Laser scanning welding of 2060 Al-Li alloy with filler wire

-

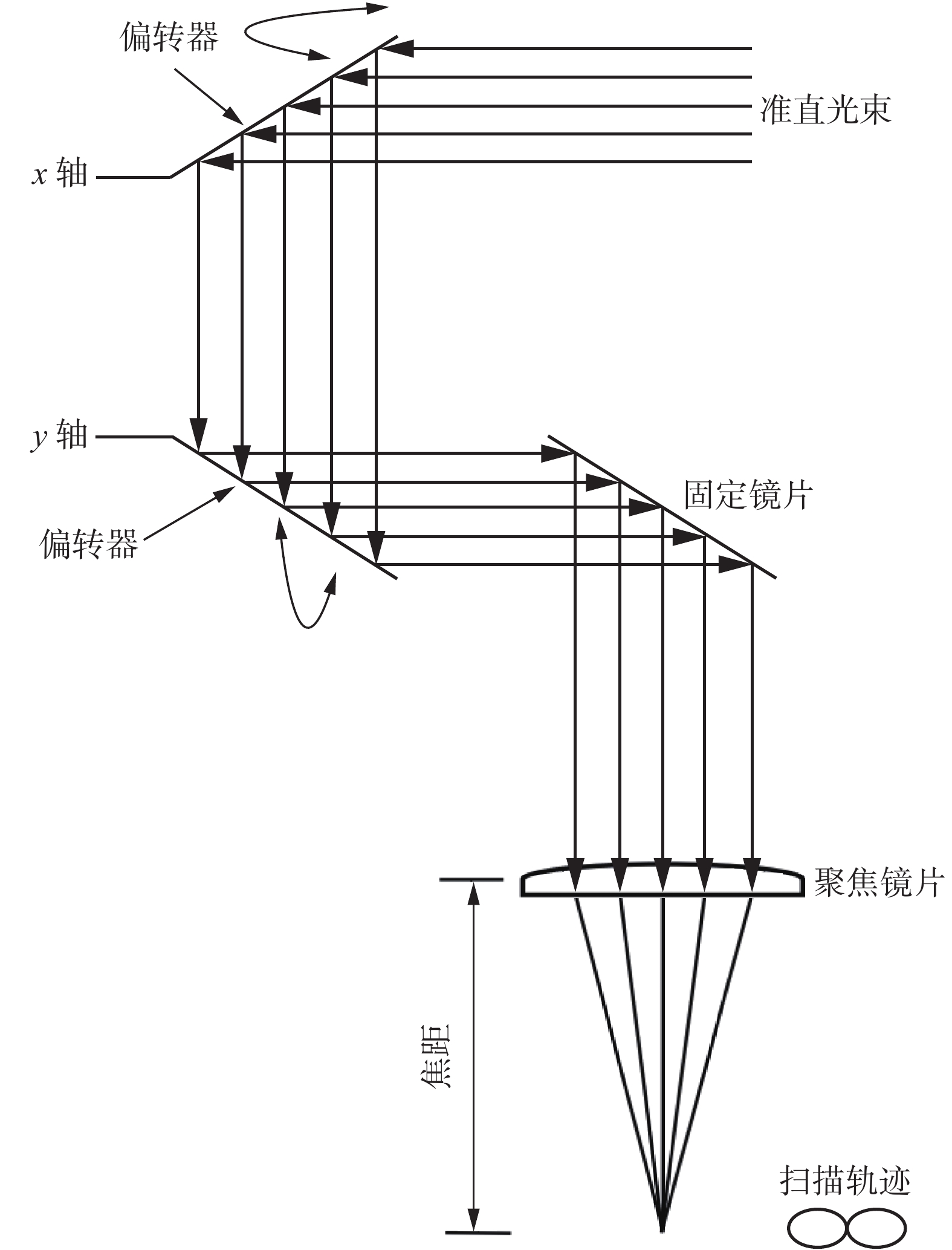

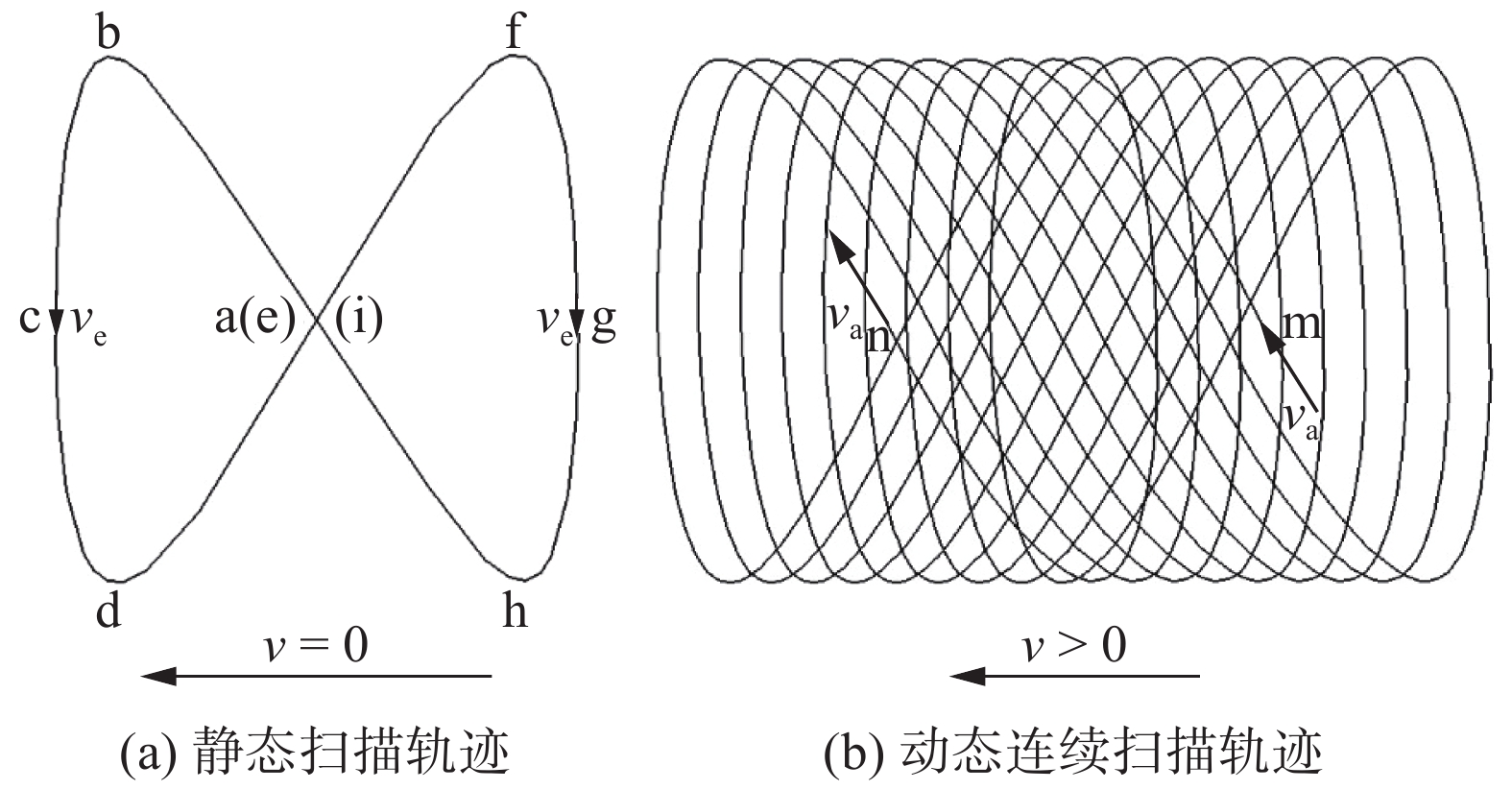

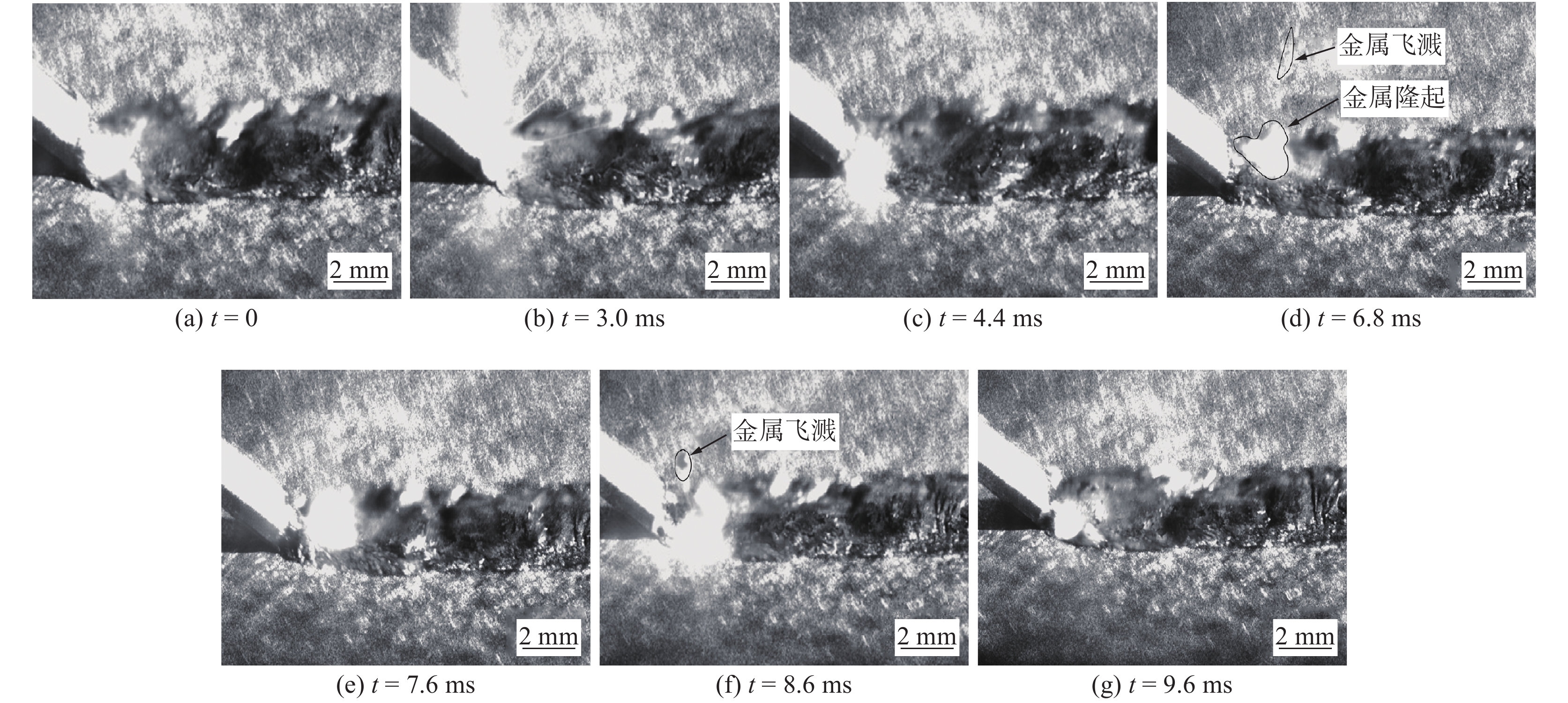

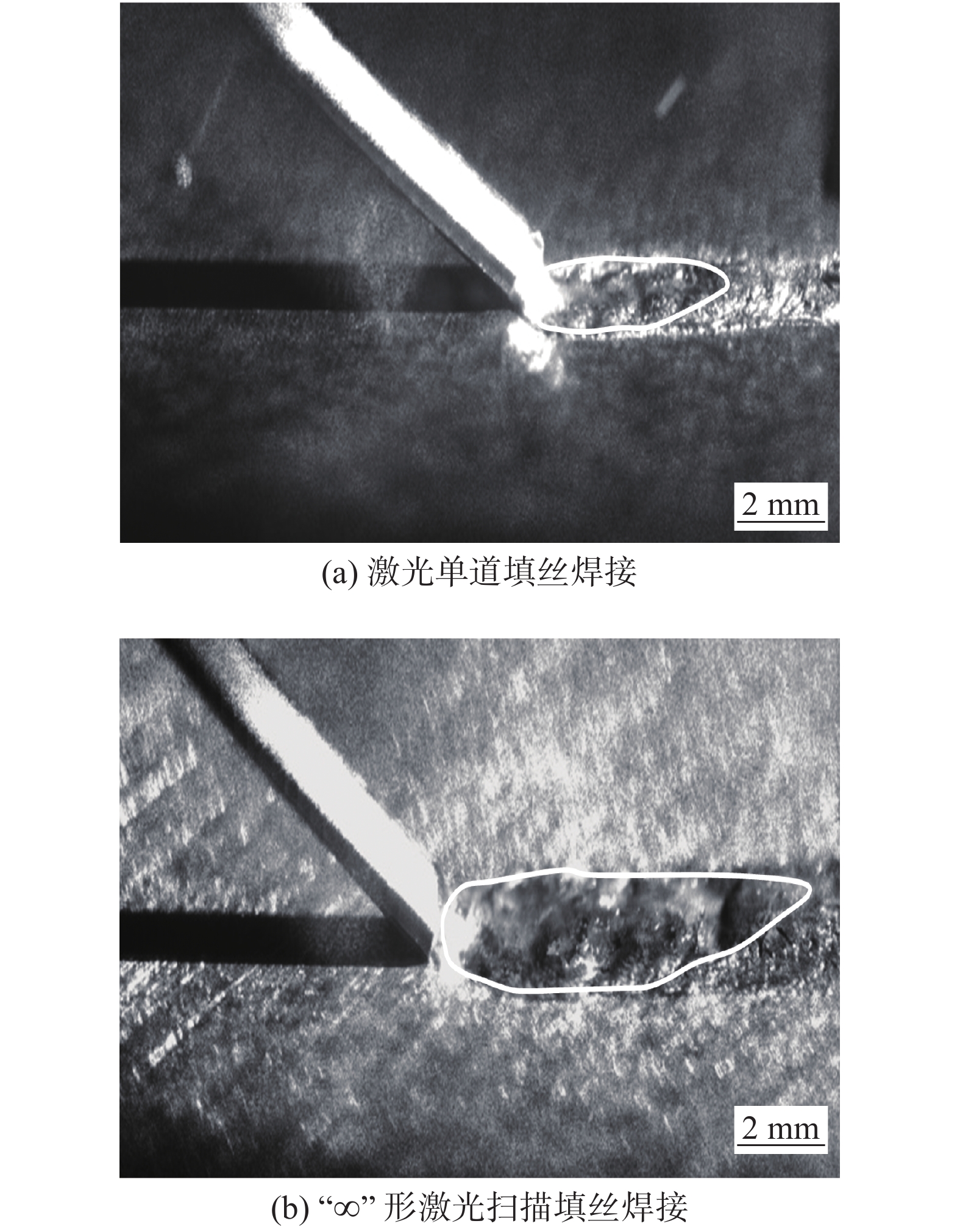

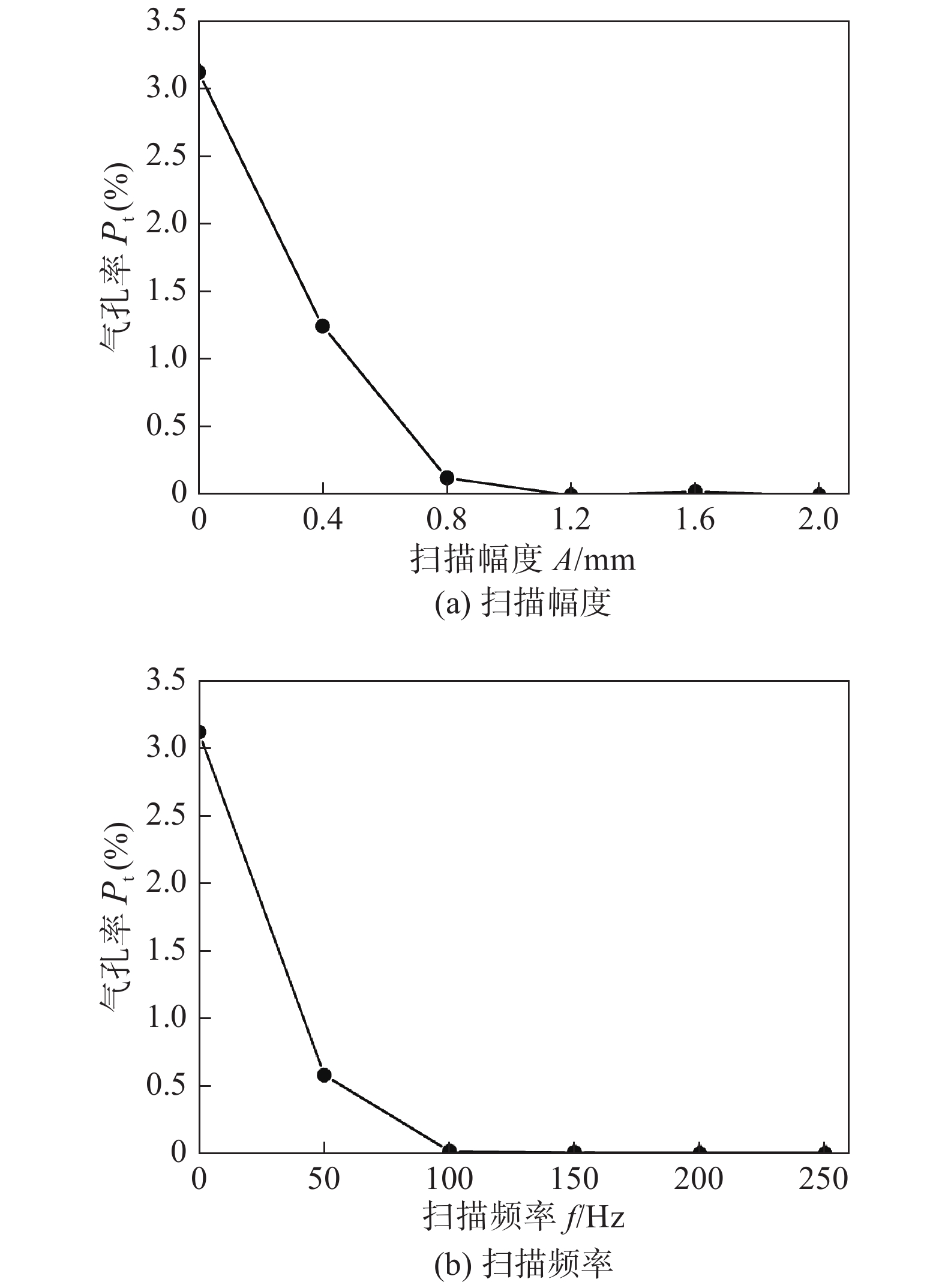

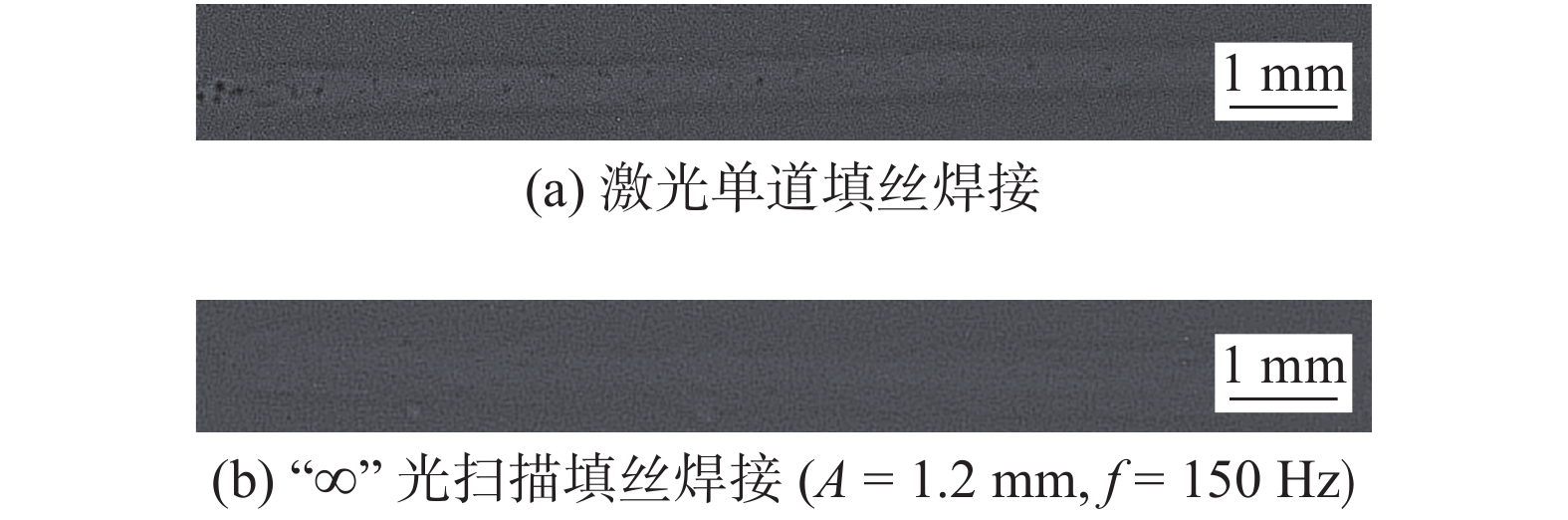

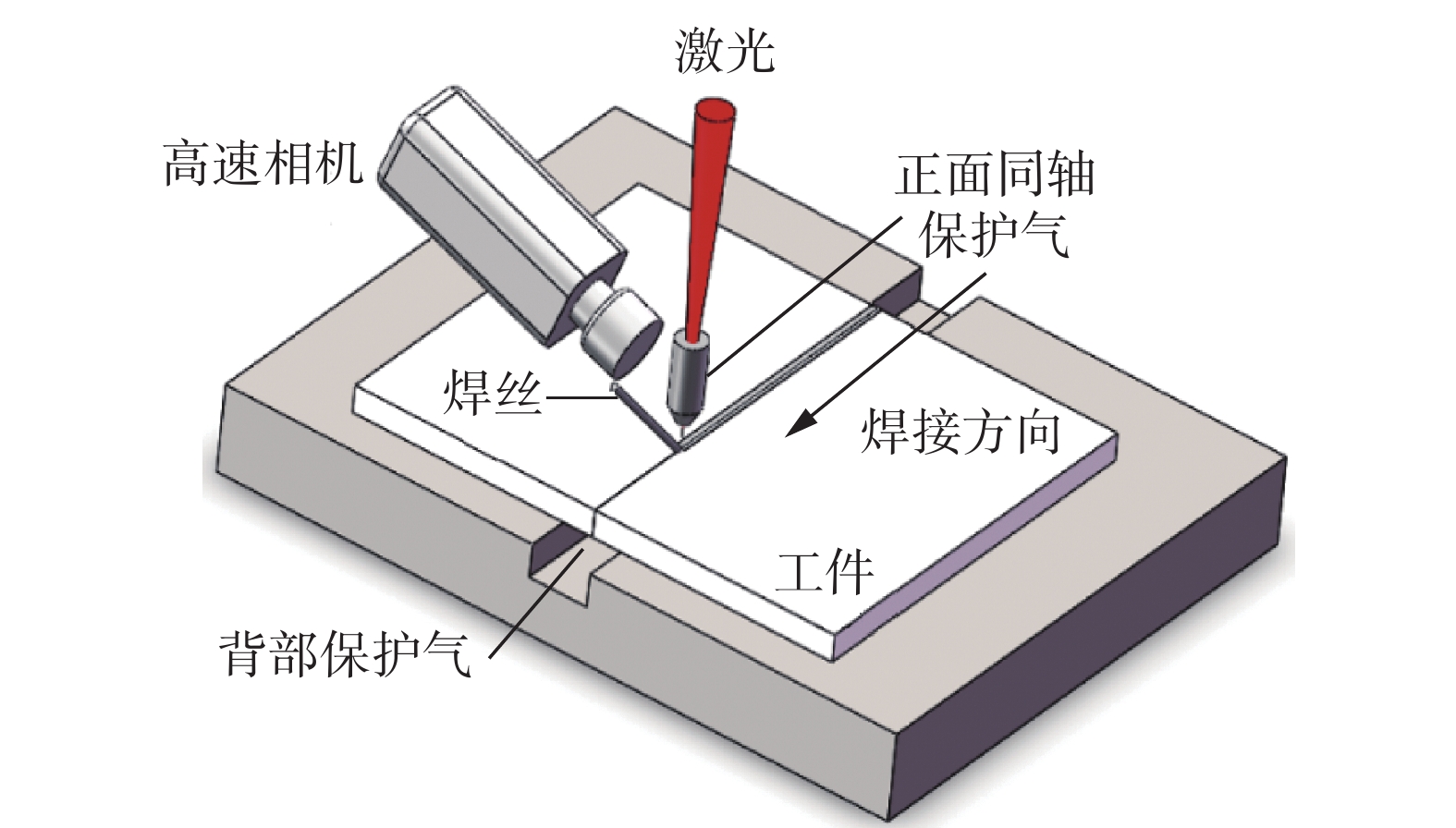

摘要: 针对铝锂合金焊后易产生气孔、抗拉强度低的缺点,提出“∞”形激光扫描填丝焊接工艺方法,以2 mm厚2060铝锂合金为研究对象开展对接焊接试验研究,探究激光扫描填丝焊接方法对铝锂合金焊接缺陷抑制作用. 借助高速相机摄像系统,探究了激光扫描填丝焊接工艺下熔池的动态演变过程,同时探究了扫描参数对焊缝气孔的影响规律及扫描填丝工艺对气孔的抑制机理. 采用曲面响应统计方法探究工艺参数对抗拉强度的影响,并给出工艺参数组合与抗拉强度的定量关系及最优参数组合,焊接接头最大抗拉强度可达382 MPa,为母材的76.4%. 结果表明,“∞”形激光扫描填丝焊接工艺下熔池流动平稳,小孔喷发强度较弱且呈现出周期性;“∞”形激光扫描填丝焊接工艺可以有效抑制焊缝气孔,提高铝锂合金焊接质量.Abstract: In order to solve the problems of porosity and insufficient tensile strength of aluminum lithium alloy weld, a method of laser scanning welding with filler wire was proposed. Taking 2060 Al-Li alloy with 2 mm thickness as research objects, the suppression effect of laser scanning welding with filler wire on welding defects of Al-Li alloy was investigated. A high-speed camera system was built to explore the mechanism and the change of the dynamic evolution of the molten pool. The influence of scanning parameters on the formation of porosity in weld seam and the mechanism of inhibiting porosity of laser scanning welding with filler wire technique were investigated. Response surface methodology was applied to explore the influence of process parameters on tensile strength. The quantitative relationship between process parameter combination, tensile strength and the optimal parameter combination were proposed. The maximum tensile strength of the weld is 382 MPa, which is 76.4% of the base metal. The research shows that the flow of the molten pool is stable, and meanwhile the eruption of the keyhole is weak and showing the periodicity, in the process of “∞” shaped laser scanning welding with filler wire. And the process of “∞” shaped laser scanning welding with filler wire can effectively inhibit weld porosity and improve the welding quality of Al-Li alloy.

-

-

表 1 2060铝锂合金和ER4047焊丝的化学成分(质量分数, %)

Table 1 Chemical compositions of 2060 aluminum lithium alloy and ER4047 wire

材料 Li Mg Zn Mn Ag Zr Si Fe Cu Al 2060 0.75 0.85 0.42 0.30 0.30 0.11 0.05 0.1 — 余量 ER4047 — 0.1 0.30 0.11 — — 12 0.08 0.30 余量 表 2 单因素试验工艺参数

Table 2 Single factor experiment process parameters

激光功率P/W 离焦量Δf/mm 焊接速度v/(m·min−1) 送丝速度vf/(m·min−1) 扫描幅度A/mm 扫描频率f/Hz 3 400 −1 3.2 3.2 0,0.4,0.8,1.2,1.6,2.0 0,50,100,150,200,250 表 3 曲面响应试验参数

Table 3 Response surface test parameters

因素 激光功率P/W 焊接/送丝速度v/(m·min−1) 扫描幅度A/mm 扫描频率

f/HzA B C D 低水平 3 100 3 0.8 50 高水平 3 900 5 1.6 150 表 4 曲面响应变量分析

Table 4 Variable analysis of response surface

方差来源 平方和S 2 自由度df 均方E 回归值F P值 显著性 模型 79 969.66 14 5 712.12 6.53 0.000 6 显著 激光功率A 3 961.42 1 3 961.42 4.53 0.051 6 焊接速度/送丝速度B 1 571.17 1 1 571.17 1.80 0.201 6 扫描幅度C 1 149.93 1 1 149.93 1.31 0.270 9 扫描频率D 37 382.65 1 37 382.65 42.72 < 0.000 1 显著 AB 9.18 1 9.18 0.010 0.919 9 AC 2 039.43 1 2 039.43 2.33 0.149 1 AD 479.39 1 479.39 0.55 0.471 4 BC 90.44 1 90.44 0.10 0.752 6 BD 4 142.85 1 4 142.85 4.73 0.047 2 显著 CD 7 185.11 1 7 185.11 8.21 0.012 5 显著 A2 9 531.95 1 9 531.95 10.89 0.005 3 显著 B2 4 875.72 1 4 875.72 5.57 0.033 3 显著 C2 1 660.37 1 1 660.37 1.90 0.190 0 D2 14 900.79 1 14 900.79 17.03 0.001 0 显著 -

[1] 陈国庆, 尹乾兴, 司晓庆, 等. 铝锂合金焊接技术的研究现状分析[J]. 焊接学报, 2019, 40(8): 155 − 160. Chen Guoqing, Yin Qianxing, Si Xiaoqing, et al. Research status analysis of aluminum-lithium alloy welding[J]. Transactions of the China Welding Institution, 2019, 40(8): 155 − 160.

[2] 周利, 李高辉, 刘朝磊, 等. 铝锂合金焊接技术的研究现状[J]. 焊接, 2017(1): 7 − 12, 68. doi: 10.3969/j.issn.1001-1382.2017.01.003 Zhou Li, Li Gaohui, Liu Zhaolei, et al. Research progress in welding technology of Al-Li alloy[J]. Welding & Joining, 2017(1): 7 − 12, 68. doi: 10.3969/j.issn.1001-1382.2017.01.003

[3] Dittrich D. Laser beam welding of hard to weld Al alloys for a reginal aircraft fuselage design-first results[J]. Physics Procedia, 2011, 12(1): 113 − 122.

[4] 林凯莉, 杨武雄, 吕俊霞, 等. 2198-T851铝锂合金激光焊接工艺研究[J]. 中国激光, 2014, 41(1): 90 − 95. Lin Kaili, Yang Wuxiong, Lu Junxia, et al. Laser beam welding study of 2198-T851 aluminum-lithium alloy[J]. Chinese Journal of Lasers, 2014, 41(1): 90 − 95.

[5] Lukin V I, Skupov A A, Ioda E N. Investigation of the weldability of an aluminium–lithium alloy[J]. Welding International, 2018, 32(3): 214 − 218. doi: 10.1080/09507116.2017.1388047

[6] 安娜, 张心怡, 杨武雄, 等. 2060铝锂合金电流辅助激光填丝焊接工艺分析[J]. 焊接学报, 2017, 38(3): 83 − 86. An Na, Zhang Xinyi, Yang Wuxiong, et al. Electrical current assisted laser welding of 2060 aluminum lithium alloy with filler wire[J]. Transactions of the China Welding Institution, 2017, 38(3): 83 − 86.

[7] 刘震磊, 崔祜涛, 姬书得, 等. 工艺参数影响2060铝锂合金搅拌摩擦焊接头的成形规律[J]. 焊接学报, 2016, 37(7): 79 − 82. Liu Zhenlei, Cui Hutao, Ji Shude, et al. Effect of process parameters on the forming law of friction stir welded joint of 2060 Al-Li alloy[J]. Transactions of The China Welding Institution, 2016, 37(7): 79 − 82.

[8] Salari E, Jahazi M, Khodabandeh A, et al. Friction stir lap welding of 5456 aluminum alloy with different sheet thickness: process optimization and microstructure evolution[J]. International Journal of Advanced Manufacturing Technology, 2016, 82(1-4): 39 − 48. doi: 10.1007/s00170-015-7342-5

[9] Katayama S, Nagayama H, Mizutani M, et al. Fiber laser welding of aluminium alloy[J]. Welding International, 2009, 23(10): 744 − 752. doi: 10.1080/09507110902836911

[10] Kacar I, Ozturk F, Yilbas B S. A review of and current state-of-the-art in laser beam welding in the automotive industry[J]. Laser in Engineering, 2016, 33(4−6): 327 − 338.

[11] Katayama S, Kawahito Y. Elucidation of phenomena in high power fiber laser welding, and development of prevention procedures of welding defects[J]. Proceedings of Spie the International Society for Optical Engineering, 2009, 7195: 7195R1 − 9.

[12] Huang L, Hua X, Wu D, et al. Numerical study of keyhole instability and porosity formation mechanism in laser welding of aluminum alloy and steel[J]. Materials Processing Technology, 2018, 252: 421 − 431. doi: 10.1016/j.jmatprotec.2017.10.011

[13] Lin R, Wang H P, Lu F, et al. Numerical study of keyhole dynamics and keyhole-induced porosity formation in remote laser welding of Al alloys[J]. Heat and Mass Transfer, 2017, 108: 244 − 256. doi: 10.1016/j.ijheatmasstransfer.2016.12.019

[14] Zhang L J, Zhang J X, Gumenyuk A, et al. Numerical simulation of full penetration laser welding of thick steel plate with high power high brightness laser[J]. Materials Processing Technology, 2014, 214(8): 1710 − 1720. doi: 10.1016/j.jmatprotec.2014.03.016

[15] Matsunawa A, Mizutani M, Katayama S. Porosity formation mechanism and its prevention in laser welding[J]. Welding International, 2003, 17(6): 431 − 437. doi: 10.1533/wint.2003.3138

下载:

下载: