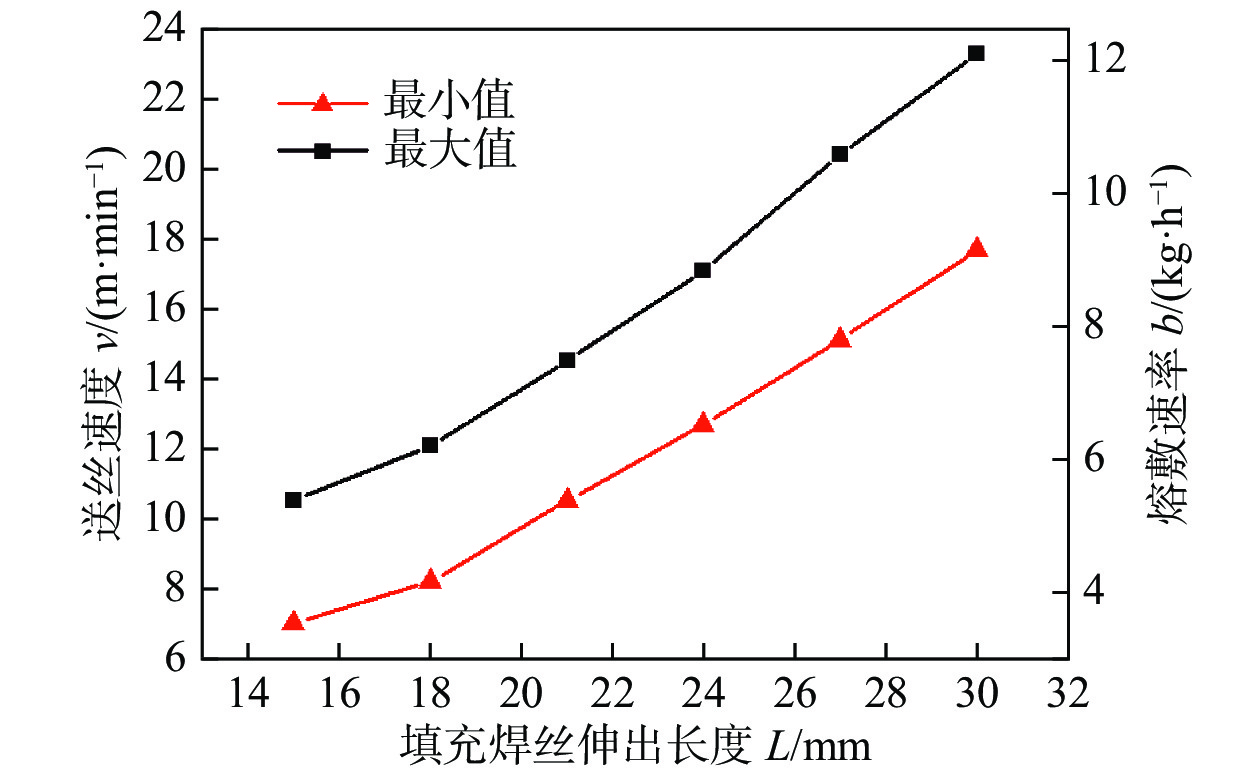

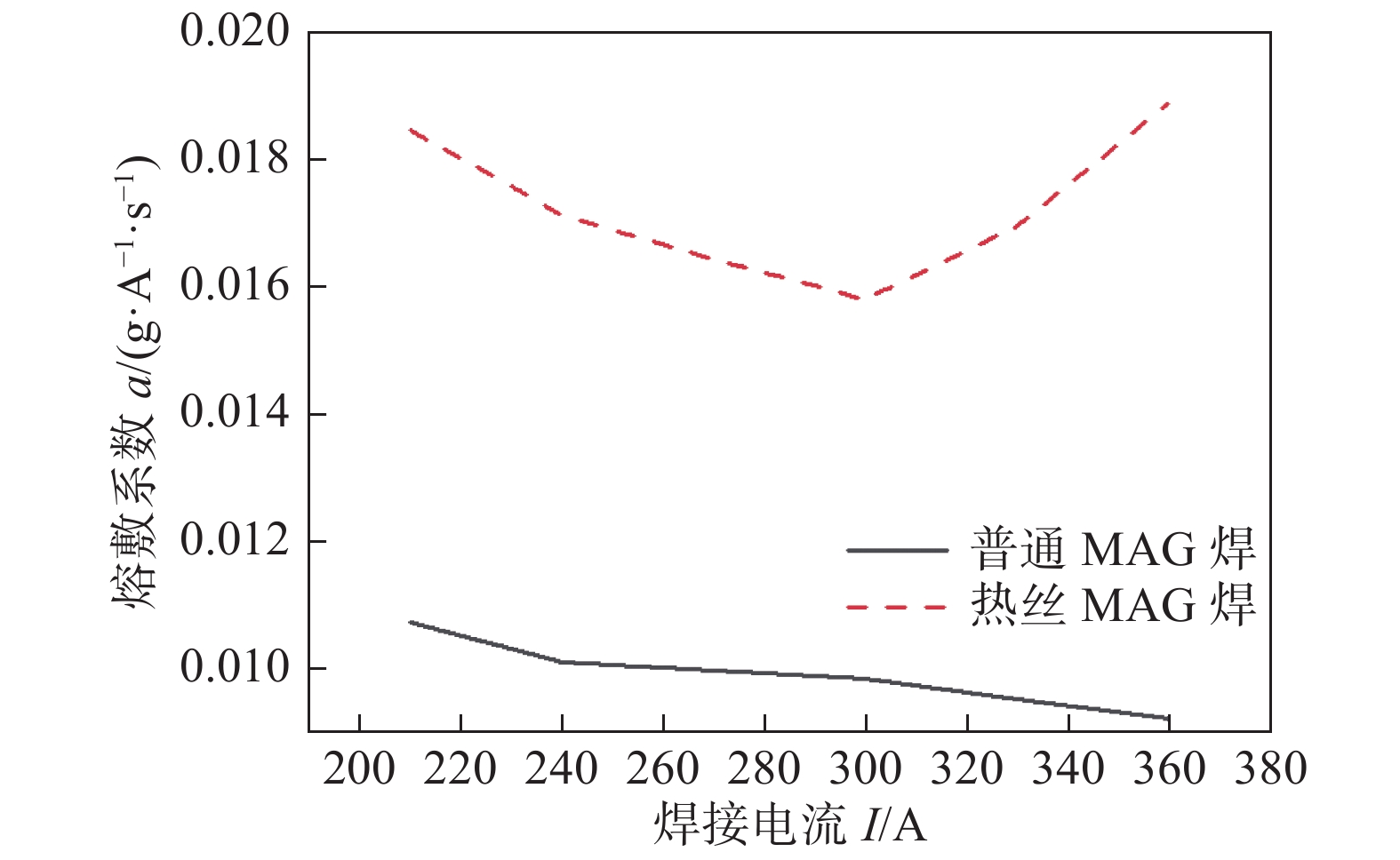

摘要: 交流热丝GMAW工艺是一种高效焊接工艺,其主弧为传统GMAW电弧. 填充焊丝和熔池及母材构成闭合回路,交流脉冲预热电流流经该回路,产生电阻热并预热填充焊丝. 当被预热到高温的填充焊丝进入熔池后,在液态金属作用下迅速熔化. 进行了高效热丝GMAW工艺的试验研究,找到填充焊丝预热电流、填充焊丝伸出长度、焊丝间距、主弧焊接规范等参数之间的匹配规律,实现了20 kg/h以上的熔敷速率. 分析了前述影响因子对熔敷效率的影响规律. 结果表明,热丝GMAW在提高熔敷速率和熔敷系数方面相对传统焊接工艺有明显优势,可以实现高熔敷率低热输入的工艺效果. 该工艺在高强钢大厚板焊接等领域具有广阔的应用前景.Abstract: Alternating current and hot wire GMAW process is a kind of efficient welding process, the main arc of which is the traditional GMAW arc. Under the action of AC pulse preheating current, the filler wire can flow form a closed loop with the welding pool structure in the base metal. The current flows through the loop to generate resistance heat to preheat the filler wire. The filled wire preheated to high temperature will melt rapidly under the thermal influence of the liquid metal after entering the molten pool. In this experiment, the high efficiency hot wire GMAW process was studied. The study found the matching rules among the parameters such as the preheating current of the filler wire, the extension length of the filler wire, the distance between the filler wire, the main arc welding specification, etc. Finally, it was realized the deposition rate above 20 kg/h. Through the analysis of the influence rules of the above factors on the deposition efficiency, the results show that: compared with the traditional welding process, hot wire GMAW has obvious advantages in improving the deposition rate and deposition coefficient. This process has a broad application prospect in the field of high strength steel thick plate welding.

-

Keywords:

- hot wire /

- process window /

- deposition rate /

- deposition coefficient

-

0. 序言

钛及钛合金与不锈钢的复合构件以其相对较低的成本、较高的耐蚀性以及良好的力学性能在核工业、石油化工和航空航天领域有着广阔的应用前景,因此获得高性能钛/钢接头对于高端制造业的高质量发展尤为重要[1-2].然而钛合金与不锈钢之间冶金相容性极差,接头极易形成脆性Ti-Fe金属间化合物(intermetallic compounds, IMCs),导致接头性能严重劣化[3].采用电弧焊、激光焊等熔化焊会使两侧母材过度溶解,产生较厚的IMCs反应层以及较大的残余应力[4-5],对接头力学性能产生不利影响. 而扩散焊是通过元素扩散和界面迁移实现母材之间连接,焊接过程中热输入小两侧母材不发生熔化,界面反应层较窄,是实现异质金属高精度、小变形连接的可靠方法[6].

在真空扩散焊工艺中,中间层成分以及形态的设计是实现接头高质量连接的重要环节[7],采用高熵合金(high-entropy alloy,HEA)作为中间层抑制界面IMCs是近年异质金属连接研究的热点[8],高熵合金的高熵效应使界面更倾向形成简单无序固溶体,迟滞扩散效应使原子更难以在金属中扩散,从而减少IMCs的形成倾向.Li等人[9-10]将AlCoCrFeNi2.1分别与304不锈钢、镍基高温合金进行了扩散连接,由于AlCoCrFeNi2.1中FCC和B2相间元素扩散速率的差异,扩散区产生了由FCC等相组成的固溶体区域,提高了接头的抗剪强度;此外,Li等人[11]进一步设计AlCoCrCuNi2高熵合金作为中间层,利用迟滞扩散效应抑制了IMCs的形成和生长,表明了Al-TMs(transition metal)系高熵合金作为中间层扩散连接316L和TC4钛合金的巨大潜力.然而,现有的Al-TMs高熵合金熔点普遍较高[12],且中间层箔片只能连接平直表面,这限制了高熵合金作为中间层在高性能扩散连接领域的广泛应用.通过丝网印刷技术预置粉体代替金属箔片作为中间层材料,可将中间层均匀印刷于具有复杂界面的待焊工件,从而扩大其作为中间层进行异质金属扩散焊的应用场景.通过提高焊接温度和压力,实现高熵合金粉末中间层致密化和均匀化,从而提升钛/钢异质金属扩散焊接头的力学性能.由于高熵合金的迟滞扩散效应,其接头界面孔洞消失是由粘塑性变形机制主导的,而非扩散机制.在粘塑性变形机制作用下孔洞数量的减少和界面附近连续固溶体形成倾向的增大,但是需要1 050 ℃以上的高温[13].文中利用低熔点的银铜共晶液相作为烧结助剂,开发了具有液相分离特征的AlCoCrNiCuAg高熵合金中间层材料,这一成分通过形成部分液相金属完成扩散连接过程,从而在较低温度下促进高熵合金的粘塑性变形与扩散作用,为消除Al-TMs系高熵合金扩散焊接时的孔洞缺陷提供了有利的途径.

AlCoCrNiCuAg有望通过多组元协同作用实现异质金属接头的高质量连接,其中,Co,Ni和Cr作为不锈钢母材中的合金元素与Fe冶金相容性好,有助于在界面附近构筑连续的固溶体区,同时,Ni-Ti IMCs比Fe-Ti IMCs具有更高的塑性[14],因此期望通过添加Ni元素形成Ti2Ni,TiNi等IMCs实现替代FeTi,Fe2Ti[15]进而降低脆性的目的.此外,添加作为钛合金母材中的合金元素Al以针状析出的形式钉扎在不锈钢界面一侧,残余Ag,Cu元素在钛合金界面附近缓释了应力[16].

文中设计了AlCoCrNiCuAg高熵合金粉末中间层用于TC4钛合金与316L不锈钢的真空扩散连接,研究焊接温度对接头组织演变、元素扩散行为和力学性能的影响规律,厘清TC4/316L扩散焊接头界面层和IMCs形成机理,揭示多元素协同扩散作用下界面有序相高熵化形成规律,为异种金属高性能焊接提供理论依据和实验支撑.

1. 试验方法

配置纯度为99.99%的等摩尔比 (Al,Co,Cr,Ni,Cu,Ag) 原料,采用真空电弧熔炼的方法获得了AlCoCrNiCuAg高熵合金铸锭.应用单辊快速凝固装置促进高熵合金向非晶态转变及成分均匀化,辊轮线速度为40 ~ 60 m/s,将铸锭制备成厚度约为70 μm合金箔带.采用转速400 r/min、球料比20∶1和球磨时间40 h的行星式高能球磨机,将箔带球磨至粒径小于5 μm的粉末,使高熵合金进一步均匀化.称取8%树脂乙基纤维素、52%溶剂丁基卡必醇以及40%溶剂松油醇,使用高速分散搅拌机,在室温下以500 r/min的转速搅拌3 h,冷却得到有机载体,之后称取70% AlCoCrNiCuAg粉末,再依次投放27%有机载体、1.5%消泡剂聚硅氧烷及1.5%分散剂三乙醇胺,最终使用高速分散搅拌机以300 r/min的转速搅拌10 min,用三辊机研磨4 ~ 5遍,得到浆状高熵合金粉末.开始试验前,将粉末浆料通过丝网印刷技术印刷在经水砂纸打磨表面达到2000号的316L不锈钢母材表面,平均印刷厚度为40 μm,在鼓风式烘箱中150 ℃烘烤30 min后取出冷却.经丝网印刷后的母材微观形貌和宏观形貌,如图1所示.

选取市售厚度为5 mm的TC4钛合金和316L不锈钢,采用电火花线切割加工,尺寸分别为15 mm × 15 mm.母材和高熵中间层的成分见表1.对TC4钛合金母材的焊接表面用水砂纸进行打磨,表面达到2000号后将其浸入丙酮,超声清洗10 min.随后将两种母材及中间层进行装配后放入ZTF2-10型真空扩散设备中进行焊接.一般选取母材熔点的0.6 ~ 0.8作为扩散连接温度的范围.考虑到TC4钛合金的熔点为1 600 ℃、316L不锈钢的熔点为1 370 ℃,将扩散焊接的温度区间设置为850 ~ 1 040 ℃的范围.同时考虑到HEAs具有迟滞扩散效应,以及TC4钛合金的β转变温度(1 000 ± 14 ℃)产生的影响,最终将扩散连接温度的区间选定在890 ~ 1 010 ℃.采用如图2所示阶梯状工艺进行扩散焊试验,保持10 ℃ /min的加热速度将焊接试样升温到800 ℃保温30 min.施予20 MPa压力使扩散焊接的结合面紧密接触,为防止钛合金在高温下变形,升温至800 ℃以上时降低压力到1 MPa并加热到扩散连接温度(890 ℃、930 ℃、970 ℃、

1010 ℃)进行30 min的扩散连接,最终随炉冷却至室温.表 1 母材和中间层的化学成分 (质量分数,%)Table 1. Chemical compositions of the base metals and interlayer材料 Cr Ni Al V Mo Co Cu Ag Mn Ti Fe TC4 — — 6.1 5.7 — — — — — 余量 — 316L 16.5 10.2 — — 2.0 — — — 1.6 — 余量 HEA interlayer 13.1 21.8 6.8 — — 14.9 16.0 27.3 — — — 采用Zeiss-SUPRA55扫描电镜(scanning electron microscope,SEM)观察高熵合金中间层粉末粒径及形态,采用TAQ 600差热分析仪(differential thermal analyzer,DTA)分析高熵合金中间层的热物性能,采用D8 Advance X射线衍射仪(X-Ray diffractometer,XRD)对高熵粉末的晶体结构进行测试,采用JXA-8530F Plus电子探针显微镜分析仪(electron probe microanalysis,EPMA)检测了高熵合金铸锭和扩散焊接头的微观组织和元素分布.扩散焊结束后将试样切割成尺寸为5 mm × 5 mm × 10 mm的块,采用INSTRON 6800万能试验机进行抗剪强度测试,压头速度0.5 mm/min,利用EPMA观察断裂路径,利用SEM和 EDS对剪切试样的断口表面进行观察.

2. 试验结果与分析

2.1 AlCoCrNiCuAg高熵合金显微组织

铸态AlCoCrNiCuAg 高熵合金的背散射电子图像,如图3所示,可以观察到铸锭液相呈现典型分离特征,属于不互熔合金.特征区化学成分见表2,结合EPMA定量点分析可知P2点,Al,Co,Cr,Ni的含量均在20.80% ~ 25.02%范围内,推测上部深色区域为AlCoCrNi富集相.根据Ag-Cu二元平相图,Cu在Ag中的最大溶解度为13.6%,而Ag在Cu中的最大溶解度为4.9%,点P4主要成分78.15% Ag和19.43% Cu,推测为富Ag的FCC相,点P5主要成分77.90% Cu和7.17% Ag,推测为富Cu的FCC相,所以HEA铸态显微组织中的浅色区域是由底部Ag基固溶体和Cu基固溶体组成的过共晶组织,为富含Ag-Cu的FCC相.位于铸锭上部的点P1元素组成与点P4相似,推测HEA凝固时Ag-Cu共晶合金沿晶界析出,部分析出的银铜共晶组成通道,用于分离出来的液体沿通道流向底部. AlCoCrNiCuAg高熵合金铸锭上部与下部结合处的元素分布,如图4所示. 从中还可以观察到Al和Ni元素在与Ag-Cu过共晶界面附近析出,这与主要成分为32.57% Al和26.02% Ni的点P3一致,推测为B2-NiAl相[17],因此上部的深色区域与AlCoCrCuFeNi合金相似,即由富含Cr,Ni,Al的BCC相[18]和富含Ni,Al的B2相组成的亚稳结构.

表 2 图3中标记点化学成分 (质量分数,%)Table 2. Elemental quantitative analysis results of the marked locations in Fig. 3位置 Al Co Cr Cu Ni Ag 可能相 P1 1.87 2.42 1.97 10.97 2.59 80.18 Ag-rich FCC P2 20.80 22.76 25.02 7.15 24.17 0.01 BCC P3 32.57 7.09 19.12 11.34 26.02 3.85 B2-NiAl P4 1.82 0.17 0.19 19.43 0.24 78.15 Ag-rich FCC P5 7.42 0.18 0.22 38.27 0.47 53.44 FCC P6 14.34 0.17 0.27 77.90 0.16 7.17 Cu-rich FCC 虽然一般认为B2相为脆性相,对接头力学性能有害,但高温稳定的B2析出物的出现,使接头即使在高温下也可以获得较高的力学性能[19].为使液态难混溶高熵合金均匀化,使用快速急冷装置制成箔带,后用行星式球磨机将箔带制成粉末.高能球磨制备的粉末在试验条件下可以获得均匀的组织[20],如图5所示.高熵粉末的DSC曲线见图5(a),可以看出粉末在809 ℃附近以及947 ℃和

1075 ℃出现3个吸热峰,根据银铜平衡相图[21],可知809 ℃为富银铜合金熔化,947 ℃和1075 ℃分别为富AlCoCrNi的BCC和B2相的熔化温度.图5 (b)为高熵合金粉末的XRD图谱,在衍射角2θ在31.1°、44.6°、45.1°等处呈现若干个减弱并宽化的衍射峰.一般而言,完整晶体结构衍射线强、衍射峰尖锐且对称,而非晶材料结晶度低,晶粒非常细小,衍射线的峰形相较晶体结构变得宽而散,出现漫衍射峰.非晶相越多,在XRD中其单峰衍射强度越弱,宽化越明显,这说明粉末颗粒经快速急冷甩带并球磨后已经有相当比例呈现非晶结构.图5 (c)为球磨后合金粉末的微观形貌,可以看出粉末成粒径在2 mm以下,结合XRD图谱可知,经甩带、球磨后,粉末成分已相对均匀.2.2 添加AlCoCrNiCuAg中间层接头的界面微观组织

在不同焊接温度下使用制备的AlCoCrNiCuAg高熵粉末中间层扩散连接TC4钛合金/316L不锈钢,接头界面微观组织,如图6所示.典型的扩散焊接头微观组织在较低焊接温度890 ℃和较高焊接温度下970 ℃、

1010 ℃呈现不同组织形貌见图6(a),在890 ℃焊接温度下,接头各反应层界面较平直,当温度升高到970 ℃时,反应层由平直界面变为波浪状界面,说明有液相产生.表3为图6中对应位置EPMA点分析成分,由EDS点分析结果可以看出,890℃焊接温度下接头界面处Fe,Ti元素虽发生了一定程度的互扩散,但接头界面处仍存在未反应中间层和少量未焊合区域、微米级裂纹,这是由于温度较低时界面处元素未得到充分扩散,因此无法实现良好的冶金结合,当焊接温度超过970℃时,原子热运动加剧,界面产生的缺陷消失.表 3 图6中标记点化学成分(质量分数,%)Table 3. Elemental quantitative analysis results of the marked locations in Fig. 6位置 Ti Fe Al Co Cr Ni Cu Ag V 可能相 P1 73.26 0.52 18.51 0.50 1.62 0.48 0.60 2.18 2.31 β-Ti P2 49.46 1.33 7.68 2.26 1.67 2.87 1.30 32.76 0.67 β-Ti + AgTi P3 59.50 6.05 5.04 8.67 7.05 9.61 1.89 3.23 1.09 β-Ti + Ti(Fe,Ni) P4 1.15 64.07 3.76 4.55 22.64 3.62 0.02 0.08 0.11 α-(Fe,Cr) + γ-(Fe,Cr) P5 70.07 9.69 9.35 0.50 3.58 2.02 0.72 0.84 3.23 β-Ti + FeTi P6 63.98 14.96 4.17 1.33 2.41 10.14 0.76 0.22 2.02 β-Ti + Ti(Fe,Ni) + Ti2Ni P7 49.88 32.60 2.51 1.05 4.03 8.20 0.72 0.07 0.93 Ti(Fe,Ni) P8 27.55 52.01 0.59 0.24 12.34 6.76 0.06 0.02 0.43 TiFe2 + χ-Fe2Cr5Ti17 P9 8.63 60.15 0.70 0.24 23.64 6.18 0.07 0.01 0.38 χ-Fe2Cr5Ti17 + λ-(Fe,Cr)2Ti + α-Fe P10 5.66 62.71 1.35 0.22 23.74 5.67 0.21 0.01 0.43 χ-Fe2Cr5Ti17 + λ-(Fe,Cr)2Ti + α-Fe P11 0.38 66.52 0.12 0.24 17.76 14.66 0.22 0.01 0.10 γ-Fe 接头界面元素线扫描分析结果,如图7所示,可以观察到此时扩散区内Ti,Fe,Cr,Ni 4种元素出现明显的过渡平台,在扩散焊接头界面处存在成分突变,表明在接头有IMCs反应层生成.随着焊接温度升高反应层宽度随之增加,在1 010 ℃焊接温度下,IMCs层厚度增加至最大见图6(b)b ~ 图6(c).当焊接温度由970 ℃升高至1 010 ℃时,扩散反应区厚度由10.30 μm增加至12.55 μm,Ⅰ区由3.75 μm增加至4.70 μm,Ⅱ区由0.40 μm增加至0.80 μm,Ⅲ区由1.20 μm增加至1.6 μm,Ⅳ区由4.95 μm增加至5.45 μm,说明随着扩散温度升高,界面处发生的反应和互扩散作用随之增强.

2.3 接头界面微观组织演变

如图6 (a)所示,890 ℃焊接温度下扩散焊接头由可分为Ⅰ、Ⅱ、Ⅲ 3个区域.其中Ⅰ区为TC4/HEA侧扩散区,由表3标记点化学成分分析可知点P1主要成分为73.26% Ti,推测为β-Ti.点P2主要成分为32.76% Ag + 49.46% Ti,推测为TiAg相,由于Ti元素在Cu熔体和Ag熔体中的熵分别是−10 kJ/mol和39 kJ/mol[22],因此Ti与Cu比Ti与Ag更容易发生反应.大量的Cu元素扩散至TC4母材中,致使Ag元素保留在焊缝处形成了较多TiAg相及Ag基固溶体.此外,由于Cu,Ni元素为β稳定元素,在TC4一侧形成较宽的β-Ti区域.Ⅱ层为高熵粉末烧结区,Ⅲ区为HEA/316L扩散区,Cr元素发生上坡扩散,由于Cr在γ-Fe中的最大溶解度为11.9%,根据相图可判断Ⅲ为α-(Fe,Cr)相以及γ-Fe相.此外,在316L母材处还形成了少量微米级的针状富Al相[23],这些针状的富Al相钉扎在界面附近,提升了接头力学性能.

图6 (b)和图6(c)为970 ℃及1 010 ℃焊接温度下扩散焊接头界面微观组织,可以观察到界面存在Ⅰ、Ⅱ、Ⅲ和Ⅳ 4个反应层,两个焊接温度下接头组织相似,仅反应层厚度有所不同.点P5主要由70.7% Ti和9.69% Fe组成,可以判断是α-Ti相转变为β-Ti相,9.69% Fe元素表明不锈钢中有少量元素扩散至β-Ti相.由P6、P7点可以看出,Ⅰ层是以Ti,Fe,Ni为主要元素构成的三元合金体系,推测为β-Ti,Ti(Fe,Ni)及Ti2Ni反应相,位于Ⅱ层的P8点推测为TiFe2 + χ-(Fe2Cr5Ti17)相,位于Ⅲ层P9点为χ-(Fe2Cr5Ti17) + λ-(Fe,Cr)2Ti + α-Fe相,至Ⅳ层逐渐靠近316L界面,Ti含量减少,Ti-Fe,Ti-Ni仅存微量,α-Fe相随之生成,相组成为λ + χ + α-Fe相[24].此外,在Ⅰ区左侧由于Fe,Ni和Cu等β-Ti稳定元素使TC4发生了α-Ti向β-Ti的转变,同时温度的升高促进了基体中针状(α + β)-Ti组织的生长,形成魏氏组织[25].为进一步确定

1010 ℃焊接温度下各反应层组织,对扩散焊接头界面进行了元素面扫描,如图8所示.Ti元素含量在Ⅰ、Ⅱ、Ⅲ层中剧烈变化,在Ⅰ层中由左侧β-Ti中的约70%降至约49%,在Ⅱ层中继续下降至约30%,Fe,Cr元素在Ⅰ、Ⅱ层变化趋势一致,但仅从这两个元素的面扫描结果并不能区分Ⅲ、Ⅳ层.结合EDS分析结果确认TC4钛合金和316L不锈钢真空扩散焊的接头在1 010 ℃焊接温度下的界面组成为α-Ti + β-Ti/β-Ti/β-Ti + Ti(Fe,Ni) + Ti2Ni/ Ti(Fe,Ni) /TiFe2 + χ-Fe2Cr5Ti17/ χ-Fe2Cr5Ti17 + λ-(Fe,Cr)2Ti + α-Fe/γ-Fe.为了描述TC4/316L扩散焊接界面组织在连接过程中的演变机制,提出了如图9所示的简化示意图,包括物理接触和原子扩散、共晶液相产生和孔洞形成、富Ag相残余和孔洞收缩和反应相生长和演化4个阶段.

物理接触和原子扩散阶段主要发生于400 ℃以下有机载体分解完全后,在轴向压力和温度的作用下,粉末中间层被压紧达到致密状态.随着温度的升高,中间层与母材发生塑性变形与原子互扩散.当焊接温度超过800 ℃时,首先在晶界和颗粒边界上产生了Ag-Cu共晶液相,这些液相少部分的元素扩散进入两侧母材,大部分液相在与轴向压力的共同作用下使堆叠的中间层颗粒快速软化甚至垮塌,并被挤出焊缝.界面粉末堆叠产生的缝隙和液相流失使孔洞形成.随着液相的流失,界面剩余富Ag相与BCC、B2等高熔点相,孔洞开始收缩、闭合进而圆滑化.焊接温度890 ℃的接头界面几乎没有存在于中间层的BCC及B2-NiAl相,这与其随着共晶液相受压被挤出烧结组织有关.同时,随着大量液相被挤出界面,导致Cu,Ag,Co等元素大量损失,因此界面中的Ag,Cu等含量明显小于高熵合金铸锭名义成分,Cu-Ti等IMCs也所剩无几.但是,由于Ag-Cu液相的产生,界面处存在能量起伏和成分起伏,这为其他元素的扩散提供了活化能.此外,构成界面的Al,Ni,Cu,Ag等作为合金元素产生的高熵效应减小了IMCs的形成倾向[26],依然对提高接头的力学性能有促进作用.

焊接温度升高至970 ℃以上时,元素扩散加剧,两侧母材中的元素扩散至界面,中间层与两侧母材反应充分,TC4钛合金中的Ti与316L不锈钢中的Fe、Cr、Ni反应,形成IMCs层.根据报道,IMCs层的厚度存在最佳值,Fe-Ti IMCs层的最佳厚度约为2 ± 0.5 μm[18],当反应层厚度距离临界值过大或过小时,都会导致界面强度下降,1 010 ℃焊接温度下界面元素扩散充分及IMCs层厚度的增加可能是强度提升的原因,具体内容将在下一节讨论.接头界面在Ⅱ层生成的Ti-Ni IMCs替代了部分Ti-Fe IMCs,由于Ti-Ni IMCs具有更高的塑性,其对提高扩散焊接头的力学性能有积极作用.Ⅲ层Cr元素上坡扩散,Ti-Cr较高的混合焓阻挡了Ti的继续扩散.随着两侧母材中的原子进入界面并形成一系列IMCs,界面同时进行孔洞消失与致密化,最终两侧母材实现扩散连接.如果扩散温度偏低,界面反应层厚度过小,且不可避免存在着由粉末烧结引入的孔洞缺陷,恶化了焊缝力学性能.随着焊接温度的升高,界面处烧结孔洞大量减少,这是在

1010 ℃下接头抗剪强度提高的原因之一.2.4 接头力学性能及断口形貌分析

不同扩散温度下接头抗剪强度,如图10所示,随着扩散温度的升高,抗剪强度逐渐升高,在1 010 ℃时达到最大值181 MPa.图11为890 ℃、970 ℃和

1010 ℃焊接温度下接头的断裂路径,890 ℃焊接温度下界面粉碎于Ⅱ区;970 ℃及1010 ℃焊接温度下断裂均发生在反应层Ⅱ和Ⅲ区.为进一步分析扩散焊接头的断裂机制和断口成分,对接头进行了断口形貌分析和特征区域的能谱分析.不同温度下扩散焊接头断口形貌,如图12所示,EDS分析结果见表4. 在890 ℃焊接温度下,断口处可见解理面,为脆性断裂.且放大的图12 (a1)可以看出断口仍存在颗粒状区域,推测其是与母材未充分扩散、反应的中间层,这与图11 (a)中断裂路径相符.930 ℃焊接温度下断口如图12 (b)所示,从中可见大量粗化的烧结孔洞形成连续的孔洞聚集区,IMCs在中间以岛状分布.这些孔洞产生大量裂纹源,在界面孔洞和脆硬IMCs的共同作用下,接头在机加工时断裂.

表 4 图12中标记点化学成分 (质量分数,%)Table 4. Elemental quantitative analysis results of the marked locations in Fig. 9位置 Ti Fe Al Co Cr Ni Ni Ag 可能相 P1 30.06 56.76 1.81 0.08 7.05 10.76 0.04 0.01 TiFe2 P2 53.65 30.69 2.85 1.89 3.32 6.19 1.44 0.01 β-Ti + TiFe P3 64.90 15.11 3.18 3.10 2.18 10.12 1.30 0.11 β-Ti + Ti(Fe,Ni) P4 18.12 67.99 5.25 0.86 5.19 2.25 0.21 0.13 TiFe2 + χ + α-Fe P5 59.29 22.53 3.65 2.24 3.00 7.71 1.52 0.07 β-Ti + Ti(Fe,Ni) P6 78.26 11.29 1.62 1.54 1.44 5.22 0.59 0.03 β-Ti + Ti(Fe,Ni) P7 56.94 28.98 1.99 1.33 4.12 5.37 1.29 0.00 β-Ti + Ti(Fe,Ni) P8 24.61 53.89 0.64 0.25 13.28 4.28 0.15 0.42 Ti(Fe,Ni) + χ-Fe2Cr5Ti17 由图12 (c)所示,在970 ℃焊接温度下中间层在温度及轴向压力作用下经历颗粒压紧、塑性变形以及扩散蠕变后达到相对致密,实现了钛/钢异质金属连接. 断口表面可见放射区及纤维区,放射区与纤维区连接边界呈弧形.在产生液相之前,粉末颗粒间松散垛叠,界面尚不存在应力和应变.随着温度逐渐上升,同时试样被施加一定的压力,粉末颗粒间相互挤压产生的变形逐渐增加,颗粒在边界处发生晶格畸变产生了较大的应变能.在1 010 ℃下的断口形貌见图12 (d),解理面上的舌状花样和解理台阶为典型脆性断裂.随着温度升高,焊缝致密程度显著提高,界面处孔洞显著减少.

在970 ℃及1 010 ℃时,断口主要存在β-Ti、Ti(Fe,Ni)、χ-Fe2Cr5Ti17等相.接头断裂于TiFe2以及富Cr的χ-Fe2Cr5Ti17等反应层.结合图11 (b) ~ 图11(c)所示的断裂路径,当焊接温度达到970 ℃以上时,接头断裂于图6 (b)所示的Ⅱ和Ⅲ层,这两个反应层主要由TiFe2和χ-Fe2Cr5Ti17组成.这是由于TiFe与TiFe2具有较大的晶格错配度,为非共格界面,难以构成取向关系,所以两反应层之间具有较高的界面能[27].文中焊接温度由970 ℃升高至1 010 ℃时,Ti(Fe,Ni)及α-Fe反应层厚度相较TiFe2 + χ-Fe2Cr5Ti17层均有较大程度的增加.当TiFe + α-Fe相的厚度为最小的8.70 μm时,接头抗剪强度仅为92 MPa;随着Ⅰ层和Ⅵ层厚度增大至10.15 μm,接头抗剪强度达到最大值181 MPa.

3. 结论

(1) 采用AlCoCrNiCuAg高熵粉末中间层实现了TC4钛合金/316L不锈钢扩散焊接头的高质量扩散连接.随着焊接温度的升高,AlCoCrNiCuAg高熵中间层的Ag-Cu液相分离现象为界面提供的成分起伏和能量起伏,促进了元素扩散.扩散焊接头界面处形成的孔洞等缺陷通过扩散机制大幅减少,提升了界面致密度.

(2) 随着焊接温度升高,界面层的厚度增大,接头抗剪强度逐渐提高,裂纹萌生于界面反应生成的TiFe2反应层.该反应层裂纹扩展、破碎导致界面断裂.当焊接温度为1 010 ℃时抗剪强度达到最大值181 MPa.

(3) 在焊接温度为1 010 ℃时,扩散焊接头界面扩散区依次由α-Ti + β-Ti/β-Ti/β-Ti + Ti(Fe,Ni) + Ti2Ni/Ti(Fe,Ni)/TiFe2 + Fe2Cr5Ti17/ Fe2Cr5Ti17 + λ-(Fe,Cr)2Ti + α-Fe/γ-Fe组成.部分TiFe,TiFe2被TiNi等塑性更好的相取代,高熵效应促使316L合金侧生成α-Fe,γ-Fe等连续固溶层,并与TC4侧的Ti(Fe,Ni)反应层协同阻碍裂纹的扩展,提升了接头力学性能.

-

-

[1] 范成磊, 梁迎春, 杨春利, 等. 铝合金高频感应热丝TIG焊接方法[J]. 焊接学报, 2006, 27(7): 49 − 52. doi: 10.3321/j.issn:0253-360X.2006.07.013 Fan Chenglei, Liang Yingchun, Yang Chunli, et al. TIG welding method of aluminum alloy high-frequency induction hot wire[J]. Transactions of the China Welding Institution, 2006, 27(7): 49 − 52. doi: 10.3321/j.issn:0253-360X.2006.07.013

[2] 吕世雄, 孙清洁, 范阳阳, 等. 电弧热丝TIG焊工艺特点分析[J]. 焊接, 2007(10): 41 − 43. doi: 10.3969/j.issn.1001-1382.2007.10.010 Lü Shixiong, Sun Qingjie, Fan Yangyang, et al. Analysis of the characteristics of arc hot wire TIG welding process[J]. Welding & Joining, 2007(10): 41 − 43. doi: 10.3969/j.issn.1001-1382.2007.10.010

[3] Aravinda P, Irappa S, Basavarajappa, et al. Assessment of impact strength of welds produced by cold wire and hot wire gas tungsten arc welding (GTAW) processes[J]. Materials Today: Proceedings, 2020, 24(Pt 2): 983 − 994.

[4] He H, Wu C, Lin S, et al. Pulsed TIG welding-brazing of aluminum-stainless steel with an Al-Cu twin hot wire[J]. Journal of Materials Engineering & Performance, 2019, 28(3): 1180 − 1189.

[5] Liu W, Ma J, Liu S, et al. Experimental and numerical investigation of laser hot wire welding[J]. International Journal of Advanced Manufacturing Technology, 2015, 78(9−12): 1485 − 1499. doi: 10.1007/s00170-014-6756-9

[6] 苗玉刚, 马照伟, 赵慧慧, 等. 高强钢旁路热丝等离子弧打底焊接头组织和性能[J]. 焊接学报, 2019, 40(1): 99 − 103. Miao Yugang, Ma Zhaowei, Zhao Huihui, et al. Microstructure and performance of backing welding joint of high strength steel by bypass-current wire-heating PAW[J]. Transactions of the China Welding Institution, 2019, 40(1): 99 − 103.

[7] 余淑荣, 程能第, 黄健康, 等. 旁路耦合电弧增材制造热过程与组织关系[J]. 焊接学报, 2019, 40(8): 1 − 6. Yu Shurong, Cheng Nengdi, Huang Jiankang, et al. Relationship between thermal process and microstructure during additive manufacturing of double-electrode gas metal arc welding[J]. Transactions of the China Welding Institution, 2019, 40(8): 1 − 6.

[8] Shah P, Agrawal C. A review on twin tungsten inert gas welding process accompanied by hot wire pulsed power source[J]. Journal of Welding and Joining, 2019, 37(2): 41 − 51.

[9] Kim K, Bang H, Bang H, et al. Hot wire laser welding of multilayer for narrow gap-analysis of wire melting/transfer and arc formation phenomenon by high speed imaging[J]. Journal of Welding and Joining, 2016, 34(5): 26 − 32.

[10] 李泳格. 一种新型热丝TIG复合焊接装置的研制[D]. 北京: 北京工业大学, 2015. Li Yongge. Development of a new hot wire TIG composite welding device[D]. Beijing: Beijing University of Technology, 2015.

下载:

下载: