Microstructure and mechanical properties of deposited metal for nuclear plant nickel alloy welding wire

-

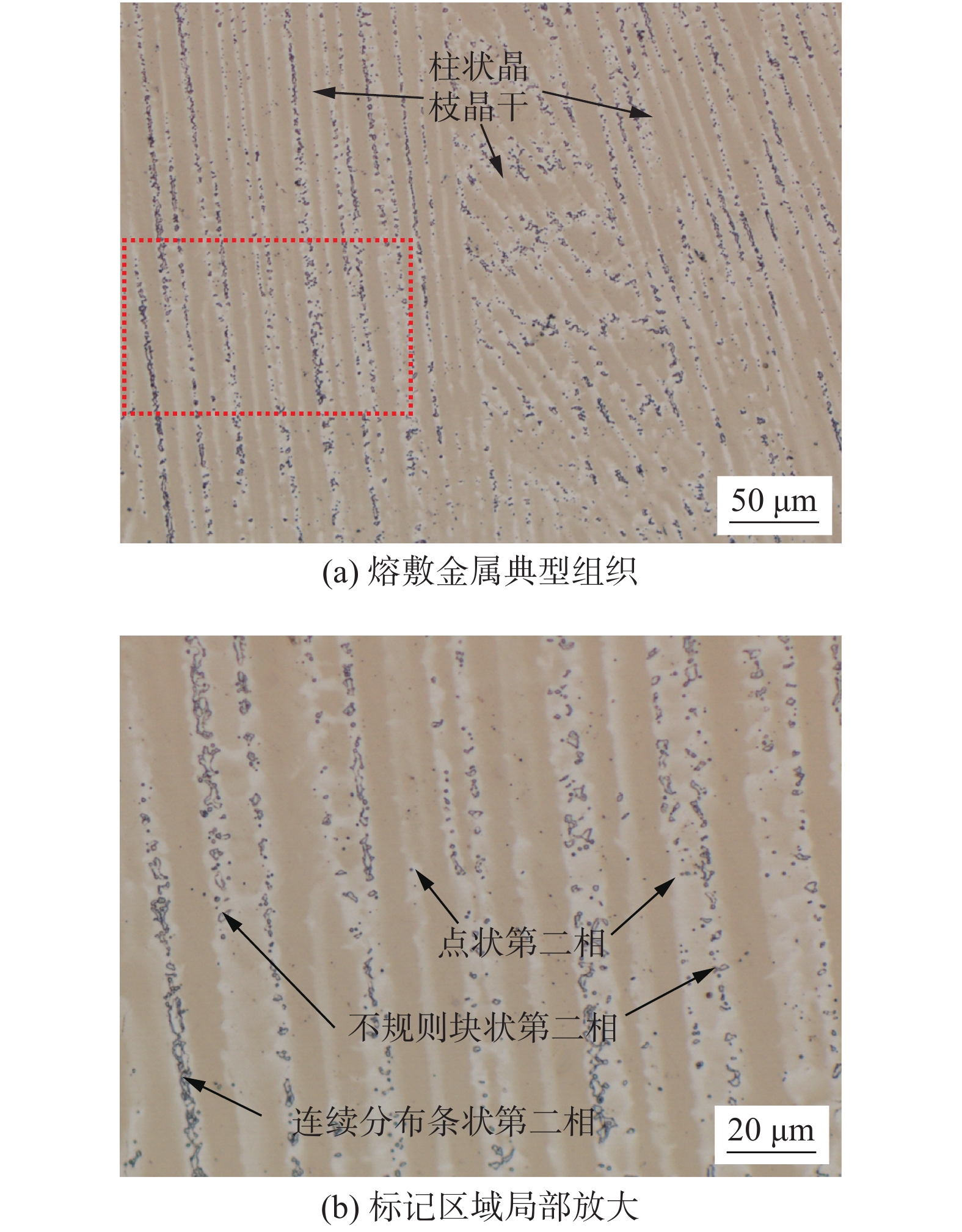

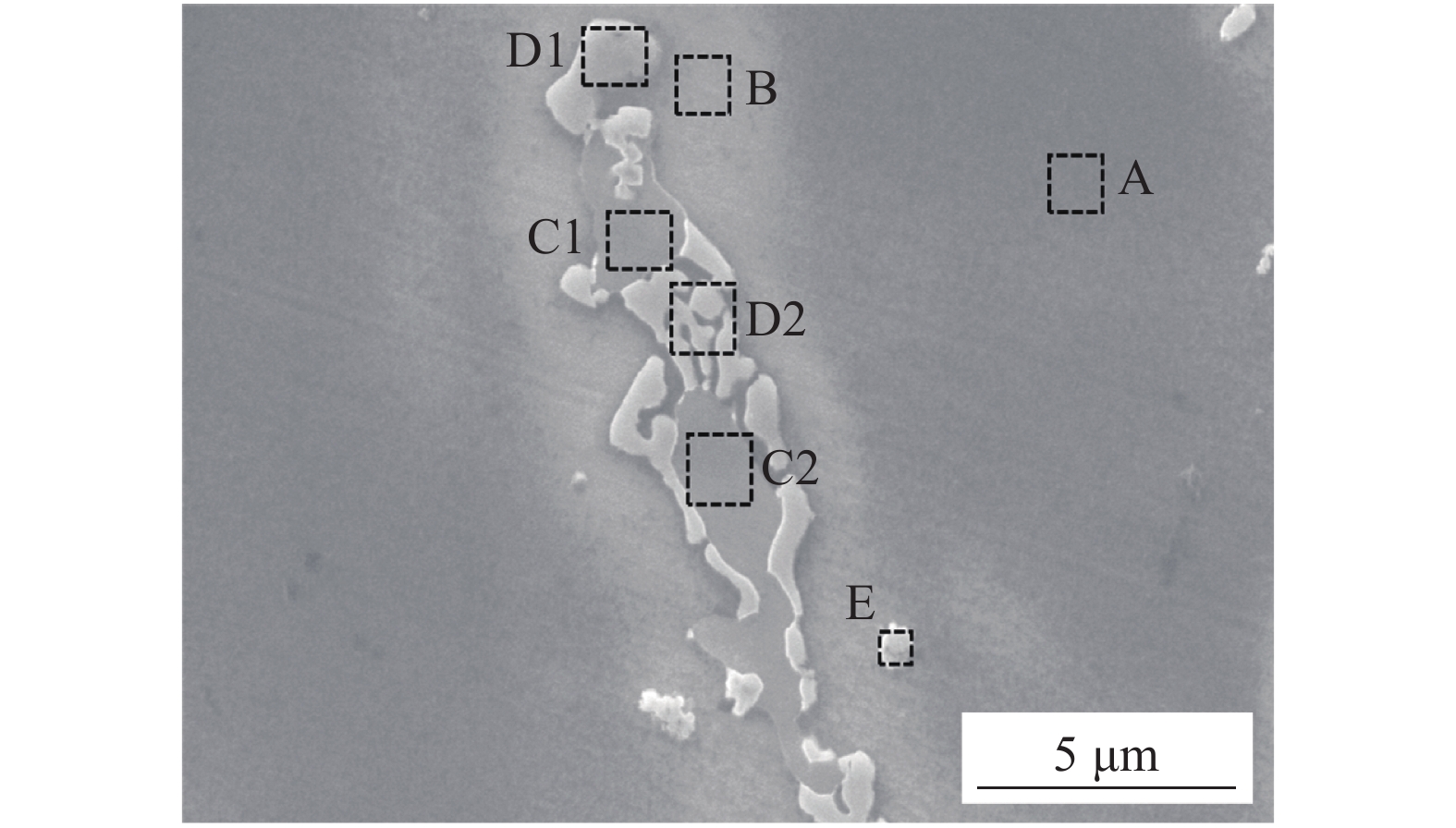

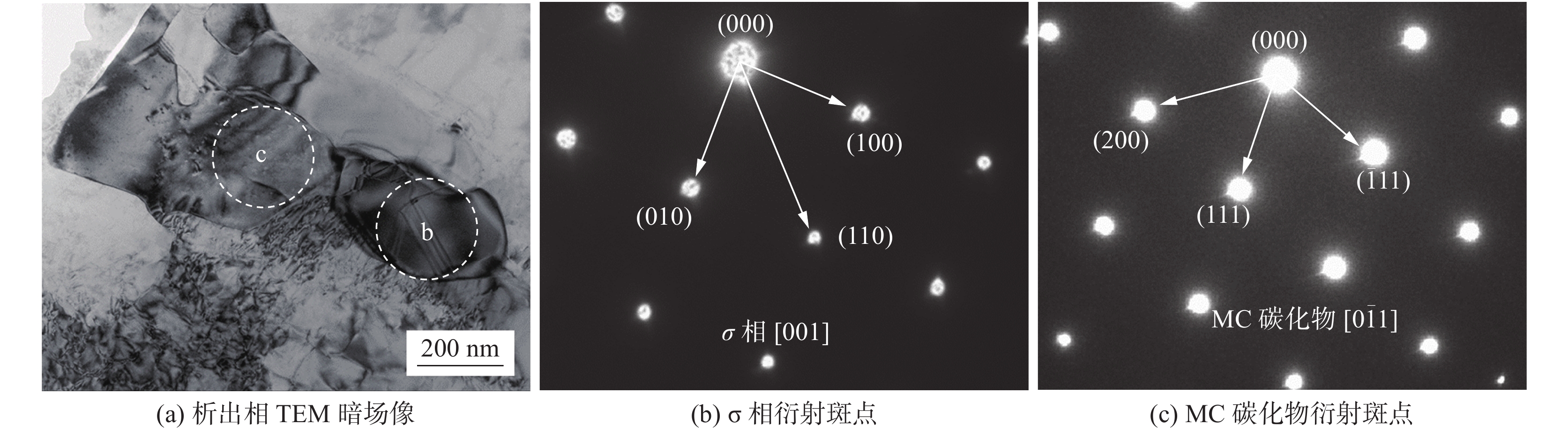

摘要: 通过采用JMatPro软件,OM,SEM,TEM等手段分析了试制镍基合金焊丝GTAW熔敷金属的组织与力学性能. 结果表明:试验焊丝熔敷金属金相组织主要由柱状树枝晶γ相(NiCrFe固溶体)、枝晶间富Mo和Nb的偏析γ相以及枝晶间分布的(Nb,Ti)C碳化物、(Ni,Cr,Fe)2(Nb,Mo)型Laves相、MoCrFe型σ相等组成. Mo,Nb等元素在组织中存在偏析现象,相比于焊丝化学成分,熔敷金属中枝晶干γ相Fe含量较高,Mo,Nb含量较低,而枝晶间Mo,Nb含量较高、Fe含量较低. 熔敷金属室温、350 ℃高温抗拉及屈服强度较高、塑性较好,室温拉伸断口形貌以沿晶分布的韧窝为主,在韧窝底部存在密集的析出相.Abstract: Microstructure and mechanical properties of deposited metal with experimental nickel alloy wires by GTAW was investigated by JMatPro software, OM, SEM, TEM etc. Results indicated that there were columnar γ matrix, interdentritic precipitates including σ phase, MC carbides, Laves phases in the deposited metal. Compared with nominal chemical compositions, dendrite core has higher Fe content and lower Nb, Mo content, while interdendritic segregation zone has higher Nb, Mo content and lower Fe content. MC carbide was (Nb,Ti)C, Laves is rich in Mo and Cr with structural formula (Ni,Cr,Fe)2(Nb,Mo), σ phases is rich in Mo and Cr with MoCrFe tetragonal structure. The deposited metal has high strength and good ductility at room temperature and 350 ℃. Dimples along grain boundary dominants the fracture morphology of tensile specimen at room temperature, with dense precipitates in the bottom of dimples.

-

Keywords:

- nickel alloy /

- nuclear plant /

- Laves phase /

- σ phase

-

-

表 1 GTAW工艺参数

Table 1 GTAW parameters

焊接电流I/A 电弧电压U/V 焊接速度v1/(mm·min−1) 送丝速度v2/(mm·min−1) 保护气体 层温控制T/℃ 220 13.5 120 1 150 纯Ar ≤ 150 表 2 试验用焊丝的化学成分(质量分数,%)

Table 2 Chemical compositions of experimental wire

C Si Mn S P Nb Fe Mo Al Ti Cr Ni 0.02 0.07 0.96 0.001 0.002 2.01 9.44 5.06 0.28 0.20 29.02 余量 表 3 熔敷金属各典型相能谱分析结果(质量分数,%)

Table 3 EDS results of typical phases in deposited metal

分析区域 Nb Mo Ti Ni Cr Fe A 0.87 4.64 0.09 52.02 30.17 11.54 B 2.69 6.91 0.50 48.41 30.40 9.11 C1 5.17 17.18 — 32.17 35.31 7.13 C2 5.32 17.21 — 31.31 35.11 7.23 D1 22.06 9.69 0.08 32.98 20.16 5.65 D2 19.21 10.69 — 33.25 21.92 6.35 E 30.01 3.73 9.23 14.27 11.78 3.29 -

[1] 莫文林, 陆善平, 李殿中, 等. 一种核电核岛主设备用镍基焊丝的研制[J]. 焊接学报, 2014, 35(6): 90 − 94. Mo Wenlin, Lu Shanping, Li Dianzhong, et al. Research and development of Ni-based filler metal wire for key components of nuclear power plant[J]. Transactions of the China Welding Institution, 2014, 35(6): 90 − 94.

[2] 薄春雨, 杨玉亭, 侴树国, 等. 690镍基合金焊接结晶裂纹形成机理分析[J]. 焊接学报, 2007, 28(10): 69 − 72. doi: 10.3321/j.issn:0253-360x.2007.10.018 Bo Chunyu, Yang Yuting, Chou Shuguo, et al. Solidification cracking mechanism of 690 nickeil-based alloy surfacing metal[J]. Transactions of the China Welding Institution, 2007, 28(10): 69 − 72. doi: 10.3321/j.issn:0253-360x.2007.10.018

[3] Wang C, Wu Y, Guo Y A, et al. Precipitation behavior of sigma phase and its influence on mechanical properties of a Ni-Fe based alloy[J]. Journal of Alloys and Compounds, 2019, 784(5): 266 − 275.

[4] 邢希学, 邸新杰. 一种镍基高温合金熔敷金属的组织及性能[J]. 焊接学报, 2014, 35(9): 73 − 76. Xing Xixue, Di Xinjie. Microstructure and properties of a nickel-base superalloy deposited metal[J]. Transactions of the China Welding Institution, 2014, 35(9): 73 − 76.

[5] Wheeling R A, Lippold J C. Characterization of weld metal microstructure in a Ni-30Cr alloy with additions of niobium and molybdenum[J]. Materials Characterization, 2016, 115(5): 97 − 103.

[6] Li X Q, Hao B H, Chen Y X, et al. The microscopic mechanical performance for nonuniform welded joint of nickel-based alloy with nanoindentation[J]. China Welding, 2019, 28(2): 29 − 34.

[7] Perricone M J, Dupont J N. Effect of composition on the solidification behavior of several Ni-Cr-Mo and Fe-Ni-Cr-Mo alloys[J]. Metallurgical & Materials Transactions A, 2006, 37(4): 1267 − 1280.

[8] Dupont J N, Notis M R, Marder A R, et al. Solidification of Nb-bearing superalloys:part I. reaction sequences[J]. Metallurgical & Materials Transactions A, 1998, 29(11): 2785 − 2796.

[9] Dupont J N, Marder A R, Notis M R, et al. Solidification of Nb-bearing superalloys: part II. pseudo ternary solidification surfaces[J]. Metallurgical and Materials Transactions A, 1998, 29(11): 2797 − 2806. doi: 10.1007/s11661-998-0320-x

[10] Zhang X, Li D Z, Li Y Y, et al. Effect of Nb and Mo on the microstructure, mechanical properties and ductility-dip cracking of Ni-Cr-Fe weld metals[J]. Acta Metallurgica Sinica, 2016, 29(10): 928 − 939.

[11] Di X J, Chen B. Solidification behaviour of a high chromium nickel base alloy weld deposited metal[J]. Science and Technology of Welding and Joining, 2015, 20(4): 325 − 329. doi: 10.1179/1362171815Y.0000000019

[12] Jeng S L, Chang Y H. Microstructure and flow behavior of Ni-Cr-Fe welds with Nb and Mo additions[J]. Materials Science and Engineering A, 2013, 560(1): 343 − 350.

-

期刊类型引用(0)

其他类型引用(2)

下载:

下载: