Explosive welding and performance test of Al0.1CoCrFeNi high-entropy alloy/TA2 composite plate

-

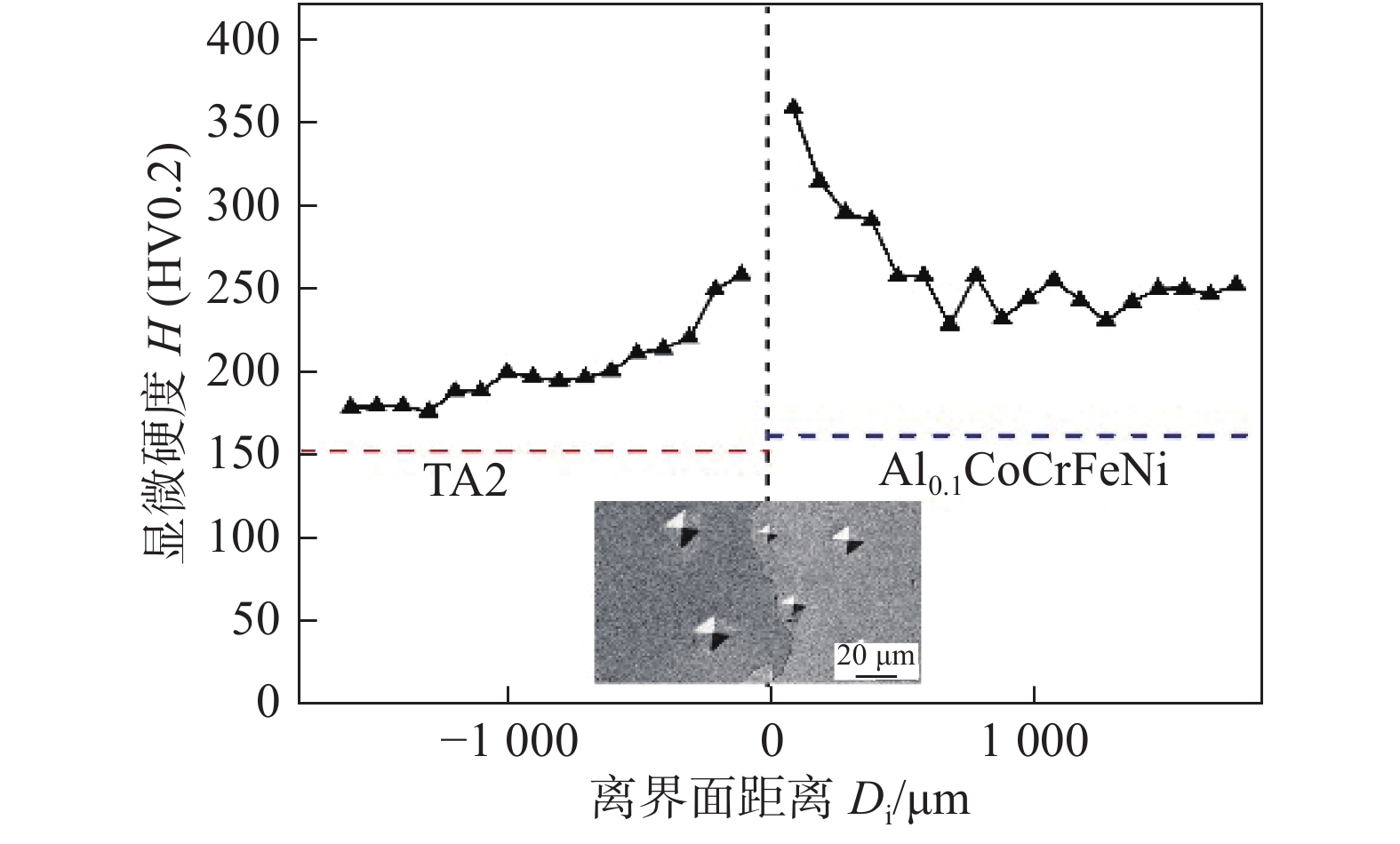

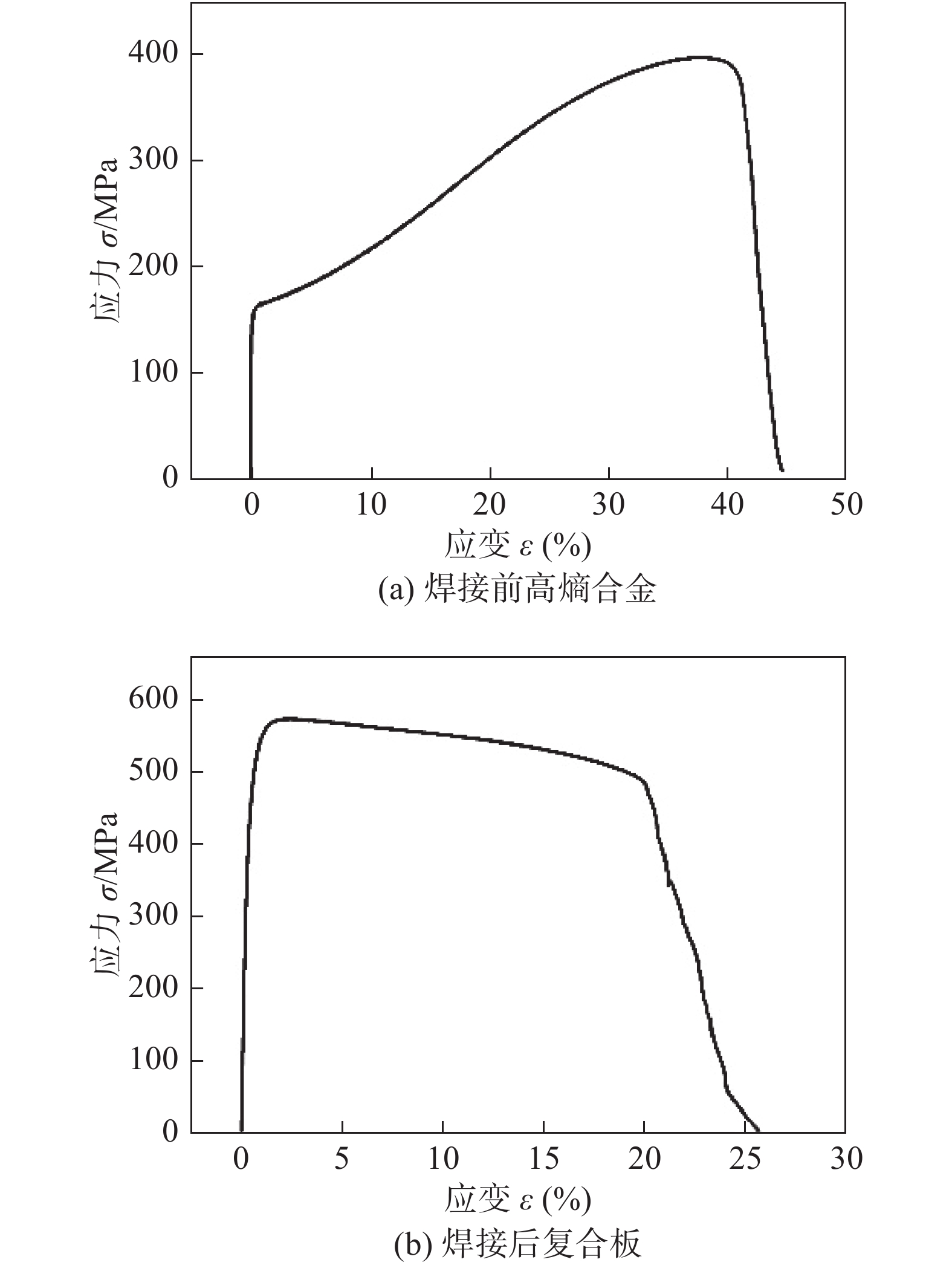

摘要: 高熵合金是一种新兴的多主元合金,具有作为结构材料的潜力,但对高熵合金焊接工艺的研究还很有限. 通过爆炸焊接实现了Al0.1CoCrFeNi高熵合金与TA2工业纯钛的复合连接,并研究了Al0.1CoCrFeNi/TA2复合板的微观结构和力学性能. 结果表明,Al0.1CoCrFeNi/TA2复合板具有不连续熔化区的波状结合界面,熔化区中呈现多元素混合状态,并且具有较均匀的元素分布. 熔化区的硬度大于界面附近的硬度,并且硬度随着离界面距离的增加逐渐降低,但仍高于原始材料. 相对于焊接前的Al0.1CoCrFeNi高熵合金的强度(398 MPa),爆炸焊接后的Al0.1CoCrFeNi/TA2复合板强度明显提高(567 MPa),但断后伸长率降低. 说明爆炸焊接可以有效的将Al0.1CoCrFeNi高熵合金与TA2工业纯钛相结合,而形成的复合板具有良好的力学性能.Abstract: High-entropy alloy (HEA) is an emerging material which possesses great potential as a structure material, but there are relatively few studies devoted to HEA joining technology. The TA2 commercial pure titanium plate and Al0.1CoCrFeNi HEA are joined by explosive welding technology. The microstructure analysis and mechanical tests of Al0.1CoCrFeNi/TA2 composite plate are conducted. These results show that the Al0.1CoCrFeNi/TA2 composite plate possesses a wavy bonding interface with a discontinuous melted zone. Moreover, the melted zone presents a multi-element mixed state, and a relatively uniform element distribution occurs in the melted zone. The hardness of the melting zone is greater than that of TA2 side and Al0.1CoCrFeNi HEA side. And it gradually decreases with the increase of the distance from the interface. However, the hardness of the composite plate is still higher than that of the parent materials. Compared with the strength of the Al0.1CoCrFeNi HEA plate (398 MPa), the strength of the Al0.1CoCrFeNi/TA2 composite plate after explosive welding is significantly increased (567 MPa). On the contrary, elongation is reduced after explosive welding. The results tests show that explosive welding is an effective method for joining TA2 commercial pure titanium with Al0.1CoCrFeNi high-entropy alloy, and the welded composite plate shows great mechanical performance.

-

Keywords:

- explosive welding /

- high-entropy alloy /

- titanium alloy /

- microstructure /

- mechanical properties

-

0. 序言

合金的开发一般基于单个主要元素,很少有两个主要元素. 在2004年,Yeh等人[1]提出了一种含有多主元的新合金系统-高熵合金. 将5种及5种以上金属元素以等摩尔比或近等摩尔比混合得到的合金称为高熵合金[2]. 高熵合金通常为体心立方(BCC)或面心立方结构(FCC)的固溶体,高熵效应是形成这种独特固溶体结构的主要原因[3]. 基于其固溶体结构,高熵合金具有出色的耐腐蚀性能[4]、耐磨性[5]和强度[2]等. 由于在高辐射剂量下其不易形成缺陷,高熵合金在核能和高效火力发电领域中具有应用的潜力. Garlapati等人[6]研究发现单相Al0.1CoCrFeNi高熵合金对离子辐照表现出很大的相稳定性.

目前对于高熵合金的研究多数集中在含AlCrFeNi元素的体系,高熵合金的结构和性能与合金成分有着密切的联系,并可以通过添加不同的合金元素对合金的性能进行调控,以获得具有不同特性的高熵合金体系[7-8]. 然而,单一金属或合金难以满足众多领域对材料性能的综合要求,国内外学者越来越重视对双层或多层异种金属复合材料的研究. 因此高熵合金对技术加工和制造的适用性也至关重要[9].

焊接是在大多数行业中使用的关键技术之一,例如航空航天、建筑结构和能源. 在相似或不同的材料系统中与高熵合金复合,对于扩大高熵合金的应用越来越重要. 因此,了解高熵合金在焊接过程中的行为和力学性能具有重要意义[10]. 目前,已有一些关于高熵合金的焊接技术的研究,例如电弧焊[11]、电子束焊接[12]、激光焊接[13]和搅拌摩擦焊[14]等. 但大多研究仅集中于将两个高熵合金焊接在一起,关于高熵合金与传统金属的焊接研究仍然有限[15].

爆炸焊接方法可以焊接各种相似或不同金属[16],例如铝/铜[17]、钛/铝[18]和钢/钛[19]等,通常这些组合难以通过其它焊接工艺结合. 爆炸焊接是一种固态过程,在由爆炸加速的覆板的冲击所产生的高压下,两层或多层异种金属产生冶金结合[20-21]. 通过爆炸焊接实现了Ni合金和Al合金等常用金属的冶金结合,其接头组织及力学性能也得到研究[22-23]. 但是目前尚未检索到高熵合金爆炸焊接的相关研究论文.

Al0.1CoCrFeNi高熵合金与TA2工业纯钛结合形成的复合板通过扫描电镜(SEM)和能谱议(EDS)对界面的微观结构和元素分布进行了表征. 此外,对复合板进行了显微硬度、抗拉强度和抗剪强度测试以评估其力学性能,并观察了断裂后的形貌.

1. 试验方法

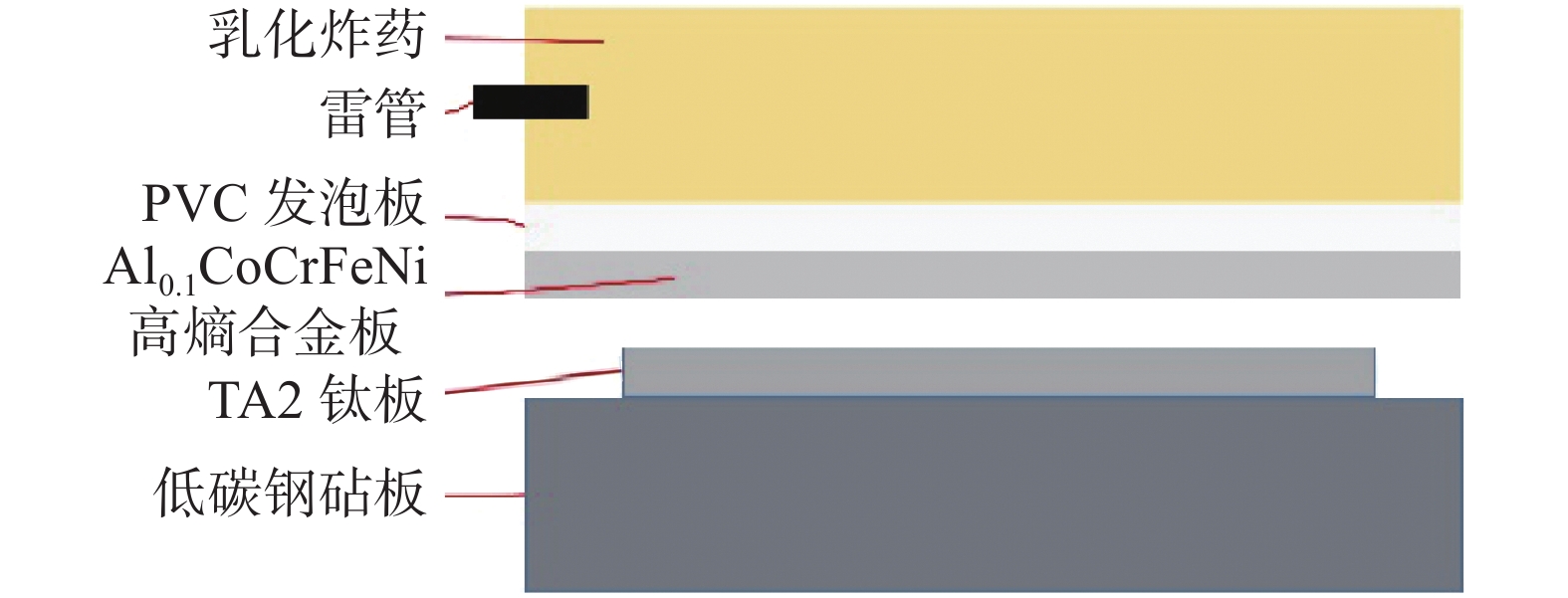

通过感应熔化纯度高于99.9%的Al,Co,Cr,Fe,Ni按照1∶10∶10∶10∶10的比例来制备名义成分为Al0.1CoCrFeNi高熵合金的铸锭[24-26]. 将Al0.1CoCrFeNi高熵合金铸锭切割为75 mm × 60 mm × 2 mm的板状材料用作基板. 为了避免雷管区及边界效应的影响,使用的TA2工业纯钛的长和宽都要大于基板,其尺寸为150 mm × 100 mm × 2 mm,TA2工业纯钛的化学成分如表1所示. 将TA2工业纯钛用作覆板,其上放置170 mm × 120 mm × 2 mm尺寸的PVC发泡板(密度约为0.38 g/cm3)保护,防止表面烧蚀. 此外,TA2工业纯钛覆板与Al0.1CoCrFeNi高熵合金基板间的距离保持为6 mm. 按质量分布混合25%的玻璃微球(HGM,直径约为55 μm,壁厚1 ~ 2 μm)与75%的乳化基质制成乳化炸药,乳化基质的成分如表2所示. 乳化炸药的密度约为0.8 g/cm3,爆轰速度约为2400 m/s. 在8 mm厚度铝蜂窝(正六边形胞格边长为8 mm,壁厚为60 μm)中装入乳化炸药制成铝蜂窝结构炸药[27],并放置到结构顶端. Al0.1CoCrFeNi高熵合金与TA2工业纯钛爆炸焊装配示意图如图1所示.

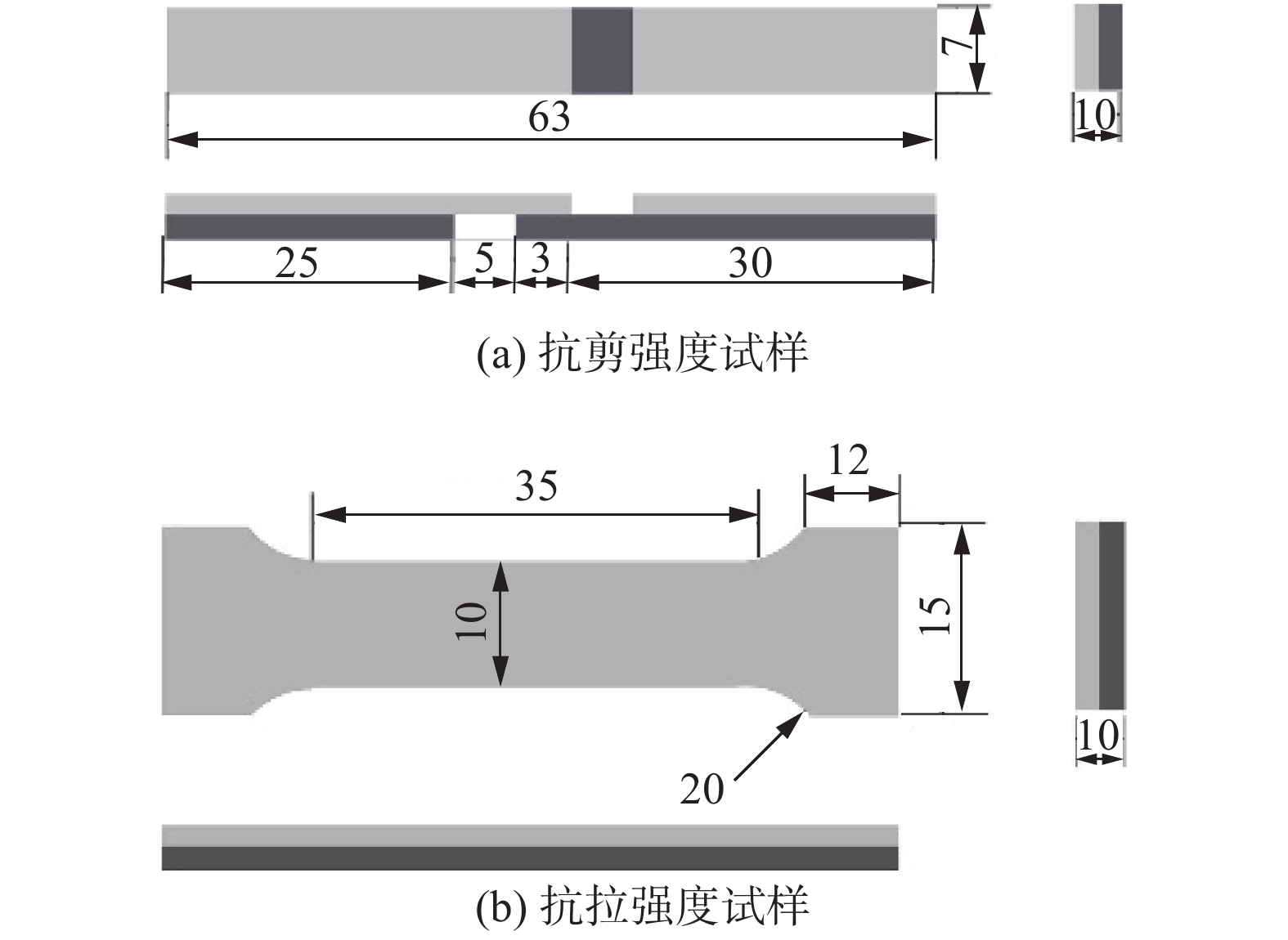

表 1 TA2工业纯钛的化学成分(质量分数,%)Table 1. Chemical compositions of TA2 commercial pure titanium plateFe C N H O Ti 0.080 0.01 0.009 0.008 0.10 余量 表 2 乳化基质的成分(质量分数,%)Table 2. Components of the emulsion matrixNH4NO3 NaNO3 H2O C18H38 C24H44O6 C12H26 75 10 8 4 2 1 为了研究结合界面的微观结构,沿着爆炸方向切割了试样,并对截面进行了打磨和抛光. 使用扫描电镜SEM(GeminiSEM 500)检查结合界面的微观结构,并通过能谱议(EDS)进行成分分布研究. 为了评估复合后的力学性能,沿垂直于焊接样品界面的方向进行维氏显微硬度测试,负载为200 g,时间为15 s. 为了表征复合材料的力学性能,沿着爆炸焊接方向切割了抗拉强度和抗剪强度试样,具体尺寸如图2所示,其中抗拉强度试样原始材料与焊后材料的厚度分别为2与4 mm. 根据标准GB/T 6396—2008,抗拉强度与抗剪强度的拉伸应变率为1 × 10−4 s−1,并通过SEM检查试样的断裂表面.

2. 界面形貌和微观结构分析

2.1 界面波形特征分析

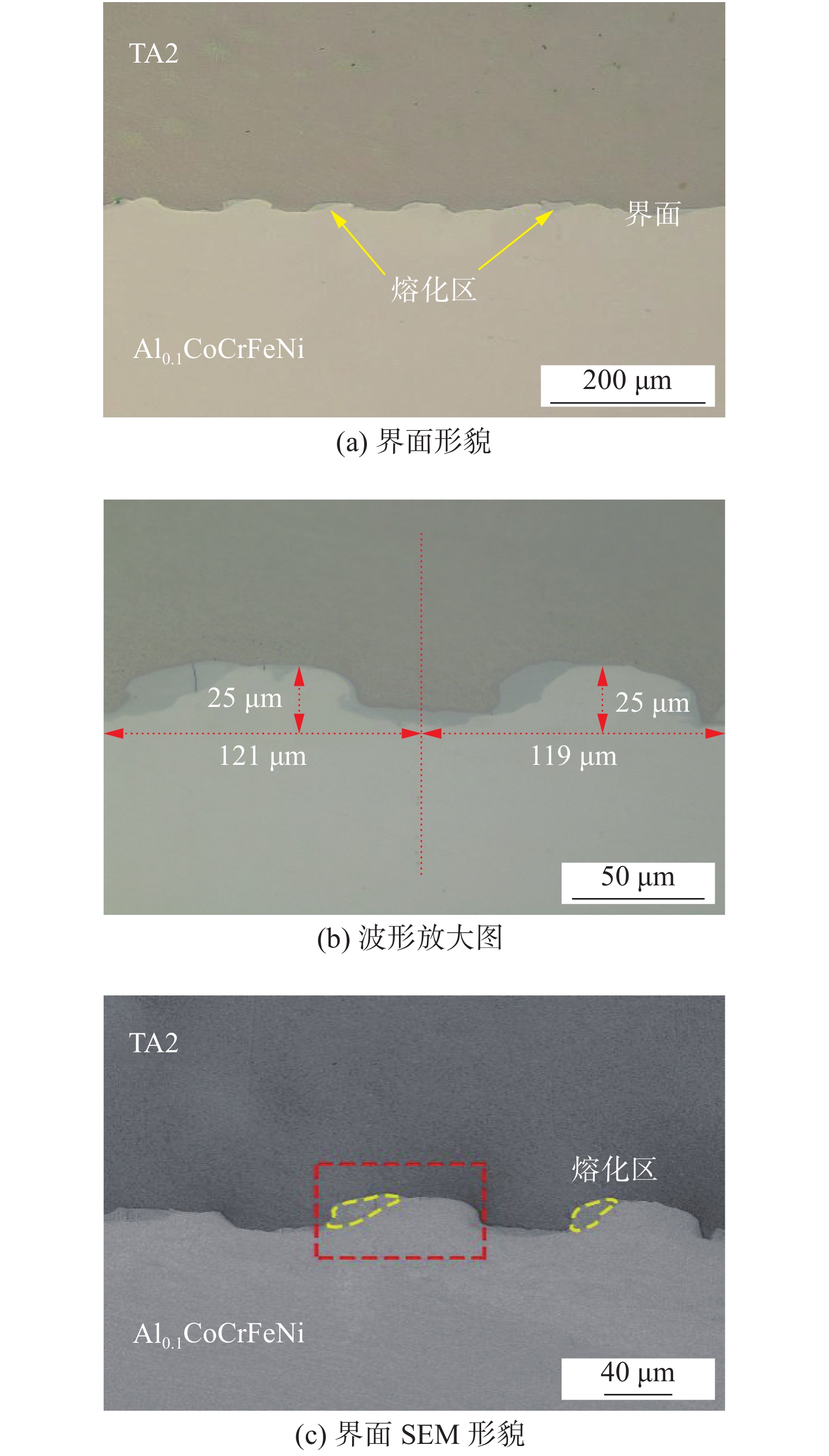

图3所示为Al0.1CoCrFeNi/TA2复合板不同放大倍率下的光学显微图像. 从图3a看出,结合界面没有出现明显的孔隙和裂纹,且呈现出周期性的波形. 如图3b所示,波形的波幅和波长分别约为25和120 μm. 波状结合可以增大界面的接触面积,形成啮合效果,这表明爆炸焊接的Al0.1CoCrFeNi/TA2复合板界面具有较高的结合强度[28].

进一步对复合板的界面进行形貌分析,如图3c所示,熔化区结构有规律地出现在隆起部分(黄色虚线框所示),即熔化区周期性地形成于界面波峰处. 熔化区是波状结合界面的一个典型特征. 在爆炸产生的冲击和高温高压作用下,结合区域的金属表面呈现流体状态. 覆板的射流与母板上产生的凸起相互作用,使得射流向下偏转并使基板变形,从而在基板中形成凹陷,并因此形成新的凸起,连续碰撞形成在碰撞板的相对侧上的凸起的循环过程形成了材料间混合的熔化区[29]. 同时,碰撞面上产生的熔融金属被包裹,使界面不能形成连续的熔化层,形成了图3c所示的界面结构,而这种不连续的熔化层相对于连续熔化界面更有利于提升复合板的结合强度[17].

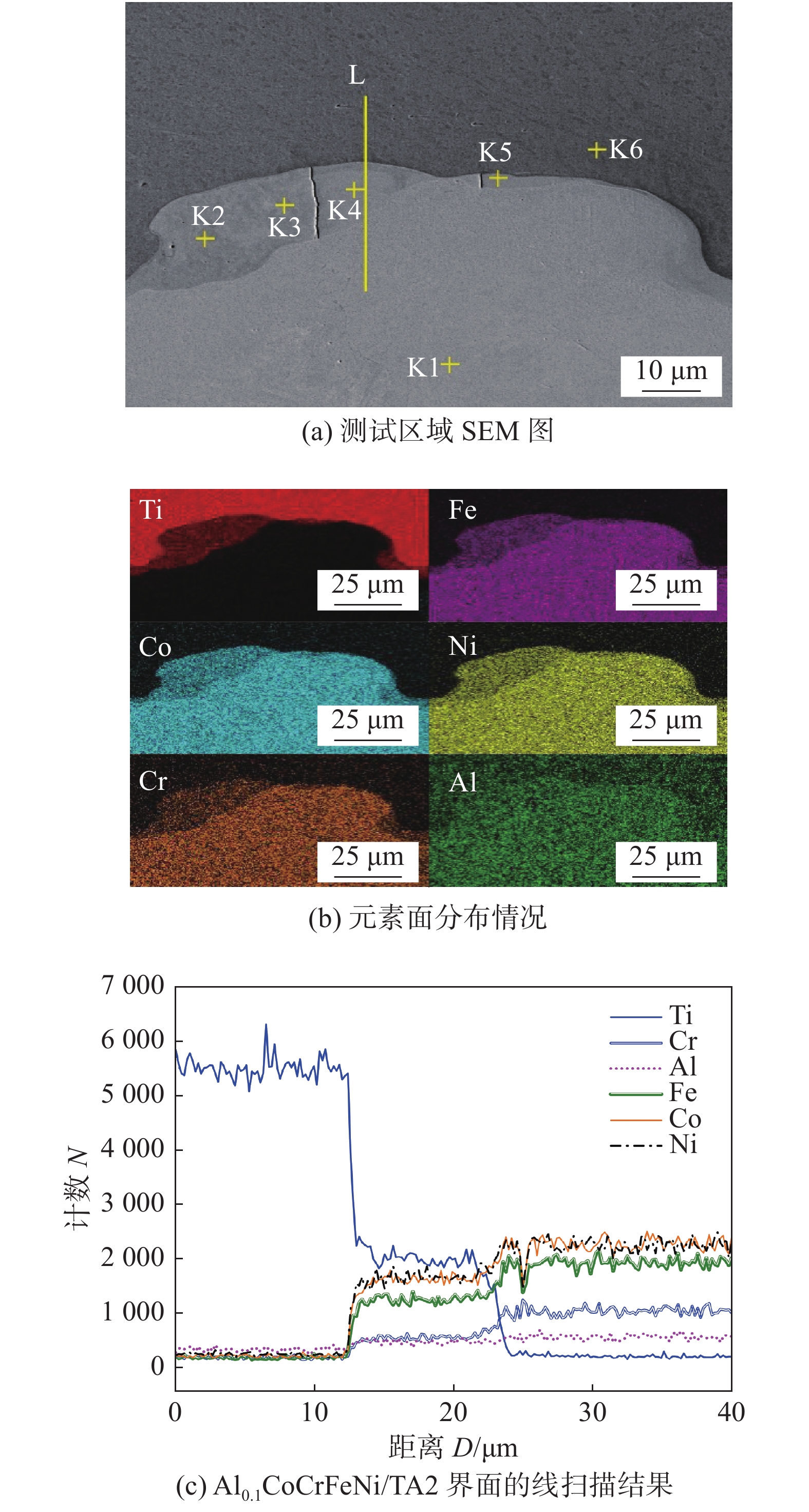

对Al0.1CoCrFeNi/TA2复合板的界面进行了元素分布表征,如图4所示. Al0.1CoCrFeNi高熵合金中元素的分布没有变化,并且所有元素在基体中较为均匀地分布. 为了进一步研究结合界面的熔化区,对该样品进行了线扫描并对不同点的元素进行了分析. 图4c所示为沿图4a中线L的元素分布情况. 线扫描分析显示,在熔化区中元素分布呈现平台状. 从高熵合金侧到钛侧的区域分界处,Ti元素的浓度迅速增加,而其它元素在结合界面之后消失. 该分析表明,除了在熔化区存在两种物质的混合外,结合界面上还存在不连续过渡层,而窄的扩散区域可以限制其中金属间化合物的形成[30]. 此外,在整个结合界面上,结合形式主要是直接地固态冶金结合,这种特征也可从图4中界面处元素分布的突变发现. 界面附近不同位置的元素分析如表3所示,在熔化区中Ti,Fe,Co,Ni,Cr的原子比例大约为2∶1∶1∶1∶1,熔化区可能由Ti与Al0.1CoCrFeNi高熵合金以2∶1的比例混合产生. 爆炸焊接过程中,由于高速冲击,复合板的界面处产生的温度高于两侧金属的熔点[31]. 而积累的高温增加原子扩散系数以及金属射流的混合搅拌,从而导致不连续熔化界面结构的形成[29].

表 3 Al0.1CoCrFeNi/TA2复合板中对应点的化学组成(质量分数,%)Table 3. The chemical composition of corresponding points for Al0.1CoCrFeNi/TA2 composite plate位置编号 Ti Fe Co Ni Cr Al K1 − 23.24 26.42 26.24 21.98 2.12 K2 32.81 15.24 16.98 16.32 17.28 1.37 K3 31.52 15.91 17.61 16.73 16.89 1.34 K4 29.35 16.13 18.07 17.30 17.82 1.32 K5 31.62 15.42 17.40 16.46 17.83 1.27 K6 100 − − − − − 在AlxCoCrFeNi高熵合金体系中,随着铝含量的降低,合金塑性增加[32]. Al0.1CoCrFeNi高熵合金是具有良好塑性的FCC结构,因此基体并未因冲击产生裂纹. 而图4a焊接界面的熔化区中则观察到一些垂直于界面、并未分离界面的横向裂纹,这表明在熔化区中产生了脆性混合物,但裂纹未扩展到基体材料. 结合表3中对界面处对应点的元素分析,AlxCoCrFeNi体系与Ti元素混合后,熔化区的硬度可能会显著提高[33],这与后续的硬度测试结果一致.

3. 力学性能测试与分析

3.1 显微硬度试验

为了评估Al0.1CoCrFeNi/TA2复合板的力学性能,使用维氏压痕技术测试了焊接后复合板、TA2工业纯钛和Al0.1CoCrFeNi高熵合金的显微硬度. 图5所示为界面附近的爆炸焊接样品的硬度曲线. Ti合金的硬度在靠近界面处增加,并随着远离界面逐渐降低而在距界面1000 μm以外处,大约为180 HV,稍高于焊接前Ti合金的155 HV的硬度值. 靠近界面的较高硬度可能是由于碰撞时的冲击压力或强烈的塑性变形所致[29, 34]. Al0.1CoCrFeNi高熵合金的硬度也在界面附近明显增加,但在远离界面处硬度相对焊接前有明显提高,显微硬度达到 ~ 250 HV,这可能由于在碰撞的冲击压力下使得铸态组织更加密实且因冲击产生了硬化所致[35]. 熔化区的硬度测试如图5中SEM图像所示,可以观察到熔化区的硬度明显高于临近基体中的硬度. 在Al0.1CoCrFeNi高熵合金与其它金属的焊接过程中,Al0.1CoCrFeNi高熵合金中的元素可能进入晶格并改变金属的力学性能[36]. 结合熔化区的元素分析可以发现,Al0.1CoCrFeNi高熵合金与Ti混合后产生了高硬度的脆性混合区.

3.2 抗拉强度

为了研究爆炸焊接后Al0.1CoCrFeNi/TA2复合板的力学性能,分别对Al0.1CoCrFeNi/TA2复合板及其对应Al0.1CoCrFeNi高熵合金母材进行了抗拉强度测试. 图6所示为Al0.1CoCrFeNi/TA2复合板及Al0.1CoCrFeNi高熵合金母材在抗拉强度测试前后的宏观形貌. 可以看出两者都在拉伸过程中发生了一定程度的颈缩,并且Al0.1CoCrFeNi高熵合金表面出现明显的滑移带. 从图6b可以观察到,在抗拉强度测试后Al0.1CoCrFeNi/TA2复合板没有分离,这表明了Al0.1CoCrFeNi高熵合金与TA2工业纯钛具有优良的结合强度. 图7所示为Al0.1CoCrFeNi/TA2复合板和Al0.1CoCrFeNi高熵合金母材抗拉强度测试的应力—应变曲线. Al0.1CoCrFeNi/TA2复合板的抗拉强度为567 MPa,高于焊接前Al0.1CoCrFeNi高熵合金母材的抗拉强度398 MPa. 但是Al0.1CoCrFeNi/TA2复合板的断后伸长率为25.6%,低于Al0.1CoCrFeNi高熵合金板44.7%的断后伸长率. Al0.1CoCrFeNi/TA2复合板抗拉强度的增加和断后伸长率的降低主要是由爆炸焊接引起的加工硬化造成[36].

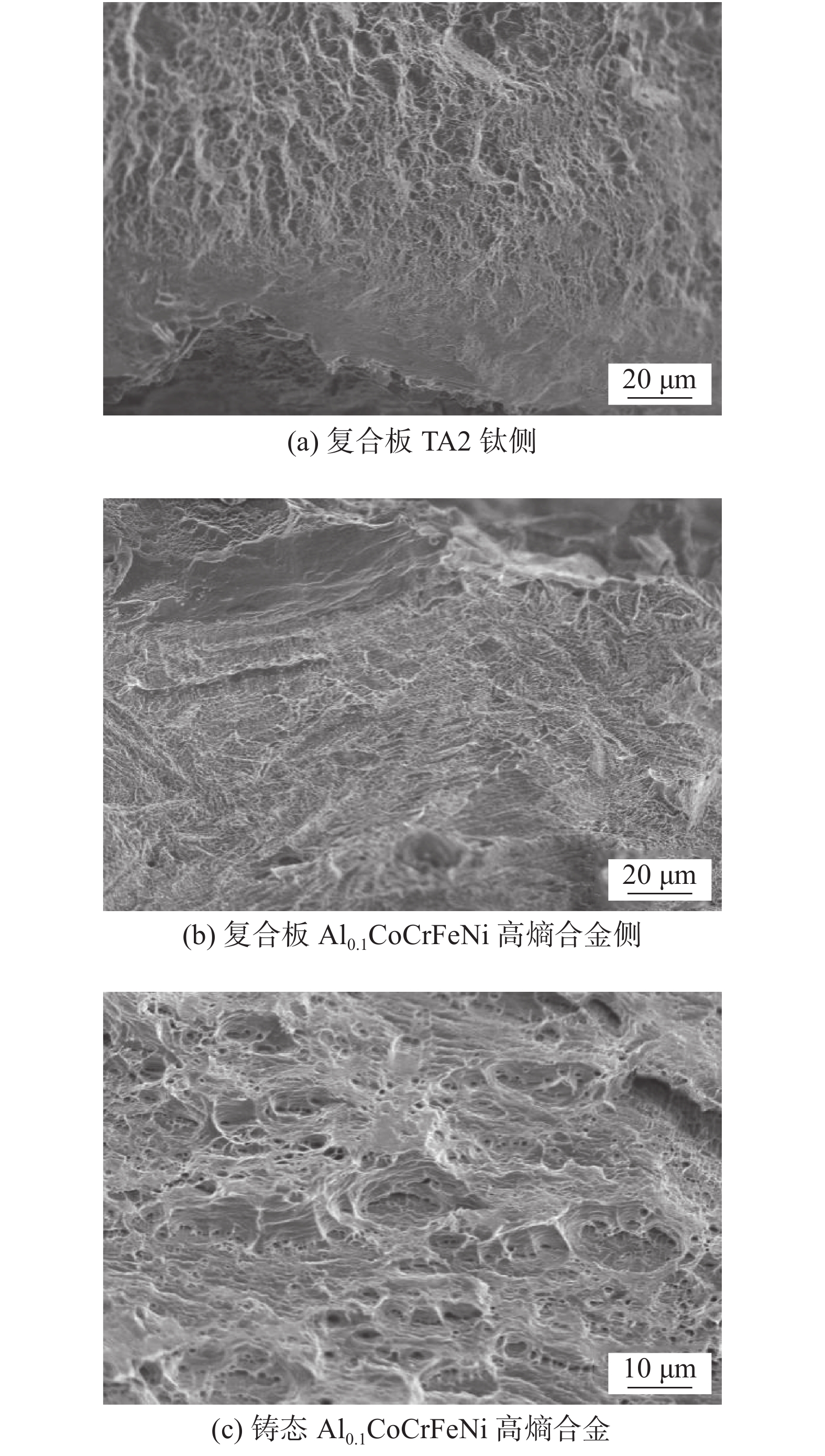

经过抗拉测试后,通过SEM观察材料的断口形貌,如图8所示. 由于Al0.1CoCrFeNi高熵合金具有良好的塑性,因此可以在未焊接的Al0.1CoCrFeNi高熵合金的断口上观察到许多韧窝,如图8c所示. 在爆炸焊接过程中,覆板与基板间的高速碰撞会在焊接区域中引起强烈的塑性变形,从而使得界面附近的金属发生明显的加工硬化. 从图8中可以看出,结合界面附近的TA2侧具有明显的解理断裂的明确特征,而远离界面的TA2和Al0.1CoCrFeNi高熵合金的基体显示出许多韧窝. 界面区域出现的解理断裂的特征可以归因于结合界面中局部熔化区的形成和冲击变形引起的加工硬化. 在这些区域中,严重变形的晶粒和脆性的化合物的存在降低了界面附近材料的延展性,导致了裂纹的产生并沿着载荷方向的扩展[37].

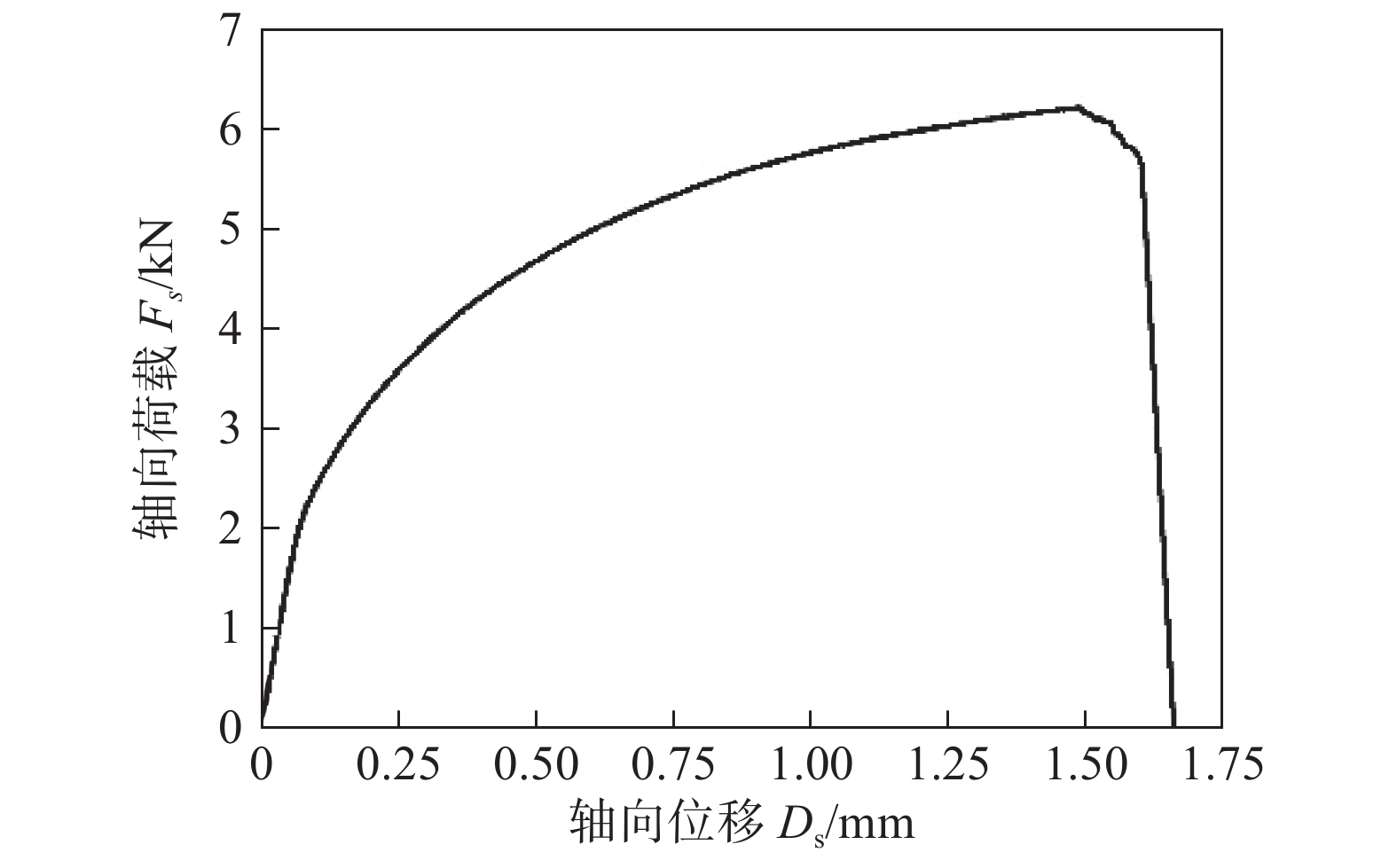

波状结合有利于在界面两侧的基体之间产生强大的机械锁定效果[38]. 图9显示了Al0.1CoCrFeNi/TA2复合板在抗剪强度测试过程中的力−位移曲线. 沿平行爆轰波方向进行抗剪强度测试后,可得复合板的抗剪强度约为287 MPa. 当抗剪强度测试方向与爆炸焊接方向相同时,波状结合产生的机械锁定效果有利于提高界面的结合强度[19],这在力−位移曲线中表现为较平稳的上升阶段,并在下降阶段仍经历了一定的变形.

图10所示为Al0.1CoCrFeNi/TA2复合板抗剪强度测试的断口SEM形貌和EDS结果. 从图中可以看出,Al0.1CoCrFeNi/TA2复合板界面的剪切断裂形态剪切区域的界面呈现出不连续熔化区的波状形貌,表现为局部熔化区和基体材料的交替出现. 其主要原因可能是Al0.1CoCrFeNi/TA2复合板界面上的局部熔化区形成了较硬的多元素混合物. 断口的元素测试结果也与抗剪强度测试前可以从剪切区域的界面上观察到带有熔化区的波状结合相一致. 在外力作用下,较硬的熔化区中的裂纹会迅速扩展到相对较软的一侧并相互连接,然后在机械锁定效应失效后发生断裂.

4. 结论

(1) 爆炸焊接技术可获焊接质量良好的Al0.1CoCrFeNi/TA2复合板,焊接界面呈现出波状结合,并且具有不连续的熔化区.

(2) 在Al0.1CoCrFeNi/TA2复合板界面处,元素含量具有明显的分界;而熔化区中各元素呈现均匀分布,并且产生了脆性的混合物.

(3) Al0.1CoCrFeNi高熵合金和TA2工业纯钛的显微硬度值均在结合界面处达到了峰值,随着离结合界面距离的增加而呈现出递减的趋势,最终在远离结合界面的区域趋于稳定且高于基体的硬度. 此外,熔化区的硬度明显高于界面两侧的基体.

(4) Al0.1CoCrFeNi高熵合金与TA2工业纯钛的复合界面在抗拉强度测试后没有发生分离,复合后的材料强度相对于复合前的高熵合金增加,而延展性减低. 抗拉强度测试中裂纹沿脆性的熔化区扩展,抗拉强度断口中熔化区与界面两侧的材料基体交替分布. 拉伸断裂后,界面附近出现解理断裂特征,而远离界面处呈现韧性断裂.

-

表 1 TA2工业纯钛的化学成分(质量分数,%)

Table 1 Chemical compositions of TA2 commercial pure titanium plate

Fe C N H O Ti 0.080 0.01 0.009 0.008 0.10 余量 表 2 乳化基质的成分(质量分数,%)

Table 2 Components of the emulsion matrix

NH4NO3 NaNO3 H2O C18H38 C24H44O6 C12H26 75 10 8 4 2 1 表 3 Al0.1CoCrFeNi/TA2复合板中对应点的化学组成(质量分数,%)

Table 3 The chemical composition of corresponding points for Al0.1CoCrFeNi/TA2 composite plate

位置编号 Ti Fe Co Ni Cr Al K1 − 23.24 26.42 26.24 21.98 2.12 K2 32.81 15.24 16.98 16.32 17.28 1.37 K3 31.52 15.91 17.61 16.73 16.89 1.34 K4 29.35 16.13 18.07 17.30 17.82 1.32 K5 31.62 15.42 17.40 16.46 17.83 1.27 K6 100 − − − − − -

[1] Yeh J W, Chen S K, Lin S J, et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299 − 303. doi: 10.1002/adem.200300567

[2] Li Z M, Pradeep K G, Deng Y, et al. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off[J]. Nature, 2016, 534(7606): 227 − 230. doi: 10.1038/nature17981

[3] Miracle D B, Senkov O N. A critical review of high entropy alloys and related concepts[J]. Acta Materialia, 2017, 122: 448 − 511. doi: 10.1016/j.actamat.2016.08.081

[4] Shi Y, Yang B, Xie X, et al. Corrosion of AlxCoCrFeNi high-entropy alloys: Al-content and potential scan-rate dependent pitting behavior[J]. Corrosion Science, 2017, 119: 33 − 45. doi: 10.1016/j.corsci.2017.02.019

[5] Chuang M H, Tsai M H, Wang W R, et al. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys[J]. Acta Materialia, 2011, 59(16): 6308 − 6317. doi: 10.1016/j.actamat.2011.06.041

[6] Garlapati M M, Vaidya M, Karati A, et al. Influence of Al content on thermal stability of nanocrystalline AlxCoCrFeNi high entropy alloys at low and intermediate temperatures[J]. Advanced Powder Technology, 2020, 31(5): 1985 − 1993.

[7] Wang R, Zhang K, Davies C, et al. Evolution of microstructure, mechanical and corrosion properties of AlCoCrFeNi high-entropy alloy prepared by direct laser fabrication[J]. Journal of Alloys and Compounds, 2017, 694: 971 − 981. doi: 10.1016/j.jallcom.2016.10.138

[8] Liu X, Cheng H, Li Z, et al. Microstructure and mechanical properties of FeCoCrNiMnTi0.1C0.1 high-entropy alloy produced by mechanical alloying and vacuum hot pressing sintering[J]. Vacuum, 2019, 165: 297 − 304. doi: 10.1016/j.vacuum.2019.04.043

[9] Gangireddy S, Gwalani B, Soni V, et al. Contrasting mechanical behavior in precipitation hardenable AlxCoCrFeNi high entropy alloy microstructures: single phase FCC vs. dual phase FCC-BCC[J]. Materials Science and Engineering: A, 2019, 739: 158 − 166. doi: 10.1016/j.msea.2018.10.021

[10] Wang T, Shukla S, Komarasamy M, et al. Towards heterogeneous AlxCoCrFeNi high entropy alloy via friction stir processing[J]. Materials Letters, 2019, 236: 472 − 475. doi: 10.1016/j.matlet.2018.10.161

[11] Sokkalingam R, Mishra S, Cheethirala S R, et al. Enhanced relative slip distance in gas-tungsten-arc-welded Al0.5CoCrFeNi high-entropy alloy[J]. Metallurgical And Materials Transactions A, 2017, 48A(8): 3630 − 3634.

[12] Wu Z, David S A, Feng Z, et al. Weldability of a high entropy CrMnFeCoNi alloy[J]. Scripta Materialia, 2016, 124: 81 − 85. doi: 10.1016/j.scriptamat.2016.06.046

[13] Kashaev N, Ventzke V, Stepanov N, et al. Laser beam welding of a CoCrFeNiMn-type high entropy alloy produced by self-propagating high-temperature synthesis[J]. Intermetallics, 2018, 96: 63 − 71. doi: 10.1016/j.intermet.2018.02.014

[14] Zhu Z G, Sun Y F, Goh M H, et al. Friction stir welding of a CoCrFeNiAl0.3 high entropy alloy[J]. Materials Letters, 2017, 205: 142 − 144. doi: 10.1016/j.matlet.2017.06.073

[15] Yang Y C, Liu C, Lin C Y, et al. Core effect of local atomic configuration and design principles in AlxCoCrFeNi high-entropy alloys[J]. Scripta Materialia, 2020, 178: 181 − 186. doi: 10.1016/j.scriptamat.2019.11.016

[16] Zhang T, Wang W, Zhang W, et al. Microstructure evolution and mechanical properties of an AA6061/AZ31B alloy plate fabricated by explosive welding[J]. Journal of Alloys and Compounds, 2018, 735: 1759 − 1768. doi: 10.1016/j.jallcom.2017.11.285

[17] 周国安, 马宏昊, 沈兆武, 等. 正火处理对Cu/Al爆炸焊接板显微结构及力学性能的影响[J]. 焊接学报, 2019, 40(6): 46 − 51. doi: 10.12073/j.hjxb.2019400153 Zhou Guoan, Ma Honghao, Shen Zhaowu, et al. Influence of normalizing on microstructure and mechanical properties of Cu/Al explosive welded plate[J]. Transactions of the China Welding Institution, 2019, 40(6): 46 − 51. doi: 10.12073/j.hjxb.2019400153

[18] 房中行, 史长根, 冯柯, 等. TA2-1060-TA2复合板爆炸焊接试验及性能测试[J]. 焊接学报, 2019, 40(9): 87 − 92. Fang Zhonghang, Shi Changgen, Feng Ke, et al. Explosive welding experiment and property test of TA2-1060-TA2 cladding plate[J]. Transactions of the China Welding Institution, 2019, 40(9): 87 − 92.

[19] Ning J, Zhang L J, Xie M X, et al. Microstructure and property inhomogeneity investigations of bonded Zr/Ti/steel trimetallic sheet fabricated by explosive welding[J]. Journal of Alloys and Compounds, 2017, 698: 835 − 851. doi: 10.1016/j.jallcom.2016.12.213

[20] Zhang H, Jiao K X, Zhang J L, et al. Experimental and numerical investigations of interface characteristics of copper/steel composite prepared by explosive welding[J]. Materials & Design, 2018, 154: 140 − 152.

[21] 陈洪胜, 王文先, 陈伟, 等. 镁/铝层合板FSW接头微观组织及力学性能[J]. 焊接学报, 2020, 41(3): 38 − 44. Chen H S, Wang W X, Chen W, et al. Microstructure and mechanical properties of FSW joint of Mg/Al clad sheets[J]. Transactions of the China Welding Institution,, 2020, 41(3): 38 − 44.

[22] Findik F. Recent developments in explosive welding[J]. Materials & Design, 2011, 32(3): 1081 − 1093.

[23] Bataev I, Ogneva T, Bataev A, et al. Explosively welded multilayer Ni–Al composites[J]. Materials & Design, 2015, 88: 1082 − 1087.

[24] Xu X D, Liu P, Tang Z, et al. Transmission electron microscopy characterization of dislocation structure in a face-centered cubic high-entropy alloy Al0.1CoCrFeNi[J]. Acta Materialia, 2018, 144: 107 − 115. doi: 10.1016/j.actamat.2017.10.050

[25] Komarasamy M, Alagarsamy K, Mishra R S. Serration behavior and negative strain rate sensitivity of Al0.1CoCrFeNi high entropy alloy[J]. Intermetallics, 2017, 84: 20 − 24. doi: 10.1016/j.intermet.2016.12.016

[26] Sharma A, Balasubramanian G. Dislocation dynamics in Al0.1CoCrFeNi high-entropy alloy under tensile loading[J]. Intermetallics, 2017, 91: 31 − 34. doi: 10.1016/j.intermet.2017.08.004

[27] Li X, Ma H, Shen Z. Research on explosive welding of aluminum alloy to steel with dovetail grooves[J]. Materials & Design, 2015, 87: 815 − 824.

[28] Athar M H, Tolaminejad B. Weldability window and the effect of interface morphology on the properties of Al/Cu/Al laminated composites fabricated by explosive welding[J]. Materials & Design, 2015, 86: 516 − 525.

[29] Sun W, Guo J, Zhang W, et al. Microstructure and strengthening mechanism of Ti/Cu laminated composite produced by underwater explosive welding[J]. Journal of Materials Engineering And Performance, 2020, 29(8): 5069 − 5079. doi: 10.1007/s11665-020-05044-w

[30] Xia H B, Wang S G, Ben H F. Microstructure and mechanical properties of Ti/Al explosive cladding[J]. Materials & Design, 2014, 56: 1014 − 1019.

[31] Chu Q, Zhang M, Li J, et al. Experimental and numerical investigation of microstructure and mechanical behavior of titanium/steel interfaces prepared by explosive welding[J]. Materials Science and Engineering: A, 2017, 689: 323 − 331. doi: 10.1016/j.msea.2017.02.075

[32] Wang W R, Wang W L, Wang S C, et al. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys[J]. Intermetallics, 2012, 26: 44 − 51. doi: 10.1016/j.intermet.2012.03.005

[33] Zhao Y, Wang M, Cui H, et al. Effects of Ti-to-Al ratios on the phases, microstructures, mechanical properties, and corrosion resistance of Al2-xCoCrFeNiTix high-entropy alloys[J]. Journal of Alloys and Compounds, 2019, 805: 585 − 596. doi: 10.1016/j.jallcom.2019.07.100

[34] Zhang T, Wang W, Zhou J, et al. Interfacial characteristics and nano-mechanical properties of dissimilar 304 austenitic stainless steel/AZ31B Mg alloy welding joint[J]. Journal of Manufacturing Processes, 2019, 42: 257 − 265. doi: 10.1016/j.jmapro.2019.04.031

[35] Wang C, Tracy CL, Park S, et al. Phase transformations of Al-bearing high-entropy alloys AlxCoCrFeNi (x = 0, 0.1, 0.3, 0.75, 1.5) at high pressure[J]. Applied Physics Letters, 2019, 114(9): 091902. doi: 10.1063/1.5079868

[36] Zhang M, Zhang T, Cai J Q, et al. Effect of heat treatment on microstucture and properties of explosive welding clad plate of TA1/Q345[J]. China Welding, 2018, 27(1): 26 − 31.

[37] Hoseini-Athar M M, Tolaminejad B. Interface morphology and mechanical properties of Al-Cu-Al laminated composites fabricated by explosive welding and subsequent rolling process[J]. Metals and Materials International, 2016, 22(4): 670 − 680. doi: 10.1007/s12540-016-5687-4

[38] Shi C G, Sun Z R, Fang Z H, et al. Design and test of a protective structure for the double vertical explosive welding of large titanium/steel plate[J]. China Welding, 2019, 28(3): 7 − 14.

-

期刊类型引用(10)

1. 程宗辉,陈云鹏,舒送,蔡绪康,王磊磊. 激光熔化沉积钛合金-高熵合金梯度材料组织演变研究. 精密成形工程. 2024(04): 129-137 .  百度学术

百度学术

2. 刘爱国,王昕龙,王微伟. 基于CiteSpace的国内高熵合金焊接研究进展分析. 焊接技术. 2024(10): 7-12 .  百度学术

百度学术

3. 梁国峰,黄佳雯,胡家念,朱桂春,刘中枢,陈翔. 爆炸焊接A7075/A1060/Ti-6Al-4V三层金属板研究. 工程爆破. 2024(06): 138-144 .  百度学术

百度学术

4. 余丽玲,张成聪,王巍麟,夏佩云,赵慧慧,吴开明. 高熵合金焊接性研究现状与展望. 钢铁研究学报. 2023(04): 365-374 .  百度学术

百度学术

5. 李雪交,钱敬业,毕志雄,张廷赵,代弦德,荣凯. 基于自约束结构炸药的T2/Q345爆炸焊接及数值模拟. 焊接学报. 2023(03): 70-76+132-133 .  本站查看

本站查看

6. 袁嘉欣,邵飞,白林越,徐倩,孙斌,王敬涛. 基于试验和数值模拟的TC1/1060/6061爆炸焊接复合板界面分析. 焊接学报. 2023(09): 81-87+133-134 .  本站查看

本站查看

7. 李文轩,戴美想,吴晓明,孙泽瑞,房中行. 异种金属爆炸焊接窗口分析与应用. 焊接学报. 2022(03): 68-73+86+117 .  本站查看

本站查看

8. 曾翔宇,李晓杰,金平. 碳钢爆炸焊界面形貌预测及影响因素分析. 焊接. 2022(04): 23-31 .  百度学术

百度学术

9. 毕志雄,李雪交,吴勇,熊苏,汪泉,荣凯. 钛箔/钢爆炸焊接的界面结合性能. 焊接学报. 2022(04): 81-85+118 .  本站查看

本站查看

10. 赵丹. 高熵合金的焊接研究综述. 材料热处理学报. 2022(11): 12-18 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: