Reactive air brazing of SOFC using Ag-CuO-Al2O3 composite braze and the service performance study

-

摘要: 选用纳米Al2O3颗粒作为增强相,成功开发了Ag-CuO-Al2O3复合钎料,并将其应用于空气反应钎焊固体氧化物燃料电池(SOFC)组件. 对复合钎料的空气反应钎焊工艺进行研究,在1 050 ℃/30 min工艺条件下实现了SOFC电池片与铝化不锈钢连接体的无缺陷连接,分析了接头两侧界面连接特征以及纳米Al2O3增强相在连接过程中的演化行为. 对焊后接头进行高温服役性能测试,探究了接头组织和性能在高温氧化(空气)和还原(H2-50H2O-N2)气氛中的演化规律. 结果表明,铝化不锈钢的Al2O3保护层对不锈钢基体起到了良好的保护作用,避免了不锈钢基体在连接以及高温服役过程中的性能衰减,在确保接头组织稳定性中发挥了关键作用. 系统分析了高温服役过程对接头气密性的影响,综合评定了Ag-CuO-Al2O3复合钎料空气反应钎焊SOFC组件的适用性.Abstract: In this study, the Ag-CuO-Al2O3 composite braze was successfully developed through adding Al2O3 nanoparticle reinforcements, which was suitable for reactive air brazing (RAB) solid oxide fuel cell (SOFC) components. The RAB joining process was investigated in detail. The cell was successfully joined to the aluminized steel at 1 050 ℃ for 30 min. The interfacial joining properties were studied. The evolution behavior of Al2O3 nanoparticle reinforcements in the RAB process was also analyzed. As-brazed joints were tested in high-temperature service atmospheres. The microstructure properties of joints after aging in high-temperature oxidization (air) and reduction (H2-50H2O-N2) atmospheres was investigated. It is shown that the Al2O3 protective layer of aluminized steel had good protective effects on the steel matrix, avoiding its performance degradation during brazing and high-temperature aging. The Al2O3 protective layer play a key role in ensuring the stability of joint structure. The influence of the high-temperature service on the gas-tightness of joints was systematically studied. The applicability of the Ag-CuO-Al2O3 composite braze used for RAB joining SOFC components was comprehensively evaluated.

-

0. 序言

固体氧化物燃料电池(SOFC)是一种清洁高效的高温固体电化学能源转换系统,具备成本低、污染小、能量转化率高、燃料多样化以及噪音小等优势. 目前已经在便携式电源、汽车电源和工业电站等领域取得了实际应用[1-3]. 为了满足高功率输出需求,需要将多个单电池互连构建电池堆,其中实现电池片(cell)与不锈钢连接体(interconnect)的气密连接是构建SOFC电池堆的关键技术[4-5].

SOFC电池堆需要在高温(800 ℃)氧化/还原气氛下长期服役,接头将面临化学腐蚀和热应力的挑战,连接位置气体泄漏将导致电池堆性能严重衰减[6]. 当前,适用于SOFC组件封接的方法包括玻璃连接和空气反应钎焊连接. 玻璃钎料成本低易于制备,但玻璃钎料在高温服役过程易产生晶化现象,导致接头脆性增加,容易形成裂纹缺陷,不利于接头组织和性能的稳定,此外,玻璃材料通常对应力引起的开裂抑制作用较差,在应力较大的移动应用中开裂倾向更加明显[7-8]. 空气反应钎焊(reactive air brazing, RAB)与玻璃连接类似,在空气中进行连接,不需要真空或惰性气氛保护. 钎料体系以贵金属为主,添加适量金属氧化物用于提高钎料的润湿性能,Ag-CuO是常用的RAB钎料体系;以贵金属为主的接头具备良好的变形能力,可以吸收部分热应力和冲击应力. 但是,Ag-CuO钎料热膨胀系数(CTE)为 ~ 19.1 × 10–6 K−1,与SOFC组件(~ 12.3 × 10–6 K−1)存在较大CTE失配,导致接头在加热和冷却过程中产生较大热应力,成为电池堆连接失效的主要原因[9-10].

加入低CTE增强相调节金属基复合钎料热膨胀行为,是真空钎焊中常用的方法,纳米尺度增强相有助于提高复合钎料流动性,不易形成空隙或裂纹缺陷[11-12]. 基于此,选用纳米Al2O3作为增强相,开发了新型的纳米Al2O3增强Ag-CuO复合钎料,研究了RAB工艺和接头高温服役性能,探究了氧化和还原气氛中组织演化规律.

1. 试验方法

试验使用的阳极支撑型SOFC电池片为多层结构,包括NiO-YSZ阳极支撑体、Ni-YSZ阳极、YSZ电解质、CGO多孔扩散阻挡层和LSC阴极,其中YSZ/多孔CGO构成的复合层为电池片的待连接位置. SOFC专用铁素体不锈钢Crofer22H由德国蒂森克虏伯生产,Crofer22H不锈钢中添加Nb和W元素与Si元素反应形成拉夫斯相(Lavers-phase),在基体中弥散分布提高了不锈钢的高温服役性能. 为了提高不锈钢Crofer22H抗氧化性能,焊前对待焊表面铝化,获得厚度为2 μm连续的Al2O3保护层,不锈钢铝化工艺和保护层性能已经在之前的研究中进行详细报道[13]. 将电池片和铝化Crofer22H分别加工成10 mm × 10 mm和20 mm × 20 mm的样品用于RAB连接试验.

研究已经表明Ag-8mol%CuO作为基体钎料,既能与纳米Al2O3保持良好的相容性,又能确保复合钎料在YSZ陶瓷表面润湿性良好,当纳米Al2O3含量为8%(质量分数)时,接头获得最大连接强度[14]. 因此,选用Ag-8mol%CuO作为基体钎料,添加8%纳米Al2O3获得复合钎料. 配制好的复合钎料经过10 h球磨混合后,使用粉末压片机制备厚度约为100 μm的钎料片. 将试样由下至上按照铝化Crofer22H/Ag-CuO-Al2O3/电池片的顺序进行装配,如图1所示. 将装配好的试件放入加压马弗炉中进行RAB连接,施加16 N/cm2的装配压力,以180 ℃/h的升温速率加热至1 050 ℃,保温30 min,以180 ℃/h的速率冷却至室温. 将焊后样品加热至800 ℃保温300 h,用于测试接头高温服役性能,其中高温氧化试验在空气气氛中进行,模拟SOFC阴极工作气氛,高温还原试验在4%H2-50%H2O-N2潮湿还原性气氛进行,用于模拟SOFC阳极工作气氛.

采用扫描电镜和能谱分析仪对接头进行组织分析;采用自制的气密性测试装置对接头进行气密性检测,每组参数制备5个试样,用于减小测量误差,气密性测试试样制备及计算方法已经在之前的研究中进行了报道[9].

2. 试验结果与分析

2.1 接头组织分析

对电池片和铝化Crofer22H进行RAB连接,获得的接头组织及对应的元素面扫描如图2所示. 由图2a分析可得,Ag-CuO-Al2O3复合钎料实现了电池片与铝化Crofer22H可靠连接,焊缝无气孔和裂纹等缺陷,Al2O3增强相均匀分布在钎缝中,经过高温连接过程后,纳米Al2O3已经烧结长大达到了微米尺寸,研究已经指出在1 050 ℃/30 min的RAB工艺下,存在部分未烧结长大纳米Al2O3,最终接头形成了微米-纳米Al2O3增强相共存的现象[14]. 对电池片侧连接界面(区域1)进行高倍组织观察和元素面分析,结果如图2b所示. Ag元素面分布确认钎料已经渗入CGO孔洞中,并与致密的YSZ层实现了紧密连接,钎料基体与电池片界面形成了可靠的机械互锁结构. 结合Cu和Al的元素分布以及对应物相的EDS分析结果可知,浅灰色物相为CuO,深灰色物相为CuO与Al2O3增强相反应形成的CuAl2O4相. 钎缝位置(区域2)组织以及元素面分析如图2c所示,在钎缝中可以观察到CuO,Al2O3以及CuAl2O4相,Ag基钎料与各物相均保持了良好的相容性,CuO与Al2O3的适度反应,有助于消除复合钎料经常出现的未焊合缺陷. 图2d显示了铝化Crofer22H侧(区域3)组织和元素面分析,钎料基体与粗糙的铝化Crofer22H表面同样形成了机械互锁结构. 钎料中CuO与Al2O3保护层发生反应形成了CuAl2O4相,但是并没有破坏Al2O3保护层的完整性,结合不锈钢基体Fe,Cr,Mn元素面分布可知,Al2O3保护层对不锈钢基体构成了良好的保护,避免了钎料中的CuO与不锈钢反应造成的基体腐蚀,有效阻隔了不锈钢基体元素向钎缝的扩散,确保了钎缝组织稳定性,消除了RAB连接过程不锈钢基体的腐蚀氧化.

图3显示了两侧连接界面形成的机械互锁结构示意图,机械互锁连接对于强化界面连接,提高接头稳定性起到了关键作用. 电池片侧钎料充分进入CGO孔洞结构有助于缓解界面应力,减少界面连接失效;钎料与铝化Crofer22H形成的机械互锁结构,充分发挥了粗糙表面在提高界面连接方面作用,提高了接头连接稳定性.

2.2 高温服役过程对接头组织的影响

2.2.1 接头组织在氧化性气氛中的稳定性

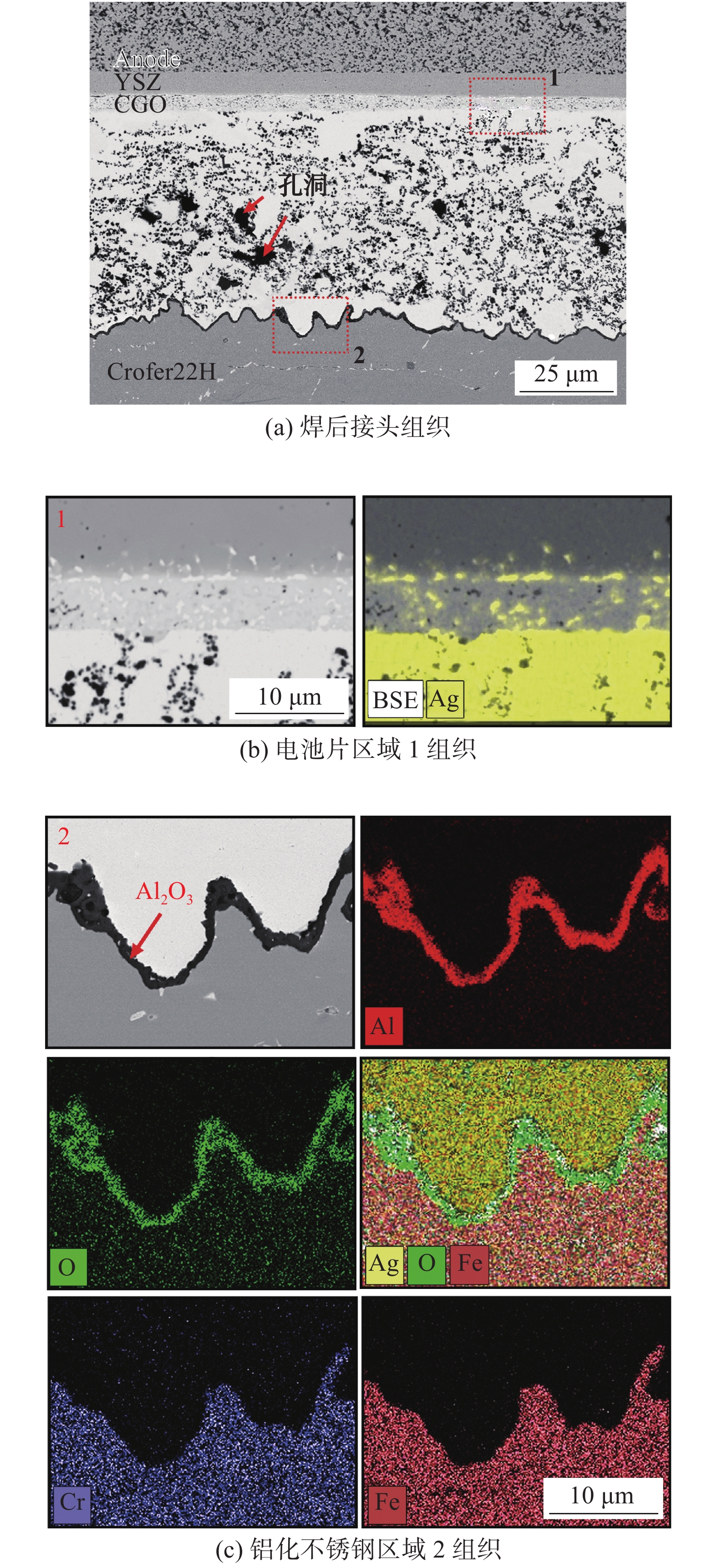

图4显示了焊后接头在空气气氛中800 ℃高温氧化300 h后的组织变化,分析表明,高温氧化并没有对接头组织造成明显的影响,在接头中未观察到裂纹或气孔缺陷,复合钎料与电池片和铝化Crofer22H均保持了紧固连接. 对电池片侧的连接界面(区域1)进行高倍观察结果如图4b所示,钎料基体Ag依然充分渗入CGO的孔洞结构,与YSZ电介质层可靠连接,电池片侧的机械互锁结构并没有受到破坏. Cu和Al元素的面扫描分析也确认,CuO,Al2O3和CuAl2O4相稳定性良好. 铝化不锈钢侧连接界面(区域2)分析结果如图4c所示,结果表明,经过长时间高温氧化后,Al2O3保护层依然致密连续,与不锈钢基体结合良好,结合不锈钢Fe,Cr和Mn元素的分布可知,在高温氧化服役过程,Al2O3保护层对不锈钢基体构成有效的保护,不锈钢基体未被氧化,有效阻隔了Fe,Cr和Mn元素向钎缝的扩散,确保了接头组织在高温氧化气氛中具备良好的稳定性.

2.2.2 接头组织在还原性气氛中的稳定性

焊后接头在4%H2-50%H2O-N2还原气氛中经过800 ℃/300 h的高温还原测试后,对接头组织进行观察,结果如图5所示. 分析表明,高温还原后两侧连接界面均未产生裂纹缺陷,依然与电池片和铝化Crofer22H保持良好连接,但是在钎缝中观察到了少量的孔洞缺陷,整个接头未检测到CuO相,这是由于氢气扩散进入钎料中,将CuO和CuAl2O4相还原成Cu,随后固溶在周围的Ag基体中,对孔洞周围的EDS点分析可以检测到4%Cu(原子分数),可以确认氢致还原过程的发生. 由于孔洞缺陷并没有相互连通,所以可以推断对接头的气密性并不会造成严重影响. 电池片侧的高温观察如图5b所示,分析表明,高温还原过程同样不会对电池片侧的机械互锁结构造成破坏,Ag基体充分进入CGO孔洞结构,与YSZ保持紧密连接,稳定的机械互锁结构确保了连接界面在高温服役过程不易失效. 图5c显示了铝化Crofer22H侧的放大图像和元素面分析,结果可知,Al2O3保护层在高温还原过程同样对Crofer22H基体构成了有效的保护,与基体紧固连接,避免了不锈钢元素向钎缝扩散,确保了接头组织稳定性. 总之,使用Ag-CuO-Al2O3复合钎料RAB连接获得的接头具备良好的组织稳定性,主要归因于以下因素:①不锈钢铝化后获得的Al2O3保护层对Crofer22H构成了有效保护,阻隔了Fe,Cr元素向钎缝扩散,避免接头在连接以及服役过程形成复杂反应产物;②复合钎料体系中Al2O3增强相在高温双重气氛下均具备优异稳定性,避免了钎缝组织物相变化;③两侧连接界面形成了两种机械互锁结构,可以有效避免高温服役阶段界面连接失效.

2.3 接头气密性分析

为了研究高温服役测试对接头气密性的影响,将样品在相同的氧化性气氛(空气)和还原性气氛(4%H2-50%H2O-N2)进行800 ℃/300 h高温老化后,对接头气密性进行了测试,获得的接头气体泄漏率如图6所示. 分析表明,接头在焊后以及高温老化测试后都具备了良好的气密性,气体泄漏率为2.1 × 10–5~ 2.7 × 10–3 sccm/cm. 虽然高温还原后接头形成了少量的氢致孔洞缺陷,但是由于没有形成连续的气体通道,所以对接头的气密性并没有造成影响,接头经过高温还原后依然保持了极低的气体泄漏率. 文中获得的接头气体泄漏率远低于文献报道中Ag-Al2O3[15]和Ag-Al2TiO5[9]复合钎料的气体泄漏率,纳米Al2O3增强Ag-CuO基复合钎料满足SOFC电池堆的高温服役需求.

3. 结论

(1) 使用Ag-CuO-Al2O3复合钎料实现了SOFC电池片与铝化Crofer22H的RAB连接,钎料充分渗入CGO孔洞结构与YSZ紧固结合,同时与铝化Crofer22H的粗糙表面结合良好,在两侧界面均形成了稳定的机械互锁连接.

(2) 接头组织经过800 ℃/300 h氧化(空气)和还原(H2-50H2O-N2)气氛服役后具备良好的稳定性,两侧界面的机械互锁结构确保了可靠的界面连接,Al2O3增强相稳定性良好,Al2O3保护层有效阻隔了不锈钢元素向钎缝的扩散.

(3) 接头焊后以及双重气氛高温服役后均保持极低的气体泄漏率(2.1 × 10–3~2.7 × 10–3sccm/cm),高温还原过程形成的不连续氢致孔洞缺陷并没有对接头气密性造成影响,满足SOFC电池堆气密性需求.

-

-

[1] Zheng Y, Zhang C M, Ran R, et al. A new symmetric solid-oxide fuel cell with La0.8Sr0.2Sc0.2Mn0.8O3-δ perovskite oxide as both the anode and cathode[J]. Acta Materialia, 2009, 57: 1165 − 1175. doi: 10.1016/j.actamat.2008.10.047

[2] Haile S M. Fuel cell materials and components[J]. Acta Materialia, 2003, 51: 5981 − 6000. doi: 10.1016/j.actamat.2003.08.004

[3] Yan D, Liang L J, Yang J J, et al. Performance degradation and analysis of 10-cell anode-supported SOFC stack with external manifold structure[J]. Energy, 2017, 125: 663 − 670. doi: 10.1016/j.energy.2016.12.107

[4] Singh R N. High-temperature seals for solid oxide fuel cells (SOFC)[J]. Journal of Materials Engineering and Performance, 2006, 15: 422 − 426. doi: 10.1361/105994906X117224

[5] 蒋文春, 张玉财, 关学伟. 平板式SOFC钎焊自适应密封热应力与变形分析[J]. 焊接学报, 2012, 33(11): 55 − 58. Jiang Wenchun, Zhang Yucai, Guan Xuewei. Thermal stress and deformation in bonded compliant seal design for planar SOFC[J]. Transactions of the China Welding Institution, 2012, 33(11): 55 − 58.

[6] Fergus J W. Sealants for slid oxide fuel cells[J]. Journal of Power Sources, 2005, 147: 46 − 57. doi: 10.1016/j.jpowsour.2005.05.002

[7] 王美容, 雷玉珍, 唐冬燕, 等. 钎焊时间对K9玻璃/B2O3-Bi2O3-TiO2/纯钛钎焊接头组织和性能影响[J]. 焊接学报, 2019, 40(1): 80 − 83. Wang Meirong, Lei Yuzhen, Tang Dongyan, et al. Effect of holding time on the interfacial microstructure and mechanical properties of K9 glass/B2O3-Bi2O3-TiO2/pure Ti brazing joints[J]. Transactions of the China Welding Institution, 2019, 40(1): 80 − 83.

[8] Malzbender J, Zhao Y, Beck T. Fracture and creep of glass-ceramic solid oxide fuel cell sealant materials[J]. Journal of Power Sources, 2014, 246: 574 − 580. doi: 10.1016/j.jpowsour.2013.08.010

[9] Kiebach R, Engelbrecht, Grahl L, et al. An Ag based brazing system with tunable thermal expansion for the use as sealant for solid oxide cells[J]. Journal of Power Sources, 2016, 315: 339 − 350. doi: 10.1016/j.jpowsour.2016.03.030

[10] Chen H, Li L J, Kemps R, et al. Reactive air brazing for brazing for sealing mixed ionic electronic conducting hollow fibre membranes[J]. Acta Materialia, 2015, 88: 74 − 82. doi: 10.1016/j.actamat.2015.01.029

[11] Wang Z Y, Ba J, Qi J L, et al. Graphene-coated copper foam interlayer for brazing carbon/carbon composite niobium[J]. China Welding, 2019, 28(4): 33 − 38. doi: 10.1016/j.jpowsour.2008.10.117

[12] 孙磊, 陈明和, 谢兰生, 等. 纳米铝颗粒增强 Sn1.0Ag0.5Cu 钎料性能及激励[J]. 焊接学报, 2018, 39(8): 47 − 50. Sun Lei, Chen Minghe, Xie Lansheng, et al. Properties and mechanism of nano Al particles reinforced Sn1.0Ag0.5Cu solders[J]. Transactions of the China Welding Institution, 2018, 39(8): 47 − 50.

[13] Si X Q, Cao J, Ritucci I, et al. Enhancing the long-term stability of Ag based seals for solid oxide fuel/electrolysis application by simple interconnect aluminization[J]. International Journal of Hydrogen Energy, 2019, 44: 3063 − 3074. doi: 10.1016/j.ijhydene.2018.11.071

[14] Si X Q, Cao J, Song X G, et al. Reactive air brazing of YSZ ceramic with novel Al2O3 nanoparticles reinforced Ag-CuO-Al2O3 composite filler: microstructure and joint properties[J]. Materials and Design, 2017, 114: 176 − 184. doi: 10.1016/j.matdes.2016.10.062

[15] Zhou X L, Sun K N, Yan Y, et al. Investigation on silver electric adhesive doped with Al2O3 ceramic particles for sealing planar solid oxide fuel cell[J]. Journal of Power Sources, 2009, 192: 408 − 413. doi: 10.1016/j.jpowsour.2009.03.047

下载:

下载: