Preparation and characterization of structure and properties of nanoTiSiN films deposited on Mg alloys

-

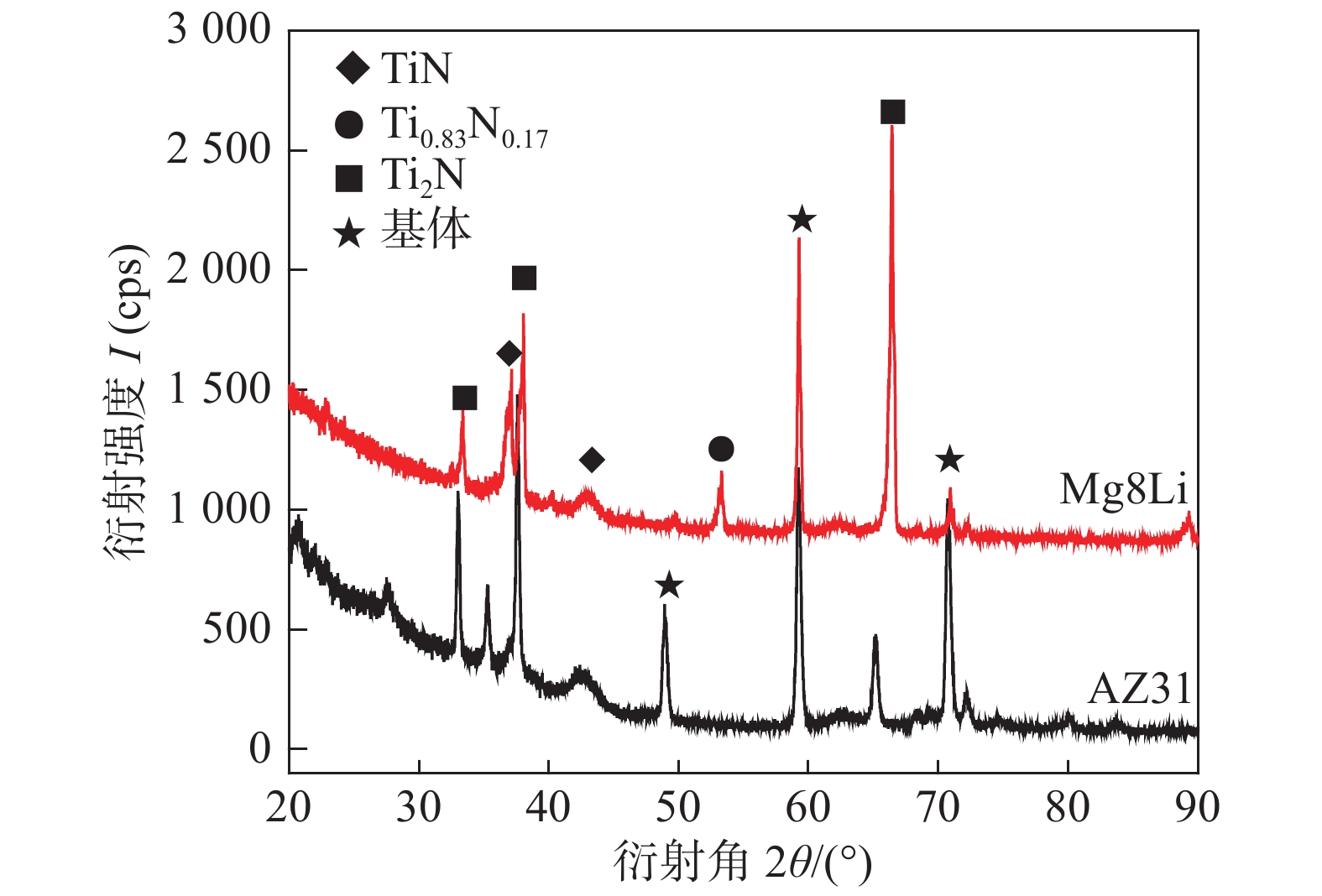

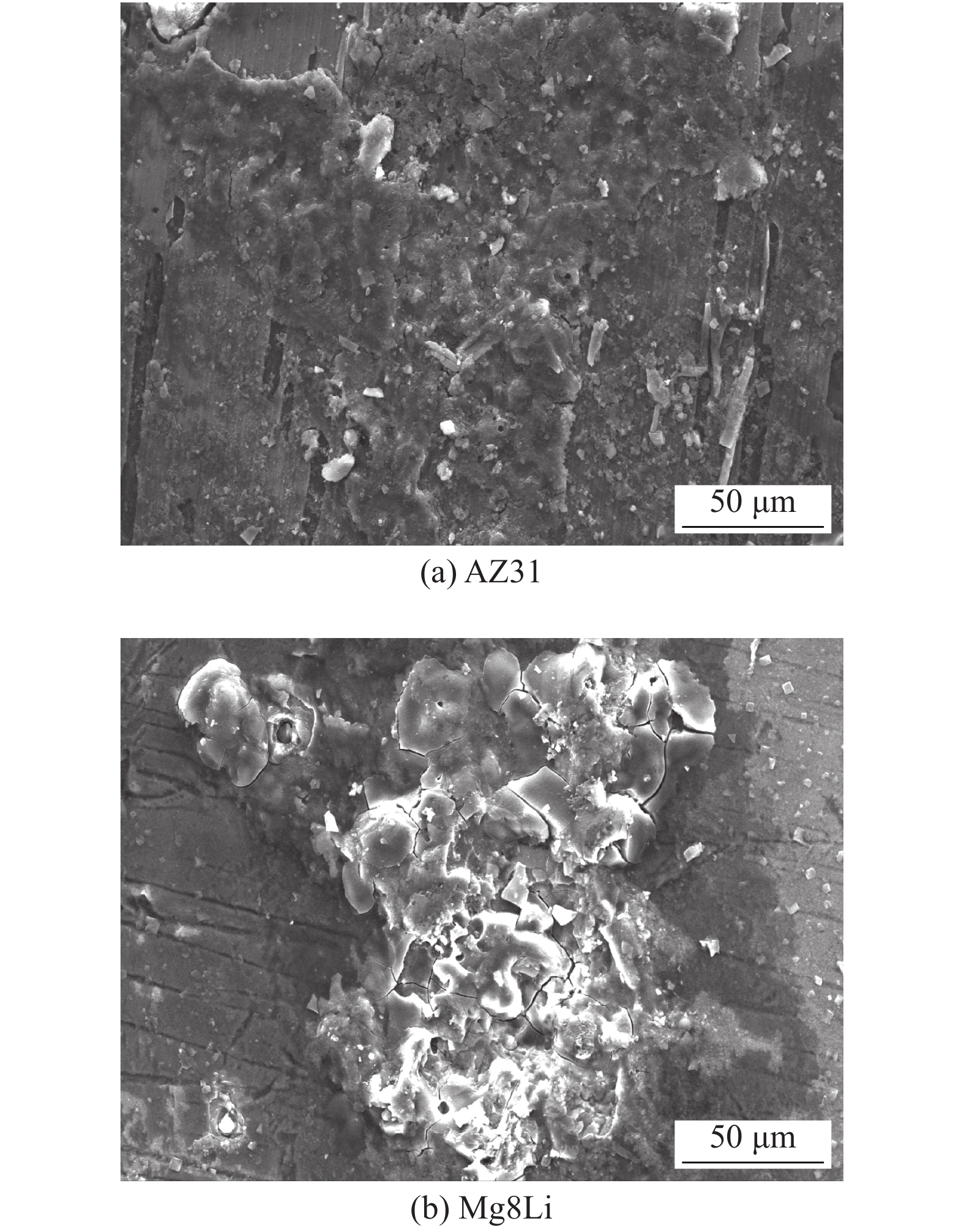

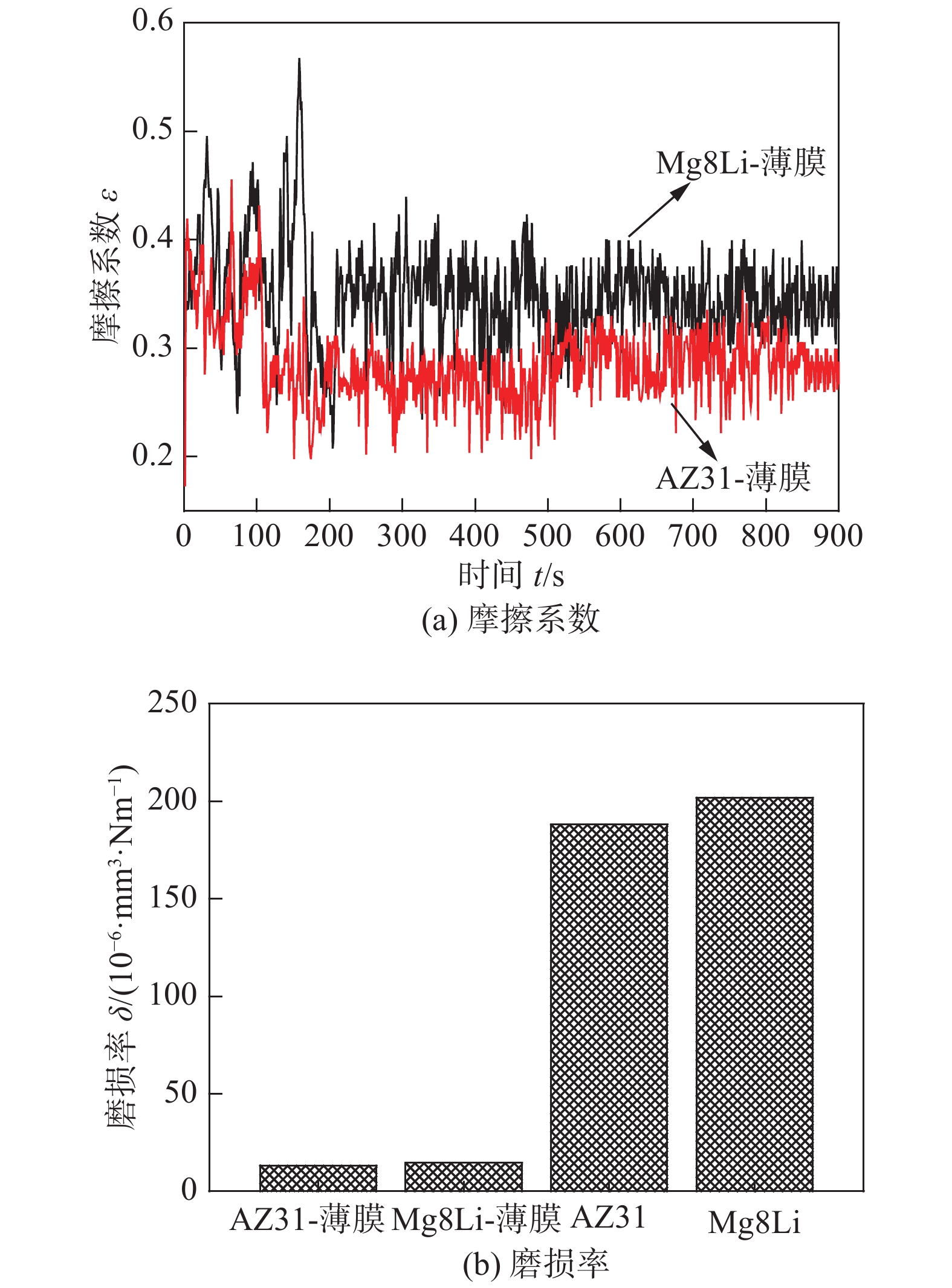

摘要: 为提高镁合金耐蚀和耐磨性,扩大其在航空领域的应用,采用反应磁控溅射法,分别在AZ31和Mg8Li两种镁合金基体上制备了复合TiSiN薄膜. 采用X射线荧光光谱、扫描电镜、原子力显微镜和X射线小角掠入射分别对薄膜表面元素分布、形貌、膜层结构和晶粒尺寸进行了分析. 采用电化学工作站和球盘式摩擦磨损试验机分别对薄膜在3.5%NaCl溶液中的腐蚀行为和在空气中的摩擦磨损性能进行了研究. 结果表明,薄膜中Ti和Si元素比例与靶材相近,元素在整个膜层表面呈高低交替的环形分布,Mg8Li基体上薄膜的分布较为均匀;薄膜主要由TiN和Ti2N两相组成,AZ31表面薄膜的晶粒尺寸和粗糙度均小于Mg8Li表面的薄膜;两种基体镀膜后的腐蚀电流密度降低了三个数量级,摩擦系数低于0.4,磨损率在10−6 m3/Nm数量级.

-

关键词:

- 镁合金 /

- TiSiN/Ti薄膜 /

- 耐蚀性 /

- 耐磨性 /

- 磁控溅射

Abstract: The work aims to improve corrosion and wear resistance of Mg alloys, TiSiN composite films were prepared on two groups Mg alloys by reactive magnetron sputtering in mixed Ar+N2 atmosphere by sputtering Ti-Si target. Chemical composition, surface morphology, crystalline structure and grain size were investigated by X-fluorescence (XRF), scanning electron microscopy (SEM), atomic force microscope (AFM) and grazing incidence X-ray diffraction (GIXRD), respectively. The corrosion behavior and wear resistance were studied by electrochemical workstation in 3.5% NaCl solution and ball-on-disc tribometer in air, respectively. Results show that the Ti, Si content of film is close to target material and present an alternating ring distribution on the whole coating surface, and Ti, Si elements in Mg8Li film are more evenly distributed. Crystal structure of films is mainly composed of Ti2N and TiN, the grain size and roughness of AZ31 film is lower than Mg8Li film. The corrosion current density of coatings decreased by three orders of magnitude, the friction coefficient is less than 0.4 and wear loss rate in an order of 10−6 m3·N−1m−1 magnitude. The films have good corrosion and wear resistance, the properties of thin film is affected by surface roughness and crystal size.-

Keywords:

- Mg alloy /

- TiSiN/Ti films /

- corrosion behavior /

- wear resistance /

- magnetron sputtering

-

0. 序言

钛合金因其轻质、高强、耐高温、耐腐蚀等优异性能,被广泛应用于航空航天、海洋工程、化工及压力容器等领域[1]. 随着我国先进飞行器的发展,将钛合金应用于管路系统,相比于传统的不锈钢或铝合金管材,钛合金管不仅能够承担更大的工作压力,还能够满足航空航天领域对可靠性及持久性的要求[2-3].

在实际应用过程中,钛合金管材、板材或型材均会受到空间位置及装配精度局限,势必要采用合适的焊接方法对其进行连接. 目前,薄板钛合金常用的焊接方法为钨极氩弧焊接(TIG),吴巍等人[4]研究发现钛合金常规TIG焊接接头的焊缝和热影响区晶粒严重粗化,在热影响区粗晶区部位存在硬度的软化区,随着焊接热输入增加,硬度值逐渐减小. 吴健文等人[5]采用快频脉冲TIG技术搅拌熔池内部液态金属,进而减小TC4钛合金焊缝晶粒和热影响区粗化,焊缝区组织为网篮状马氏体α'相.

随着激光焊接的普遍应用,TC4钛合金激光焊接技术也得到大量研究[6-8]. 南京航空航天大学黄炜等人[9]研究发现TC4钛合金激光焊接接头主要分为细晶区、柱状晶区和等轴晶区,熔合区组织主要为网篮状针状α'马氏体和未转变的β相,热影响区主要为初生α相和针状α'马氏体. 日本大阪大学Liu等人[10]认为随着激光焊接速度的增加,熔合区的针状α'马氏体变得更加细小,使得熔合区硬度值维持在较高的水平. 西安交通大学Xu等人[11]研究发现TC4激光焊接接头硬度值分布与微观组织密切相关,焊缝熔合线位置具有最大硬度值,而随距焊缝中心距离增加,显微硬度值逐渐减小.

TC4钛合金焊接接头宏观形貌、微观组织及显微硬度与TIG和激光焊接方法及工艺参数密切相关,因此主要对TIG和激光焊接方法下的工艺、组织、性能的相互关系进行系统研究.

1. 试验方法

研究所采用的试验材料为TC4钛合金,试样长为100 mm、宽为100 mm、厚2.0 mm,化学成分如表1所示. 采用TIG和激光表面自熔焊接方法,焊接方向垂直于板材轧制方向,焊接示意图如图1所示. 施焊前,采用砂纸对试样表面进行打磨,并采用NaOH和HCl溶液对试样进行处理,以去除表面的氧化膜,最后用酒精对试样进行冲洗并烘干.

表 1 TC4钛合金主要化学成分(质量分数, %)Table 1. Chemical composition of TC4 alloyAl V Fe Si C N H O Ti 5.5 ~ 6.8 3.5 ~ 4.5 0.30 0.15 0.10 0.05 0.015 0.15 余量 TIG电弧焊接试验过程中主要研究焊接电流和焊接速度对焊接接头横截面形貌和微观组织的影响规律;激光焊接主要研究激光输出功率对接头微观组织的影响. TIG和激光焊接过程中均采用纯氩气对高温焊接熔池区域进行保护,其中钨极保护喷嘴气体流量为8 L/min,焊接拖罩气体流量为10 L/min.

焊后采用线切割在焊缝相同位置上截取金相试样,经过磨抛后采用Kroll试剂对金相试样进行腐蚀,采用光学显微镜对焊接接头的组织状态进行分析,并采用显微硬度计测量接头的显微硬度分布,焊接接头测量点间距均为0.2 mm,加载载荷1 kg,持续15 s.

2. 试验结果

2.1 焊接接头宏观形貌及晶粒尺寸

图2为不同焊接参数下的TC4钛合金TIG焊接接头焊缝横截面形貌,具体数据如表2所示. 可以看出TC4钛合金TIG焊接接头主要分为母材、热影响区和焊缝区. 并且随着焊接电流增加或焊接速度减小,TC4钛合金焊接接头焊缝区和热影响区宽度逐渐增加,且焊缝区和热影响区的晶粒尺寸也逐渐增加.

表 2 不同TIG焊接参数下的焊缝横截面形状参数Table 2. The shape parameters of TIG weld cross sections with various parameters序号 焊接电流I/A 焊接电压U/V 焊接速度 v/(m·min−1) 热输入Q/(J·mm−1) 焊缝宽度d1/mm 单侧热影响区宽度d2/mm 1 180 14.3 0.8 116 5.81 1.57 2 200 14.8 0.8 133 6.50 1.71 3 220 15.4 0.8 152 7.04 1.80 4 220 15.2 1.0 120 5.69 1.58 5 220 15.2 1.2 100 5.11 1.36 TC4钛合金焊接接头的组织转变比较复杂,焊缝区域的晶粒组织形态和尺寸主要取决于最高加热温度、高温停留时间及冷却速率. 钛合金熔点高、导热性能差,焊接过程中接头在高温停留时间长,并且焊后冷却过程迅速,使得焊缝和热影响区的微观组织发生显著变化. 根据晶粒尺寸特征TC4钛合金TIG焊接接头可以细分为焊缝柱状晶区、焊缝粗晶区、热影响区粗晶区、热影响区细晶区和母材. 其中焊缝柱状晶区晶粒呈45°夹角从两侧对称向焊缝中心位置生长,晶粒具有较大的长宽比,而焊缝粗晶区和热影响区粗晶区晶粒基本呈现等轴状态. 当焊接电流为220 A、焊接速度为0.8 m/min时,此时具有最大的焊接热输入,焊缝区表面宽度为7.04 mm,单侧热影响区宽度为1.80 mm,焊缝中心区域呈现铸态组织特征,晶粒显著粗化,为粗大的柱状晶组织.

图3为不同参数下的焊缝晶粒尺寸分布特征,可以发现从焊缝中心向两侧,晶粒尺寸逐渐减小,呈现非线性梯度变化特征,在柱状晶/焊缝粗晶区、焊缝粗晶区/热影响区粗晶区具有最大的晶粒梯度. 随着焊接电流增加或焊接速度降低,焊缝中心柱状晶区的宽度逐渐减小,并向粗晶区转变,焊缝区晶粒尺寸变化趋势逐渐趋于平缓. 特别是当焊接速度增加至1.2 m/min时,焊缝中心区域的晶粒尺寸基本一致,粗大柱状晶区域减小,晶粒长宽比降低,与粗晶区基本具有相似的晶粒尺寸.

图4为不同激光焊接参数下的焊缝横截面形貌,如表3所示. 可以看到不同激光焊接功率下的TC4钛合金焊缝横截面形貌基本相似,焊缝区和热影响区宽度变化不明显,不同激光功率参数下的接头焊缝区宽度为2.50 mm,约为TIG焊缝区宽度的40%;单侧热影响区宽度为0.50 mm,约为TIG焊热影响区宽度的30%. 接头焊缝区主要为柱状晶组织,具有联生结晶生长的特征,相比于TIG焊接柱状晶尺寸显著降低. 这是由于激光焊接具有较快的加热和冷却速率,熔池液态金属主要依附于母材半熔化晶粒形核长大,熔池高温停留时间相对较短,晶粒来不及长大变凝固. 在热影响区主要分为近缝区的完全转变热影响区,组织为粗大等轴晶;以及近母材区的未完全转变热影响区,组织为的细小等轴晶和板条组织,主要与最高加热温度有关.

表 3 不同激光焊接参数下的焊缝横截面形状参数Table 3. The shape parameters of laser weld cross sections with various parameters序号 激光功率P/kW 焊接速度v /(m·min−1) 离焦量dF /mm 热输入Q /(J·mm−1) 焊缝宽度d1 /mm 单侧热影响区宽度d2 /mm 1 3.4 3.0 0 68 2.61 0.53 2 3.8 3.0 0 76 2.77 0.35 3 4.2 3.0 0 84 2.49 0.38 4 4.6 3.0 0 92 2.50 0.40 2.2 焊缝微观组织与显微硬度

图5和图6分别为TIG焊接(220 A,1.2 m/min)和激光焊接(4.2 kW,3.0 m/min)接头的微观组织特征,虽然两者焊接热源形式有所差异,但是TC4钛合金焊接接头不同区域微观组织特征基本相似. 在TC4钛合金加热过程中,当温度超过α/β转变温度时,TC4母材中的α相向β向转变,由于合金元素在β相中的扩散系数较大,β晶粒将快速长大. 在随后的焊缝快速冷却过程中,焊接熔池将会保存原来粗大的β晶粒至固相. 因此焊缝组织中为由粗大的β柱状晶转变而来的针状马氏体α'相,高温β晶粒的晶界清晰. 此时针状马氏体α'相具有一定的晶体学相位关系,主要是从β晶界向晶内生长. 然而,对比TIG焊焊接接头和激光焊接接头组织特征,可以发现,由于激光焊接热输入小、熔池高温停留时间短暂、加热及冷却过程快速,使得TC4钛合金焊缝组织的针状α'马氏体更加细小.

在近缝区热影响区的加热温度超过α/β转变温度,α相全部转变为β相,由于此处的加热温度低于焊缝区域,且冷却速度相比于焊缝较快,因此形成β等轴晶粒,晶粒尺寸相比于焊缝较小. 在随后的冷却过程中,β相转变为α'相. 由于此时熔池的冷却速度相对较大,使得针状马氏体α'相既能够在β晶界形核,又能够在β晶内形核,生成网篮组织. 随着距焊缝中心位置的增加,热影响区的加热温度仅能使部分α相转变为β相,高温为α + β双相,由于此时的加热温度较低且冷却速度较快,β晶粒来不及快速长大,晶粒尺寸较小;与随后的快速冷却使得未转变的α保留下来,生成原生α + 针状马氏体α'双相组织.

图7为TC4钛合金TIG和激光焊接接头不同区域的显微硬度分布,由图可以发现,激光焊接接头焊缝区显微硬度基本保持在370 HV,在熔合线位置硬度值达到最高值为393 HV,在热影响区显微硬度值迅速降低. 激光焊接接头的冷却速度较快,导致生成较多的针状α'相,使得焊缝显微硬度值相比于母材整体偏高.

此外,TIG焊接接头的显微硬度值要明显低于激光焊接接头,焊缝区显微硬度值为350 HV,在近缝热影响区粗晶区存在软化区,显微硬度值达到最低值300 HV,随后在热影响细晶区有所增加,并逐渐降低至母材320 HV左右. 这是因为钛合金导热性差,热影响区近缝区长时间处于过热状态,β晶粒严重长大,在随后的冷却过程中,较快的冷却速度使得未转变的α相保留下来,形成α + α'双相组织,在硬度方面体现为熔合线附近粗晶区的显微硬度值降低.

3. 结论

(1)在实现2.0 mm厚度TC4钛合金全熔透条件下,激光焊接具有较小的热输入和较高的焊接速度,激光焊接接头焊缝区和热影响区宽度分别为TIG焊接接头的40 %和30 %.

(2)TC4钛合金TIG和激光焊接接头晶粒尺寸随距焊缝中心位置的增加逐渐减小. 相比于TIG焊接,激光焊接接头焊缝区柱状晶和热影响区等轴晶的晶粒尺寸均显著减小. 且随着焊接热输入增加,TC4钛合金TIG焊接接头的晶粒尺寸逐渐增大,而激光焊接接头晶粒尺寸对热输入的敏感性较低.

(3)相比于TIG焊接,TC4钛合金激光焊接具有快速加热和冷却的特征,焊缝区呈现魏氏组织特征,针状α'马氏体相互交错,且马氏体更加细小,接头的显微硬度值相对较高. 而TC4钛合金TIG焊接接头在近缝热影响区粗晶区存在软化现象,显微硬度值低于母材.

-

表 1 基体和膜层表面元素测试结果(质量分数,%)

Table 1 Results of element values of substrates and TiSiN film by XRF (wt. %)

材料 基体 薄膜膜层 Mg Al Zn Mn Li Ti Si N AZ31 95.909 2 3.084 5 0.700 3 0.306 0 — 65.727 3 15.913 2 18.359 5 Mg8Li 91.808 1 — — — 余量 65.575 1 15.519 7 18.905 2 表 2 薄膜粗糙度

Table 2 Roughness of films

基体 颗粒平均

粒径d/nm表面粗糙度

平均值Ra/nm表面粗糙度

均方根Rms/nmAZ31 22.475 6.79 8.63 Mg-8Li 44.434 12.70 17.10 -

[1] Apelfeld A, Krit B, Ludin V, et al. The characterization of plasma electrolytic oxidation coatings on AZ41 magnesium alloy[J]. Surface & Coatings Technology, 2017, 322: 127 − 133.

[2] Hikmet Altun, Ssdri Sen. The effect of PVD coatings on the corrosion behaviour of AZ91 magnesium alloy[J]. Materials & Design, 2006, 27(10): 1174 − 1179.

[3] 曹慧, 张发, 孟超平. 钢表面纳米TiAlN薄膜的结构表征与性能研究[J]. 表面技术, 2016, 45(10): 108 − 113. Cao Hui, Zhang Fa, Meng Chaoping. Structural characteristics and performance of nano TiAlN film deposited on steels[J]. Surface Technology, 2016, 45(10): 108 − 113.

[4] 王晓奇, 曹慧, 雷彪. W18Cr4V表面TiN/TiCN硬质涂层的制备与表征[J]. 机械科学与技术, 2018, 37(11): 1762 − 1767. Wang Xiaoqi, Cao Hui, Lei Biao. Deposited preparation and characteristic of hard TiN/TiCN coating on W18Cr4V substrate[J]. Mechanical Science and Technology, 2018, 37(11): 1762 − 1767.

[5] 张兴元, 江四川, 杨辉, 等. 制备工艺参数对镁合金表面沉积TiCN薄膜耐蚀性的影响[J]. 材料导报, 2013, 27(9): 115 − 117. Zhang Xingyuan, Jiang Sichuan, Yang Hui, et al. Effect of deposition parameters on corrosion resistance of the AZ31 magnesium alloy coated by TiCN film[J]. Material Review, 2013, 27(9): 115 − 117.

[6] 姚晓红, 田林海, 张杨, 等. 镁合金表面非平衡磁控溅射CrN镀层结合性能和摩擦磨损性能[J]. 稀有金属材料与工程, 2013, 42(3): 589 − 592. Yao Xiaohong, Tian Linhai, Zhang Yang, et al. Adhesion and wear properties of Cr-N coatings on magnesium alloy by unbalanced magnetron sputtering[J]. Rare Metal Materials and Engineering, 2013, 42(3): 589 − 592.

[7] 李忠厚, 郭腾腾, 宫学博, 等. 磁控溅射镀钛提高AZ31镁合金耐磨耐蚀性能的研究[J]. 表面技术, 2014, 43(6): 121 − 124. Li Zhonghou, Guo Tengteng, Gong Xuebo, et al. Research on improving the corrosion resistance and wear resistance of magnesium alloy by magnetron sputtering Ti[J]. Surface Technology, 2014, 43(6): 121 − 124.

[8] Wu Guosong, Zeng Xiaoqin, Yuan Guangyin. Growth and corrosion of aluminum PVD-coating on AZ31 magnesium alloy[J]. Materials Letters, 2008, 62: 4325 − 4327. doi: 10.1016/j.matlet.2008.07.014

[9] Surmeneva M A, Surmenev R A. Microstructure characterization and corrosion behaviour of a nanohydroxyapatite coating deposited on AZ31 magnesium alloy using radio frequency magnetron sputtering[J]. Vacuum, 2015, 117: 60 − 62. doi: 10.1016/j.vacuum.2015.04.004

[10] 农尚斌, 喻利花, 许俊华. Ti-Si-N复合膜的微结构及性能研究表面技术[J]. 表面技术, 2008, 37(2): 45 − 48. Nong Shangbin, Yu Lihua, Xu Junhua. Microstructure and properties of Ti-Si-N nano composites deposited by magnetron sputtering[J]. Surface Technology, 2008, 37(2): 45 − 48.

[11] 徐建华, 马大衍, 马胜利, 等. Ti-Si-N纳米复合超硬薄膜的高温热稳定性[J]. 稀有金属材料与工程, 2005, 34(11): 1178 − 1180. Xu Jianhua, Ma Dayan, Ma Shengli, et al. Thermal stability of Ti-Si-N super hard nanocomposite coatings[J]. Rare Metal Materials and Engineering, 2005, 34(11): 1178 − 1180.

[12] Chang Chi-Lung, Chen Wei-Chih, Tsai Pi-Chuen, et al. Characteristics and performance of TiSiN/TiAlN multilayers coating synthesized by cathodic arc plasma evaporation[J]. Surface & Coatings Technology, 2007, 202: 987 − 992.

[13] Li Haitao, Wang Qiang, Zhuang Minghui, et al. Characterization and residual stress analysis of TiN/TiCN films on AZ31 magnesium alloy by PVD[J]. Vacuum, 2015, 112: 66 − 69. doi: 10.1016/j.vacuum.2014.11.019

[14] Ji Peng, Long Ruiying, Hou Legan, et al. Study on hydrophobicity and wettability transition of Ni-Cu-SiC coating on Mg-Li alloy[J]. Surface & Coatings Technology, 2018, 350: 428 − 435.

[15] 李海涛, 杨文杰, 王军, 等. 焊接工艺对TP304钢焊缝金属组织及性能的影响[J]. 焊接学报, 2012, 33(4): 89 − 90. Li Haitao, Yang Wenjie, Wang jun, et al. Study of microstructure and properties in weld metal of TP304 steel under three processes[J]. Transactions of the China Welding Institution, 2012, 33(4): 89 − 90.

[16] Sanjeev K, Sharma, Deuk Young-kim. Abnormal residual stress in nanostructured Al thin films grown on Ti/glass substrates[J]. Current Applied Physics, 2013, 13(9): 1874 − 1879. doi: 10.1016/j.cap.2013.07.022

[17] 吴国松. 镁合金表面PVD膜层的制备与腐蚀破坏[D]. 上海: 上海交通大学, 2006. Wu Guosong. Preparation and corrosion failuer of PVD coating on Magnesiam alloy surface[D]. Shanghai: Shanghai Jiao Tong University, 2006.

-

期刊类型引用(7)

1. 赵忠华,吴海荣,谢洪志,张桐源,郭晶. 薄板钛合金激光焊接接头力学性能研究. 飞机设计. 2025(02): 66-69+80 .  百度学术

百度学术

2. 吕泽阳,王宇宙,刘何意. 钛合金对接与角接氩弧焊缝性能研究. 冶金与材料. 2025(05): 73-75 .  百度学术

百度学术

3. 冯栋,周卫涛,颉文峰. 焊接工艺对薄壁环形钛合金焊缝成形及承载能力的影响. 焊接. 2023(04): 55-59 .  百度学术

百度学术

4. 乔永丰,雷玉成,姚奕强,王泽宇,朱强. 焊接方法对316L不锈钢焊缝抗辐照损伤性能的影响. 焊接学报. 2023(05): 77-83+94+133-134 .  本站查看

本站查看

5. 马寅,韩晓辉,李刚卿,杨志斌,宋东哲,靳月强. TC4钛合金激光-MIG复合焊接头组织性能. 电焊机. 2023(08): 93-97+114 .  百度学术

百度学术

6. 曾俊谚,庄园,杨涛,钟玉婷,杨响明. 基于飞秒激光的钛合金表面微纳米结构制备及腐蚀行为. 焊接. 2023(08): 37-43 .  百度学术

百度学术

7. 孙修圣. 钛管道K-TIG深熔焊工艺研究及应用. 压力容器. 2023(09): 23-30 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: