Effect of rotational speed on forming and tensile shear properties of 2060 Al-Li RFSSW joint

-

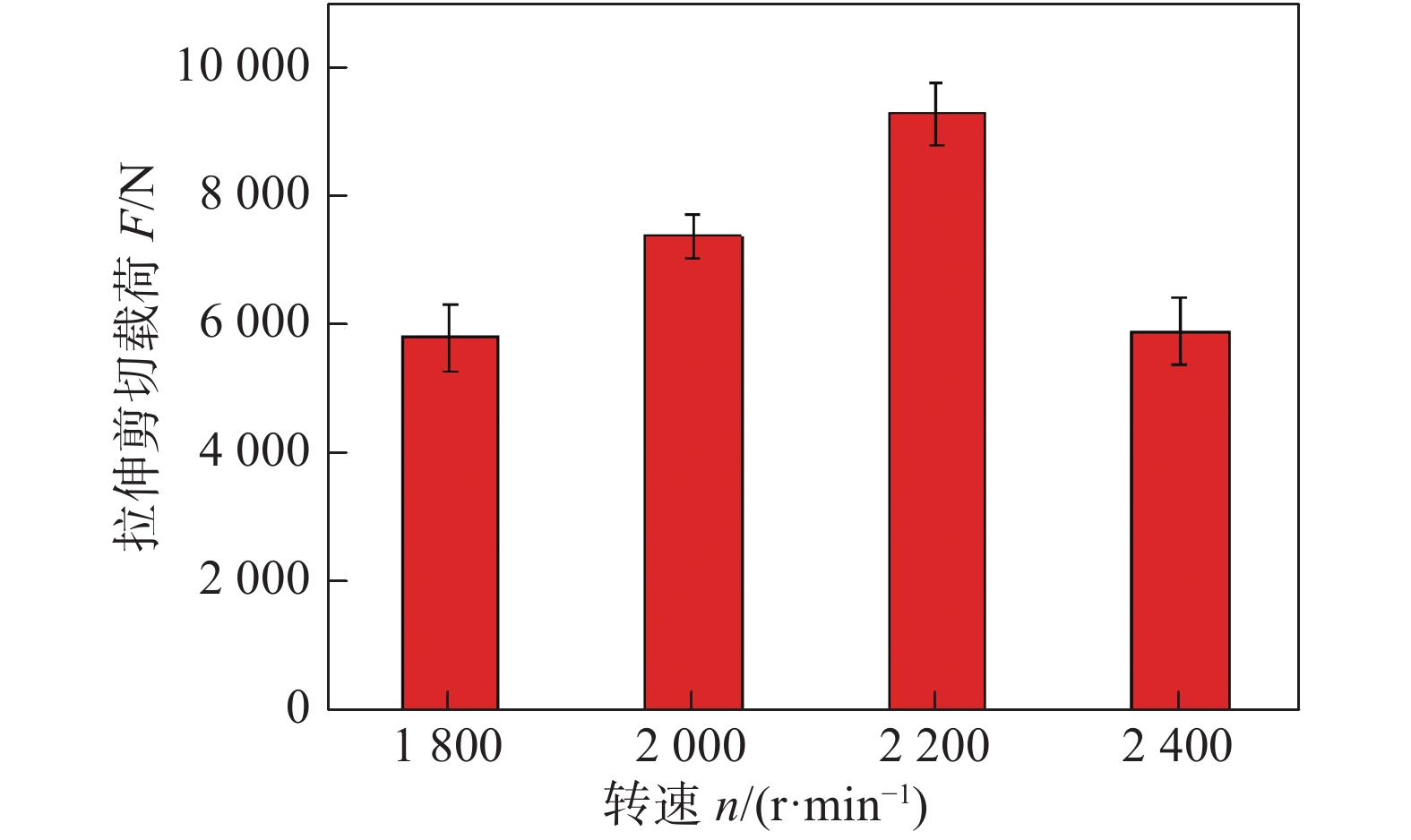

摘要: 以2060铝锂合金为研究对象,进行了回填式搅拌摩擦点焊试验,研究了不同转速下接头内部成形及其与拉伸性能的关系. 结果表明,点焊接头在不同转速下出现了未完全回填缺陷、孔洞缺陷及向下弯曲的钩状结构. 未完全回填缺陷与孔洞缺陷在低转速与高转速下易出现,钩状结构向下弯曲且随转速的增加其高度先增加再减小. 拉剪载荷随转速的提高先增加再降低;在转速为2 200 r/min时,接头拉剪载荷达到9 800 N. 拉剪试样的断裂方式均为剪切断裂,断裂位置可分为三类:沿搭接界面断裂、沿套筒作用区底部断裂及沿包含两者的混合断裂.Abstract: This study chose 2060 Al-Li alloy as the objective to perform RFSSW experiments. The purpose is to investigate the rotational speed on interior form and tensile shear properties of RFSSW joint. The results show that the incomplete refilled defect, void and hook occur in the RFSSW joints under different rotational speeds. Furthermore, the incomplete refilled defect and void easily occur at low and high rotational speeds. Meanwhile, hook bends toward downward and its height first increases and then reduces. The tensile shear load of joint increases and then decreases with increasing rotational speed. The maximum value reaches to 9 800 N under 2 200 r/min. The fracture mode of RFSSW joint is shear fracture, and the fracture location includes three types. They are along the lap interface, along the bottom of the sleeve affected zone and along the above-mentioned mixture fracture.

-

Keywords:

- 2060 Al-Li alloy /

- refill friction stir spot welding /

- defect /

- tensile shear load

-

0. 序 言

由于锂元素的加入,铝锂合金不仅具有低的比重与高的刚度,还保持了较高的强度、较好的腐蚀性能和抗疲劳性能. 近年来,铝锂合金受到航空、航天以及航海行业的广泛关注[1]. 搭接是典型金属结构件的接头形式,可用机械连接与焊接进行制造. 其中,包括铆接在内的机械连接将增加接头质量,而电阻电焊等传统的熔化焊易使接头内部出现热裂纹及孔洞等缺陷. 德国GKSS中心于2002年发明的回填式搅拌摩擦点焊(refill friction stir spot welding,RFSSW)是一种新型的固相焊接技术. RFSSW不仅可避免传统机械连接的增重,同时也可克服一系列熔化焊所产生的缺陷.

国内外学者对RFSSW的研究主要集中在接头的微观组织与力学性能[2-7]. Plaine等人[3]研究了工艺参数对6181-T4铝合金与Ti-6Al-4V钛合金异种材料接头力学性能的影响,结果指出转速是控制接头拉剪性能的主要因素. Campanelli等人[4]指出6061-T6铝合金RFSSW接头的热影响区与焊核区(Stir zone,SZ)晶粒随着转速的增加发生粗化. 与其它铝合金相比,铝锂合金RFSSW研究的较少. Shi等人[6]的研究指出,2 mm厚的2198铝锂合金接头的拉剪强度随着转速的增加呈现先增加再降低的趋势. 由此可见,转速是影响RFSSW接头组织及力学性能的关键因素之一.

2060铝锂合金是第三代铝锂合金的典型代表,目前多用在飞机壁板、蒙皮等结构. 国内外未见对2060铝锂合金RFSSW的报道. 以2060铝锂合金为对象,研究转速对RFSSW接头内部显微结构及拉剪性能的影响. 有利于推动RFSSW工艺焊接机理的研究,进一步扩大RFSSW的应用范围.

1. 试验方法

选用上、下板厚均为3 mm的2060铝锂合金为研究对象,尺寸为150 mm × 40 mm. RFSSW焊接过程中搭接部分的面积为40 mm × 40 mm. 焊接工具由压紧环、套筒及搅拌针组成,其外径分别为18,9及6 mm. 采用套筒下扎式的RFSSW焊接方法,焊接参数的选择:下扎速率及回填速率均为60 mm/min,下扎深度为4 mm,转速分别为1 800,2 000,2 200及2 400 r/min.

焊前将搭接面用砂纸打磨干净并用丙酮去除油污等杂质. 采用电火花线切割设备对焊后的接头进行加工,制备金相试样与拉剪试样. 金相试样沿焊点中心切割;经打磨、抛光及腐蚀后,用光学显微镜对接头横截面进行观察. 图1为拉剪试样的示意图. 拉剪试验在型号为RG4300的试验机上进行,使用扫描电镜对试样断口形貌进行观察.

2. 试验结果与分析

2.1 RFSSW接头缺陷的成形

RFSSW的焊接工艺特点决定了套筒回抽路径及搭接界面为接头的薄弱区域,文中对此区域进行重点分析. 图2为上板上部套筒作用区(sleeve affected zone,SAZ)与热力影响区(thermal-mechanically affected zone,TMAZ)界面. 从图中可以看出,低转速1 800 r/min下的横截面出现了未完全回填缺陷,未完全回填缺陷的底面距离上表面高度为92.4 μm;当转速达到2 000 ~ 2 200 r/min时,接头未完全回填缺陷消失,但表面出现轻微凹陷.;当转速提高到2 400 r/min时,未完全回填缺陷再次出现且表面出现较大的飞边.

图3为套筒作用区底部的缺陷. 从图中可以看出,当转速过低或过高时,套筒作用区底部出现了孔洞缺陷,其向套筒回抽路径及搅拌针作用区底部延伸. 转速为1 800 r/min时,接头内部孔洞缺陷的尺寸较大;转速为2 000 r/min时,孔洞缺陷的尺寸有所减小;当转速增大到2 200 r/min时,孔洞缺陷消失;继续增大转速到2 400 r/min时,孔洞再次出现.

众所周知,钩状结构是决定搭接接头强度关键因素之一. 图4为不同转速下的钩状结构形貌. 对于2060铝锂合金而言,钩状结构的尖端向下板弯曲,不同于5系与6系铝合金RFSSW接头中呈现向上弯曲或倒置的“V”形钩状结构[8]. 将钩状结构尖端距离搭接界面的高度称之为钩状结构弯曲高度H. 高度H随着转速的增加呈现先增加后降低的趋势;在转速为1 800,2 000,2 200及2 400 r/min下H值分别为61.4,68.8,82.4及54.2 μm.

2.2 RFSSW接头的拉剪性能

图5为不同转速下RFSSW接头的拉剪性能. 从图中可以看出,接头拉剪载荷随着转速的增加先增加再降低;当转速为2 200 r/min时,拉剪性能达到最大值,其值为9 800 N. Shen等人[9]指出钩状结构尖端的孔洞尺寸与接头剪切强度有直接关系,孔洞缺陷是影响接头静载强度的决定性因素. 在研究中,转速1 800 r/min下RFSSW接头内部的最大的孔洞缺陷直接导致剪切载荷最低. 对于钩状结构向上弯曲的接头来说,Cao等人[10]认为接头拉剪性能随钩状结构高度的增加而降低. 对于2060铝锂合金来说,带有向下弯曲钩状结构的无孔洞接头的拉剪性能达到最大值.

图6为不同转速下接头断裂位置及断裂表面形貌. 分析可知,不同转速下拉剪试样的断裂位置存在明显的差异. 据文献[10-11]报道,拉剪试样的断裂形式主要包括剪切断裂、剪切塞型断裂及塞型断裂. 在所选的工艺参数范围内,拉剪试样的断裂形式只出现了剪切断裂. 剪切断裂的断裂位置有三种:沿搭接界面断裂(转速为1 800 r/min);沿套筒作用区底面断裂(转速为2 200 r/min);既沿搭接界面又经过套筒作用区底部(转速为2 000 r/min与2 400 r/min). 从图6不同区域的局部放大图可知,套筒作用区底部的孔洞缺陷在断裂面中表现为未连接形貌,如图中区域A与区域B;对于内部无缺陷的接头而言,套筒作用区底部呈现韧窝状,表现为韧性断裂,如区域C所示;对于沿搭接界面与套筒作用区底部断裂的接头来说,在两界面过渡区域的斜截面上可见撕裂表面.

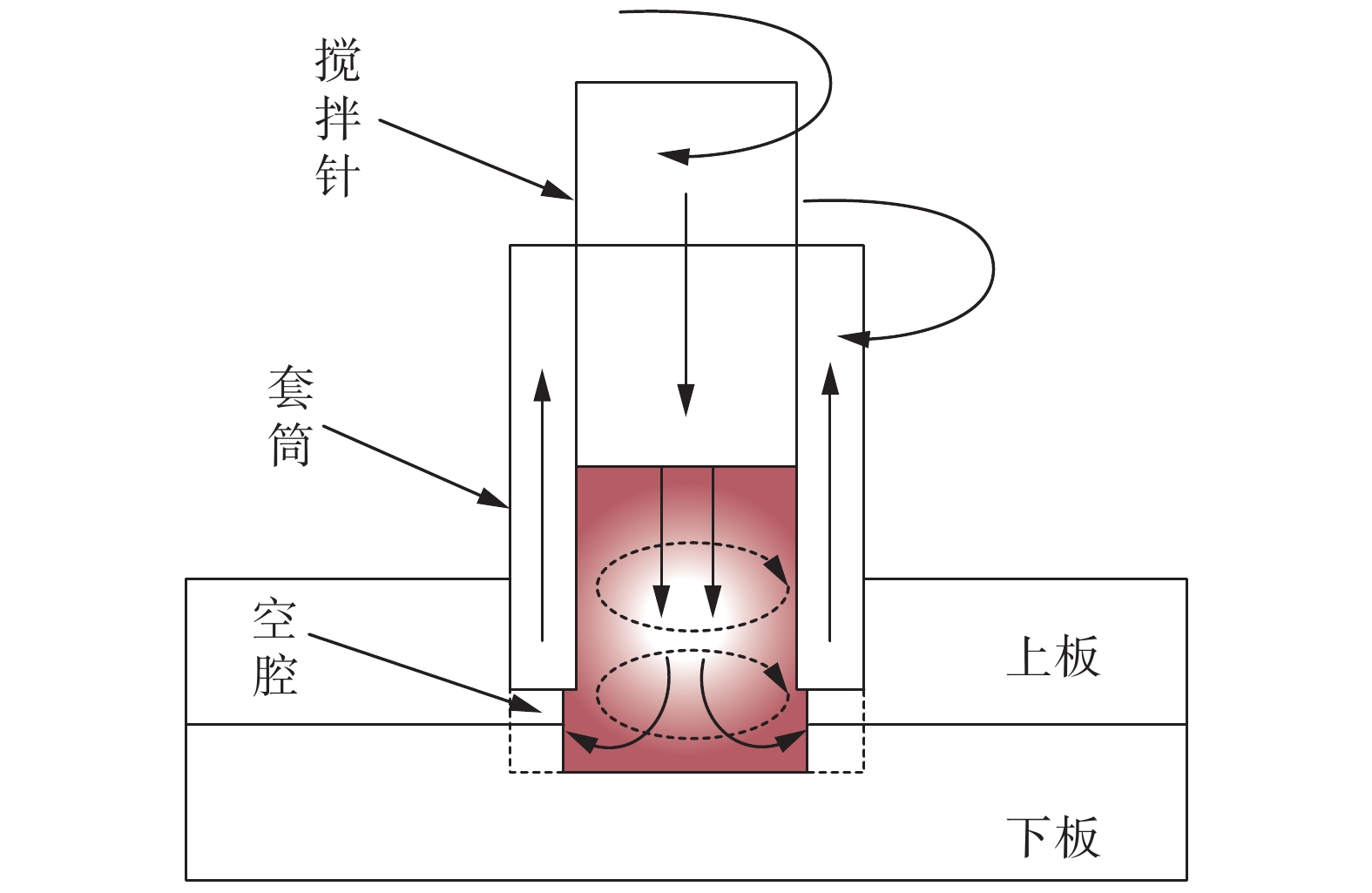

3. 讨 论

对于RFSSW工艺来说,回填阶段对于接头内部成形至关重要. 图7为RFSSW回填阶段的材料流动示意图. 当套筒下扎到设定深度后,套筒与搅拌针同时反向运动;向上运动的套筒在其底部形成一定体积的空腔,向下运动的搅拌针推动套筒内部材料挤入套筒底部瞬时形成的空腔. 从材料流动规律来看,套筒内部向下运动的材料在顶锻力的作用下需瞬时改变90°方向而流向空腔中. 由于套筒与搅拌针的旋转与顶锻作用,被挤入空腔中的热塑性材料受到套筒内壁向上的摩擦力与材料内摩擦引起的与材料运动趋势相反的阻力. 当摩擦力的阻力小于搅拌针施加的作用力时,热塑性材料将无法瞬时填充空腔而形成图3所示的孔洞缺陷. 随着套筒转速的增大,材料产热增多使其流动应力减小,在相同的搅拌针顶锻力下,材料可顺利填充套筒底部的空腔. 因此,套筒作用区底部缺陷随着转速的增加逐步减小甚至消失. 当转速足够大时(2 400 r/min),套筒内部材料与套筒外边缘材料的热塑性状态差异较大,导致连接边界再次出现孔洞缺陷.

从钩状结构的形貌来看,2060铝锂合金RFSSW接头内部的钩状结构向下弯曲,不同于5系及6系铝合金搭接接头内部的钩状结构. 钩状结构的形成机制较为复杂,其不仅与下扎阶段及回填阶段的材料流动有关,还与材料本身的热物性能有关. 不同于向上弯曲的钩状结构,此处钩状结构由于向下弯曲,对接头拉剪载荷影响较小.

在外载荷的作用下,孔洞的扩展路径包括沿SZ/TMAZ界面与沿上下板搭接界面. SZ/TMAZ界面经历了套筒的搅拌与摩擦后其连接强度增加,而搭接界面仅在搅拌针的顶锻力作用下实现扩散连接. 从力的加载方向来看,搭接界面与外载的方向基本一致,有利于剪切断裂的发生. 低转速(1 800 r/min)下较大的孔洞缺陷减小了搭接界面的承载能力,钩状缺陷的弯曲程度较小,裂纹在套筒作用区底部的孔洞缺陷处直接沿着钩状缺陷扩展,最终在搭接面处断裂. 随着转速增加(2 000及2 400 r/min),减小的孔洞缺陷增加了搭接界面的承载能力,搭接界面连接强度增加且钩状缺陷的弯曲高度也逐渐增加,裂纹沿搭接界面扩展的同时也沿套筒作用区底部扩展. 在接头无缺陷的情况下,搭接界面的强度增加且大于套筒作用区底部的连接强度,钩状缺陷的高度达到82.4 μm,拉剪试样在套筒作用区底部发生断裂(2 200 r/min). 综上,拉剪接头的断裂位置主要和孔洞及钩状缺陷的弯曲高度有关.

4. 结 论

(1) 在转速为1 800 ~ 2 200 r/min下,2060铝锂合金RFSSW接头内部的孔洞缺陷随转速的增加逐渐减小直至消失;当转速增加到2 400 r/min时,孔洞缺陷再次出现. 接头内部钩状结构向下弯曲且弯曲高度随转速的增加先增加再降低.

(2) 在转速为1 800 ~ 2 400 r/min下,2060铝锂合金RFSSW接头的拉剪载荷随转速的增加呈现先增加再降低的趋势;在转速2 200 r/min下的拉剪载荷达到最大值9 800 N. 拉剪试样的断裂位置分为沿搭接界面断裂、沿套筒作用区底部断裂及包含上述两者的混合断裂,其具体断裂位置与不同转速下孔洞缺陷尺寸及钩状结构的弯曲高度有关.

-

-

[1] 林 松, 张 坤, 王卫兵, 等. 2060铝锂合金FSW接头微观组织和力学性能[J]. 焊接学报, 2017, 38(6): 101 − 104. Lin Song, Zhang Kun, Wang Weibing, et al. Microstructures and mechanical properties of 2060 aluminum-lithium alloy FSW joint[J]. Transactions of the China Welding Institution, 2017, 38(6): 101 − 104.

[2] Zhou L, Luo L Y, Zhang T P, et al. Effect of rotation speed on microstructure and mechanical properties of refill friction stir spot welded 6061-T6 aluminum alloy[J]. International Journal of Advanced Manufacturing Technology, 2017, 92: 3425 − 3433. doi: 10.1007/s00170-017-0359-1

[3] Plaine A H, Gonzalez A R, Suhuddin U F H, et al. The optimization of friction spot welding process parameters in AA6181-T4 and Ti6Al4V dissimilar joints[J]. Materials & Design, 2015, 83: 36 − 41.

[4] Campanelli L C, Suhuddin U F H, Antonialli A I S, et al. Materiallurgy and mechanical performance of AZ31 magnesium alloy friction spot welds[J]. Journal of Materials Processing Technology, 2013, 213: 515 − 521. doi: 10.1016/j.jmatprotec.2012.11.002

[5] Li Z W, Yue Y M, Ma L, et al. Effects of pin geometry on the material flow behavior of friction stir spot welded 2A12 aluminum alloy[J]. China Welding, 2015, 24(2): 25 − 29.

[6] Shi Y, Yue Y, Zhang L, et al. Refill friction stir spot welding of 2198-T8 aluminum alloy[J]. Transactions of the Indian Institute of Metals, 2017, 71(1): 139 − 145.

[7] 姬书得, 王 月, 马 琳, 等. 回填时间对RFSSW接头断裂行为的影响[J]. 焊接学报, 2017, 38(5): 40 − 43. doi: 10.12073/j.hjxb.20170509 Ji Shude, Wang Yue, Ma Lin, et al. Effect of refill time on fracture feature of refill friction stir spot welding[J]. Transactions of the China Welding Institution, 2017, 38(5): 40 − 43. doi: 10.12073/j.hjxb.20170509

[8] Parra B, Saccon V T, Alcântara N G D, et al. An investigation on friction spot welding in AA6181-T4 alloy[J]. Tecnologia Em Metalurgia Materiais E Mineraã§ã£o, 2011, 8(3): 184 − 190. doi: 10.4322/tmm.2011.029

[9] Shen Z K, Yang X Q, Zhang Z H, et al. Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints[J]. Materials & Design, 2012, 44: 476 − 86.

[10] Cao J Y, Wang M, Kong L, et al. Microstructure, texture and mechanical properties during refill friction stir spot welding of 6061-T6 alloy[J]. Materials Characterization, 2017, 128: 54 − 62. doi: 10.1016/j.matchar.2017.03.023

[11] Li Z W, Ji S D, Ma Y N, et al. Fracture mechanism of refill friction stir spot-welded 2024-T4 aluminum alloy[J]. The International Journal of Advanced Manufacturing Technology, 2016, 86: 1925 − 1932. doi: 10.1007/s00170-015-8276-7

-

期刊类型引用(4)

1. 褚强,杨夏炜,李文亚,范文龙,邹阳帆,郝思洁. 铝锂合金无针搅拌摩擦点焊接头组织演变与强化机制研究. 机械工程学报. 2024(02): 150-158 .  百度学术

百度学术

2. 贺巍亮,霍曼. 随焊激冷控制铝锂合金焊接接头残余应力规律研究. 金属功能材料. 2023(02): 54-60 .  百度学术

百度学术

3. 高彦军,刘西伟,刘旭升,邵震,崔雷. 2060-T8铝锂合金顶锻式摩擦塞补焊接头组织性能研究. 电焊机. 2022(07): 69-75+99 .  百度学术

百度学术

4. 张满当,赵运强,董春林,谭锦红,易耀勇,吴伟. 铝锂合金机器人搅拌摩擦焊接头组织和性能. 焊接学报. 2021(05): 71-76+102-103 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: