Influence of process parameters on microstructure and mechanical properties in high power ultrasonic welding of Cu/Al

-

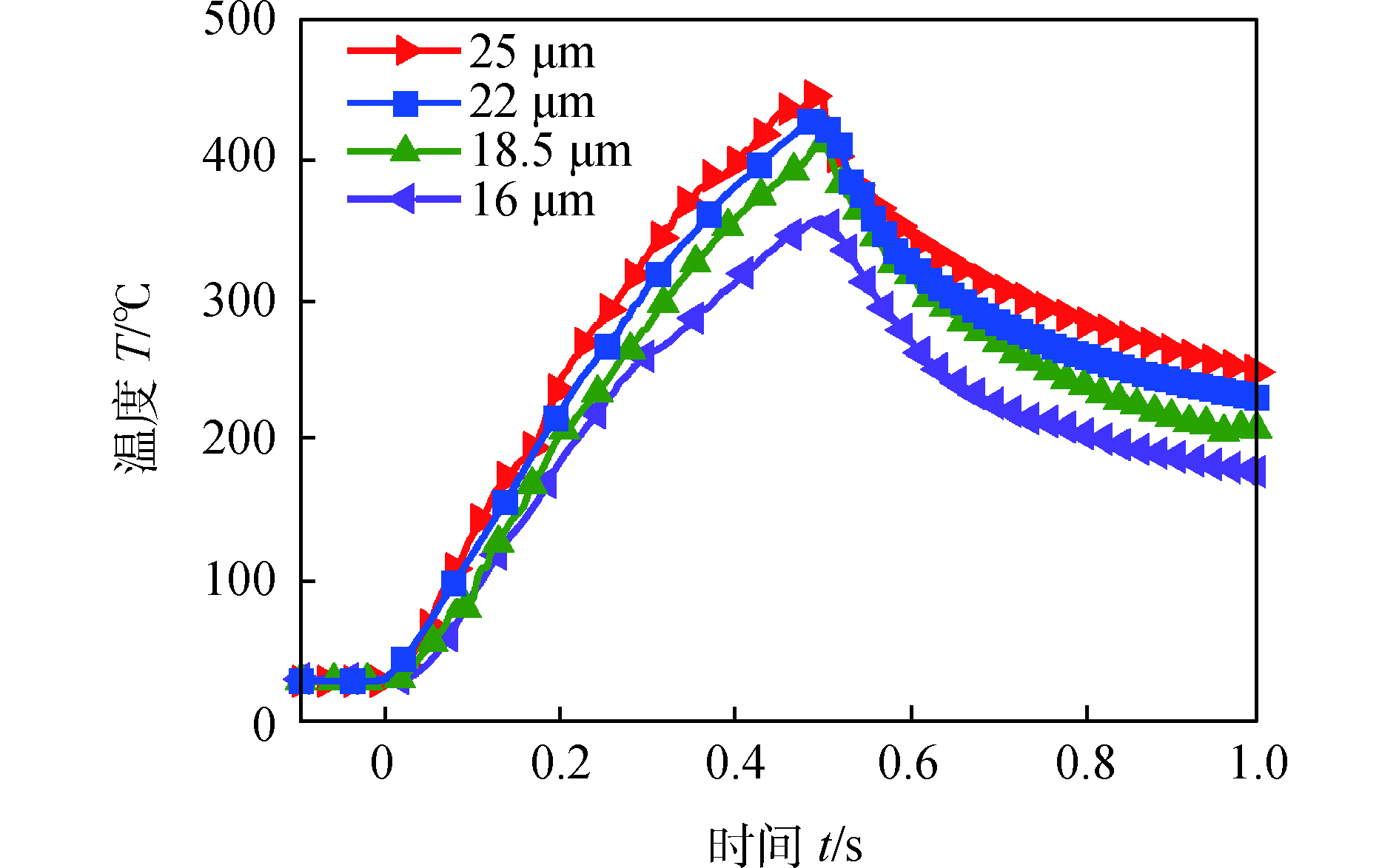

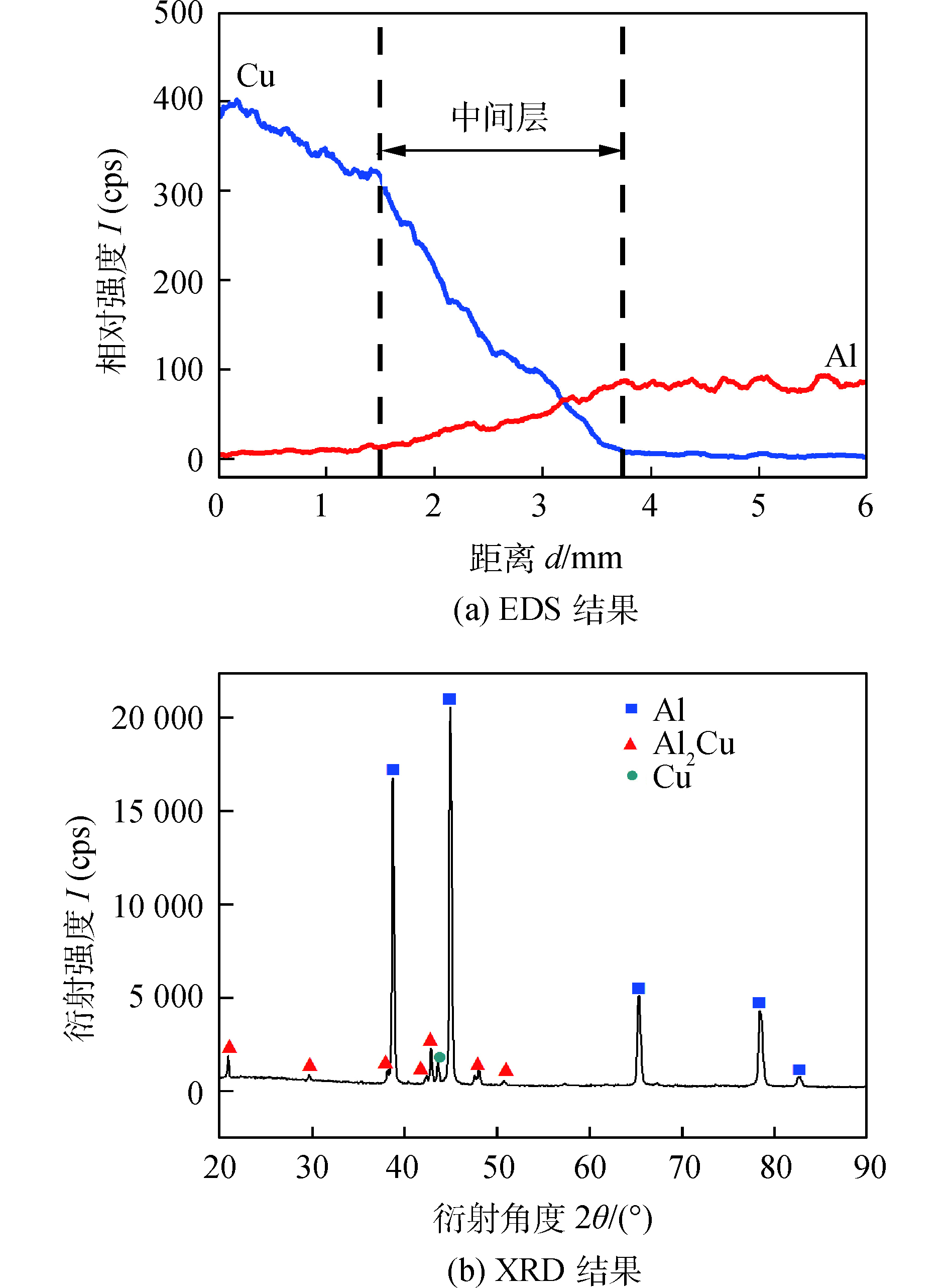

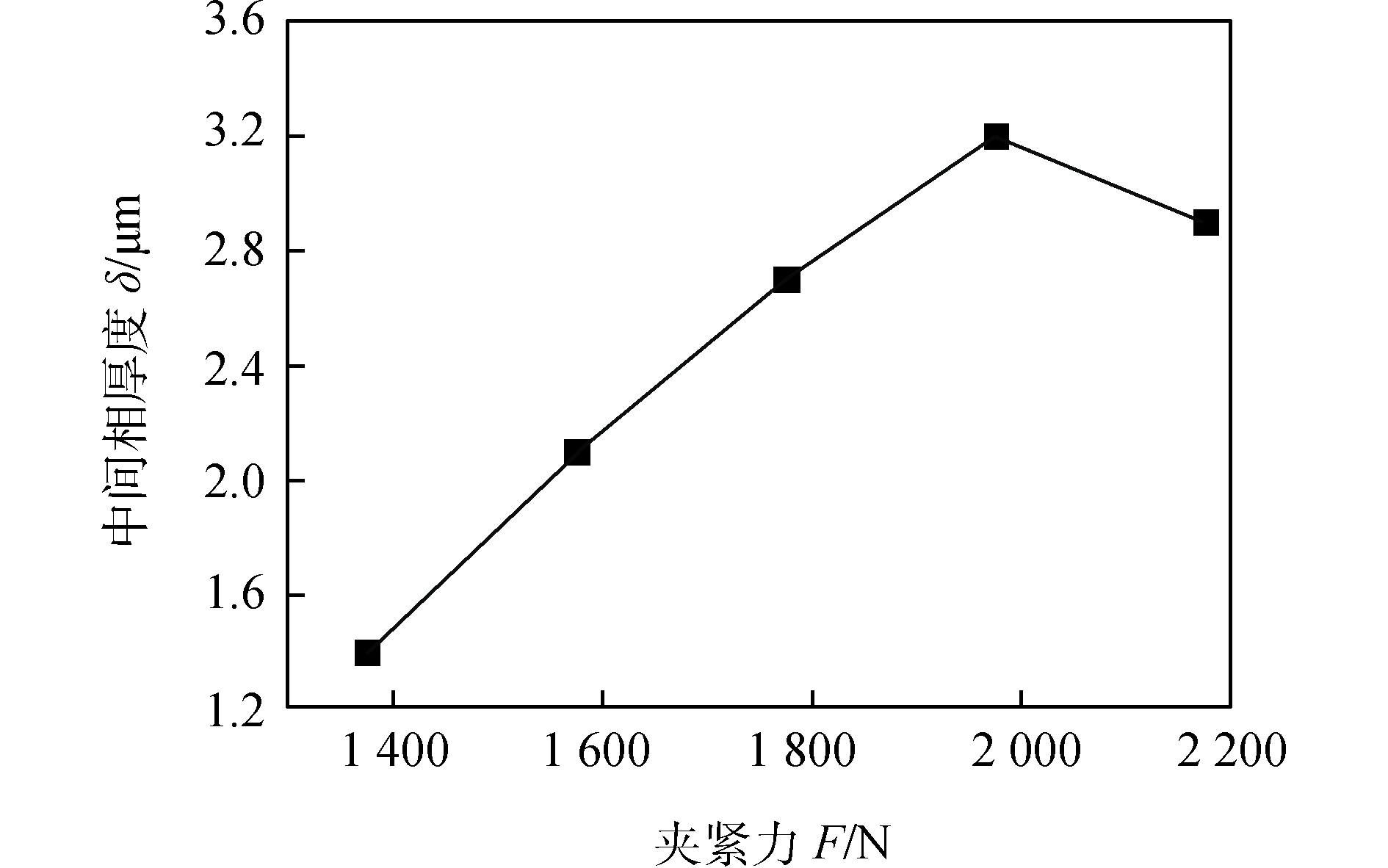

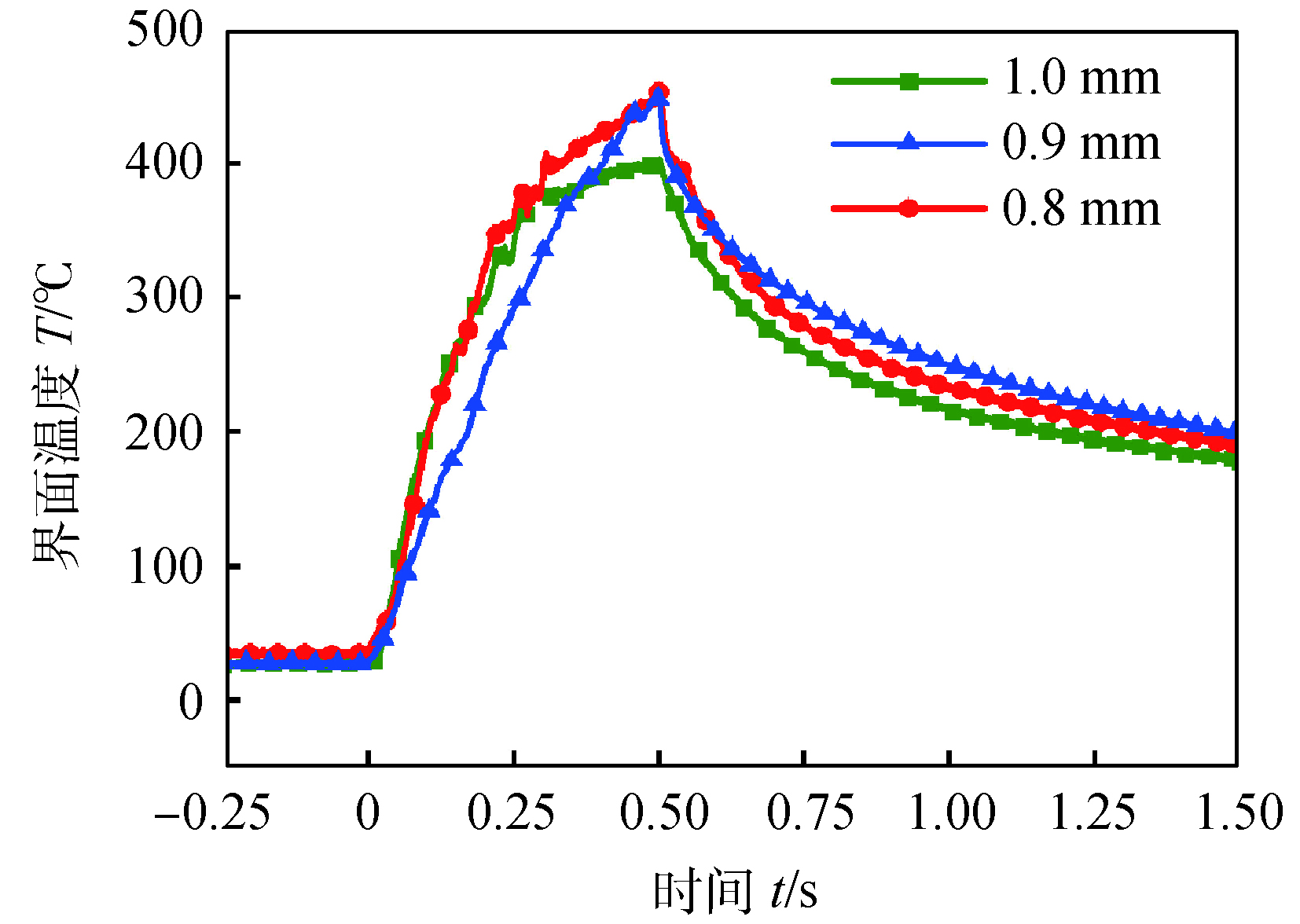

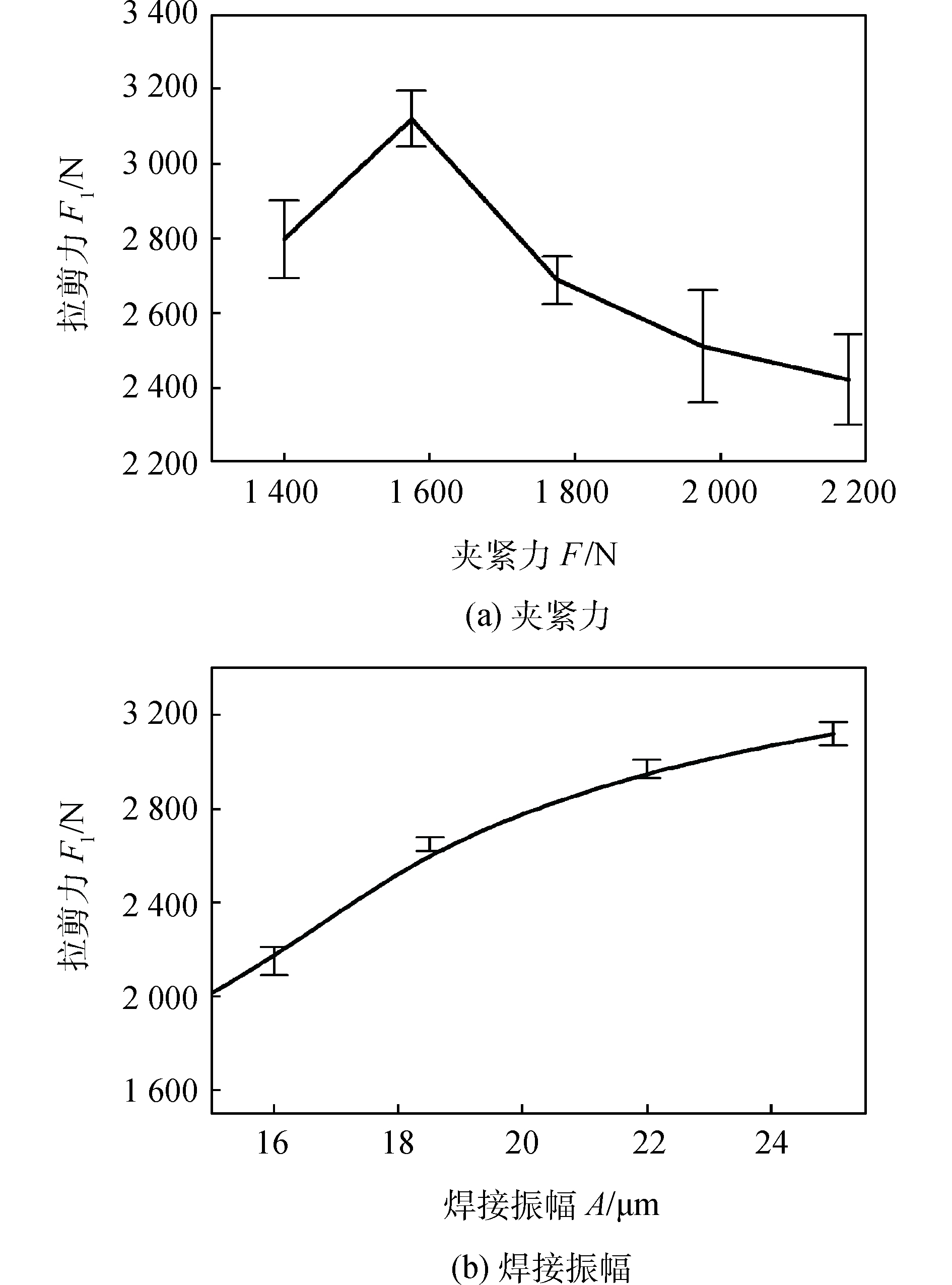

摘要: 尽管大功率超声波焊接可以更好的焊接较高的导电、导热性的材料,但是对焊接机理的认识还很少. 为了深入明晰焊接过程以及得到高质量的Cu/Al焊接接头,研究了不同夹紧力、焊接时间、焊接振幅以及焊头形状对Cu/Al大功率超声波焊接的界面温度、中间相生长和接头力学性能的影响. 结果表明,随着夹紧力的增大,界面中间相厚度先增大后减小. 随着焊接振幅的下降,界面温度的降幅增大且中间相厚度呈现近似线性下降. 最优的焊头齿数为9个,焊头齿数的增多和减少均会导致界面温度降低和焊接裂纹产生. 为获得较高的Cu/Al大功率超声波焊接质量,焊接振幅应设置为最高. 对焊接接头的拉伸断口进行扫描电镜测试表明,Cu/Al超声波焊接接头的断裂模式是韧性-脆性复合断裂. 研究结果为优化超声波焊接工艺参数提供了指导.Abstract: Although high power ultrasonic spot welding(USW) can obtain better welding quality about highly conductive materials, the welding mechanism is still unclear. To improve the understanding of the USW process and to enhance the weld strength in similar Cu/Al welding, the effect of clampling force, welding time, vibration amplitude and profile of the sonotrode tips on the temperature rise, intermetallic compound (IMC) growth of welding interface and mechanical properties of joint during Cu/Al high power ultrasonic welding process are investigared. Increasing of clampling force, the thickness of the IMC first increases and then decreases. The interface temperature decreases and the thickness of the IMC decreases linearly with vibration amplitude. The optimal number of welding head teeth is 9. Increasing and decreasing the number of sonotrode teeth will lead to lower interface temperature and formation of welding cracks. In order to obtain high welding quality of Cu/Al joint, the vibration amplitude sholud be set to its maximum. Scanning electron microscopy (SEM) test is performed on the fracture of the Cu/Al joint and shows that the fracture of Cu/Al ultrasonic welded joint is ductile-brittle hybrid mode. The research results provide guidance for optimizing the ultrasonic welding parameters.

-

Keywords:

- ultrasonic welding /

- dissimilar metals /

- intermetallic compound /

- mechanical property

-

0. 序言

熔化极活性气体保护焊(metal active gas, MAG)以其生产效率高、质量稳定、成本低和适用性强等优势,被广泛应用于航空、造船、化工、建筑、机械制造等行业[1]. 熔透控制是MAG单面焊双面自由成形工艺的一项关键技术. 在实际应用中,由于坡口间隙、散热条件变化等不确定因素的存在,使得恒规范焊接往往很难获得完全熔透和背面成形均匀的焊缝. 随着机器视觉、图像处理和人工智能等技术的发展及在焊接领域中的应用,通过智能手段模拟焊工观察、感知、判决和调整等操作行为对熔池形态和大小进行有效控制,成为实现焊接熔透状态控制的主要途径之一[2].

基于视觉传感的熔透状态信息实时获取是熔透在线控制的一个关键环节,由于熔透状态信息很难直接测量,多数情况下需通过检测焊件正面熔池来预测背面的熔透状态[3-4]. 熔透状态识别预测可采用人工神经网络[5-10]、经典机器学习[11-12]及深度学习[13-16]等智能方法来实现. 文献[5]针对双丝脉冲焊工艺,利用近红外视觉传感及图像处理技术提取与熔透相关的视觉特征信息,建立了基于人工神经网络的熔透识别预测模型,测试结果表明,选取合适的隐层神经元节点数可有效提高模型熔透识别的准确率. 文献[9]以脉冲GTAW(gas tungsten arc welding)焊接过程为对象,综合考虑熔池正面参数与焊接规范参数对焊缝熔透状态的影响,建立了脉冲GTAW平板对接熔池多参数神经网络模型,为焊接熔透控制器的设计提供了基础. 文献[12]采用支持向量机(support vector machines, SVM)算法建立铝合金变极性TIG焊熔透状态分类模型,以熔池正面参量及相关工艺参数作为模型的输入进行熔透状态分类识别. 文献[13]对GTAW焊接过程中的图像构建数据集,利用卷积神经网络对图像与熔深建立联系,以实现对焊接过程中的熔深预测. 在焊接熔透控制方面,主要的控制策略有模糊控制、模糊神经网络控制、非线性模型及其混合控制方式等[9, 17-19].

对于基于神经网络、机器学习等智能算法的熔透状态识别预测模型而言,随着输入特征参量的增加,模型的预测精度在一定程度上有所提高. 但高维输入也不可避免地带来冗余特征和产生大量冗余信息,导致难以通过数据分析处理来获取熔透状态随熔池正面特征变化的规律,从而无法建立二者之间的对应关系. 因此,如何从样本数据集中挖掘有效信息和获取知识,构建一个以熔池正面特征来表征熔透状态的简洁的知识模型,进而基于合适的控制策略,通过实时检测和控制正面熔池来实现熔透在线控制,这对于简化熔透控制模型和提高控制系统的实时性具有重要意义.

粗糙集理论(rough set, RS)作为一种数据表达、学习和归纳的有效的数学工具,自Pawlak提出以来已被广泛应用于知识发现、机器学习、模式识别、决策支持、归纳推理等诸多领域[20-21],在焊接领域的应用也逐渐引起重视并取得一定进展[22-24]. 粗糙集的核心思想是保持分类能力不变的前提下,通过知识约简导出决策或分类规则. 因此,若能通过粗糙集的知识获取方法来确定各熔透状态下对应的熔池正面特征,进而利用模糊逻辑能仿人判决操作的特点,建立一个关于熔池正面特征的模糊控制模型,则闭环控制中可免除熔透识别预测的环节,通过实时监控熔池正面参数以达到控制熔透的目标. 为此,文中提出一种焊接熔透状态的粗糙-模糊控制方法. 构造2种基于变精度粗糙集理论的属性约简算法,给出一种利用最小化模糊熵确定隶属函数的基本思路. 针对变间隙焊接熔透控制问题,利用粗糙集知识获取方法提取熔透状态分类规则,基于熔池特征与熔透状态之间的对应关系建立熔池特征参数的模糊控制模型,设计2组变间隙焊接实验进行验证,并对实验结果进行讨论和分析.

1. 变精度粗糙集的基本概念

经典Pawlak粗糙集处理的分类是建立在完全“属于”或“不属于”关系之上的精确分类,但在实际应用中噪声等干扰往往在所难免,这导致经典粗糙集的分类效果难以达到预期. 为增强经典模型的抗干扰能力,文献[25-26]提出一种拓展粗糙集模型——变精度粗糙集(variable precision rough set, VPRS).

设

$ U $ 为非空有限论域,定义一包含函数$ \kappa :{U^2} \to [0,1] $ ,使得任给$ X,Y \subseteq U, $ $$ \kappa (X,Y) = \left\{ \begin{gathered} \frac{{{\text{Card}}(X \cap Y)}}{{{\text{Card(}}X)}},{\text{ }}X \ne \emptyset {\text{ }} \\ {\text{1, }}X = \emptyset \\ \end{gathered} \right. $$ (1) 式中:

$ {\text{Card(}} \cdot {\text{)}} $ 表示集合的基数,称$ \kappa (X,Y) $ 为X关于Y的相对正确分类率.设

$ (U,C \cup \{ d\} ) $ 是一决策信息系统,其中$ C $ 是条件属性集,$ d $ 是决策属性;$ {X_i}(i = 1,2, \cdots ,m) $ 是由划分$ U{\text{/}}C $ 导出的条件类,$ {Y_j}(j = 1,2, \cdots ,n) $ 是由划分$ U{\text{/\{ }}d{\text{\} }} $ 导出的决策类,给定$ \beta \in (0.5,1] $ ,则$ {Y_j} $ 关于$ C $ 的$ \beta $ 下近似集为$$ {\underline C ^\beta }({Y_j}) = \{ {X_i} \in U{\text{/}}C:\kappa ({X_i},{Y_j}) \geqslant \beta \} $$ (2) $ d $ 关于$ C $ 的$ \beta $ 相对正域为$$ POS_C^\beta (d) = \mathop \cup \limits_{{Y_j} \in U{\text{/\{ }}d\} } {\underline C ^\beta }({Y_j}) $$ (3) $ d $ 关于$ C $ 的$ \beta $ 近似分类质量(近似依赖)为$$ \gamma _C^\beta (d) = {{{\text{Card(}}POS_C^\beta (d))} \mathord{\left/ {\vphantom {{{\text{Card(}}POS_C^\beta (d))} {{\text{Card}}(U)}}} \right. } {{\text{Card}}(U)}} $$ (4) 近似分类质量反映了在某一正确分类率阈值

$ \beta $ 下,条件分类$ U{\text{/}}C $ 可以确定划分到决策分类${U}/d $ 的对象数目在论域$ {U} $ 中所占比例.给定决策信息系统

$ (U,C \cup \{ d\} ) $ ,对任意$ B \subseteq C $ 和$ a \in B $ ,若满足$$ \left\{ \begin{gathered} 条件1:\gamma _B^\beta (d) = \gamma _C^\beta (d) \\ 条件2:\gamma _{B - \{ a\} }^\beta (d) \ne \gamma _C^\beta (d) \\ \end{gathered} \right. $$ (5) 则称

$ B $ 为$ C $ 关于$ d $ 的一个$ \beta $ 近似约简[25],记作$ RED_d^\beta (C) $ . 在式(5)中,条件1给出了约简计算终止的前提,而条件2则要求约简结果是一个最小约简.属性重要性在是粗糙集知识约简中的一个关键概念,其表示形式主要有基于代数观的定义和基于信息论的定义两种[27]. 给定决策信息系统

$ (U,C \cup \{ d\} ) $ ,对任意$ a \in B $ ,$ a $ 在$ C $ 中重要性的代数定义可表示为$$ SIG(a,C,d) = \gamma _C^\beta (d) - \gamma _{C - \{ a\} }^\beta (d) $$ (6) 式(6)表示从条件属性集

$ C $ 中去除$ a $ 后所引起的分类质量的变化;$ a $ 在$ C $ 中重要性的信息定义可表示为$$ SIG(a,C,d) = H(d{\text{|}}C - \{ a\} ) - H(d{\text{|}}C) $$ (7) 式(7)反映了从

$ C $ 中去除$ a $ 后所引起的条件信息熵的变化. 当属性重要性的代数定义为0时,其信息定义未必为0;反之若属性重要性的信息定义为0,则其代数定义也为0,即属性重要性的信息定义包含了其代数定义.2. 焊接熔透过程的粗糙-模糊控制

粗糙-模糊控制(rough-fuzzy control)是将粗糙集与模糊逻辑两种软计算方法相结合,建立一个面向复杂被控对象的知识模型,通过推理决策实现复杂过程的实时控制. 就焊接工艺而言,焊接熔透状态的粗糙-模糊控制方法主要包括以下几个步骤.

(1)构建熔透状态决策信息系统

(2)连续数据离散化

(3)熔池特征选择与分类规则获取

(4)建立熔池特征参数模糊控制模型

(5)模型推理决策

其中,熔池特征选择和分类规则提取是该方法的核心环节,如图1所示.

2.1 熔透状态决策信息的构建

焊接熔池正面形态是三维熔池的二维映射,基于粗糙集理论的知识表达方式,一个焊接熔透状态决策信息系统

$ S = (U,C \cup \{ d\} ,V) $ 可形式化表示为一张二维信息表(决策信息表),如表1所示,其中$ U $ 是由焊接样本$ {x_i}(i = 1,2, \cdots ,m) $ 构成的集合(论域);$ C $ 为条件属性集, 由一组熔池正面形状参数$ {c_j}(j = 1,2, \cdots ,n) $ 构成;$ d $ 为决策属性,表示熔透状态;任给$ a \in C \cup \{ d\} $ ,有$ a:U \to {V_a} $ ,称$ V = \bigcup {{V_a}} $ 为$ C \cup \{ d\} $ 的值域,其中$ {v_{ij}} = {c_j}({x_i}) $ ,$ {v_{di}} = d({x_i}) \in V $ ,称$ {v_{ij}} $ 、$ {v_{di}} $ 为条件属性值和决策属性值. 简记$ S = (U,C \cup \{ d\} ) $ .表 1 焊接熔透状态决策信息表Table 1. Decision information table for welding penetration states焊接样本集U 熔池形状

参数c1熔池形状

参数c2… 熔池形状

参数cn熔透状态

dx1 v11 v12 … v1n vd1 x2 v21 v22 … v2n vd2 … … … … … … xm vm1 vm2 … vmn vdm 为获取熔池形状参数与熔透状态之间关系的粗糙集知识模型,可通过焊接实验平台获取建模数据,试验中由CCD拍摄的焊接熔池正面图像,经图像处理后提取熔池表面的几何特征参数,如图2所示,表征熔透状态的熔池背面宽度则通过焊后测量而得.

2.2 连续数据离散化

运用粗糙集理论进行数据分析的对象通常为离散型数据,因而通过工艺实验获取焊接熔透状态决策信息系统的建模数据之后,需对具有连续特征的原始数据进行离散化处理. 现有的离散化方法有多种,如经验知识法、沿概念树提升法、基于粗糙集的方法、聚类分析法等[28]. 但不同算法在应用过程中均有其局限性,经验知识法要求对数据特征有充分的认识,沿概念树提升法要求离散之前构造属性概念树,基于粗糙集的算法需要建模数据完全覆盖整个样本空间. 模糊聚类是一种基于划分的聚类算法,它根据类内相似、类外相异的原则,通过对数据进行模糊划分得到有限的几个类别. 与上述方法相比它无需足够的先验知识,也无需建立概念树,并且当建模数据未完全覆盖样本空间时,仍可通过模糊判决获得新样本的分类结果. 针对焊接信息系统中连续数据不可避免地存在“亦此亦彼”的模糊不确定性,文中采用模糊c-均值聚类算法(fuzzy c-means, FCM)对表1决策信息系统中的条件属性值(熔池形状参数值)进行离散化处理. 对于决策属性值的离散化,可根据文献[29]给出的焊缝熔透规格标准来确定.

2.3 熔池特征选择与分类规则获取

在熔池形态参数体系中,常见的可用于表征熔透性的特征参数主要有熔池长度、宽度、半长、周长、面积、尾面积等几何参数,以及长宽比、后拖角、尾轮廓角等形状参数[30],理论上这些参数都可作为焊接熔透过程的控制变量,但对于一个基于规则类知识的焊接控制系统而言,如变量过多不仅会使规则数量急剧增加,造成所谓的“组合爆炸”,同时如何建立这些规则也是一个很棘手的问题. 由于不同的焊接工艺和焊接条件对焊缝熔透性的影响不同,因此有必要结合具体的焊接工艺及条件,对决策信息系统中的熔池形态特征参数进行筛选,以期获得一个以最小特征参数集合来描述熔透状态的简化知识模型.

特征选择又称属性约简,作为粗糙集理论的最核心内容之一,其目标是在保持条件属性(特征)对决策属性(特征)分类能力不变的情况下,从决策信息系统中选择对分类能力有重要影响的条件属性,同时去除冗余、不重要的条件属性. 如前所述,建立在集合之间完全包含关系基础之上的Pawlak粗糙集并不具备处理噪声数据的能力,而焊接是一个包含高噪声、强干扰的复杂过程,存在诸多不确定性因素,为增强粗糙集的抗噪容错性,文中采用其拓展形式——变精度粗糙集理论(VPRS)对焊接熔透决策信息系统中的离散数据进行分析处理. 根据分类能力定义的不同,基于VPRS的属性约简有分类质量、相对正域和决策类下近似分布3种不同层次的定义,这里采用Ziarko约简定义,即依据分类质量的标准进行属性约简[25].

在已有的基于粗糙集属性约简的特征选择算法中,可根据算法是否采用启发信息分为理论算法和启发式算法两种. 就理论约简算法而言,在计算过程中通过尝试属性的各种组合来求取约简结果,当属性规模较大时易产生组合爆炸问题,故求解信息系统的最小或最优约简是NP难题. 为此本文采用属性添加法,利用启发式信息给出如下2种基于VPRS的约简算法,以获取熔池形态特征参数选择的次优解.

算法1. 基于最大分类质量的快速约简(fast reduct based on maximum classification quality, FRBMCQ)

输入: 决策信息系统

$ S = (U,C \cup \{ d\} ) $ , 正确分类率阈值$ \beta $ .输出:

$ S $ 的一个属性约简$ RED $ .步骤1. 计算决策属性

$ d $ 关于条件属性集$ C $ 的分类质量$ \gamma _C^\beta $ ;步骤2.

$ RED \leftarrow \emptyset $ ,步骤2.1对每个属性

$ {c_j} \in C - RED(j = 1,2, \cdots ,n) $ ,计算决策属性$ d $ 关于属性集$ RED \cup \{ {c_j}\} $ 的分类质量$ \gamma _{RED \cup \{ {c_j}\} }^\beta $ ;步骤2.2选择使

$ \gamma _{RED \cup \{ {c_j}\} }^\beta $ 为最大值的属性$$ {c_j}(j = 1,2, \cdots ,n) , RED \leftarrow RED \cup \{ {c_j}\} ; $$ 步骤2.3若

$ \gamma _{RED}^\beta \geqslant \gamma _C^\beta $ , 则输出$ RED $ ; 否则转步骤2.1.FRBMCQ算法首先令属性约简集

$ RED $ 为空集,然后选择使近似分类质量达到最大的属性,逐个将其添加到$ RED $ 中,直至其分类质量满足终止条件$ \gamma _{RED}^\beta \geqslant \gamma _C^\beta $ . 该算法利用了启发式信息,认为那些使分类质量增量为最大的属性应是重要属性,并通过逐一添加而达到决策信息表的快速约简.值得注意的是,VPRS模型中正确分类率

$ \kappa (X,Y) $ 及其阈值$ \beta $ 的引入,使得条件属性对决策属性的分类质量并不总是随条件属性个数增加而单调不减,约简过程中可能会出现“增加-减少-增加”的反复现象. 这是因为,随着条件属性数量的增加,尽管条件类的知识粒度被细化,但条件类对决策类的正确分类率$ \kappa (X,Y) $ 将呈非均匀分布,当各条件类对应的分类率差异较大时,对于那些$ \kappa (X,Y) $ 值较小的条件类,计算过程中因给定阈值$ \beta $ 的限制而被排除在相对正域之外,从而导致条件属性对决策属性的分类质量随着条件属性个数的增加而减少. 因此,在属性选择过程中,任一属性能否被选择以及选择的次序,取决于选择添加该属性后所引起的分类质量的变化,若使分类质量为最大则选择添加至RED中,否则将不被选择.从分类质量会出现随属性个数增加而减少的角度看,属性约简不仅可以保持分类能力,还可能提高分类能力,即约简过程中得到的属性组合,其分类能力甚至会超过原始决策信息表. 为此对Ziarko约简定义进行适当修正,将条件A1)改为

$ \gamma _{RED}^\beta (d) \geqslant \gamma _C^\beta (d) $ ,即约简后的分类质量不小于原决策信息表的分类质量. FRBMCQ算法以属性添加为基础,以最大分类质量作为属性选择的判决依据,不仅可使约简过程保持相对稳定,并且能以较小的属性组合快速提高分类质量,进而获得约简计算的近似最优解或次优解.算法2. 基于属性重要性的快速约简(Fast reduct based on attribute significance, FRBAS)

输入: 决策信息系统

$ S = (U,C \cup \{ d\} ) $ , 正确分类率阈值$ \beta $ .输出:

$ S $ 的一个属性约简$ RED $ .步骤1. 计算决策属性

$ d $ 关于条件属性集$ C $ 的分类质量$ \gamma _C^\beta $ ;步骤2. 计算每个条件属性

$ {c_j}(j = 1,2, \cdots ,n) $ 在$ C $ 中的重要性$ SIG({c_j},C,d) $ ,将$ {c_j} $ 按$ SIG({c_j},C,d) $ 降序排列,其中$ SIG({c_j},C,d) = H(\{ d\} {\text{|}}C - \{ {c_j}\} ) - H(\{ d\} {\text{|}}C) $ ;步骤3.

$ RED \leftarrow \emptyset $ , 按$ SIG({c_j},C,d) $ 递减的顺序对每个$ {c_j} \in C $ 重复如下操作:步骤3.1

$ RED \leftarrow RED \cup \{ {c_j}\} $ , 计算决策属性$ d $ 关于$ RED $ 的分类质量$ \gamma _{RED}^\beta $ ;步骤3.2 若

$ \gamma _{RED}^\beta \geqslant \gamma _C^\beta $ , 则输出$ RED $ ; 否则转Step3.1.FRBAS算法采用属性重要度为启发信息,以

$ C $ 中去除任一属性$ {c_j} $ 所引起的条件信息熵的变化$ H(\{ d\} {\text{|}}C - \{ {c_j}\} ) - H(\{ d\} {\text{|}}C) $ 作为$ {c_j} $ 对决策属性$ d $ 的重要性度量,重要度$ SIG({c_j},C,d) $ 值越大,则属性$ {c_j} $ 对$ d $ 的重要性就越大,将$ C $ 中所有属性按重要度由大到小进行排序,依次将其添加到$ RED $ 中,直至满足终止条件$ \gamma _{RED}^\beta \geqslant \gamma _C^\beta $ .粗糙集理论除了提供决策信息系统中属性(知识)约简的方法外,还具有从决策信息系统提取“If...then...”形式的决策或分类规则的能力. 设

$ S' = (U,RED \cup \{ d\} ) $ 是一个经特征选择后的熔透状态决策信息系统,$ {X_i} = {U \mathord{\left/ {\vphantom {U {RED}}} \right. } {RED}} $ 、$ {Y_j} = {U \mathord{\left/ {\vphantom {U {\{ d\} }}} \right. } {\{ d\} }} $ 分别为$ RED $ 和$ d $ 对$ U $ 进行划分导出的条件类和决策类,对任意$ x \in {X_i} $ 和$ x \in {Y_j} $ ,在$ S' $ 中关于$ {X_i} $ 和$ {Y_j} $ 的描述为$$ \left\{ \begin{gathered} Des({X_i}) = \mathop \wedge \limits_{{c_k} \in RED} ({c_k} = {c_k}(x)) \\ Des({Y_j}) = (d = d(x)) \\ \end{gathered} \right. $$ (8) 式中:

$ {c_k}(x) $ 、$ d(x) $ 分别是$ {c_k} $ 和$ d $ 关于$ x $ 的属性值.根据熔池特征来判决焊缝熔透状态的一组分类规则

$ {R_x} $ 可表示为$$ {R_x}:Des({X_i}) \Rightarrow Des({Y_j}){\text{ }}(con{f_{ij}}) $$ (9) 式中:

$ Des({X_i}) $ 、$ Des({Y_j}) $ 分别为“If...then...”规则的前件和后件;$ con{f_{ij}} $ 为规则置信度,满足$$ con{f_{ij}} = {{{\text{Card(}}{X_i} \cap {Y_j}{\text{)}}} \mathord{\left/ {\vphantom {{{\text{Card(}}{X_i} \cap {Y_j}{\text{)}}} {{\text{Card(}}{X_i}{\text{)}}}}} \right. } {{\text{Card(}}{X_i}{\text{)}}}} $$ (10) 2.4 建立熔池特征参数模糊控制模型

采用属性约简获得一个描述熔透状态的熔池最小特征集之后,就可确定作为焊接过程被控制量的熔池几何形态参数,并根据熔池特征参数与熔透状态的对应关系,建立一个焊接熔池表面参数的模糊控制模型,焊接过程中通过对这些参数的控制以实现焊缝熔透的实时控制. 对于模糊系统而言,无论是单变量控制(SISO)还是多变量控制(MISO)形式,建模通常包括制定控制规则、构造隶属函数、构建模糊关系矩阵等环节.

制定熔池几何参数控制规则是建模的核心内容,首先需确定输入变量(被控量)和输出变量(操作量)的语言值,即给出各模糊状态及相应的模糊集,语言值一般可分成3 ~ 7个奇数挡,如{负大, 零, 正大}、{负大, 负中, 零, 正中, 正大}等. 考察焊工对熔池形态及大小实施控制的过程,并将这些操作经验进行归纳总结,可得到一组通过语言值来描述控制模型的模糊规则,通常以“If A and B Then C”的形式加以描述. 对于包含有多个熔池特征参数的多变量控制模型,如各变量之间关联性较小,则根据其与操作量的关系分别制定出各自的模糊控制规则.

通过构造隶属函数来定义语言值是建立熔池特征参数模糊控制模型的关键环节. 隶属函数的确定方法有十几种,如直觉法、德尔菲法、二元对比排序法、模糊统计试验法等[31]. 但多数方法受人的主观因素和心理因素的影响大,或受限于对领域知识的掌握而无法直接应用于焊接过程控制的场合. 焊接过程建模中,通过对采集到的部分实验数据的分析,对某些输入输出变量的模糊状态所呈现的特征已有大致的了解,如何构造隶属函数对这些状态进行恰当地描述,使得所建立的隶属函数既能反映模糊状态的模糊性,又尽可能清晰地描述这些变量所表达的客观内容,本文给出一种通过最小化模糊熵来确定隶属函数的方法,其基本思想是:根据先验知识和采集的数据,给出描述模糊状态的候选隶属函数,然后依据最小化模糊熵的原则计算相关参数,进而获得合适的隶属函数.

在确定熔池特征参数模糊控制规则及定义相关语言值之后,将这些规则通过模糊逻辑运算转化为从输入到输出的一个模糊关系矩阵

$ R $ . 对于典型的单变量、双输入和单输出控制模型,设$ {E_i} $ ,$ E{C_j} $ ,$ {U_{ij}} $ 分别为定义于误差论域$ X $ 、误差变化率论域$ Y $ 和输出变量论域$ Z $ 之上的模糊子集,则控制规则表可表示为定义于$ X \times Y \times Z $ 之上的一个模糊关系矩阵$$ R = \bigcup\nolimits_{i,j} {{E_i} \times E{C_j} \times {U_{ij}}} $$ (11) 使得任给

$ e \in X,{\text{ }}ec \in Y,{\text{ }}u \in Z $ , 均有$$ R(e,ec,u) = \mathop \vee \limits_{i,j} \left( {{E_i}(e) \wedge E{C_j}(ec) \wedge {U_{ij}}(u)} \right) $$ (12) 式中:

$ \wedge , \vee $ 分别表示合取(取小)运算与析取(取大)运算. 若控制模型为包含$ p(p \geqslant 2) $ 个熔池特征参数的多变量-单输出的形式,则需根据各熔池参数与操作量间的控制规则表,分别建立相应的模糊关系矩阵$ {R_1},{R_2}, \cdots ,{R_p} $ .2.5 模型推理决策

根据熔池特征参数模糊控制模型,将输入精确量

$ (e',ec') $ 模糊化得到输入模糊量$ E' \times EC' $ ,然后通过与模糊关系矩阵$ R $ 的合成运算,可得到单变量控制模型的输出模糊量$$ U' = (E' \times EC') \circ R $$ (13) 式中:“

$ \circ $ ”为合成运算. 对于多变量模型,各输入精确量$ ({e'_k},e{c'_k}) $ 对应的输出模糊量为$$ {U'_k} = ({E'_k} \times E{C'_k}) \circ {R_k} , k = 1,2, \cdots ,p $$ (14) 利用加权判决可得到综合输出模糊量

$$ U' = {{\sum\nolimits_k {{w_k}{{U'}_k}} } \mathord{\left/ {\vphantom {{\sum\nolimits_k {{w_k}{{U'}_k}} } {\sum\nolimits_k {{w_k}} }}} \right. } {\sum\nolimits_k {{w_k}} }} $$ (15) 式中:

$ {w_k} $ 为权重系数,进而通过解模糊计算得到输出精确量$ u' $ ,如图3所示.3. 变间隙焊接熔透控制

坡口间隙作为影响焊缝熔透状态的一个重要工艺参数,主要用于保证根部焊透,因此间隙大小应根据焊接规范合理选择并保持一致,若间隙过小则无法焊透,而过大则易导致过熔透、焊塌乃至烧穿. 但在实际焊接过程中,受坡口加工精度及焊件装配误差的影响,焊缝间隙往往难以保证均匀一致,有时甚至差别较大,恒规范焊接易产生熔透成形不良的缺陷. 基于智能方法模拟焊工对熔池观察、推断和操作等行为是实现焊接熔透控制的一个有效途径,利用变间隙与变电流焊接工艺试验,通过视觉传感及图像处理获取建模数据,运用上节提出的粗糙-模糊控制方法建立熔池表面特征参数的模糊控制模型,通过推理判决以实现变间隙条件下的焊接熔透控制.

3.1 熔透状态决策信息系统建立

焊接电流是影响熔池形态和熔透状态的主要规范参数之一,焊接过程中当坡口间隙发生变化时,通过调节电流即可对焊接熔池及熔透过程的进行控制. 为建立一个在不同坡口间隙及焊接电流条件下,对熔池表面形态特征与熔透状态之间关系进行描述的知识模型,设计一种变间隙-电流焊接试验,通过GMAW焊接试验系统完成. 该系统主要由焊接试验平台和图像采集系统两部分组成,其结构如框图4所示.

采用MAG对接平焊工艺,母材为Q235,试件规格为300 mm × 150 mm × 6 mm,焊丝材料为直径1.2 mm的H08Mn2SiA焊丝,焊丝伸出长度为1.2 mm,焊接速度为47 cm/min,焊接电流为155,165,185,205,215 A, 电弧电压为20.9 V,坡口为1.5 mm钝边的60° Y形坡口,坡口间隙为0.4,0.7,1.2,1.7,2.0 mm,保护气体为80%Ar + 20%CO2,保护气体流量为15 L/min,CCD采样时间间隔为400 ms.

试验采取焊接电流与坡口间隙组合的方式共进行25组,各组试板焊接完成后分别测量熔池背面宽度

$ {W_B} $ ,其结果如表2所示,其中“—”表示焊穿. 由表2不难看出,焊缝背面宽度随着焊接电流和焊缝间隙的增加而单调不减,当电流及间隙均较大时,焊接过程中试板出现大范围焊穿的现象.表 2 变间隙-电流焊接下的焊缝背面熔宽Table 2. Weld back width under variable gap-current welding conditions (mm)坡口间隙

G /mm焊接电流I /A 155 165 185 205 215 0.4 0 0 0 0 3.44 0.7 0 0 0 3.39 4.72 1.2 2.09 2.42 3.09 4.31 5.15 1.7 2.59 3.40 4.03 5.03 5.37 2.0 3.67 3.87 4.90 — — 试验过程中由CCD拍摄的各熔透状态下的熔池图像,经过滤波去噪、阈值分割、边缘检测等环节的处理,提取其相应的熔池轮廓. 在获取的25组熔池图像样本中,(205, 2.0)和(215, 2.0)这两组样本因出现大范围焊穿而不纳入图像处理的环节.

图5给出了3组未熔透、全熔透和过熔透的熔池正面图像及其轮廓曲线,其中

$ I \times G $ 分别取(165, 0.4)、(185, 1.2)、(205, 1.7). 在图5中,熔池头部有少部分图像因被喷嘴遮挡而无法获取其轮廓信息,但焊接过程中熔池的物化冶金反应和几何形态变化主要集中在熔池的中后区域,因此可依据熔池尾部区域的图像信息进行熔池表面几何特征提取与分析.由图5不难看出,与未熔透图像相比,全熔透状态下的熔池尾部变大,形状变长、尖削;从熔透到过熔透,熔池尾部面积继续增大,熔池图像的细尖程度更加明显. 这是因为,从未熔透到熔透状态,一方面,随着焊接电流的增加,熔池半长、宽度、尾面积等几何参数有增大的趋势,同时受焊接温度场运动的影响,使得电弧轴线后方沿熔池长度方向的温度梯度小于宽度方向,熔池半长的增幅要大于熔池宽度的增幅;另一方面,随着焊缝间隙的增加,在坡口上方铺展的融化金属进入坡口内部,使得熔池表面几何尺寸有减小的趋势,并且熔池宽度方向减少速度要高于熔池长度方向. 焊接电流和坡口间隙两种因素综合作用的结果,使得熔池半长增大且宽度略微增加,熔池尾部呈细长而尖削形. 随着焊接电流和间隙的进一步增大,过熔透现象产生,熔池在增大的同时其下榻量也随之增加,电流与间隙两者综合作用下熔池尾面积趋向增大,但由于熔池宽度的增量不足以抵消熔池下榻引起的其宽度的减少,熔宽略微减小,熔池尾部形态进一步变细变尖.

据以上分析,可给出与焊接熔透状态相关的熔池几何形状参数主要有:熔池尾部长度

$ {L_{\rm{T}}} $ 、熔池最大宽度$ W $ 、熔池尾部面积$ {S_{\rm{T}}} $ 、熔池尾部长宽比$ {L_{\rm{T}}}{\text{/}}W $ 、熔池后拖角$ \alpha $ . 为进一步刻画熔池尾部形状随焊接电流和焊缝间隙变化的趋势,这里引入2个用以描述熔池尾部尖削程度的形状参数:熔池尾面积系数$ {C_{{\rm{TS}}}} $ 和熔池尾宽系数$ {C_{{\rm{TW}}}} $ ,其定义如下$$ \left\{ \begin{gathered} {C_{{\rm{TS}}}} = {{{S_{\rm{T}}}} \mathord{\left/ {\vphantom {{{S_{\rm{T}}}} {({L_{\rm{T}}} \cdot W)}}} \right. } {({L_{\rm{T}}} \cdot W)}} \\ {C_{{\rm{TW}}}} = {{{W_{{L_{\rm{T}}}/2}}} \mathord{\left/ {\vphantom {{{W_{{L_{\rm{T}}}/2}}} W}} \right. } W} \\ \end{gathered} \right. $$ (16) 式中:

$ {W_{{L_{\rm{T}}}{\text{/}}2}} $ 为熔池在$ 1{\text{/}}2 $ 尾部长度处的宽度,如图6所示.根据上述熔池表面轮廓图像参数化定义,通过参数计算得到描述各熔透状态的熔池表面特征参数值,由此可建立变间隙-电流焊接条件下熔透状态决策信息系统,如表3所示,该系统是一个由23组样本、7个条件属性和1个决策属性构成的数据集,其中决策属性为熔池背面宽度

$ {W_B} $ .表 3 变间隙电流焊接熔透状态决策信息表Table 3. Decision information table for penetration status of variable gap-current welding样本号 熔池尾部长度

$ {L_{\rm{T}}} $/μm熔池最大宽度

$ W $/μm熔池尾部长宽比

${L_{\rm{T}}}$/W熔池尾部面积

$ {S_T} $/μm2熔池尾面积系数

${C_{{\rm{TS}}} }$熔池后拖角

$ \alpha $(°)熔池尾宽系数

${C_{{\rm{TW}}} }$熔池背面宽度

$ {W_B} $/mmx1 203.5 227.4 0.895 34 264.2 0.740 58.39 0.818 0 x2 227.1 246.4 0.922 40220.0 0.718 56.96 0.795 0 x3 287.2 279.0 1.029 55 542.4 0.693 51.84 0.766 0 … … … … … … … … … x10 356.5 286.8 1.243 61 489.8 0.601 43.82 0.611 4.724 x11 198.2 195.4 1.015 25 912.6 0.669 52.58 0.722 2.092 x12 229.0 222.6 1.029 33977.0 0.667 51.84 0.708 2.420 … … … … … … … … … x21 222.7 184.4 1.207 26597.0 0.647 45.06 0.678 3.672 x22 250.0 210.8 1.186 33 429.4 0.634 45.74 0.662 3.872 x23 323.8 222.4 1.458 35 481.6 0.618 37.94 0.621 4.904 3.2 特征选择与分类规则获取

在基于变精度粗糙集知识约简算法对决策信息表3进行特征筛选之前,需对表中的连续型属性进行离散化预处理. 对于条件属性,采用模糊c-均值聚类(FCM)将连续数据划分为3类,划分结果按由小到大的顺序进行排列,分别表示为符号值“1”、“2”和“3”. 图7给出了熔池尾宽系数

$ {C_{TW}} $ 的聚类分析结果,其中类别[0.587, 0.621]、[0.654, 0.722]和[0.753, 0.818]的聚类中心为0.613、0.684和0.787,其离散值分别取1、2和3. 对于决策属性$ {W_B} $ ,可依据单面焊双面自由成形熔透状态分类标准划分为未熔透、全熔透和过熔透3类[29],其离散化区间为[0, 2]、[2, 4]和[4, 6],分别以符号值“0”、“1”和“2”来表示. 离散化后的熔透状态决策信息系统如表4所示.分别利用前文给出的FRBMCQ算法和FRBAS算法,对表4中的决策信息系统进行特征选择计算,均得到一个通过熔池表面几何特征来描述熔透状态的最小特征集

$ RED = \{ {C_{TW}}\} $ ,如图8所示,其中包含度阈值$ \beta = 0.8 $ ,由此提取出以下焊接熔透状态分类规则R1: 若

$ {C_{TW}} = 3 $ , 则$ {W_B} = 0 $ ($ conf = 1 $ )R2: 若

$ {C_{TW}} = 2 $ , 则$ {W_B} = 1 $ ($ conf = 9/11 $ )R3: 若

$ {C_{TW}} = 1 $ , 则$ {W_B} = 2 $ ($ conf = 1 $ )其中

$ conf{\text{(}} \cdot {\text{)}} $ 为规则置信度. 由图8b可以看到:从条件信息熵的角度考察各熔池特征参数的重要性,其重要度$ SIG( \cdot ) $ 按由大到小依次为表 4 离散化后的熔透状态决策信息表Table 4. Decision information table of penetration state after discretization样本号 熔池尾部长度

LT熔池最大宽度

W熔池尾部长宽比

LT/W熔池尾部面积

ST熔池尾面积系数

CTS熔池后拖角

α熔池尾宽系数

CTW熔池背面宽度

WBx1 1 2 1 1 3 3 3 0 x2 1 2 1 1 3 3 3 0 x3 2 3 1 3 3 3 3 0 … … … … … … … … … x10 3 3 2 3 1 2 1 2 x11 1 1 1 1 2 3 2 1 x12 1 2 1 1 2 3 2 1 … … … … … … … … … x21 1 1 2 1 2 2 2 1 x22 1 1 2 1 2 2 2 1 x23 2 2 2 1 1 1 1 2 $$ {C_{TW}} > {C_{TS}} > {L_T}{\text{/}}W > \alpha = {S_T} = W = {L_T} $$ (17) 即在变间隙与变电流焊接条件下,熔池尾宽系数

$ {C_{TW}} $ 对确定熔透状态$ {W_B} $ 最重要,其次分别是尾面积系数$ {C_{TS}} $ 和熔池尾长宽比$ {L_T}{\text{/}}W $ ,熔池后拖角$ \alpha $ 、熔池尾面积$ {S_T} $ 、熔池宽度$ W $ 和熔池半长$ {L_T} $ 对$ {W_B} $ 的重要程度均为零. 如前所述,一方面,在焊接电流和坡口间隙的两种因素综合作用下,$ {L_T} $ 、$ W $ 、$ {S_T} $ 和$ \alpha $ 等表面特征参数随熔深及熔透状态单调变化的规律被打破,使得这些参数从决策信息系统去除之后,不会引起系统不确定性及分类质量发生变化;另一方面,$ {C_{TW}} $ 、$ {C_{TS}} $ 和$ {L_T}{\text{/}}W $ 可用于描述熔池形态随熔深单调变化的某些特征(如尖削度、细长度等),因而将其去除之后将导致系统不确定性增加或分类质量下降.由

$ {\gamma _{RED}} = {\gamma _{{C_{TW}}}} = {\gamma _C} = 1 $ 可知,仅保留条件属性$ {C_{TW}} $ 的决策信息表与未约简的原始决策信息表具有相同的分类能力,因而决策信息系统的一个最小约简为$ RED = \{ {C_{TW}}\} $ . 从约简结果导出的分类规则表明,熔池尾宽系数$ {C_{TW}} $ 与焊缝熔透状态$ {W_B} $ 之间存在一一对应关系,且$ {C_{TW}} $ 随着熔深的增加而单调减少,为此,只需以熔池尾宽系数作为被控制量建立单变量控制模型,就可实现对焊接熔透过程的控制.3.3 控制模型和推理策略

根据变间隙MAG焊时熔池尾宽系数随熔深增加而单调递减的变化规律,可建立一个以熔池尾宽系数作为控制量的单变量模糊控制模型,如图9所示,输入变量为熔池尾宽系数的误差

$ e $ 及误差变化率$ e_c $ ,输出变量为焊接电流变化量$ \Delta I $ ,$ {\tilde C_{TW}} $ 为尾宽系数期望值,取焊接条件$ (185,1.2) $ 熔透类图像的熔池尾宽系数.为建立控制规则,将输入变量和输出变量语言值分为

$ NB $ (负大)、$ ZE $ (零)和$ PB $ (正大)3档,由于$ {C_{TW}} $ 随熔深单调减少而熔深随焊接电流单调增加,可推知$ {C_{TW}} $ 随焊接电流单调减少. 通过总结归纳焊工对熔池形态与大小实施控制的一般操作经验,可得到以下9条控制规则,如表5所示.表 5 熔池尾部宽度系数控制规则Table 5. Control rules for width coefficient of molten pool tail误差变化率ec 误差e NB ZE PB NB NB NB ZE ZE NB ZE PB PB ZE PB PB 利用变间隙-电流焊接试验得到的各熔透状态下的熔池尾宽系数,文中给出一种通过最小化模糊熵来确定误差e的隶属函数的方法.

第一步,由表3计算

$ {C_{TW}} $ 各测量值与期望值的误差$ e $ ,得到误差论域$ E $ 的一个子集$ E' $ . 利用FCM算法将$ E' $ 分成$ NB $ 类、$ ZE $ 类和$ PB $ 类,如表6所示,其中$ \bar e $ 为各类误差的聚类中心.表 6 误差类型及其聚类中心Table 6. Types of error and their clustering centers类型 $ e $ $ \bar e $ NB −0.074, −0.055, −0.051, −0.05, −0.041, −0.04 −0.047 ZE −0.007, −0.004, 0, 0.001, 0.002, 0.017, 0.025,

0.04, 0.043, 0.047, 0.0610.023 PB 0.092, 0.105, 0.121, 0.133, 0.134, 0.157 0.127 第二步,选择梯形模糊分布作为误差论域

$ E $ 的隶属函数,如图10所示,其中$ {t_0} \in ( - 0.007,0.023) $ 、$ {t_1} \in (0.092,0.127) $ 和$ {t_2} \in ( - 0.047, - 0.04) $ 为待定参数.第三步以模糊熵

$ H( \cdot ) $ 作为模糊集的模糊性度量建立如下优化模型$$ \begin{split} & \min H(NB,ZE,PB)= \frac{1}{{23\ln 2}}\sum\limits_{i = 1}^{23} (h(NB({e_i})) + h(ZE({e_i})) +\\& h(PB({e_i}))) \\& {\text{s}}{\text{.t}}{\text{.}} \end{split} $$ (18) $$ NB(e)=\left\{\begin{array}{l}1,\text{ }e < {t}_{2}\\ \dfrac{{t}_{0}-e}{{t}_{0}-{t}_{2}}\text{, }{t}_{2} < e < {t}_{0}\\ 0,\text{ }其他\end{array} \right.$$ (19) $$ ZE(e)=\left\{\begin{array}{l}\dfrac{e-{t}_{2}}{{t}_{0}-{t}_{2}}\text{, }{t}_{2} < e< {t}_{0}\\ 1,\text{ }{t}_{0} < e< {\overline{e}}_{ZE}\\ \dfrac{{t}_{1}-e}{{t}_{1}-{\overline{e}}_{ZE}},\text{ }{\overline{e}}_{ZE} < e< {t}_{1}\\ 0,\text{ }其他\end{array}\right. $$ (20) $$ PB(e)=\left\{\begin{array}{l}1,\text{ }e\geqslant {t}_{1}\\ \dfrac{e-{\overline{e}}_{ZE}}{{t}_{1}-{\overline{e}}_{ZE}},\text{ }{\overline{e}}_{ZE}< e < {t}_{1}\\ 0,\text{ }其他\text{ }\end{array}\right. $$ (21) 式中:

$ h(a) = - a\ln a - (1 - a)\ln (1 - a) $ . 求解上述优化模型可得到$ {t_0} = - 0.007 $ ,$ {t_1} = 0.092 $ ,$ {t_2} = - 0.04 $ ;由此可给出误差$ e $ 为NB、ZE及PB的隶属函数曲线,如图10所示. 误差变化率$ ec $ 中各模糊语言值的隶属函数分布与误差$ e $ 一致.设焊接电流变化量

$ \Delta I $ 的隶属函数为三角形模糊分布,如图11所示,其中$ {s_1} $ 和$ {s_2} $ 为待定参数. 从 “若$ e $ 为$ ZE $ 则$ \Delta I $ 为$ ZE $ ” 及 “若$ e $ 为$ PB $ 则$ \Delta I $ 为$ PB $ ”, 可推知$ \Delta I $ 与$ e $ 之间呈现一定的比例关系,满足$$ \Delta I = {\varphi _I} \cdot e = \left( {{{{s_1}} \mathord{\left/ {\vphantom {{{s_1}} {{t_1}}}} \right. } {{t_1}}}} \right) \cdot e $$ (22) 式中:

$ {\varphi _I} = {{{s_1}} \mathord{\left/ {\vphantom {{{s_1}} {{t_1}}}} \right. } {{t_1}}} $ 焊接电流在$ e = {t_1} $ 处的调节系数. 由表3,可得到对$ j = 1,2, \cdots ,n, $ 有$$ \varphi _I^{(j)} = \left| {{{(I_{PB}^{(j)} - I_{ZE}^{(j)})} \mathord{\left/ {\vphantom {{(I_{PB}^{(j)} - I_{ZE}^{(j)})} {(e_{PB}^{(j)} - e_{ZE}^{(j)})}}} \right. } {(e_{PB}^{(j)} - e_{ZE}^{(j)})}}} \right| $$ (23) 式中:

$ e_{PB}^{(j)} $ 、$ e_{ZE}^{(j)} $ 分别是$ PB $ 类和$ ZE $ 类误差,$ I_{PB}^{(j)} $ 、$ I_{ZE}^{(j)} $ 分别是对应于$ e_{PB}^{(j)} $ 和$ e_{ZE}^{(j)} $ 的焊接电流.令

$ {\varphi _I} = \max _{j = 1}^n\varphi _I^{(j)} $ . 由式(22)和(23),有$$ {s_1} = \mathop {\max }\limits_{j = 1}^n \left| {{{(I_{PB}^{(j)} - I_{ZE}^{(j)})} \mathord{\left/ {\vphantom {{(I_{PB}^{(j)} - I_{ZE}^{(j)})} {(e_{PB}^{(j)} - e_{ZE}^{(j)})}}} \right. } {(e_{PB}^{(j)} - e_{ZE}^{(j)})}}} \right| \cdot {t_1} \approx 28 $$ (24) 类似可得

$$ {s_2} = \mathop {\max }\limits_{j = 1}^n \left| {{{(I_{NB}^{(j)} - I_{ZE}^{(j)})} \mathord{\left/ {\vphantom {{(I_{NB}^{(j)} - I_{ZE}^{(j)})} {(e_{NB}^{(j)} - e_{ZE}^{(j)})}}} \right. } {(e_{NB}^{(j)} - e_{ZE}^{(j)})}}} \right| \cdot {t_2} \approx - 22 $$ (25) 通过试验进行修正,取

$ {s_1} = 25 $ ,$ {s_2} = - 25 $ .根据表5中的控制规则,采用Mamdani推理算法来确定对应于输入

$ {e^ * } $ 和$ e{c^ * } $ 的输出$ \Delta {I^ * } $ [32],其推理过程如图12所示,其中$ {e^ * } = 0.07 $ ,$ e{c^ * } = 0.02 $ .3.4 模型验证

通过变间隙MAG焊接试验对熔透状态的粗糙-模糊控制模型进行验证. 焊接试验条件: 母材Q235钢板对接,板厚6 mm,坡口60°Y形,钝边1.5 mm,焊接速度47 cm/min,CCD采样时间间隔400 ms. 按坡口间隙g变化方式不同将母材加工成G1和G2两组试件,如图13所示,试板间隙分别为1.2-0.6-1.2 mm和1.2-1.8-1.2 mm阶跃变化,分别用恒规范方式和粗糙-模糊闭环控制方式进行试验,焊接完毕后测量试板背面熔宽,以考察焊接熔透效果.

图14 ~ 图19为G1板试验结果,图14、16和18给出了G1组件在恒电流焊接时熔池尾部轮廓、尾宽系数

$ {C_{{\rm{TW}}}} $ 和焊缝背面宽度的变化,可以看到在不同间隙处熔池尾部形状呈现尖削-丰满-尖削变化的趋势,$ {C_{{\rm{TW}}}} $ 值先增加后减少,焊缝在间隙为$ 0.6{\text{ mm}} $ 处均未焊透. 在图15、17和19中,由于闭环控制对焊接电流进行了实时调节,熔池尾部轮廓的尖削程度变化较小,$ {C_{{\rm{TW}}}} $ 值除在间隙突变处有小幅波动外,其变化趋于平稳,在间隙0.6 mm处的焊缝基本全部焊透.G2组件试验结果如图20 ~ 图25所示. 恒电流下G2组件熔池尾部形态、尾宽系数和背面熔宽如图20、22和24所示,熔池尾部尖削程度随间隙变化先增后减,而

$ {C_{TW}} $ 值先减后增,在间隙为1.8 mm处出现过熔透,焊缝背宽显著增加. 图21、23和25是该组件焊接过程中施加粗糙-模糊闭环控制的效果,熔池尾部尖削程度无明显变化,尾宽系数$ {C_{TW}} $ 的测量值与期望值偏差较小,整条焊缝背面熔宽基本保持均匀一致,均值$ \overline {{W_B}} = 3.468 $ mm,平均误差$ {e_m} = 0.176 $ mm,最大误差$ {e_{\max }} = 0.388 $ mm.4. 结论

(1)通过建立熔池正面特征与熔透状态之间的对应关系是实现焊接熔透控制可取的途径之一. 针对变间隙条件下的焊接熔透控制问题,将粗糙集理论与模糊控制相结合,提出一种焊接熔透的粗糙-模糊控制方法. 通过焊接试验采集样本数据,基于粗糙集的知识表达方式,构建熔透状态决策信息系统,运用粗糙集的知识获取方法,从样本数据集中提取一组反映熔池正面特征与熔透状态之间对应关系的分类规则,在此基础上建立熔池特征参数的模糊控制模型. 焊接过程中通过实时检测熔池形状参数及其变化趋势,通过调整焊接电参数即可达到控制熔透的目标,焊接控制实验证实了该方法的有效性.

(2)利用粗糙集知识约简来获取正面熔池的最小特征集是该方法的核心环节. 粗糙集约简算法较多,不同算法会产生不同的约简结果,其中采用近似分类质量或属性重要性作为启发式信息的属性添加法,可保持约简过程的稳定性,且更易获得约简的近似最优解或次优解. 此外,通过焊接试验建立熔透状态决策信息系统也是一个关键环节,由于熔透状态与焊接工艺参数密切相关,因而需根据具体的工艺条件和焊接规范对熔池图像进行分析,以确定与熔透状态潜在相关的熔池特征参数. 例如,在变间隙-电流焊接实验中,引入尾面积系数和尾宽系数作为熔池特征参数,以描述熔池尾部形状随坡口间隙和焊接电流变化的趋势.

-

-

[1] Bakavos D, Prangnell P B. Mechanisms of joint and microstructure formation in high power ultrasonic spot welding 6111 aluminium automotive sheet[J]. Materials Science and Engineering A, 2010, 527(23): 6320 − 6334. doi: 10.1016/j.msea.2010.06.038

[2] Zhang Changqing, Lü Guangming, Jin Xin, et al. Study of joining mechanism of ABS polymer and steel/aluminum by resistance spot welding[J]. China Welding, 2018, 27(2): 57 − 61.

[3] Li Huan, Cao Biao, Liu Jian, et al. Modeling of high-power ultrasonic welding of Cu/Al joint[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(1−4): 833 − 844. doi: 10.1007/s00170-018-2002-1

[4] Ni Z L, Yang J J, Gao Z T, et al. Joint formation in ultrasonic spot welding of aluminum to copper and the effect of particle interlayer[J]. Journal of Manufacturing Processes, 2020, 50(2): 57 − 67.

[5] Zhang Z, Wang K, Li J, et al. Investigation of interfacial layer for ultrasonic spot welded aluminum to copper joints[J]. Scientific Reports, 2017, 7(1): 12505. doi: 10.1038/s41598-017-12164-2

[6] Wang G Q, Zhao Y H, Zhang L N, et al. A new weld repair technique for friction stir welded aluminium structure: inertia friction pull plug welding[J]. China Welding, 2017, 26(4): 56 − 64.

[7] Shakil M, Tariq N H, Ahmad M, et al. Effect of ultrasonic welding parameters on microstructure and mechanical properties of dissimilar joints[J]. Materials & Design, 2014, 55(3): 263 − 273.

[8] Nong L, Shao C, Kim T H, et al. Improving process robustness in ultrasonic metal welding of lithium-ion batteries[J]. Journal of Manufacturing Systems, 2018, 48(7): 45 − 54.

[9] 李东, 赵杨洋, 张延松. 焊接能量对铝/铜超声波焊接接头显微组织的影响[J]. 焊接学报, 2014, 35(2): 47 − 50. Li Dong, Zhao Yangyang, Zhang Yansong. Effect of welding energy on microstructures of the Al/Cu joints obtained by ultrasonic welding[J]. Transactions of the China Welding Institution, 2014, 35(2): 47 − 50.

[10] 解龑, 冯梦楠, 罗震. 齿形对超声波焊接泡沫镍薄板与实体铝薄板的影响[J]. 焊接学报, 2018, 39(12): 5 − 8. doi: 10.12073/j.hjxb.2018390288 Xie Yan, Feng Mengnan, Luo Zhen. Effect of teeth shape on ultrasonic spot welding joints of nickel foam sheet and aluminum solid sheet[J]. Transactions of the China Welding Institution, 2018, 39(12): 5 − 8. doi: 10.12073/j.hjxb.2018390288

[11] Feng M N, Xie Y, Zhao C F, et al. Microstructure and mechanical performance of ultrasonic spot welded open-cell Cu foam/Al joint[J]. Journal of Manufacturing Processes, 2018, 33(6): 86 − 95.

[12] Li Huan, Cao Biao, Yang Jingwei, et al. Modeling of resistance heat assisted ultrasonic welding of Cu-Al joint[J]. Journal of Materials Processing Technology, 2018, 256(6): 121 − 130.

[13] Satpathy M P, Sahoo S K. Mechanical performance and metallurgical characterization of ultrasonically welded dissimilar joints[J]. Journal of Manufacturing Processes, 2017, 25(1): 443 − 451.

[14] Bergmann J P, Regensburg A, Schürer R, et al. Effect of the interface characteristics on the joint properties and diffusion mechanisms during ultrasonic metal welding of Al/Cu[J]. Welding in the World, 2017, 61(3): 499 − 506. doi: 10.1007/s40194-017-0449-6

[15] Satpathy M P, Mohapatra K D, Sahoo S K. Ultrasonic spot welding of Al-Cu dissimilar metals: a study on parametric influence and thermo-mechanical simulation[J]. International Journal of Modelling and Simulation, 2018, 38(2): 83 − 95. doi: 10.1080/02286203.2017.1395198

[16] Yang J, Cao B, Lu Q. The effect of welding energy on the microstructural and mechanical properties of ultrasonic-welded copper joints[J]. Materials, 2017, 10(2): 1 − 13.

-

期刊类型引用(1)

1. 孟飞,徐安兵. 机器人自动双丝焊在某地铁车辆转向架侧梁焊缝的应用与优化. 现代城市轨道交通. 2024(07): 59-64 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: