Microstructure properties and anti-fatigue characteristics on CGHAZ of 600 MPa grade cold-pressed axle housing steel

-

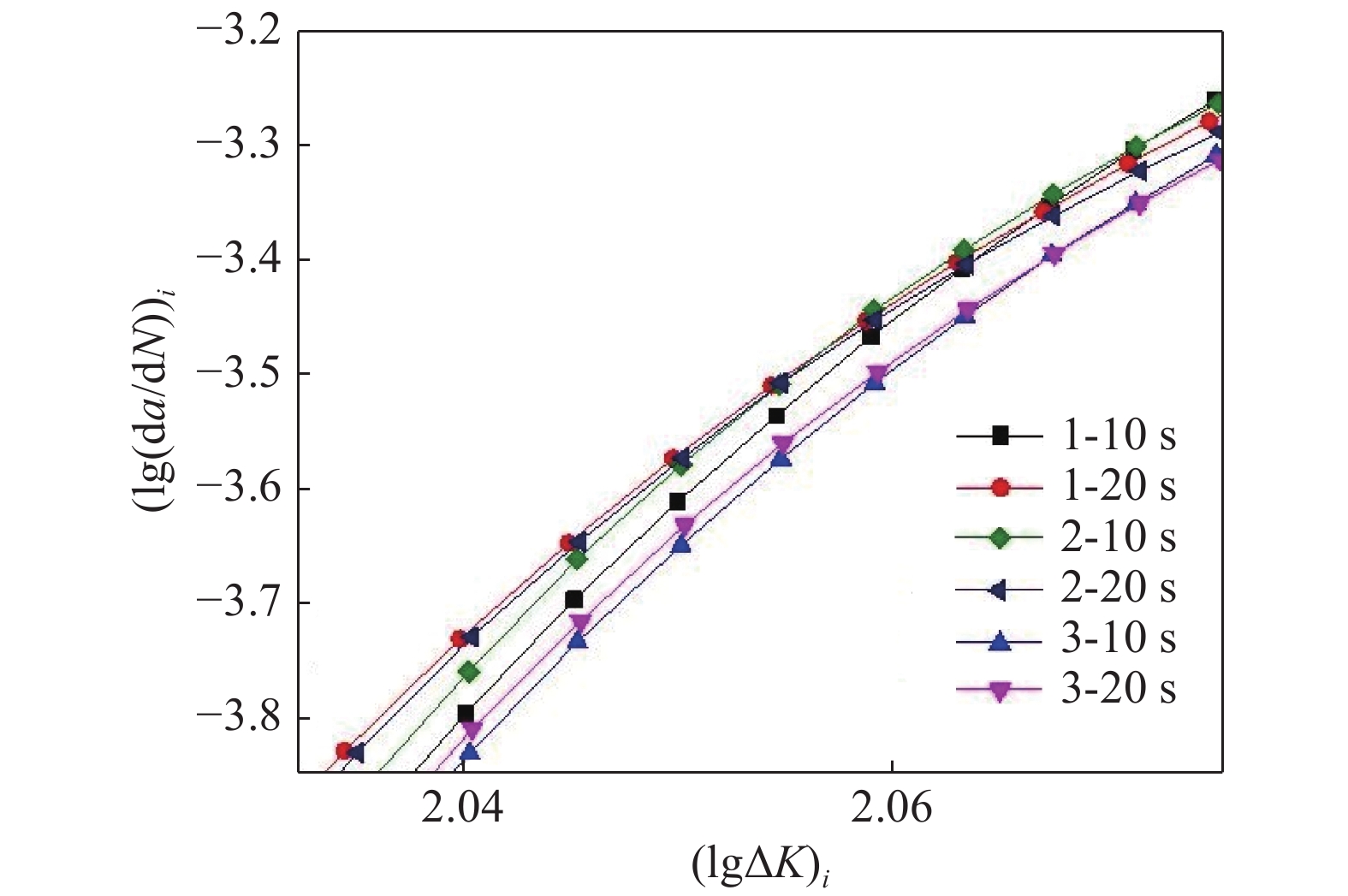

摘要: 为优化600 MPa级冷压桥壳钢的成分与组织性能,进一步提高车桥的疲劳服役寿命,利用热模拟试验机预制了桥壳钢的焊接热影响粗晶区(CGHAZ)组织,采用示波冲击法得到了CGHAZ的冲击韧性,通过维氏硬度计考察了CGHAZ的组织软化特征,通过电液伺服疲劳试验机测试了CGHAZ的疲劳裂纹扩展速率,利用激光扫描共聚焦显微镜(CLSM)、高温激光显微镜(HTLM)、扫描电子显微镜(SEM)以及电子背散射衍射(EBSD)研究了CGHAZ的组织演变,M/A的形态,大角度晶界分布和疲劳二次裂纹的扩展及其走向. 结果表明,采用Nb-V成分体系的桥壳钢脆韧转变温度低于−20 ℃. 当t8/5 ≤ 15 s时粗晶区组织不发生软化且疲劳二次裂纹在大角度晶界处发生明显偏转,其疲劳裂纹扩展速率相对Mn-Ti系和Ti-Nb系最低.Abstract: In order to optimize the composition and microstructure properties of 600 MPa cold-pressed axle housing steel, and further improve the fatigue service life of the axle, this paper uses a thermal simulation test machine to prefabricate the welding heat affected coarse grained area (CGHAZ) structure of the axle housing steel. The impact toughness of CGHAZ was obtained; the softening characteristics of CGHAZ were examined by a Vickers hardness tester; the fatigue crack growth rate of CGHAZ was tested by an electro-hydraulic servo fatigue tester; the laser scanning confocal microscope (CLSM), high temperature Laser microscopy (HTLM), scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD) studied the structural evolution of CGHAZ, the morphology of M/A, the distribution of large-angle grain boundaries, and the propagation of fatigue secondary cracks and their trends. Studies have shown that the brittle-ductile transition temperature of bridge shell steel using the Nb-V composition system is lower than −20 ℃; when t8/5 ≤ 15 s, the microstructure in the coarse grain region does not soften and fatigue secondary cracks occur at large angle grain boundaries. Deflection, the fatigue crack growth rate is the lowest compared to Mn-Ti and Ti-Nb systems.

-

0. 序言

搅拌摩擦焊(friction stir welding, FSW)作为一种固相焊接技术,具有焊缝质量高、变形小等优点[1-2]. 目前加工制造业对焊接智能化、高效化的要求日益上升,机器人搅拌摩擦焊得以更普遍的应用.在实际大型结构的FSW生产中,由于接头形式、板材加工精度以及工装夹具装配质量问题,焊接过程容易产生较大的间隙,对接头的成形和性能极为不利[3-4],当工件之间的间隙超过工件厚度的10%时,很难获得无缺陷质量良好的接头[5]. 间隙的存在导致焊核区(weld nugget zone,WNZ)材料流动不充分,焊缝出现孔洞和隧道等缺陷[6]. 同时,工件被塑化的材料流入间隙,弥补材料缺失使得焊缝位置减薄严重,降低接头承载能力[7].

研究人员[8-9]采用粉末、焊丝或者补偿条作为填充材料对大间隙下的工件进行FSW,得到成形良好无缺陷的接头,接头与常规FSW接头力学性能吻合,然而,当焊接速度过快时,这些填充材料很容易飞出间隙,从而形成缺陷. 同时填充材料需要在焊前放置在间隙内,针对复杂结构间隙及焊接过程中产生的间隙,填充材料的尺寸以及填料的连续性受到限制.

基于传统搅拌摩擦焊方法,填充材料旁轴送料,将FSW与填料过程同时进行,实现大间隙机器人搅拌摩擦填丝焊,并对其接头进行盐雾腐蚀试验,分析搅拌摩擦填丝焊接头不同区域的腐蚀行为差异.搅拌摩擦填丝焊提高了FSW对工况条件的适应性,适用于高铁、船舶和飞机上大型及复杂结构焊缝,有望为工程实际应用提供理论依据和技术支撑.

1. 试验方法

试验材料为5A06铝合金轧制板材,尺寸为300 mm × 70 mm × 3 mm,填充材料为直径1.6 mm的5B06丝材. 机器人搅拌摩擦填丝焊焊接过程示意图及焊具尺寸如图1所示,对接板材焊接间隙为2 mm. 填充丝材经过高推力送丝系统从送丝孔连续输送到储料腔内部,高速旋转的螺杆将金属丝材剪切成粒状材料,粒状材料在自身重力及与螺杆侧壁的摩擦力的影响下,在储料腔内塑化从底部的缝隙流出. 轴向压力使储料腔与板材之间产生挤压效果,粒状材料发生变形堆积并被塑化. 在旋转的搅拌针的驱动作用下,塑化的填充材料发生流动并实现与基材的连接. 试验所采用的焊接工艺参数为转速3 000 r/min,焊接速度200 mm/min,送丝速度1.8 m/min,轴向压力5 000 N,倾角1.5°.

2. 试验结果与分析

2.1 焊缝成形

图2为机器人搅拌摩擦填丝焊接头焊缝表面形貌. 焊缝表面光滑成形良好,无沟槽缺陷,在搅拌针的驱动作用下,塑化的填充材料发生流动后沉积弥补了间隙位置材料缺失,同时焊缝有一定程度的增厚,提高了接头的承载能力.

2.2 焊缝微观组织

图3为焊缝整体微观形貌及不同区域的微观组织. 焊接接头填充材料与基体母材结合良好,焊缝无孔洞及隧道缺陷,由于搅拌针的存在,搅拌针促进塑化的丝材和基材发生流动,提高了填充材料与基材的结合效果. 丝材经过螺杆的剪切及静轴肩的挤压作用,与焊核区受到搅拌针的搅拌作用一样,填充材料也经历了大塑性变形,发生动态再结晶,形成细小的等轴晶.

2.3 焊缝腐蚀性能

搅拌摩擦填丝焊接头经过7天盐雾腐蚀试验后接头各区域腐蚀形貌如图4所示. 接头表面均发生了点蚀坑的萌生, 表面出现腐蚀产物;焊核区及填充材料区域的点蚀坑尺寸较小,且分布较为均匀;母材点蚀坑分布不均匀,尺寸较大.热力影响区(thermo- mechanically affected zone,TMAZ)的点蚀坑随晶粒分布特征呈流线分布,热影响区(heat-affected zone,HAZ)的点蚀坑尺寸较大,且出现一定的聚集现象,点蚀坑发生扩展.焊核区和填充材料区表现出更好的耐腐蚀性能.

第二相分布及尺寸对点蚀坑的形成有巨大影响,第二相和基体之间形成微电偶会导致腐蚀现象发生.焊核区经过塑性变形后第二相颗粒被打碎,尺寸较小分布也更均匀,进而发生腐蚀现象后点蚀坑分布均匀细小;填充材料区域拥有更小且弥散分布的第二相颗粒,填充材料的加入增强了焊核区的耐蚀性.经过轧制后的母材中第二相颗粒尺寸较大且分布不均匀,耐蚀性较差易形成较大的点蚀坑;热力影响区点蚀坑呈流线分布,而热影响区第二相颗粒发生聚集长大,发生点蚀后有利于点蚀坑的扩展,导致热影响区的耐蚀性较差.

图5为热影响区点蚀坑SEM图及附近元素分布.发现在第二相Al6(FeMn)附近产生了明显的腐蚀现象, 点蚀坑发生扩展. 在盐雾环境中,铝合金表面虽然存在一层氧化膜,但是随着溶液中Cl−的侵入,Cl−破坏了表面氧化膜,促进点蚀现象发生. 同时热影响区第二相颗粒Al6(FeMn)与铝基体之间存在腐蚀电位差形成原电池,由于Al6(FeMn)电位高于铝基体[10],第二相颗粒在腐蚀过程中充当阴极,促使周围基体发生腐蚀,因此在第二相附近形成环形腐蚀区域产生腐蚀坑并向四周扩展. 当第二相尺寸较大时,周围基体溶解的范围增大,点蚀坑的尺寸也会更大. 基于元素分布图可以看出,在腐蚀坑附近Al元素含量减少,点蚀坑内金属发生溶解,点蚀孔内阳离子浓度升高,Cl−就会不断侵入以维持平衡.随着Cl−浓度的升高发生水解,导致点蚀坑内部氢离子浓度升高,溶液酸化,促使基体进一步溶解,点蚀坑发生扩展.

2.4 接头力学性能

图6为经过7天盐雾腐蚀接头、未腐蚀接头及母材的拉伸测试结果.未腐蚀接头抗拉强度为388.9 MPa ± 1.4 MPa,断后伸长率为20.5% ± 0.4%,分别达到母材的99%及94%. 经过7天盐雾腐蚀后接头抗拉强度降低到356.6 MPa ± 1.2 MPa,断后伸长率为18.1% ± 0.9%,盐雾腐蚀后接头强度降低了8.3%,断后伸长率下降了11.7%,盐雾腐蚀试验后接头仍保持较优的力学性能. 盐雾腐蚀环境造成焊缝表面出现点蚀坑,而富Cl−环境使基体金属进一步溶解,点蚀坑发生扩展,减少了接头有效承载面积,在承受载荷时其易成为薄弱位置,裂纹在点蚀坑位置产生,降低了接头承载能力.

3. 结论

(1) 实现了大尺寸间隙下机器人搅拌摩擦填丝焊,焊接过程与填料过程同时进行,提高了搅拌摩擦焊对接头间隙的容忍性,消除了焊缝减薄问题.

(2) 填充材料与基材实现了良好的冶金连接,经过剧烈塑性变形后,焊核区和填充材料发生动态再结晶,表现为细小的等轴晶粒.

(3) 未腐蚀接头抗拉强度达到388.9 MPa ± 1.4 MPa,断后伸长率为20.5% ± 0.4%,分别达到母材的99%及94%. 在腐蚀过程中焊核区和填充材料区耐腐蚀性能优于热影响区与母材,点蚀坑细小且均匀分布,7天盐雾腐蚀后接头保持优异的耐蚀性能.

-

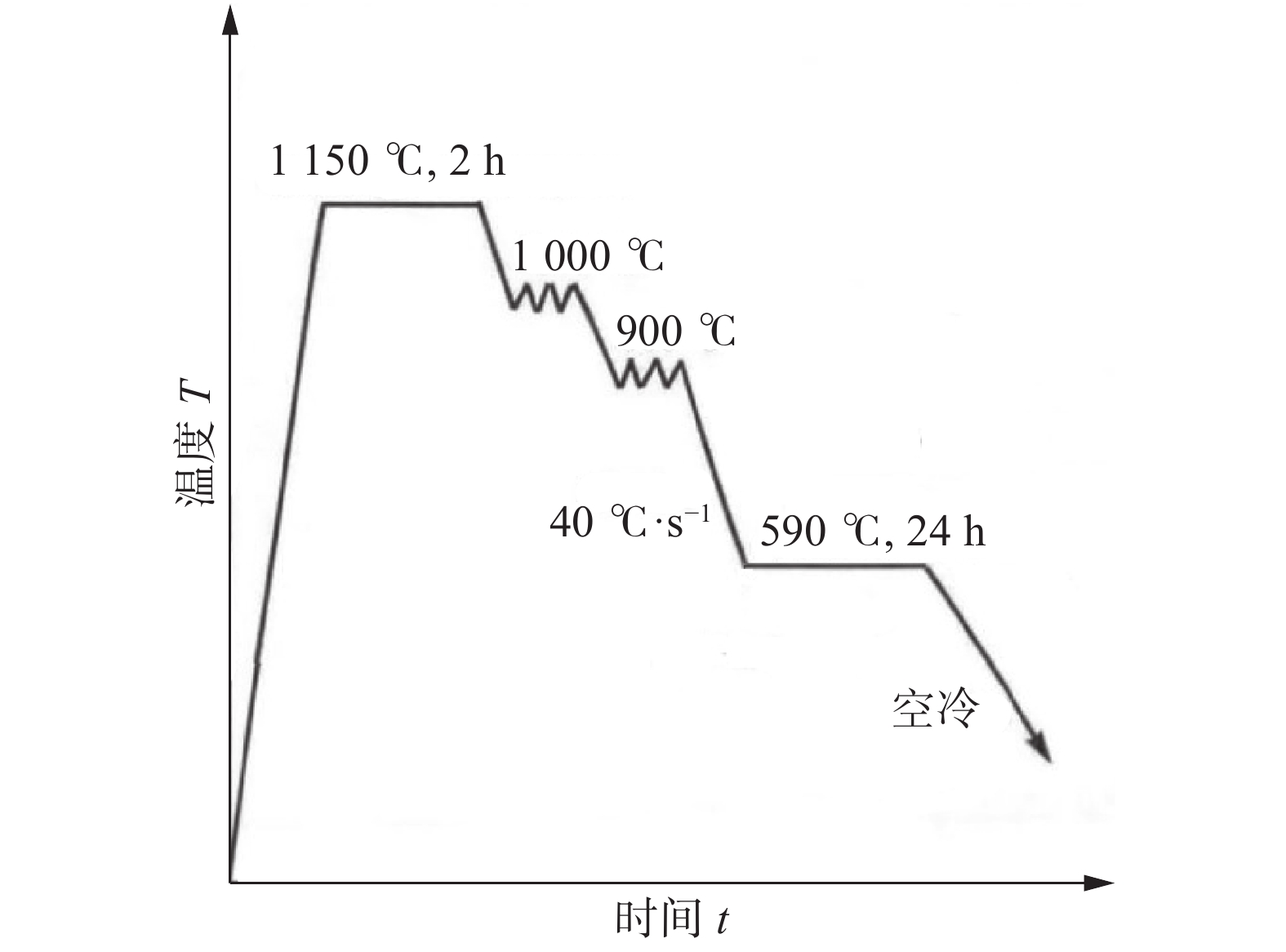

表 1 CGHAZ热模拟工艺

Table 1 the thermal simulation process of CGHAZ

预热温度

To/℃升温速率

v/(℃·s−1)峰值温度

Tc/℃保温时间

t/st8/5/s 25 250 1 250 2 7 25 250 1 250 2 10 25 250 1 250 2 15 25 250 1 250 2 20 -

[1] 李晓林, 崔阳, 肖宝亮, 等. V-N微合金钢在线快速感应回火工艺中V(C, N)析出强化机制[J]. 金属学报, 2018, 54(10): 1368 − 1376. doi: 10.11900/0412.1961.2018.00119 Li Xiaolin, Cui Yang, Xiao Baoliang, et al. Effects of on-line rapid induction tempering on pricipitation strengthening mechanism of V(C, N) in V-N microalloyed steel[J]. Acta Metallurgica Sinica, 2018, 54(10): 1368 − 1376. doi: 10.11900/0412.1961.2018.00119

[2] 刘东雨, 徐鸿, 杨昆, 等. 贝氏体/马氏体复相组织对低碳合金钢强韧性的影响[J]. 金属学报, 2004, 40(8): 882 − 886. doi: 10.3321/j.issn:0412-1961.2004.08.018 Liu Dongyu, Xu Hong, Yang Kun, et al. Effect of bainite/martensite mixed microstructure on the strength and toughness of low carbon alloy steels[J]. Acta Metallurgica Sinica, 2004, 40(8): 882 − 886. doi: 10.3321/j.issn:0412-1961.2004.08.018

[3] Hardy M. Guest editorial of “application of high strength steels in light weight commercial vehicles”[J]. Advances in Manufacturing, 2015, 3(1): 1 − 2. doi: 10.1007/s40436-015-0098-1

[4] 马鸣图, Shi M F. 先进的高强度钢及其在汽车工业中的应用[J]. 钢铁, 2004(7): 68 − 72. doi: 10.3321/j.issn:0449-749X.2004.07.018 Ma Mingtu, Shi M F. Advanced high strength steel and its applications in automobile industry[J]. Iron and Steel, 2004(7): 68 − 72. doi: 10.3321/j.issn:0449-749X.2004.07.018

[5] 张楠,田志凌,潘辉,等. 热轧汽车结构钢在轻量化商用车上的发展与应用[J]. 汽车文摘, 2020(9): 1 − 11. Zhang Nan, Tian Zhiling, Pan Hui, et al. Development and application of hot rolled automotive structural steel in lightweight commercial vehicles[J]. Automotive Digest, 2020(9): 1 − 11.

[6] 中国汽车工程学会. 节能与新能源汽车技术路线图[M]. 北京: 机械工业出版社, 2016. Chinese Society of Automotive Engineering. Energy-saving and new energy vehicle technology roadmap[M]. Beijing: Machinery Industry Press, 2016.

[7] 张大伟, 杜林秀, 肖宝亮, 等. 乘用车轮辐用600 MPa级热轧双相钢失效原因分析[J]. 金属热处理, 2018, 43(7): 224 − 228. Zhang Dawei, Du Linxiu, Xiao Baoliang, et al. Failure analysis of 600 MPa hot rolled dual phase steel for passenger car wheel spoke[J]. Heat Treatment of Metals, 2018, 43(7): 224 − 228.

[8] Wang S C, Kao P W. The effect of alloying elements on the structure and mechanical properties of ultra low carbon bainitic steels[J]. Journal of Materials Science, 1993, 28(19): 5169 − 5175. doi: 10.1007/BF00570058

[9] Gorni A A, Mei P R. Austenite transformation and age hardening of HSLA-80 and ULCB steels[J]. Journal of Materials Processing Technology, 2004, 155: 1513 − 1518. doi: 10.1016/j.jmatprotec.2004.04.245

[10] 刘伟建, 臧淼, 安海玉, 等. 热成型汽车桥壳用Q460C高强度钢板的开发[J]. 宽厚板, 2018, 24(5): 46 − 48. doi: 10.3969/j.issn.1009-7864.2018.05.014 Liu Weijian, Zang Miao, An Haiyu, et al. Development of high strength steel q460c used in hot forming automobile axle housing[J]. Wide and Heavy Plate, 2018, 24(5): 46 − 48. doi: 10.3969/j.issn.1009-7864.2018.05.014

[11] 荆洪阳, 马崇, 樊立国, 等. TMCP钢焊接热影响区局部脆化区断裂韧度测试[J]. 焊接学报, 2004, 25(3): 19 − 23. doi: 10.3321/j.issn:0253-360X.2004.03.006 Jing Hongyang, Ma Chong, Fan Liguo, et al. Investigation on measurement of fatigue toughness for local brittle zone in weld heat-affected zone of TMCP steels[J]. Transactions of The China Welding Institution, 2004, 25(3): 19 − 23. doi: 10.3321/j.issn:0253-360X.2004.03.006

[12] 付魁军, 高铭泽, 冷雪松, 等. TiNb钢焊接热影响区微观组织与冲击性能演变规律[J]. 焊接学报, 2019, 40(5): 36 − 41. Fu Kuijun, Gao Mingze, Leng Xuesong, et al. Evolution of microstructure and impact property in welding HAZ of TiNb steel[J]. Transactions of the China Welding Institution, 2019, 40(5): 36 − 41.

[13] 贺信莱, 尚成嘉, 杨善武,等. 高性能低碳贝氏体钢-成分、工艺、组织、性能与应用[M]. 北京: 冶金工业出版社, 2008. He Xinlai, Shang Chengjia, Yang Shanwu, et al. High-performance low-carbon bainitic steel-composition, workmanship Art, organization, performance and application[M]. Beijing: Metallurgical Industry Press, 2008.

[14] 宋晓飞, 林荣会, 李帅朝, 等. 基于OptiStruct的驱动桥壳轻量化设计[J]. 机械传动, 2019, 43(4): 83 − 88,97. Song Xiaofei, Lin Ronghui, Li Shuaichao, et al. Lightweight design of drive axle housing based on optiStruct[J]. Journal of Mechanical Transmission, 2019, 43(4): 83 − 88,97.

[15] 邹喜红, 刘瑜, 袁冬梅, 等. 桥壳多轴向多激励虚拟试验系统研究[J]. 振动与冲击, 2018, 37(23): 157 − 163,189. Zou Xihong, Liu Yu, Yuan Dongmei, et al. Multi-axial and multi-excitation virtual text system for axle housing[J]. Journal of Vibration and Shock, 2018, 37(23): 157 − 163,189.

[16] 张志远, 刘玉梅, 陈涛, 等. 重型牵引车后桥振动疲劳分析及试验研究[J]. 北京理工大学学报, 2018, 38(3): 267 − 271+299. Zhang Zhiyuan, Liu Yumei, Chen Tao, et al. Vibration fatigue analysis and experimental study of heavy duty truck rear axle[J]. Transactions of Beijing Institute of Technology, 2018, 38(3): 267 − 271+299.

[17] 张杰, 蔡庆伍, 武会宾, 等. 快速加热回火对690 MPa 级海洋工程用钢组织和性能的影响[J]. 金属学报, 2013, 49(12): 1549 − 1557. doi: 10.3724/SP.J.1037.2013.00290 Zhang Jie, Cai Qingwu, Wu Huibin, et al. Effect of tempering temperature on micro-structure and property of 690 MPa grade ocean engineering steel under fast heating rate[J]. Acta Metallurgica Sinica, 2013, 49(12): 1549 − 1557. doi: 10.3724/SP.J.1037.2013.00290

[18] 房玉佩, 谢振家, 尚成嘉. 感应回火对1000 MPa级高强度低合金钢碳化物析出行为及韧性的影响[J]. 金属学报, 2014, 50(12): 1413 − 1420. doi: 10.11900/0412.1961.2014.00306 Fang Yupei, Xie Zhenjia, Shang Chenjia. Effect of induction tempering on carbide precipitation behavior and toughness of a 1000 MPa grade high strength low alloy steel[J]. Acta Metallurgica Sinica, 2014, 50(12): 1413 − 1420. doi: 10.11900/0412.1961.2014.00306

[19] 杨庚蔚, 陆佳伟, 孙辉, 等. Ti-V微合金化热轧高强钢的相变规律及组织性能[J]. 钢铁研究学报, 2019, 31(8): 726 − 732. Yang Gengwei, Lu Jiawei, Sun Hui, et al. Microstructure, mechanical properties and phase transformation behavior of Ti-V microalloyed high strength hot strip steel[J]. Journal of Iron and Steel Research, 2019, 31(8): 726 − 732.

[20] 刘亚军. 基于车轮六分力测量的某商用车车架疲劳寿命分析研究[D]. 合肥: 合肥工业大学, 2018. Liu Yajun. Analysis of the fatigue life of a commercial vehicle frame based on the measurement of the six-component force of the wheel[D]. Hefei: Hefei University of Technology, 2018.

[21] 范例, 谢里阳, 张娜. 重卡驱动桥壳疲劳稳健性与轻量化设计[J]. 东北大学学报(自然科学版), 2019, 40(3): 365 − 369. Fan Li, Xie Liyang, Zhang Na. Fatigue robustness and lightweight design of driving axle housing for heavy truck[J]. Journal of Northeastern University (Natural Science), 2019, 40(3): 365 − 369.

[22] 李晓林, 肖宝亮, 崔阳, 等. 600 MPa冷压桥壳钢疲劳裂纹扩展速率[J]. 新技术新工艺, 2017(3): 1 − 4. Li Xiaolin, Xiao Baoliang, Cui Yang, et al. Fatigue crack propagation rate of 600 mpa cold stamping axle housing steel[J]. New Technology & New Process, 2017(3): 1 − 4.

[23] 李晓刚, 张楠, 赵爱民. 60 kg级埋弧焊丝熔敷金属的疲劳裂纹扩展速率[J]. 电焊机, 2016, 46(4): 98 − 100,133. Li Xiaogang, Zhang Nan, Zhao Aimin. Crack propagation rate of deposited metal of 60 KG level submerged arc welding wire[J]. Electric Welding Machine, 2016, 46(4): 98 − 100,133.

[24] 易镇. X100 管线钢焊接线能量对粗晶区组织和性能的影响[D]. 武汉: 华中科技大学, 2014. Yi Zhen. The influence of X100 pipeline steel welding heat input on the microstructure and properties of the coarse-grained zone[D]. Wuhan: Huazhong University of Science and Technology, 2014.

[25] 宋雪雁, 荆天辅, 刘文昌, 等. V-Ti微合金化贝氏体非调质钢再结晶奥氏体连续冷却转变[J]. 钢铁, 1998, 33(2): 46 − 49. Song Xueyang, Jing Tianfu, Liu Wengchang, et al. Continuous cooling transformation of recrystallized austenite for a V-Ti microalloyed bainite forging steel[J]. Iron and Steel, 1998, 33(2): 46 − 49.

[26] 缪成亮, 尚成嘉, 王学敏, 等. 高Nb X80管线钢焊接热影响区显微组织与韧性[J]. 金属学报, 2010, 46(5): 541 − 546. doi: 10.3724/SP.J.1037.2009.00803 Miu Chenliang, Shang Chengjia, Wang Xuemin, et al. Microstructure and toughness of HAZ in X80 pipeline steel with high Nb content[J]. ACTA Metallurgica Sinica, 2010, 46(5): 541 − 546. doi: 10.3724/SP.J.1037.2009.00803

[27] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006. Yong Qilong. The second phase in steel materials[M]. Beijing: Metallurgical Industry Press, 2006.

[28] 崔辰硕. V-N微合金钢贝氏体区析出行为及组织性能研究[D]. 沈阳: 东北大学, 2015. Cui Chenshuo. Study on the precipitation behavior and microstructure properties of the bainite zone of V-N microalloy steel[D]. Shenyang: Northeastern University, 2015.

[29] 张楠, 田志凌, 张书彦, 等. Q700D热影响粗晶区疲劳寿命与小裂纹扩展分析[J]. 钢铁研究学报, 2019, 31(8): 741 − 747. Zhang Nan, Tian Zhiling, Zhang Shuyan, et al. Prediction of fatigue life and behavior analysis of small creak propagation in CGHAZ of Q700D[J]. Journal of Iron and Steel Research, 2019, 31(8): 741 − 747.

[30] 张楠, 田志凌, 董现春, 等. Q960E热影响粗晶区疲劳寿命与ΔKth值的关系分析[J]. 焊接学报, 2018, 39(7): 106 − 110. Zhang Nan, Tian Zhiling, Dong Xianchun, et al. Research on relationship between ΔKth and fatigue life of heat-affected coarse grain zone in Q960E[J]. Transactions of the China Welding Institution, 2018, 39(7): 106 − 110.

[31] Chen J H, Cao R. Micromechanism of cleavage fracture of metals[M]. Beijing: Science Press, 2019.

下载:

下载: