Microstructure and high temperature mechanical properties of inertia friction welding joint of K447A + GH4169

-

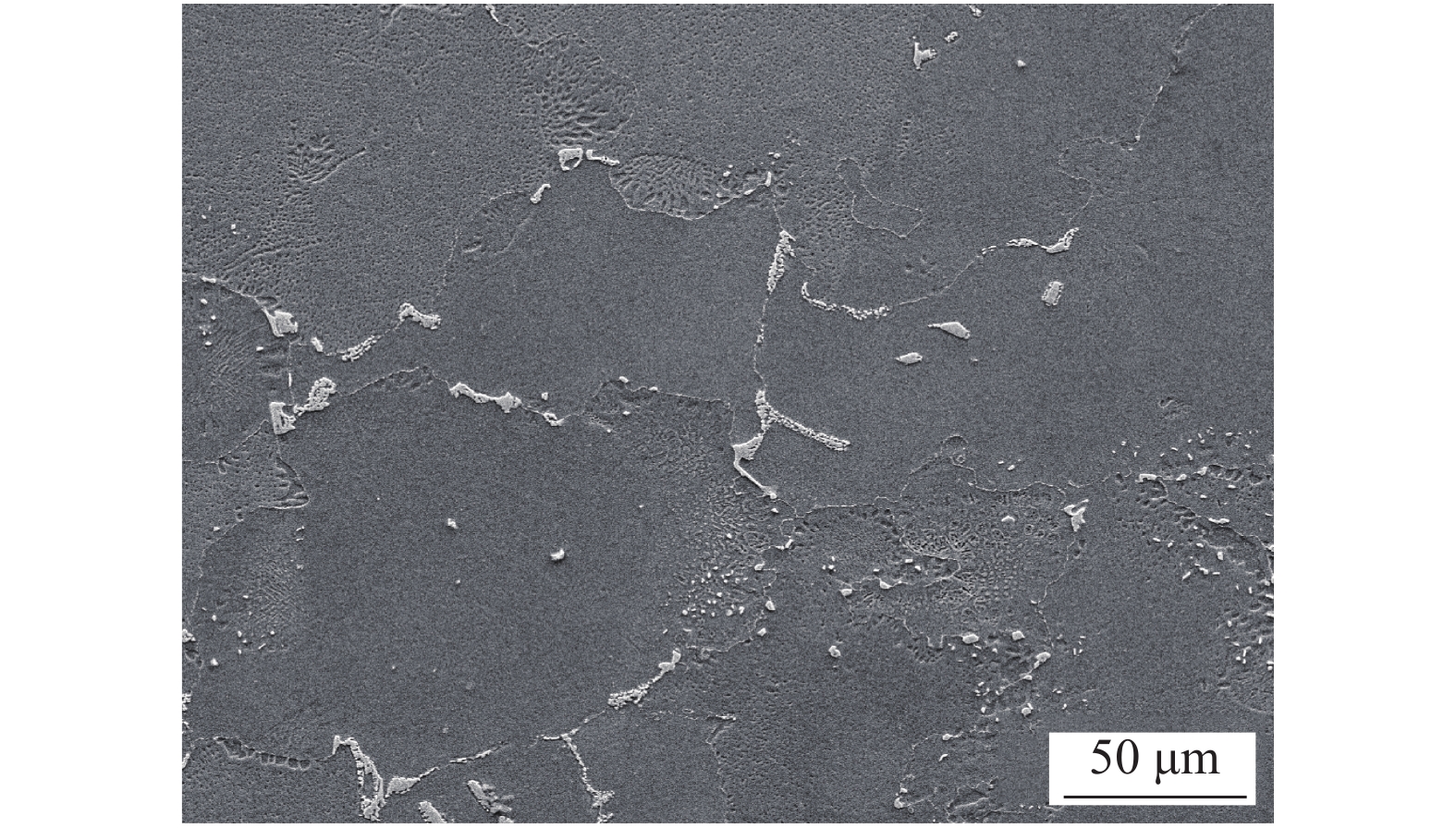

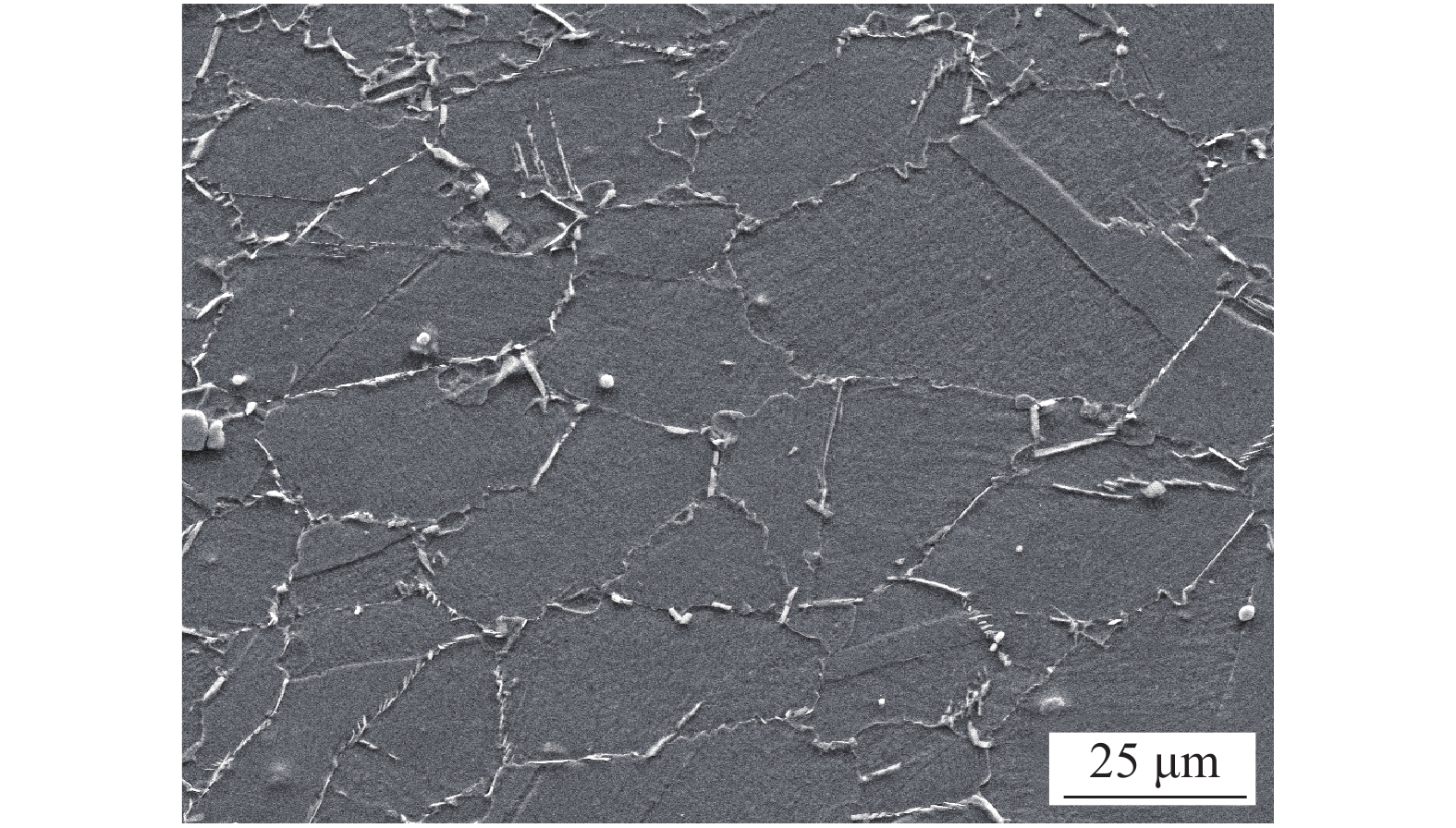

摘要: 针对新型镍基铸造高温合金K447A和变形高温合金GH4169异种材料惯性摩擦焊工艺进行研究,对热处理后接头微观组织和高温力学性能进行试验分析,结果表明,K447A和GH4169惯性摩擦焊接头飞边成形良好,飞边根部无明显缺陷存在;接头焊缝区组织为完全再结晶组织,焊缝组织中的γ''和γ'相热处理后重新弥散析出,K447A侧仅形成了3 ~ 10 μm宽的再结晶区;通过接头高温力学性能试验,结果表明,接头高温拉伸和高温扭转性能断裂位置在K447A母材侧,400 ℃高周疲劳强度达到355 MPa. 在最大应力720 MPa,试验温度400 ℃条件下低周疲劳寿命均超过30 000次.Abstract: The dissimilar materials of Ni-base cast superalloy K447A and Ni-base wrought superalloy GH4169 were welded by Inertia Friction Welding (IFW). The microstructure and high temperature mechanical properties of the joints were studied after heat treatment. The results show that good flash can be formed after IFW and no clear defects were found at the root of the flash. Fine recrystallization zone was formed in the weld zone (WZ) and fine γ'' phase and γ' phase were precipitated in the WZ after heat processing. The recrystallization zone width of the K447A side is between 3μm and 10μm. The high temperature tensile strength and torsional strength of GH4169 + K447A IFW joints were equal to K447A base metal. The high cycle fatigue strength of the joint is 355 MPa at the temperature of 400 °C. Under the condition of 400 °C and 720 MPa, the low cycle fatigue life of all the joint samples exceeded 30 000 times.

-

0. 序言

聚丙烯 (Polypropylene,PP)无纺布作为工业生产的重要原材料,封合方法主要有焊接法和胶粘法,前者属于无介质封合法,后者属于有介质封合法[1]. 因为PP无纺布表面时常难以粘合到其他表面上,且具有热塑性,所以焊接法与胶粘法相比,更适用于无纺布封合[2]. 然而,常见的用于热塑性塑料连接的焊接方式稳定性差、精度要求较高且无法保证其加工效率,难以达到流水线作业要求[3]. 超声波焊接与其他焊接技术相比,无烟无尘,且焊缝干净无阻塞,焊接成形时间为0.1 ~ 1.0s,易于自动化生产,可以较好的达到流水线作业要求[4-5]. 因此,在封合PP无纺布时采用超声焊接法不仅能提高加工的经济性,也可以提高产品质量.

封合时的焊接功率和焊接时间等超声焊接参数,对接头的性能有较大的影响[6]. 为了获得更好的非金属热塑性材料连接质量,学者主要将研究重点聚焦于优化超声焊接成形,KALYAN等人[7]通过创新涂层工艺和参数优化,提高接头强度和可靠性. DOBROTA等人[8]通过设计测试装置和分析材料特性,优化焊接参数以提高PBT-GF30和e-PTFE两种材料的焊接接头强度. KOTHURU等人[9]设计了一种矩形超声波声极,通过理论和数值分析优化其结构,以在特定工作频率下获得最大焊接长度和均匀振幅,从而提高了超声波焊接在长度和厚度方面的能力. CHEN等人[10]基于有限元模拟研究声极尖端几何形状对铜铝超声波焊接过程的影响,特别是对焊接变量和接头成形的作用机制的影响. 众多学者虽然在成形质量预测和焊接热机理方面做了大量工作,但是对不同焊接过程中焊头的优化与固定缺乏针对性的研究. 在流水线作业中,即使合适的焊接参数,也经常受到不合理的焊头尺寸限制导致效率不佳,对于改进措施还缺乏系统的评估和验证方案.

参数化处理的优化方法,分为传统数值解法和现代启发式解法. 传统数值解法的缺点是易收敛到局部最优解[11]. 现代启发式解法包括差分进化算法、粒子群算法和遗传算法等,并且可以收敛到全局最优解[12]. 多目标优化算法近年来已被广泛研究并在工业领域获得广泛应用. 多目标优化问题因几个目标函数的最优解之间存在冲突,而可由解的支配关系来找出一组不受其他解支配的最优解集,称为Pareto最优解集[13]. MOPSO算法在多目标优化问题中被广为使用,其收敛速度快,种群多样性高[14].

文中提出了一种面向生产线超声波焊接焊头尺寸的评估与优化方案. 以焊头的纵向最大振幅为评估指标,对焊头长槽尺寸的位置和形状进行模拟分析与参数优化. 以现有的超声焊头为基础,建立了焊头尺寸与性能的关系模型,基于关系模型通过MOPSO算法优化焊头尺寸,基于优化成果设计了新的焊头固定工具.

1. 长槽尺寸与焊头性能的关系模型

1.1 焊头参数化与模型训练

超声焊接系统结构, 如图1所示. 一般超声焊接工作台结构,焊头、变幅杆和换能器是最主要的部分. 系统的PP无纺布焊接示意图工艺过程,如图2所示. 主要对PP无纺布的边缘进行封合处理. 焊头参数化模型,如图3所示. 为得到大量训练样本,将图3中焊头长槽尺寸进行参数化处理,两槽的中心距为D,槽长为L,槽中心与上表面的距离为A和长槽的半径为R. 各组参数,如表1所示. 将所有的尺寸排列组合,共存在360组模型,上述尺寸设定为输入样本R=[A, L, R, D]. 随机组的有限元计算值,如图4所示. 由于只对焊头进行了参数化,于是将变幅杆与换能器进行手动网格划分,将焊头自动进行网格划分,以六面体单元为主. 变幅杆和焊头的材料为TC4(Ti-6Al-4V),泊松比为0.33,密度为

4508 kg/m3,弹性模量为116.97 GPa.表 1 参数取值Table 1. Parameter values槽中心与上表面距离

A/mm槽长

L/mm长槽半径

R/mm两槽中心距

D/mm61.5,63.5,65.5,

67.5,69.573,76,79,

82,884,5,6 23.0,25.5,

28.0,30.5各尺寸模型下的焊头纵向最大振幅、横向最大振幅、竖向最大振幅和最大应力$ {\sigma }_{\max} $为输出样本S=[γ1, γ2, γ3, σmax]. 对各组模型进行谐响应计算,得到的样本R$ _{ } $和S,平衡方程为

$$ \left\{\begin{array}{l}M\ddot{\mu}+C\dot{\mu}+K\mu=F \\ \mu=\left\{\mu_{\max}\mathit{\mathit{\mathit{\mathrm{e}}}}^{\mathrm{i}\varphi}\right\}\mathrm{e}^{\mathrm{i}\Omega t}\end{array}\right. $$ (1) 式中: M为质量矩阵;C为阻尼矩阵;K为刚度矩阵;μ为广义位移;F为外部载荷;$ {\mu }_{\max} $为各节点的振幅;i为单位复数;$\varphi $为位移相位偏移;Ω为外部强迫振动圆频率,取2πf;t为时间.

由于阻尼的存在,各节点的相位可能不同,各个节点的位移响应,如式(1)所示. 根据样本可知,网络的输入层神经元数Ni与输出层数神经元数N0均为4. 经过多次试验,将隐含层层数设置为3,每层神经元个数N1,N2和N3设置为18,12和8时得到的模型预测精度和泛化能力都较好. 为了得到精准的预测模型,要确定网络的结构和神经元的激励函数,最后确定训练方法和各项训练参数[15]. 选取logsig函数为各隐含层的激励函数,选取Purelin函数为输出层激励函数,即

$$ \left\{\begin{gathered}{{{{\boldsymbol{a}}}}_{{{\bf{h}}}}}=\frac{1}{1+\mathrm{e}{{{{^{-{{{{\boldsymbol{Z}}}}}_{{{\bf{h}}}}}}\mathrm{ }}}}} \\ \boldsymbol{y}=\boldsymbol{Z}_{\text{o}} \\ \end{gathered}\right. $$ (2) 式中:ah为隐含层输出向量;Zh为隐含层净输入向量;y为网络输出向量;Zo为输出层净输入向量.

采用均方误差函数作为网络的误差计算方法,训练算法选择Levenberg-Marquardt反向传播算法,即

$$ ({{\boldsymbol{J}}^{\mathrm{T}}} {\boldsymbol{J}}+{\boldsymbol{\lambda}}{\boldsymbol{I}}){{{\boldsymbol{h}_{{\mathrm{\boldsymbol{LM}}}}}}}= {{\boldsymbol{J}}^{\mathrm{T}}}[\widehat {{y_{{i_1}}}} - f({a_{\mathrm{n}}})] $$ (3) 其中,I表示单位矩阵;λ为阻尼因子;J为雅可比矩阵;${{y_{{i_1}}}} $为网络对第i1个样本的输出;an为神经网络预测输出;hLM为参数更新向量.

行训练前,需要将输入与输出样本分别进行归一化处理,避免R与S之间的数量级差异而导致网络训练的失败. 参考文献[16]将各项参数与样本代入进行训练,训练完成后得到了能较好反应超声焊头动态性能的18-12-8 BP神经网络模型.

1.2 网络训练结果与精准度验证

为了验证训练后的网络是否出现未收敛或者过拟合等问题,另外创建15组随机数据. 随机组的长槽尺寸,如表2所示. 分别进行网络预测和有限元计算,并对比两者的结果,随机组的网络预测值,如表3所示. 将导入表2中随机组尺寸,创建对应的有限元模型,进行谐响应计算后,得到的随机组的有限元计算值,如表4所示. 可以看出两表数据的差距不大,分析15组数据的输出值,得到随机组的网络预测误差,如表5所示. 由表5可知,模型对竖向最大振幅预测最精准,误差在0.04% ~ 1.43%;其次是对纵向最大振幅的预测,误差在0.02% ~ 2.58%;对横向最大振幅的预测误差在0.32% ~ 3.66%之间;而对于最大应力的预测效果最差,最大误差为7.02%,考虑到各项参数的预测误差均不超过10%,说明此次网络的训练效果较好,预测结果基本正确反应了真实情况.

表 2 随机组的长槽尺寸Table 2. Long slot dimensions of the random group序号 槽中心与上

表面的距离

A/mm槽长

L/mm长槽半径

R/mm两槽中心距

D/mm1 66 86 4.5 24 2 63 86 4.5 24 3 68 80 5.5 24 4 66 80 4.5 30 5 66 74 5.5 24 6 63 80 4.5 27 7 68 74 4.5 30 8 63 74 5.5 30 9 68 74 4.5 27 10 66 74 5.5 27 11 66 80 5.5 27 12 63 80 5.5 27 13 63 74 4.5 27 14 68 86 5.5 24 15 66 74 4.5 27 表 3 随机组的网络预测值Table 3. Network predicted values for the random group序号 纵向最大振幅

γ1/μm横向最大振幅

γ2/μm竖向最大振幅

γ3/μm最大应力

σmax/MPa1 28.023 9.283 9.382 191.484 2 31.693 10.236 9.374 299.783 3 24.148 9.065 9.290 163.958 4 27.841 10.194 9.250 234.061 5 21.709 9.079 9.223 130.978 6 28.469 10.547 9.341 236.185 7 23.698 9.534 9.186 153.762 8 26.341 11.467 9.148 270.740 9 22.617 9.061 9.225 128.564 10 22.980 9.281 9.211 162.817 11 27.225 9.561 9.351 248.449 12 30.390 10.863 9.363 399.301 13 24.691 10.305 9.123 156.849 14 28.080 9.196 9.302 224.794 15 23.128 9.484 9.155 129.676 表 4 随机组的有限元计算值Table 4. Finite element calculation values for the random group序号 纵向最大振幅

γ1/μm横向最大振幅

γ2/μm竖向最大振幅

γ3/μm最大应力

σmax/MPa1 28.766 9.234 9.250 205.940 2 31.700 10.269 9.275 308.216 3 23.990 9.227 9.238 159.446 4 28.071 10.161 9.277 235.685 5 21.474 9.179 9.207 135.813 6 28.576 10.685 9.282 231.679 7 23.957 9.233 9.209 147.905 8 26.407 11.390 9.271 271.043 9 22.892 9.161 9.182 124.156 10 22.831 9.218 9.237 164.459 11 27.059 9.285 9.301 247.955 12 30.423 11.046 9.321 395.756 13 24.818 10.450 9.137 153.166 14 27.850 9.287 9.298 221.264 15 23.475 9.149 9.168 134.199 表 5 随机组的网络预测误差Table 5. Prediction error of the network for the random group序号 纵向最大

振幅误差

ε₁(%)横向最大

振幅误差

ε2(%)竖向最大

振幅误差

ε3(%)最大应力

误差

ε4(%)1 2.58 0.53 1.43 7.02 2 0.02 0.32 1.07 2.74 3 0.66 1.76 0.56 2.83 4 0.82 0.32 0.29 0.69 5 1.09 1.09 0.17 3.56 6 0.37 1.29 0.64 1.94 7 1.08 3.26 0.25 3.96 8 0.25 0.68 1.33 0.11 9 1.20 1.09 0.47 3.55 10 0.65 0.68 0.28 1.00 11 0.61 2.97 0.54 0.20 12 0.11 1.66 0.45 0.90 13 0.51 1.39 0.15 2.40 14 0.83 0.98 0.04 1.60 15 1.48 3.66 0.14 3.37 经过神经网络的搭建与训练,建立了焊头长槽尺寸对焊头动态性能的关系模型. 根据表4可知,纵向最大振幅和最大应力的变化范围分别为21.474 ~ 31.700 μm和124.156 ~ 395.756 MPa,长槽尺寸的变化对纵向最大振幅γ1与最大应力σmax的影响很大. 考虑到横向最大振幅γ2的变化范围为9.149 ~ 11.39 μm,竖向最大振幅γ3的变化范围仅为9.137 ~ 9.321 μm,相差值仅为微米级,所以长槽尺寸改变对横向最大振幅与竖向最大振幅的影响很小. 因此设计合适的长槽尺寸可以增大焊接面的振动幅度,而随着焊头振动幅值的增加,焊头的最大应力也在急剧增加,第1组参数和2组参数相比,焊头纵向最大振幅增加了2.934 μm,但最大应力却增加了102.276 MPa. 考虑到在高频振动条件下,应力的增加可能会导致疲劳寿命的下降. 因此长槽尺寸的选择要综合多方面的内容进行考虑,下面将根据多个目标对长槽尺寸进行优选.

2. 基于多目标算法优化长槽尺寸

2.1 优化算法改进与优化模型建立

粒子群算法具有简单、快速、稳定和易于收敛的特点,是一种常见的智能优化算法. 粒子群算法的粒子速度和位置迭代为

$$ \left\{ \begin{gathered} v_{i_2}^{k + 1} = wv_{i_2}^k + {c_1}{r_1}\left( {p_{i_2pb}^k - x_{i_2}^k} \right) + {c_2}{r_2}\left( {p_{gb}^k - x_{i_2}^k} \right) \\ x_{i_2}^{k + 1} = x_{i_2}^k + v_{i_2}^{k + 1} \\ \end{gathered} \right. $$ (4) 式中:$ {v}_{i_2}^{k} $为粒子${i_2} $在第$ k $迭代步时的速度; $ w $为惯性权重;$ {c}_{1} $为自身学习因子;$ {c}_{2} $为群体学习因子; $ {p}_{i_2pb}^{k} $为粒子$ {i_2} $在第$ k $迭代步时的个体引导粒子;$ {p}_{gb}^{k} $为粒子群体在第$ k $迭代步的全局引导粒子; $ {r}_{1} $和$ {r}_{2} $为0 ~ 1的随机数;$ {x}_{i_2}^{k} $为粒子i2在第k迭代步时的位置.

MOPSO算法得到的解与单目标得到的解相比,一般不唯一,因此引入了一个外部精英解集,它存储着当前代数的优秀粒子,将每个迭代步中的优秀粒子加入到精英解集中并将其中的劣解淘汰从而进行解的更替. 由于在每个迭代步中,精英解集更新完成后将进行全局引导粒子的更新,根据最小角度方法,在向量空间中,所有粒子都将把与其所成角度最小的优秀粒子作为全局引导粒子[17],最小角度方法为

$$ \varphi_{i_2}=\mathrm{min}(\text{arccos}(\boldsymbol{Z}\boldsymbol{_{i\mathbf{_{\mathrm{\mathbf{2}}}}}}*\boldsymbol{Z}_{\boldsymbol{j}}/(|\left|\boldsymbol{Z}_{\boldsymbol{i}_{\mathbf{2}}} \right\| *|\left|\boldsymbol{Z}\boldsymbol{_j} \right\| ))) $$ (5) 式中:$ \boldsymbol{Z}\boldsymbol{\mathit{_{\boldsymbol{i}}}}\mathbf{_{_2}} $为粒子适应度值生成的向量;$ \boldsymbol{Z}\boldsymbol{_j} $为外部精英解集中粒子适应度值生成的向量,j取1,2,3···W;W为精英解集中的粒子数量.

将长槽尺寸与焊接性能的关系模型与多目标寻优算法结合起来对焊头尺寸进行选优,将算法得到的数值代入网络得到预测结果,根据预测结果决定粒子的路径. 经过不断迭代,外部精英解集中的粒子成为当前问题的Pareto最优解[18]. 综上所述,模型的输入输出量均为4,因此多目标算法设置$ p\mathrm{_{dim}} $为4,$ F_{\mathrm{dim}} $也为4. 设计变量选为4个参数化尺寸($ {\gamma }_{1} $,$ {\gamma }_{2} $,$ {\gamma }_{3}\mathrm{、}{\sigma }_{\max} $),适应度函数选为网络预测输出,其优化模型为

$$ \left\{ {\begin{array}{*{20}{l}} \begin{gathered} F({\boldsymbol{y}}) = [{\gamma _1}({\boldsymbol{y}}),{\gamma _2}({\boldsymbol{y}}),{\gamma _3}({\boldsymbol{y}}), {\sigma _{\max }}({\boldsymbol{y}})] \\ H = [\max ({\gamma _1}({\boldsymbol{y}})),\min ({\gamma _2}({\boldsymbol{y}}))\min ({\gamma _3}({\boldsymbol{y}})),\min ({\sigma _{\max }}({\boldsymbol{y}}))] \\ \end{gathered} \end{array}} \right. $$ (6) 式中:$ \boldsymbol{y}=[A,L,R,D]\mathrm{^T} $,优化目标为焊接面的振幅尽可能大,同时其他面的振幅和焊头应力尽可能小.

2.2 优化选型结果

通过MOPSO算法,结合前文所建立的焊头性能模型,得到了15组数据,优选值如表6所示. 经过表6优化后的$ {\gamma }_{1} $可以达到31 μm左右,相比于原机构有了较大提升;表中的$ {\gamma }_{2} $和$ {\gamma }_{3} $的数值差距都不大,说明在经过开槽处理后的大尺寸焊头能够较好的将振动解耦;对于$ {\sigma }_{\max} $来说数值变化范围较广,在考虑时应当选择较小应力表现的数据. 结合以上分析,选取表6第3组数据作为优化后的模型,即[A, L, R, D] = [65.355, 87.646, 4.091, 24.268],以下对优化效果进行验证.

表 6 优选值Table 6. Optimal values序号 槽中心与上表面的距离

A/ mm槽长

L/ mm长槽的半径

R/ mm两槽的中心距

D/ mm纵向最大振幅

$ {\gamma }_{1} $/ μm横向最大振幅

$ {\gamma }_{2} $/ μm竖向最大振幅

$ {\gamma }_{3} $/ μm最大应力

$ {\sigma }_{\max} $/ MPa1 63.721 85.759 4.815 23.902 30.957 9.939 9.371 307.441 2 67.568 87.128 4.164 29.636 30.655 9.703 9.408 260.371 3 65.355 87.646 4.091 24.268 30.154 9.474 9.405 198.244 4 62.239 77.542 5.233 30.334 30.088 12.529 9.210 412.880 5 63.051 81.099 4.596 27.937 30.055 10.975 9.376 289.682 6 63.723 85.865 4.063 23.518 29.690 9.686 9.377 211.015 7 63.344 82.905 4.000 24.359 28.735 9.935 9.349 189.654 8 68.901 86.259 5.996 25.514 28.648 9.248 9.276 270.912 9 68.794 87.252 4.962 26.076 28.567 9.235 9.333 217.682 10 67.847 86.660 4.378 26.720 28.563 9.241 9.365 184.226 11 62.479 77.383 4.250 29.110 28.539 11.973 9.091 210.101 12 67.551 87.728 4.066 24.164 28.343 9.116 9.356 164.991 13 69.345 82.223 4.171 23.386 25.259 9.007 9.405 116.051 14 63.463 78.738 4.725 23.442 25.207 9.493 9.310 167.586 15 66.985 78.774 4.176 25.927 25.125 9.254 9.378 134.279 2.3 优化前后动态性能分析

为更好的验证优化效果, 提高计算精度,将整个系统使用Hypermesh软件重新划分为六面体二次单元,各个部分的单元进行共节点处理,高精度有限元网格模型,如图4所示. 变幅杆和焊头采用钛合金材料TC4(Ti-6Al-4V),在未优化前陶瓷片处施加10 μm的纵向位移载荷,频率设置为20 kHz. 根据上述优选值将三维模型进行更新,并对优化前后的模型分别进行谐响应分析. 优化后焊头的振动性能,如图5所示. 图5(a)和图5(b)中焊接面上的纵向振幅分布不均匀,这是大尺寸长条形超声焊头的一大特点. 而优化前的纵向最大振幅分别处于焊头的左右尖端处,且只有23 μm左右,振幅太小,难以满足焊接的性能需要. 优化长槽尺寸后,焊头两侧的最大振幅均达到了30 μm以上,相比原焊头的纵向最大振幅提高了约30.43%.

图5(c)和图5(d)分别为焊头优化前后的谐振应力,由于采用了较密的网格,谐振应力数值相比原网络预测值低,但两者相差不大于5%. 焊头优化前后的谐振应力主要集中于焊头两侧的凹槽内,优化后的焊头应力相比优化前提高了约72.3%,不超过180 MPa. 结合焊头材料TC4的疲劳性能可知,优化后的焊头应力仍然远低于TC4最大等效交变应力315.02 MPa,远低于焊头材料的承受范围. 疲劳寿命达到了107次,可认为疲劳寿命为无限次.

3. 焊头固定方式

变幅杆和焊头是最常见的超声焊接固定位置,原机构的固定方式为变幅杆上固定. 原机构固定方式,如图6所示. 焊头原有固定方式位于变幅杆上,隔振性能较差,导致螺栓经常发生松动. 针对上述问题,文中在优化后的焊头处重新设计一套支撑系统. 固定后,振动从焊头经支撑工具导入固定机架,为减少能量流失与机架受到的振动冲击,支撑工具的位置需要放在焊头表面振动较小的位置上. 焊头侧面振动情况,如图7所示. 图7(a)为优化后的焊头侧面变形. 侧面总体变形振幅值存在两个较低点分别为距F1点距离为8.46 mm处和距F1点距离为66.67 mm处,如图7(b)所示.

支撑工具放置位置,如图8所示. 安装位置需尽量远离焊接面,因此第1个安装点K1的距离为66.67 mm,其总变形振幅为1.09 μm;由纵向变形振幅可知第2个安装点K2的位置为59.70 mm,纵向变形振幅为0.99 μm. 支撑工具的单元模型分别加到焊头的K1点与K2点,支撑工具对焊接系统的振动性能影响、支撑工具振动特性和支撑工具“固定”面的支反力幅值对K1点和K2点方案进行评估.

K1点和K2点安装支撑工具对比,如图9所示. K1点和K2点支撑工具始终安装于焊头振幅最小处. 在两处加入支撑工具后,焊头的纵向变形振幅最大值仅相差0.467 μm; 焊头的总体变形振幅最大值仅相差0.478 μm,且最大振幅均处于焊头的焊接面上,约为31 μm. 而焊头的振幅分布几乎没有改变,因此在两点处安装支撑工具对焊接系统的性能几乎无影响. 而K1点和K2点支撑工具的应力分别为19.738 MPa和36.834 MPa;最大振幅分别为1.504 μm和3.030 μm. K2点相比于K1点应力提高了86.615%,而最大振幅仅提高了115.812%,在K1点安装支撑工具是更好的选择. 配合支撑底座,焊头固定装配,如图10所示. 支撑工具通过压板固定于支撑底座上,与焊头相接,支撑焊头完成焊接工作. 通过定位焊头上方低振幅区域安装固定装置,显著抑制了振动能量经支撑结构向机架的传导,有效提升了焊接系统能量利用率及设备运行稳定性.

4. 结论

(1)原焊接系统动态性能分析的结果表明原焊头的振幅较小,焊接性能较差.为此将长槽尺寸进行参数化后,以分析结果训练BP算法,建立了18-12-8的BP超声焊头动态性能模型,显著减少了后续优化分析时的工作量;

(2)通过MOPSO算法结合已经建立的动态性能模型,根据Pareto解集,得到了最优的焊头尺寸参数,通过对比优化前后的焊头动态性能,验证优化方案的可行性,焊头优化后[A, L, R, D]为[65.355, 87.646, 4.091, 24.268]时,最大振幅提高了30.43%.

(3)根据焊头动态性能分析结果,设计了新的焊头固定方案,该方案刚度较高,提高了隔振性能,减少了能量损失,对焊接系统的动态性能影响小于老式固定方案.

-

表 1 K447A + GH4169惯性摩擦焊接头拉伸性能

Table 1 Mechanical property of K447A + GH4169 IFW joints

温度T/℃ 抗拉强度Rm/MPa 屈服强度Rp0.2/MPa 断面收缩率A(%) 断后伸长率Z(%) 400 1 014.5 960 2.5 4.4 650 1 009.4 877.6 3.3 4.5 表 2 K447A + GH4169惯性摩擦焊接头低周疲劳性能

Table 2 Low cycle fatigue property of IFW joints

编号 最大应力σ/MPa 寿命N(次) 1 720 30 000 780 30 000 840 9 992 2 720 30 000 780 30 000 840 27 088 3 720 30 000 780 30 000 840 6 741 4 720 30 000 780 30 000 840 30 000 900 8 546 5 720 30 000 780 30 000 840 3 008 6 720 30 000 780 30 000 840 30 000 900 18 843 7 720 30 000 780 30 000 840 30 000 900 11 309 8 720 30 000 780 30 000 840 30 000 900 9 934 9 720 34 825 10 720 150 661 -

[1] 李爱兰, 汤 鑫, 曹腊梅, 等. 热等静压温度对K447A高温合金显微组织及性能的影响[J]. 航空材料学报, 2012, 32(2): 13 − 19. doi: 10.3969/j.issn.1005-5053.2012.2.003 Li Ailan, Tang Xin, Cao Lamei, et al. Effects of HIP temperature on microstructure and mechanical properties of K447A superalloy[J]. Journal of Aeronautical Materials, 2012, 32(2): 13 − 19. doi: 10.3969/j.issn.1005-5053.2012.2.003

[2] 李爱兰, 汤 鑫, 曹腊梅, 等. 定向/细晶双性能整体叶盘材料K447合金的显微组织研究[J]. 材料工程, 2009(supplement 1): 73 − 76. Li Ailan, Tang Xin, Cao Lamei, et al. Microstructure study of directionally solidified/equiaxed double properties casting K447 alloy for integral turbine wheel[J]. Journal of Materials Engineering, 2009(supplement 1): 73 − 76.

[3] 师昌绪, 陆 达. 中国高温合金四十年[M]. 北京: 中国科学技术出版社, 1996. [4] 姬书得, 刘建光, 张利国, 等. 材料流动对连续驱动摩擦焊飞边形成的影响[J]. 焊接学报, 2013, 34(4): 31 − 34. Ji Shude, Liu Jianguang, Zhang Liguo, et al. Effect of material flow on flash formation during continuous driven friction welding[J]. Transactions of the China Welding Institute, 2013, 34(4): 31 − 34.

[5] 张春波, 周 军, 赵玉珊, 等. 不同热处理状态AMS6308钢惯性摩擦焊接头组织及力学性能[J]. 焊接学报, 2012, 36(7): 21 − 24. Zhang Chunbo, Zhou Jun, Zhao Yushan, et al. Microstructure and mechanical properties of inertia friction welding joint of AMS6308 steel at different heat treatment state[J]. Transactions of the China Welding Institute, 2012, 36(7): 21 − 24.

[6] Li W Y, Wang F F. Modeling of continuous drive friction welding of mild steel[J]. Materials Science and Enginnering A, 2011, 528(18): 5921 − 5926. doi: 10.1016/j.msea.2011.04.001

[7] Turner R P, Perumal B, Lu Y, et al. Modeling of the heat-affected and thermomechanically affected zones in a Ti-6Al-4V inertia friction weld[J]. Metallurgical and Materials Transactions B, 2019, 50(20): 1000 − 1011.

[8] Tung D J, Mahaffey D W, Senkov O N, et al. Transient behavior of torque and process efficiency during inertia friction welding[J]. Science & Technology of Welding & Joing, 2019, 24(2): 136 − 147.

[9] 杨 军, 楼松年, 严隽民, 等. GH4169高温合金惯性摩擦焊接头晶粒分布特征[J]. 焊接学报, 2001, 22(3): 31 − 35. Yang Jun, Lou Songnian, Yan Junmin, et al. Grain distribution properties of superal loy GH4169 inertia friction welded joint[J]. Transactions of the China Welding Institute, 2001, 22(3): 31 − 35.

[10] 梁 海, 刘效方. GH4169合金惯性摩擦焊参数、组织和强化机制研究[J]. 航空材料学报, 1997, 14(4): 41 − 47. Liang Hai, Liu Xiaofang. Study on parameters microstructure and strengthening mechanism in inertia friction welding of alloy GH4169[J]. Journal of aeronautical materials, 1997, 14(4): 41 − 47.

[11] Gao Ming. Preferential coarsening of γ" precipitates in inconel 718 during creep[J]. Metallurgy and Material Transaction, 1996, 27(11): 391 − 398.

[12] Sandararaman M. Some aspects of the precipitation of metastable intermetallic phases in Inconel 718[J]. Metallurgy Transaction A, 1992, 23A(7): 2015 − 2028.

下载:

下载: