Microstructure and property analysis of FeAlCuCrNiNbx high-entropy alloy surfacing layer

-

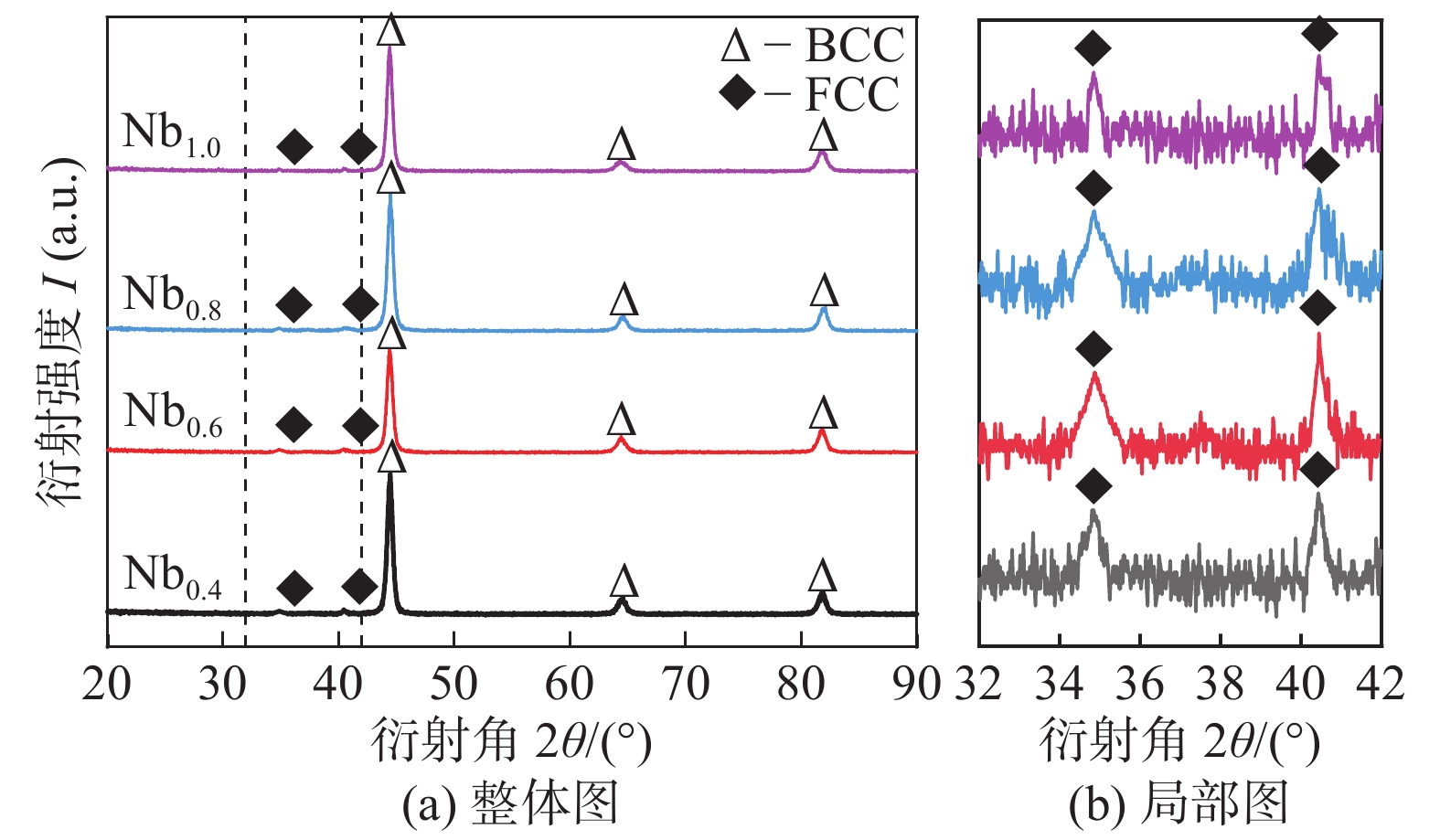

摘要: 为了研究Nb元素含量对FeAlCuCrNiNbx(x = 0.4,0.6,0.8,1.0,x为摩尔比)高熵合金的组织结构及性能的影响,采用熔化极气体保护焊技术在碳钢板表面制备出FeAlCuCrNiNbx高熵合金堆焊层,而后对堆焊层进行显微组织、物相组成、显微硬度、耐磨性和耐蚀性分析. 结果表明,FeCuCrAlNiNbx高熵合金堆焊层呈现以Fe-Cr相为基的BCC固溶体和少量MC共晶碳化物. 组织为典型的枝晶结构,由灰色的枝晶(DR)及白色的枝晶间(ID)结构组成. 对于耐磨性,加入适量的Nb元素可以显著提高堆焊层的显微硬度和耐磨性,当Nb摩尔比为0.8时,显微硬度最高,耐磨性最好,最大硬度值达到602 HV,磨损量最小为0.30 g. 对于耐蚀性,加入一定量的Nb元素后极化曲线中自腐蚀电流密度减小,腐蚀速率减慢,耐蚀性增强,均优于304不锈钢,当Nb摩尔比为1.0时,堆焊层合金耐蚀性最好.Abstract: In order to study the effect of Nb element content on the structure and properties of FeAlCuCrNiNbx (x = 0.4,0.6,0.8,1.0) high-entropy alloy, the FeAlCuCrNiNbx high-entropy alloy was prepared on the surface of carbon steel sheet by the technique of gas metal arc welding. The microstructure, phase composition, microhardness, wear resistance and corrosion resistance of surfacing layer were analyzed. The results show that: the surfacing layer of FeCuCrAlNiNbx high-entropy alloy is composed of Fe-Cr phase-based BCC solid solution and a few of MC eutectic carbide. The structure is a typical dendrite structure, which is composed of gray dendrite (DR) and white interdendrite (ID) structure. For wear resistance, addition amounts of Nb can significantly improve the microhardness and wear resistance of surfacing layer. The optimal properties of surface layer were obtained when the molar ratio of Nb element is 0.8, which maximum microhardness value is 602 HV, the minimum wear is 0.30 g, respectively. For the corrosion performance, with increase of Nb element addtion amounts, the self-corrosion current density become to reduce, the corrosion rate become to slow, and the corrosion resistance enhances. All of these are better than 304 stainless steel. When the molar ratio of Nb element is 1.0, the corrosion resistance of the surfacing alloy is the best.

-

Keywords:

- high-entropy alloy /

- microstructure /

- microhardness /

- wear resistance /

- electrochemical corrosion

-

-

表 1 H08A钢带的化学成分(质量分数,%)

Table 1 Chemical compositions of H08A steel strip

C Si Mn S P Fe < 0.01 ≤ 0.03 0.30 ~ 0.55 ≤ 0.03 ≤ 0.03 余量 表 2 各成分的理论参数值

Table 2 Theoretical parameter values of each component

成分 混合熵

ΔS/(J·mol−1·K−1)原子尺寸差 δ(%) 混合焓 ΔH/(kJ·mol−1) 价电子浓度 VEC Nb0.4 14.58 5.98 −7.16 7.41 Nb0.6 14.77 6.14 −8.39 7.32 Nb0.8 14.87 6.26 −9.44 7.24 Nb1.0 14.90 6.35 −10.33 7.16 表 3 FeAlCuCrNiNbx高熵合金堆焊层不同区域的元素含量(原子分数,%)

Table 3 Element content of different regions in FeAlCuCrNiNbx high entropy alloy surfacing layer

合金 区域 Fe Al Cu Cr Ni Nb C 沉淀物 44.38 22.74 1.75 2.69 2.29 10.85 15.30 FeAlCuCrNiNb0.4 DR 74.05 1.99 6.69 8.56 7.13 1.58 — ID 69.84 1.58 13.02 5.92 6.49 3.15 — 沉淀物 16.91 15.37 2.17 2.76 3.60 42.66 16.53 FeAlCuCrNiNb0.6 DR 73.47 2.12 5.91 8.15 7.41 2.94 — ID 66.92 2.96 11.50 7.73 6.79 4.10 — 沉淀物 11.70 11.77 1.66 2.23 3.36 49.58 19.70 FeAlCuCrNiNb0.8 DR 71.93 1.71 6.84 8.90 7.52 3.10 — ID 66.62 2.48 11.91 7.93 6.47 4.59 — 沉淀物 16.69 18.25 2.18 2.84 2.98 38.39 18.67 FeAlCuCrNiNb1.0 DR 73.99 1.96 6.18 8.22 7.37 2.28 — ID 69.36 1.90 12.38 6.55 6.09 3.72 — 表 4 FeAlCuCrNiNbx高熵合金自腐蚀电位和电流密度

Table 4 Self-corrosion potential and current density of the FeAlCuCrNiNbx high entropy alloy

合金 腐蚀电位E/V 自腐蚀电流密度I/ (mA·cm−2) 304不锈钢 −0.900 8 1.648 6 × 10−4 FeAlCuCrNiNb0.4 −0.583 7 8.980 7 × 10−5 FeAlCuCrNiNb0.6 −0.707 73 6.308 4 × 10−5 FeAlCuCrNiNb0.8 −0.663 73 4.192 9 × 10−5 FeAlCuCrNiNb1.0 −0.728 32 7.770 7 × 10−6 -

[1] Guo H, Jurgen E, Wolfgang L, et al. Novel Ti-base nanostructure- dendrite composite with enhanced plasticity[J]. Nature Materials, 2002, 2(1): 33 − 37.

[2] Zhu Z X, Xu B S, Ma S N, et al. Study on microstructure and properties of high velocity arc sprayed Fe3Al intermetallic coating[J]. China Welding, 2002, 11(1): 1 − 4.

[3] Huang K H, Yeh J W. A study on multicomponent alloy systems containing equal-mole elements[D]. Hsinchu: National Tsing Hua University, 1996.

[4] 王小荣, 王朝琴, 何鹏. 45钢表面高能微弧火花数控化沉积AlCoCrFeNi高熵合金[J]. 焊接学报, 2016, 37(10): 73 − 76. Wang Xiaorong, Wang Zhaoqin, He Peng. Numerical control deposition of AlCoCrFeNi high-entropy alloy on 45 steel by high energy micro arc spark[J]. Transactions of the China Welding Institution, 2016, 37(10): 73 − 76.

[5] Tung C C, Yeh J W, Shun T T, et al. On the elemental effect of AlCoCrCuFeNi high-entropy alloy system[J]. Materials Letters, 2007, 61(1): 1 − 5. doi: 10.1016/j.matlet.2006.03.140

[6] 尚晓娟. 激光熔覆MoFeCrTiWAlNbx高熔点高熵合金涂层[D]. 贵阳: 贵州大学, 2018. Shang Xiaojuan. Laser cladding MoFeCrTiWAlNbx High-melting point high-entropy alloy coatings[D]. Guiyang: Guizhou University, 2018.

[7] Zhang H, Ye P, He Y Z, et al. Microstructure and properties of 6FeNiCoSiCrAlTi high-entropy alloy coating prepared by laser cladding[J]. Applied Surface Science, 2011, 257(6): 2259 − 2263. doi: 10.1016/j.apsusc.2010.09.084

[8] Zou Y, Maiti S, Steurer W, et al. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy[J]. Acta Materialia, 2014, 65(6): 85 − 97.

[9] Wang S L, Cui L, Liu H, et al. Effect of molybdenum on the microstructure and wear resistance of hypoeutectic Fe-Cr-B-C hardfacing alloys[J]. China Welding, 2018, 27(4): 46 − 51.

[10] Zhang Y, Zhou Y J, Lin J P, et al. Solid-solution phase formation rules for multi-component slloys[J]. Advanced Engineering Materials, 2008, 10(6): 534 − 538. doi: 10.1002/adem.200700240

[11] Guo S, Ng C, Lu J, et al. Effect of valence electron concentration on stability of FCC or BCC phase in high entropy alloys[J]. Journal of Applied Physics, 2011, 109(10): 103505. doi: 10.1063/1.3587228

[12] 尚晓娟, 刘其斌, 郭亚雄, 等. Nb对激光熔覆MoFeCrTiWAlNb x高熔点高熵合金组织与性能的影响[J]. 功能材料, 2017, 48(12): 12214 − 12220. Shang Xiaojuan, Liu Qibin, Guo Yaxiong, et al. Effect of Nb on microstructure and properties of laser cladding MoFeCrTiWAlNbx high melting point high entropy alloy[J]. Journal of Functional Materials, 2017, 48(12): 12214 − 12220.

[13] Li X, Feng Y, Liu B, et al. Influence of NbC particles on microstructure and mechanical properties of AlCoCrFeNi high- entropy alloy coatings prepared by laser cladding[J]. Journal of Alloys and Compounds, 2019, 788: 454 − 461.

[14] 赵洪运, 刘甲坤, 骆宗安, 等. 焊接热输入对800 MPa超级钢焊接接头组织性能的影响[J]. 焊接学报, 2011, 32(8): 5 − 8. Zhao Hongyun, Liu Jiakun, Luo Zongan, et al. Effects of welding heat input on structure and properties of 800 MPa ultra fine grained steel welding joints[J]. Transactions of the China Welding Institution, 2011, 32(8): 5 − 8.

[15] Ren Fangcheng, Yao Jiaohua, Liu Rong, et al. Effect of Nb on microstructure and wear resistance of low-carbon stellite alloy laser cladding coating[J]. Heat Treatment of Metals, 2016, 41(10): 15 − 20.

[16] 赵红艳. 高熵固溶体合金的相组成和力学性能研究[D]. 大连: 大连理工大学, 2015. Zhao Hongyan. The study of phase component and mechanical performance in solid solutions high entropy alloys[D]. Dalian: Dalian University of Technology, 2015.

[17] Cheng J B, Liang X B, Xu B S. Effect of Nb addition on the structure and mechanical behaviors of CoCrCuFeNi high-entropy alloy coatings[J]. Surface and Coatings Technology, 2014, 240: 184 − 190. doi: 10.1016/j.surfcoat.2013.12.053

[18] Wu C L, Zhang S, Zhang C H, et al. Phase evolution and properties in laser surface alloying of FeCoCrAlCuNi x high-entropy alloy on copper substrate[J]. Surface and Coatings Technology, 2017, 315: 368 − 376. doi: 10.1016/j.surfcoat.2017.02.068

[19] 张俊旺, 王文先, 黄延平, 等. 奥氏体不锈钢焊缝金属的电化学腐蚀性能[J]. 焊接学报, 2007, 28(2): 103 − 107. doi: 10.3321/j.issn:0253-360X.2007.02.027 Zhang Junwang, Wang Wenxian, Huang Yanping, et al. Electrochemical corrosion properties for weld metal of austenitic stainless steel[J]. Transactions of the China Welding Institution, 2007, 28(2): 103 − 107. doi: 10.3321/j.issn:0253-360X.2007.02.027

[20] Guo Y, Shang X, Liu Q. Microstructure and properties of in-situ TiN reinforced laser cladding CoCr2FeNiTix high-entropy alloy composite coatings[J]. Surface and Coatings Technology, 2018, 344(25): 353 − 358.

[21] 贾强. CrFeCoNiTix高熵合金力学性能及耐腐蚀性能研究[D]. 哈尔滨: 哈尔滨理工大学, 2015. Jia Qiang. CrFeCoNiTix high entropy alloy mechanical properties and corrosion resistance research[D]. Haerbin: Harbin University of Science and Technology, 2015.

[22] Chen Y Y, Duval T, Hung U D, et al. Microstructure and electrochemical properties of high entropy alloys-a comparison with type-304 stainless steel[J]. Corrosion Science, 2005, 47(9): 2257 − 2279. doi: 10.1016/j.corsci.2004.11.008

-

期刊类型引用(1)

1. 王兴磊,杨赫然,孙兴伟,赵泓荀,潘飞. 基于WOA-RBF的螺杆转子双砂带磨削表面粗糙度及材料去除率预测. 制造技术与机床. 2025(04): 172-179 .  百度学术

百度学术

其他类型引用(8)

下载:

下载: