Microstructure investigation and residual stress numerical simulation on welded joint of 304/Q345R composite plate

-

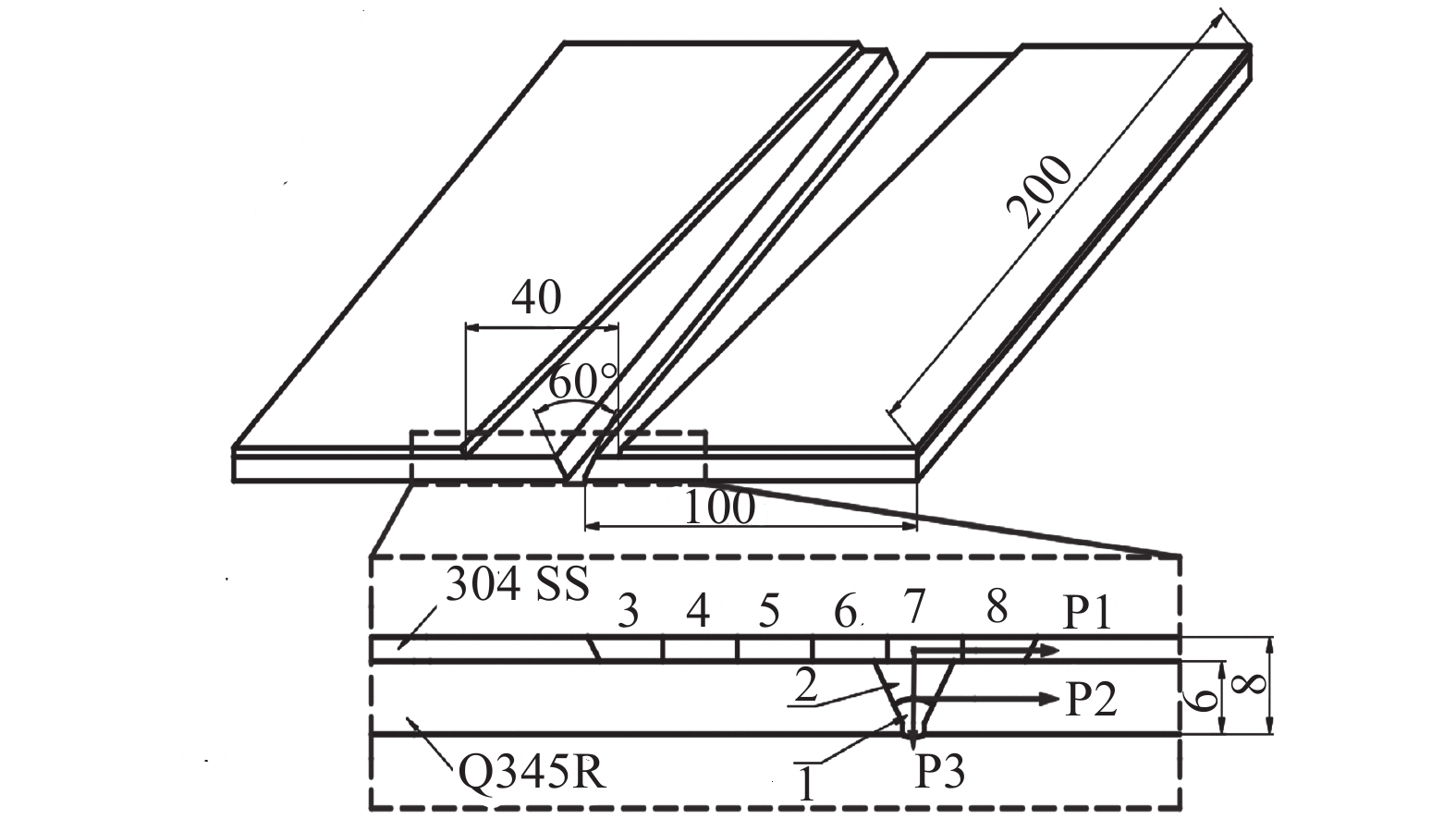

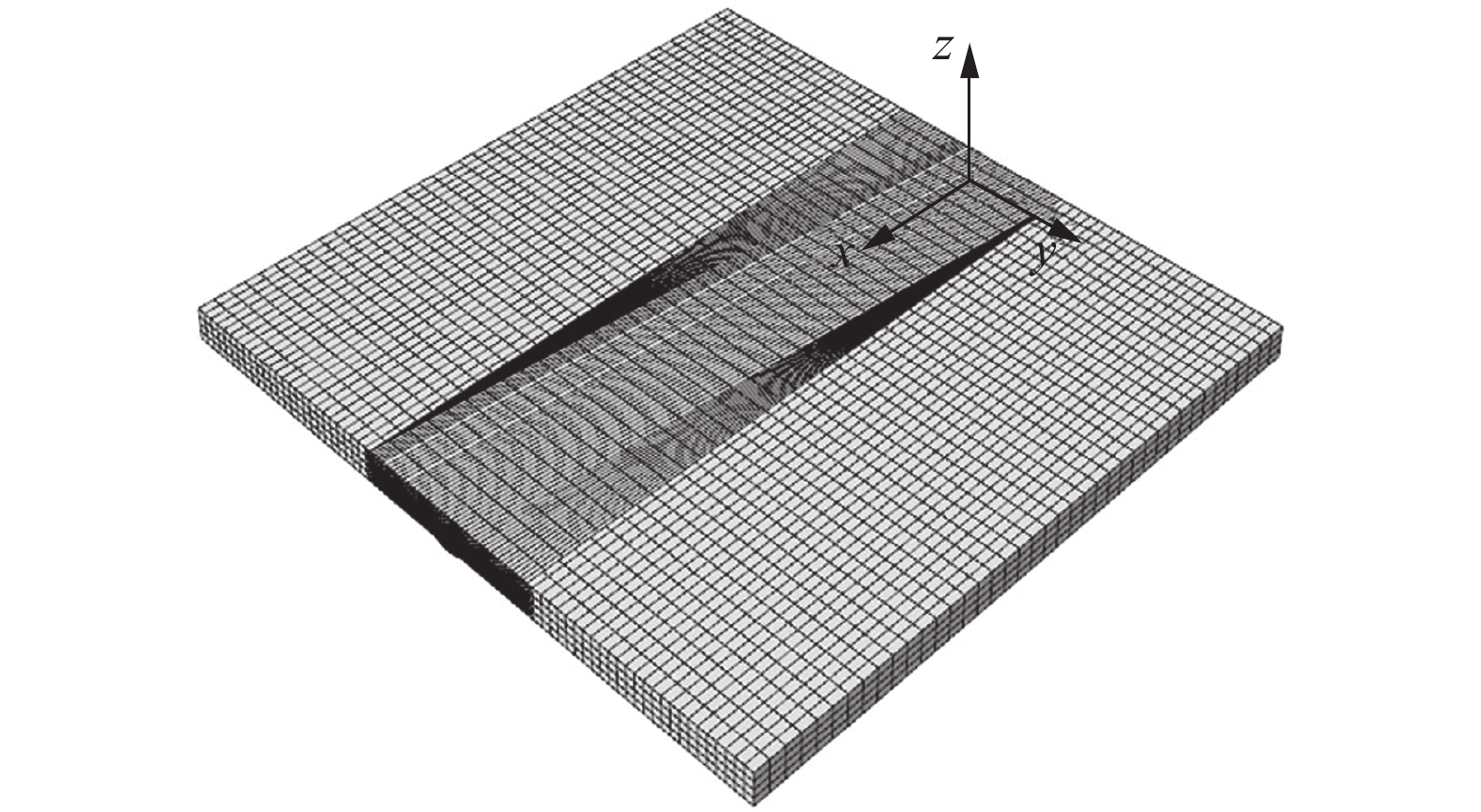

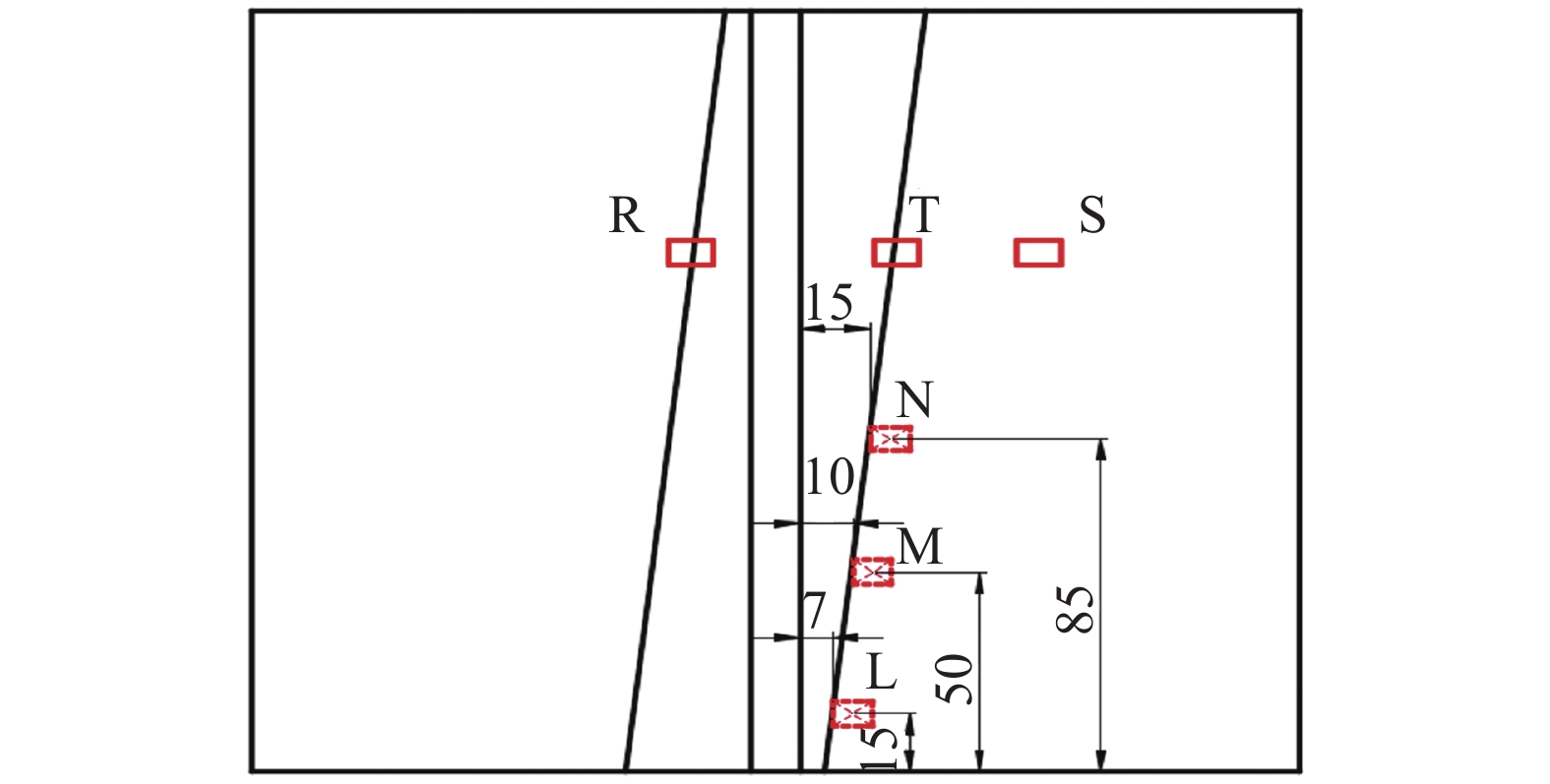

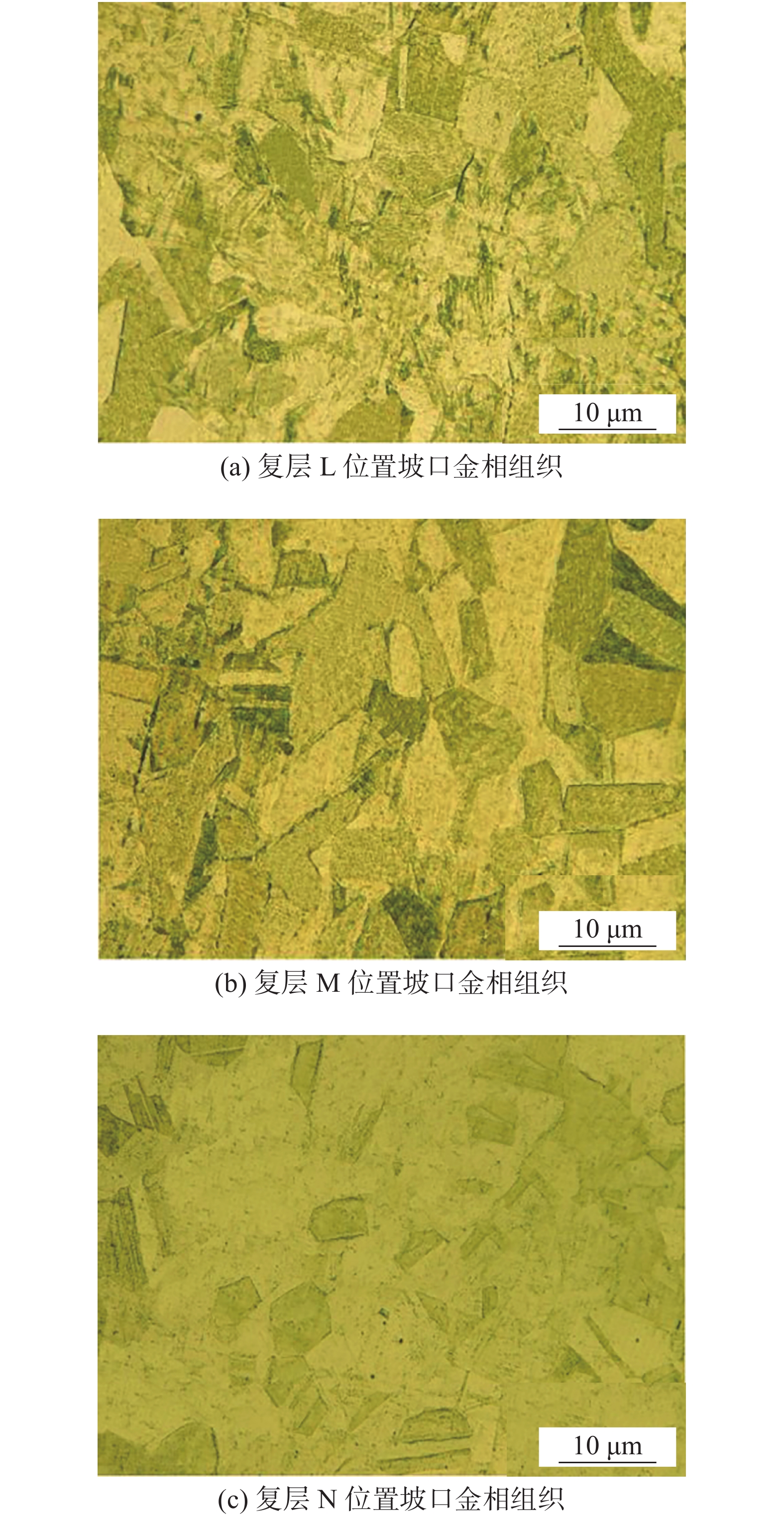

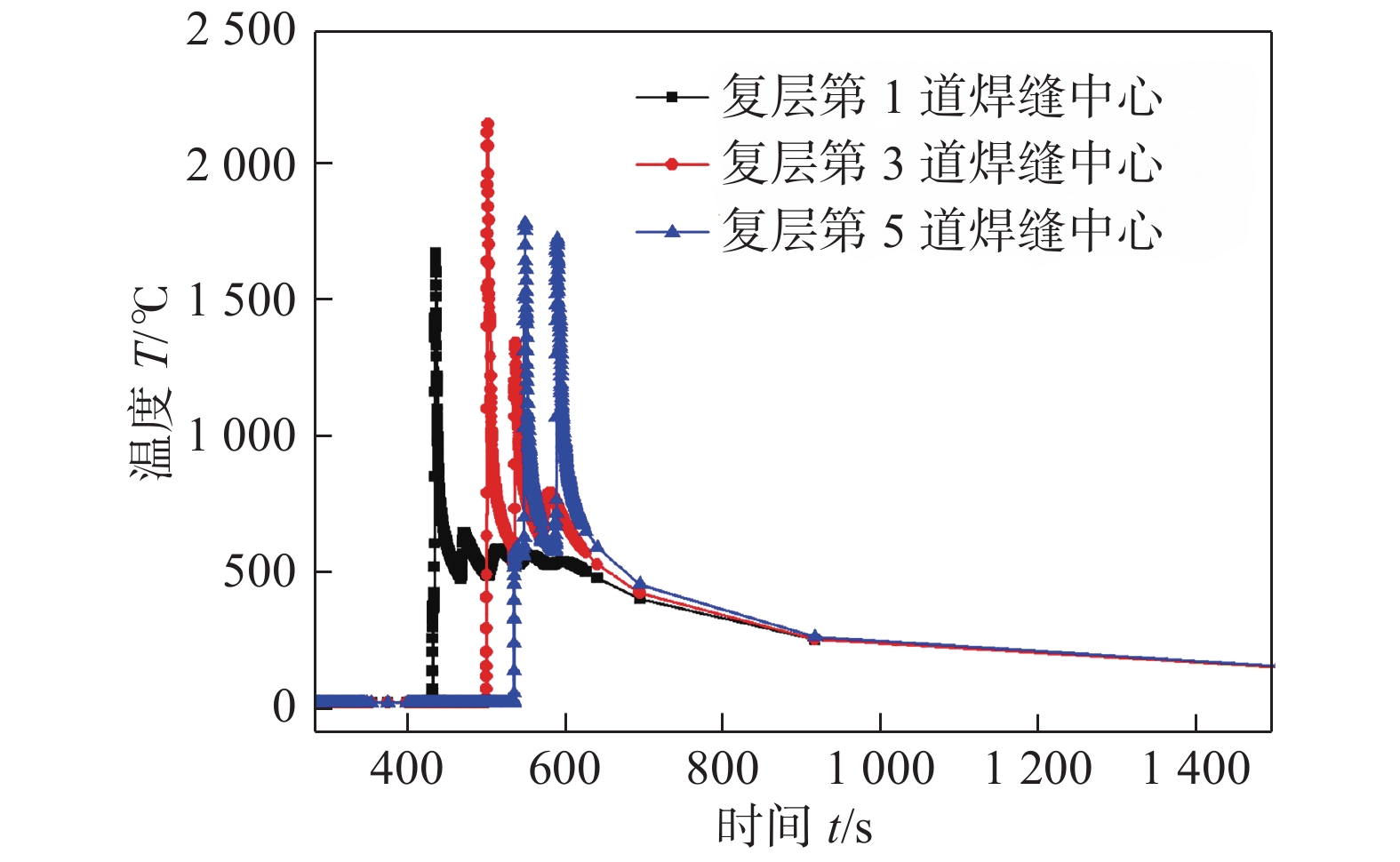

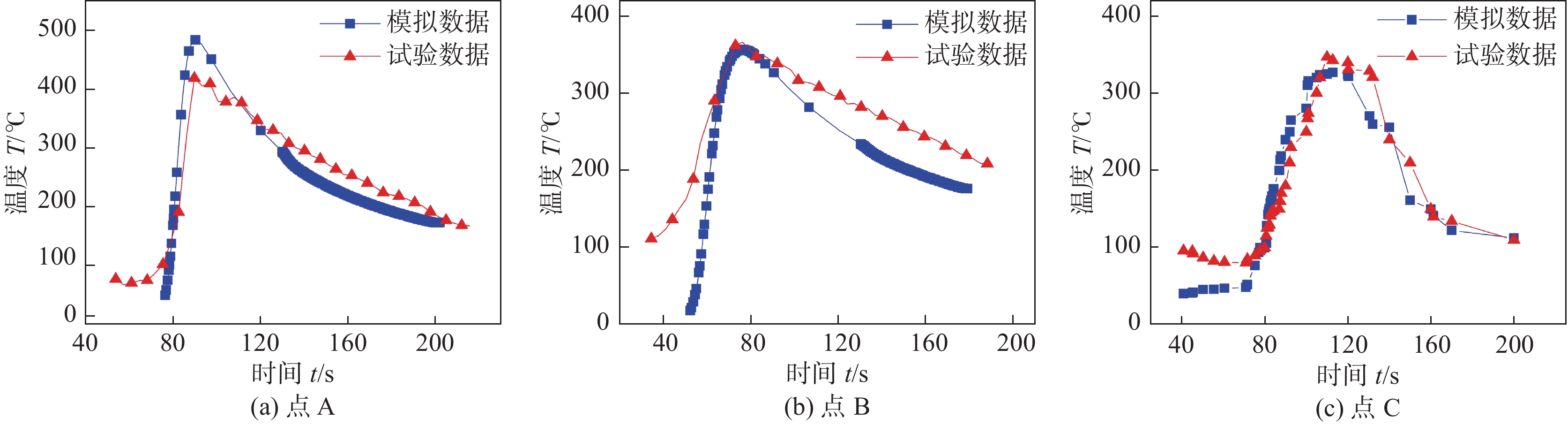

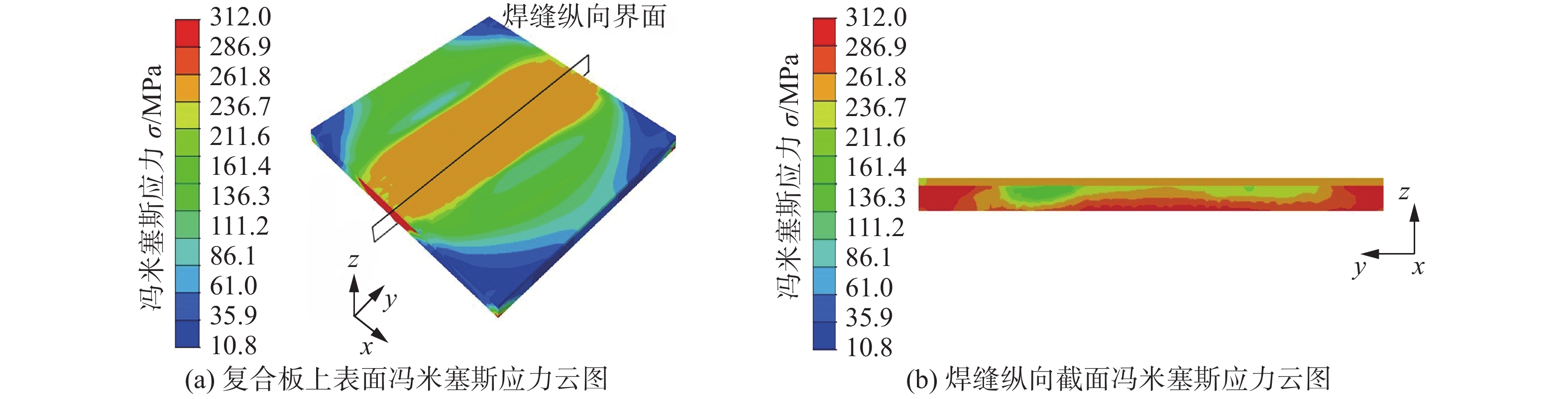

摘要: 为研究复合板在焊接过程中复杂的热力学行为,利用ABAQUS有限元软件对304/Q345R复合板的焊接过程进行了数值模拟,通过热电偶和盲孔法获得了焊接接头的热循环曲线和残余应力分布规律,验证了有限元模型的正确性. 同时采用光学显微镜和扫描电镜对焊接接头的微观组织、晶粒形貌和元素分布进行了分析,研究焊接接头部位的微观组织演化规律. 结果表明,焊接残余应力最大值为312 MPa,位于焊趾附近,残余应力沿焊缝至母材方向逐渐降低并趋于稳定. 在两种材料的交界面处发现残余应力不连续现象. 焊接接头微观组织主要由奥氏体和铁素体组成,复层熔合线附近的铁素体以板条状和针状形成带状过渡区,而熔合线附近的奥氏体晶粒成柱状形貌且尺寸更为微小.Abstract: In order to study the complex thermo-mechanical behavior of the composite plate in the welding process, a finite element model was developed to simulate the welding process of 304/Q345R composite plate. The thermal cycle curve and residual stress distribution of the welded joint were obtained by thermocouple and blind hole method. The finite element model was verified by the experimental results. Meanwhile, the microstructure, grain morphology and element distribution of the welded joint were analyzed by means of optical microscope and scanning electron microscope, and the microstructure evolution of the welded joint was investigated. The results showed that the maximum welding residual stress was 312 MPa, which was located at the weld toe, and the residual stress gradually decreased and stabilized along the direction from the weld to the base metal. At the interface of the two materials, the residual stress discontinuity was observed. The microstructure of the welded joint was composed of austenite and ferrite. The ferrite in the vicinity of the fusion line of the composite layer presents strip and needle-like shape and forms a banded transition zone, while the austenite grains in the vicinity of the fusion line presents columnar morphology and smaller size.

-

0. 序言

铝/钢复合结构兼具铝的轻质性和钢的高强性,可以使整体构件在满足使用性能的前提下降低能耗,节约成本,因而在航空航天、汽车、船舶制造等领域具有广泛的应用前景[1-2].焊接是实现铝/钢异种材料连接的高效方法之一,但由于铝/钢物化性能迥异,导致熔焊时Al-Fe界面易形成脆性金属间化合物(IMCs),严重降低接头的力学性能,极大地限制了该构件在制造领域的广泛应用.

为解决上述问题,不少学者采用电弧焊、激光焊、钎焊、搅拌摩擦焊等多种焊接方法进行铝/钢异种材料焊接[3-5],其中激光焊由于焊接过程能量精确可控、热输入小等优点,可以有效调控Al-Fe冶金反应,成为铝/钢异种材料连接比较理想的方法. Xia等人[6]进行铝/钢异种金属激光熔钎焊,发现双光点激光焊接不仅可以减小界面IMCs的整体厚度,还可以均质化界面IMCs的分布.Yan等人[7]研究发现界面多种IMCs的形成与铝/钢焊接过程中的成分偏析有关,提出减少焊接热输入抑制界面IMCs及其诱导的裂纹.Su等人[8]发现铝/钢熔焊过程加入锌基焊料,促使界面形成低硬度脆性的新型FeAl IMCs,提高接头的承载能力.研究表明,激光焊在调控界面IMCs厚度和形态方面具有明显的优势,可以改善接头成形与性能,但未能有效解决接头成分偏析与组织不均性问题,因而铝/钢异种材料的高质效焊接仍需深入研究.

外加磁场辅助激光焊接具有价格低廉、操作简单并能有效调控焊缝凝固组织等优点,受到国内外学者的广泛关注.戎易等人[9]采用交变磁场调控添加镍中间层的镁/钢接头中化合物的形貌与分布,提高了接头的力学性能.丁浩等人[10]对预制粉末的铝/钢对焊试验施加交变磁场,发现磁场对熔池的搅拌作用可以减少气孔缺陷,细化针状FeAl3 IMCs,抑制脆性Fe-Al IMCs的生长.Zhou等人[11]发现磁场对熔池的搅拌作用可以促进传热传质、液态金属对流和溶质交换,以及弥散Mg-Al IMCs的分布.可见,外加磁场辅助激光焊接方法结合了两者的优势,在提升铝/钢等异种材料接头性能方面具有巨大潜能.

基于此,文中拟通过预置纵向交变磁场对铝/钢异种材料进行激光搭接深熔焊试验,研究交变磁场对接头宏观形貌、显微组织、元素分布、力学性能及其断裂方式的影响,为外加磁场辅助铝/钢等异种材料激光焊接技术实际应用提供理论基础与工艺参考.

1. 试验方法

试验材料选用1 mm厚的DP590热镀锌钢板和6061-T6铝合金板材,其中镀锌钢板表层的镀锌层厚度为50 μm.试验样板的尺寸规格为200 mm × 150 mm × 1 mm,试验材料的化学成分如表1所示.为了提高焊接接头质量,焊前需要采用一系列物理化学方法去除待焊表面的氧化薄膜与油污.

表 1 母材的化学成分(质量分数,%)Table 1. Chemical compositions of base metal材料 C Si Mn Cr Mo Al Cu Ni Fe DP590 0.15 0.31 1.5 0.02 0.01 0.05 0.02 0.01 余量 材料 Si Fe Cu Mn Mg Cr Ti Zn Al 6061-T6 0.72 0.4 0.21 0.09 1.1 0.15 0.02 0.02 余量 试验用光纤激光器的型号为 YLS-30000,该激光器主要参数如下:焦点直径0.5 mm,焦距300 mm,激光波长1 070 nm.焊接接头采用搭接形式,搭接长度为30 mm.焊接保护气体选用氩气,以防止铝/钢焊缝在高温下氧化.为防止焊接过程产生的飞溅损坏保护镜片,需要焊接过程中施加压缩空气.铝/钢激光焊接示意图如图1所示.为了调控Fe-Al界面的冶金反应,焊接过程中需施加交变磁场,试验中磁场装置由控制柜和线圈组成,通过控制单元设定试验所需的交变磁场变量.

为了对比试验结果,在前期研究基础上,焊接过程采用加入和不加入磁场进行激光焊接研究.试验的工艺参数如表2所示.焊后采用线切割方式制备金相试样和拉伸试样,选用金相显微镜和电子扫描显微镜分别观察接头宏观形貌、微观组织及元素分布,选用万能拉力试验机进行力学性能,评估接头的质量和探究接头的失效机理.

表 2 焊接工艺参数Table 2. Welding parameters序号 功率P/kW 焊接速度v/(m·min−1) 离焦量L/mm 磁场电流I/A 磁场频率f/Hz 1 3.6 6 + 7 2 3.6 6 + 7 15 150 2. 试验结果与分析

2.1 接头表面成形

不同焊接工艺条件下铝/钢接头的焊缝成形如表3所示.可以看到铝/钢未加磁场焊接时焊缝表面平直且呈亮白色,鱼鳞状细腻连续分布,焊缝中心部位稍微下凹,表面成形质量较好.焊接过程施加交变磁场时,焊缝整体呈浅黄色,飞溅明显增多.相对未加磁场焊缝而言,熔宽开始变小,鱼鳞状长度明显拉长,且末端有一定余高,这可能与熔池中交变磁场诱导产生的洛伦兹力有关[12],交变磁场的作用促使洛仑兹力发生周期性变化,导致熔池的运动发生周期变化波动.研究还发现,施加磁场后焊缝的熔深明显增加,这与磁制动力作用下熔池内向两侧和后方流动作用减弱有关.已有文献表明[13-14],外加纵向磁场,由于Hartmann效应,熔池内液态金属Marangoni 对流减弱.熔池吸收的激光能量进一步聚集在熔池前部,使得最高温度增大,打孔作用增强,最后使得焊缝熔深增加.此外铝/钢搭接焊结合面的面积明显增加,这有助于进一步提高接头的承载能力.

表 3 不同磁场条件下焊缝成形Table 3. Weld formation at different magnetic fields序号 焊缝表面成形 焊缝横截面 1

2

2.2 接头显微组织

铝/钢激光搭接焊接头的显微组织如图2所示.从图2a可以看到低倍下铝/钢界面层主要由带状组织、块状组织以及岛状组织组成,这些组织形貌迥异,大小不一,分布极不均匀.铝/钢激光熔焊时,由于铁在铝中的固溶度较低,而焊接熔池较小、冷却时间较快,焊缝凝固过程中溶质原子无法在短时间充分扩散,导致界面层形成Fe-Al化合物(图2b),这些化合物具有较大的硬度和脆性,它们在界面层连续分布时会由于自身特性降低材料自身的塑性变形能力,增大裂纹的敏感性.研究还发现,带状组织之间形成不规则的裂纹(图2c),裂纹的形成主要与焊接过程的冶金因素和力学因素有关,前者是Fe和Al元素的偏析促进脆性Fe-Al化合物的生成,降低材料自身的塑韧性,后者是组织的差异导致接头中形成较大的应力,两者的共同作用导致裂纹产生.

外加交变磁场后,铝/钢界面形状相对未加磁场而言开始变得比较规则,焊缝区嵌入铝基体的块状Fe-Al化合物明显减少,而带状或岛状Fe-Al化合物得到细化(图2e),这依赖于交变磁场对熔池的电磁搅拌作用,该作用力促进熔池凝固过程中晶粒的破碎和二次形核,细化Fe-Al化合物组织.另外,界面层中没有发现明显的裂纹缺陷,这主要是由于熔池中电磁力的搅拌作用改变了温度梯度分布,减小了焊接热应力.从图2e和图2f可以看到部分Fe-Al化合物被α-Al包围,这表明熔池中电磁力的作用除了诱导Fe-Al化合物离散分布外,还促进熔池中溶质元素的迁移,降低焊缝中的成分偏析,其中α-Al固溶体具有良好的变形能力,外力作用下,该晶体可以优先发生塑性变形(以滑移和孪生形式)消耗大部分畸变能,进而提高材料的力学性能.

2.3 接头元素分析

铝/钢接头界面层的能谱分析结果如图3所示.从图3a可以看到,未加交变磁场焊接时,焊缝中部分Fe元素迁移进入铝侧,而仅有少量Al元素迁移进入钢侧,这主要是因为Fe原子质量大于Al原子质量,激光辐照下液态金属在重力作用下发生迁移,而界面层Fe和Al原子的富集导致连续脆而硬Fe-Al化合物的形成,这将减小界面结合处的性能.外加交变磁场后,发现部分Al元素在电磁力的作用下迁移进入焊缝,连续分布的Fe-Al脆性化合物被离散(图3b),这将减小焊缝中的成分偏析,有利于降低界面层的裂纹敏感性.

铝/钢界面析出物的能谱分析如图4和表4所示.根据Al元素的含量[15]可以推测界面形成的Fe-Al脆性IMCs主要是ζ-FeAl2,θ-FeAl3和β2-FeAl.在焊缝冶金过程中,铝和铁有限的溶解度是脆性IMCs形成的主要原因.

表 4 点能谱分析结果 (质量分数,%)Table 4. EDS spot composition analysis results能谱点 Fe Al C O Cu 可能化合物 P1 57.3 33.7 5.9 2.5 0.6 FeAl + FeAl2 P2 71.6 28.4 α-Fe + FeAl P3 90.8 6.9 2.3 α-Fe P4 80.7 19.3 FeAl + FeAl3 P5 84.5 11.9 3.6 α-Fe + FeAl 从热力学的角度可知[16],富铝的IMCs (如FeAl3等化合物)在冶金反应中由于具有较小的焓变和吉布斯自由能变而优先生成.与富铁的IMCs (如FeAl2和FeAl等化合物)相比,富铝的IMCs具有较大的脆性.富铝的IMCs析出会增大材料的裂纹倾向性和降低材料的塑韧性,因此该析出相通常是有害的,在冶金反应中应尽量减少.在铝/钢激光焊接过程中,交变磁场的加入诱导焊接熔池中产生电磁力,该作用力可以对熔池进行搅拌作用,促进熔池传热传质同时细化焊缝中晶粒,有效地实现了脆性IMCs的离散处理,将有助于接头性能的改善.

2.4 接头力学性能

为了评估两种工艺条件下焊接接头的力学性能,采用线切割方式对焊接样件进行加工制备相应的拉伸试样(图5).考虑到搭接拉伸样品的特性,在拉伸过程中需要预放置等厚的板材,确保拉伸过程中试验数据的准确性.

剪切试验测试结果如图6所示,可以看到测试试样的载荷能力、伸长量分别为0.89 kN与0.38 mm,0.96 kN与1.01 mm.与未加磁场焊接接头相比,外加磁场后焊接接头承担能力和断后伸长率分别提高8.09%和166%.接头载荷能力的提高主要与两个因素有关:搭接区域的结合面积和微观组织.从图2可以看到外加交变磁场后铝/钢接头搭接面积明显增加,这将有利于提高接头载荷能力.另外,外加交变磁场的作用促使焊接熔池中产生周期性变化的电磁力,该作用力促进溶质的迁移和IMCs组织细化,一定程度提高了材料的变形能力.接头断口形貌如图7所示,可以看到未加磁场焊接时接头断面呈现沿晶界开裂的裂纹和从材料内部开裂的微裂纹,断口形貌相对比较平整(图7a),接头的断裂形式属于脆性断裂,典型断裂形貌的产生与接头结合面处的微观组织有关.从前面的分析可以看出,未加磁场焊接铝/钢异种材料时,结合面形成大量连续分布的Fe-Al IMCs,这些IMCs具有较大的脆性和硬度,塑性变形能力比较差,外力作用下容易发生开裂,导致接头失效.焊接过程加入交变磁场后(图7b),接头断面裂纹明显减少,断口出现一些撕裂棱和韧窝,表明接头断裂过程发生一定的塑性变形,接头断裂形式属于混合断裂,这与焊缝中的组织演变有关.在外加磁场作用下,焊接熔池中产生方向周期性变化的电磁力,该作用力对熔池的进行不断搅拌,促进溶质的迁移,减少了成分的偏析.Al元素的迁移促使界面层中形成α-Al组织,该组织具有较好的塑性变形能力,可以降低裂纹的敏感性,提高材料的载荷能力.

3. 结论

(1) 外加交变磁场辅助铝/钢异种材料激光焊接可以获得成形良好的接头,焊接过程交变磁场的加入促使接头焊缝的熔宽减小、熔深增加.

(2) 未加磁场铝/钢焊接接头界面层形成连续分布的Fe-Al IMCs,诱导裂纹产生,而加入交变磁场后铝/钢焊接接头界面层组织细化,成分偏析得到减少,裂纹缺陷明细得到抑制.

(3) 焊接过程加入交变磁场后接头中形成多种IMCs(可能为ζ-FeAl2,θ-FeAl3和β2-FeAl),焊接熔池中电磁力对熔池的搅拌作用促进界面IMCs的离散分布,有效地提高材料的变形能力.

(4) 与未加磁场焊接相比,加入交变磁场后焊接接头的力学性能明显得到提高,主要原因是结合面积的增加与IMCs组织的细化,接头断裂形式由脆性断裂向混合断裂方式转变.

-

表 1 Q345R和304不锈钢化学成分(质量分数,%)

Table 1 Chemical compositions of Q345R steel and 304 stainless steel

母材 C Si Mn P S Ni Cr Fe Q345R 0.20 0.247 0.604 ≤ 0.025 0.04 0.061 0.052 余量 304 0.07 0.345 1.091 ≤ 0.045 0.036 8.215 18.09 余量 表 2 焊接材料化学成分(质量分数,%)

Table 2 Chemical compositions of the filler rods

焊接材料 C Mn Si S P Ni Cr Mo Cu Fe ER50-6 0.105 0.163 0.975 0.013 0.015 0.016 — 0.06 — 余量 J507 0.12 1.60 0.75 0.035 0.040 0.30 0.20 0.30 — 余量 302 0.064 0.80 0.70 0.010 0.030 12.50 24.00 0.40 0.20 余量 表 3 焊接工艺参数

Table 3 Technological parameters of the welding process

序号 焊接方法 焊层(道) 焊接电流I/A 电弧电压U/V 焊接时间t/s 冷却时间tc/s 焊条型号 直径ϕ/mm 1 氩弧焊 打底焊 146 22 — — ER50-6 3.2 2 焊条电弧焊 基层1 122 20 125 154 J507 3.2 3 焊条电弧焊 基层2 122 20 64 57 J507 3.2 4,5,6,7,8 焊条电弧焊 复层1,2,3,4,5 122 20 32 0 302 3.2 9 焊条电弧焊 复层6 122 20 50 冷却至室温 302 3.2 -

[1] 张俊旺, 王文先, 黄延平, 等. 奥氏体不锈钢焊缝金属的电化学腐蚀性能[J]. 焊接学报, 2007, 28(2): 103 − 108. doi: 10.3321/j.issn:0253-360X.2007.02.027 Zhang Junwang, Wang Wenxian, Huang Yanping, et al. Electrochemical corrosion properties for weld metal of austenitic stainless steel[J]. Transactions of the China Welding Institution, 2007, 28(2): 103 − 108. doi: 10.3321/j.issn:0253-360X.2007.02.027

[2] 邓德安, 蔡建鹏, 蒋小华, 等. 坡口形式对SUS304奥氏体不锈钢对接接头残余应力和变形的影响[J]. 焊接学报, 2016, 37(2): 63 − 67. Deng Dean, Cai Jianpeng, Jiang Xiaohua, et al. Influence of groove type on residual stress and distortion in SUS304 austenitic stainless steel butt weld[J]. Transactions of the China Welding Institution, 2016, 37(2): 63 − 67.

[3] Jiang W C, Luo Y, Li J H, et al. Residual stress distribution in a dissimilar weld joint by experimental and simulation study[J]. Journal of Pressure Vessel Technology, 2017, 139(1): 011402. doi: 10.1115/1.4033532

[4] Jiang W C, Liu Z B, Gong J M, et al. Numerical simulation to study the effect of repair width on residual stresses of a stainless steel clad plate[J]. International Journal of Pressure Vessels & Piping, 2010, 87(8): 457 − 463.

[5] 丁肖, 李祥. Q345R/304复合板焊接接头组织及性能研究[J]. 热加工工艺, 2015, 44(23): 234 − 236. Ding Xiao, Li Xiang. Study on microstructure and mechanical properties of Q345R/304 composite plate welded joints[J]. Hot Working Technology, 2015, 44(23): 234 − 236.

[6] 欧平, 孙坚, 张茂龙, 等. SA508/316L异种钢焊接接头的显微组织分析[J]. 材料热处理学报, 2013, 34(10): 112 − 118. Ou Ping, Sun Jian, Zhang Maolong, et al. Microstructure of SA508/316L dissimilar steel welding joints[J]. Transactions of Material and Heat Treatment, 2013, 34(10): 112 − 118.

[7] 蔡建鹏, 孙加民, 夏林印, 等. Q345钢对接接头残余应力与变形的预测[J]. 焊接学报, 2015, 36(11): 61 − 64, 68. Cai Jianpeng, Sun Jiamin, Xia Linyin, et al. Prediction on welding residual stress and deformation in Q345 steel butt-welded joints[J]. Transactions of the China Welding Institution, 2015, 36(11): 61 − 64, 68.

[8] 杨江, 王斌, 王维, 等. Q345/IN825复合板焊接接头组织与性能[J]. 材料热处理学报, 2016, 37(1): 150 − 156. Yang Jiang, Wang Bin, Wang Wei, et al. Microstructure and mechanical properties of welding joints of Q345/IN825 composite plates[J]. Transactions of Material and Heat Treatment, 2016, 37(1): 150 − 156.

[9] 杨黎明, 但楚臣. 低合金钢焊接接头金相试样的制备[J]. 理化检验(物理分册), 2016, 52(11): 790 − 792. Yang Liming, Dan Chuchen. Preparation of metallographic speciments of low alloy steel welding joints for macroscopic inspection[J]. Physical Testing and Chemical Analysis (Part A: P-hysical Testing), 2016, 52(11): 790 − 792.

[10] Goldak J, Chakravarti A, Bibby M. A double ellipsoid finite element model for welding heat sources[J]. Metal Transporters, 1985(13): 299−305.

[11] Berbenni S, Favier V, Berveiller M. Impact of the grain sizedistribution on the yield stress of heterogeneoumaterial[J]. International Journal of Plasticity, 2007, 23(1): 114 − 142. doi: 10.1016/j.ijplas.2006.03.004

[12] Zhang M, Zhang T, Cai J, et al. Effect of heat treatment on microstructure and properties of explosive welding clad plate of TA1/Q345[J]. China Welding, 2018, 27(1): 26 − 31.

-

期刊类型引用(12)

1. 贾登峰,夏腾辉,杜春平,刘晓刚,刘登峰. 304/Q345R复合板焊接接头微观组织与性能研究. 热加工工艺. 2025(03): 41-44+50 .  百度学术

百度学术

2. 李小兵,束长荣,陆立婷,陈程,郑传波,镇凡,麻晗. 不锈钢复合板的焊接工艺研究现状及进展. 中国冶金. 2025(01): 15-31 .  百度学术

百度学术

3. 冀伟,张鹏. 波形钢腹板梁T形接头焊接仿真分析与试验研究. 哈尔滨工程大学学报. 2024(04): 691-698 .  百度学术

百度学术

4. 陈坤,余薇,范益,李伟,王晓斌,邹家生,刘坤. 轧制组织对304L/Q345R复合板焊接裂纹敏感性的影响规律. 江苏科技大学学报(自然科学版). 2024(05): 32-38 .  百度学术

百度学术

5. 翁华晶,冯美艳,江吉彬,陈昌荣,练国富. V型曲面坡口打底焊成形控制与工艺参数优化. 精密成形工程. 2023(02): 188-198 .  百度学术

百度学术

6. 董宏斌,张涛,张建辉,王金霞,李学燕. 3000m~3不锈钢复合板球罐的制造与安装. 压力容器. 2023(01): 82-88 .  百度学术

百度学术

7. 刘文明,欧阳凯,张新明,张朝明,程新路,陈成. 焊后热处理对S30408/Q345R复合板焊接接头残余应力的影响. 材料热处理学报. 2023(03): 217-226 .  百度学术

百度学术

8. 李昌敏,冯伟,郭瑞鹏,杨国涛. 考虑区域影响的焊接残余应力超声法试验研究. 热加工工艺. 2023(13): 136-141+147 .  百度学术

百度学术

9. 未晓丽,王景玄. 装配式钢管混凝土梁柱节点的抗震性能研究. 青海大学学报. 2023(04): 78-85+108 .  百度学术

百度学术

10. 蒋军,房务农,刘孟德,周杨. Q370R/S31603爆炸焊复合板制4000 m~3厚壁球罐焊接工艺及接头性能. 电焊机. 2023(11): 71-76 .  百度学术

百度学术

11. 王超冉,李东. 铁素体不锈钢/16Mn钢厚板异种钢电子束焊接接头的组织与冲击韧性. 机械工程材料. 2022(02): 35-42 .  百度学术

百度学术

12. 刘德佳,扎学安,王伟雄,唐延川,赵龙志,徐宏明. 304/Q235复合板多主元高熵化焊缝的组织与性能. 金属热处理. 2022(08): 63-70 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: