Simulation of microstructure evolution of weld pool and heat-affected zone during TIG welding of nickel-base alloy

-

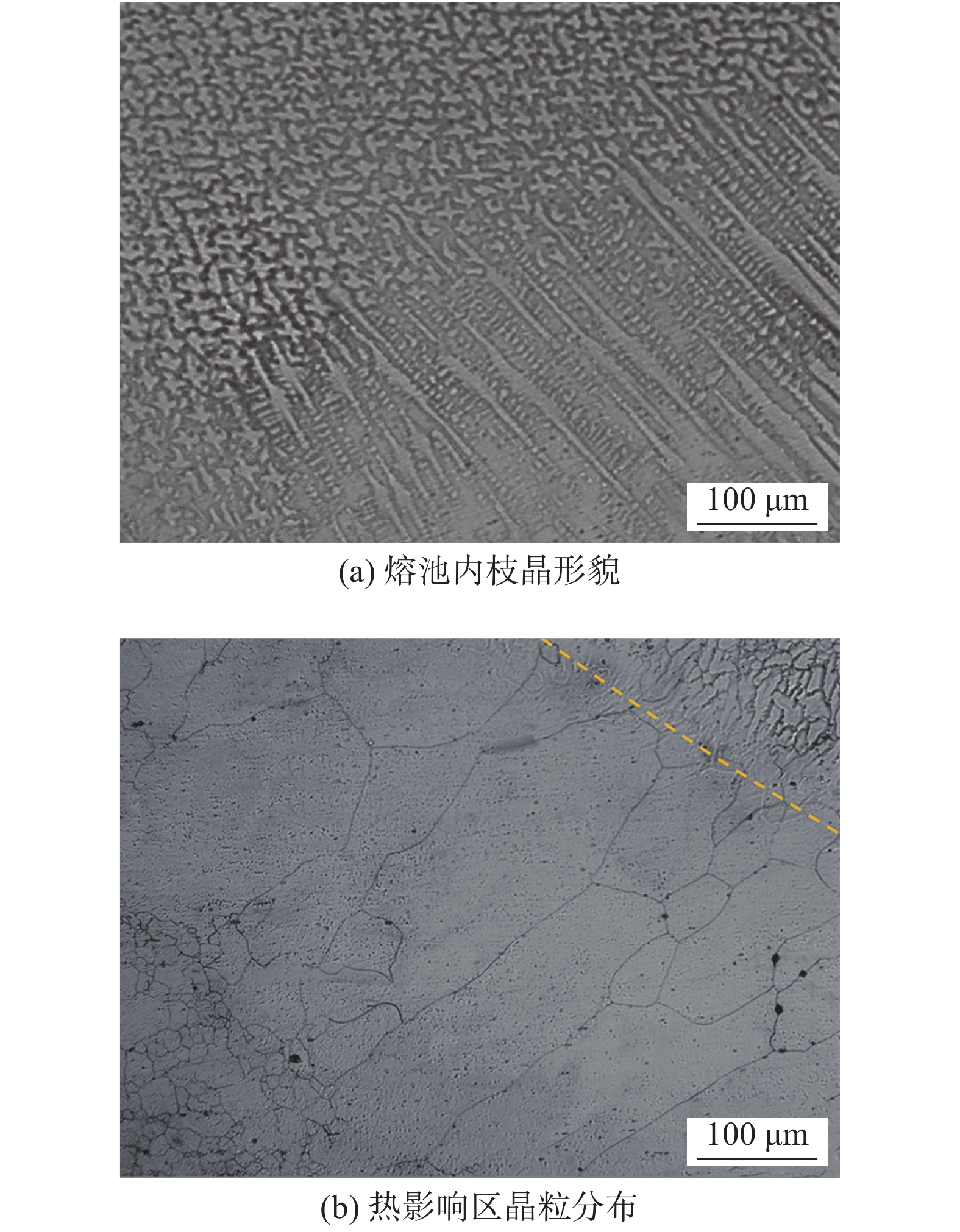

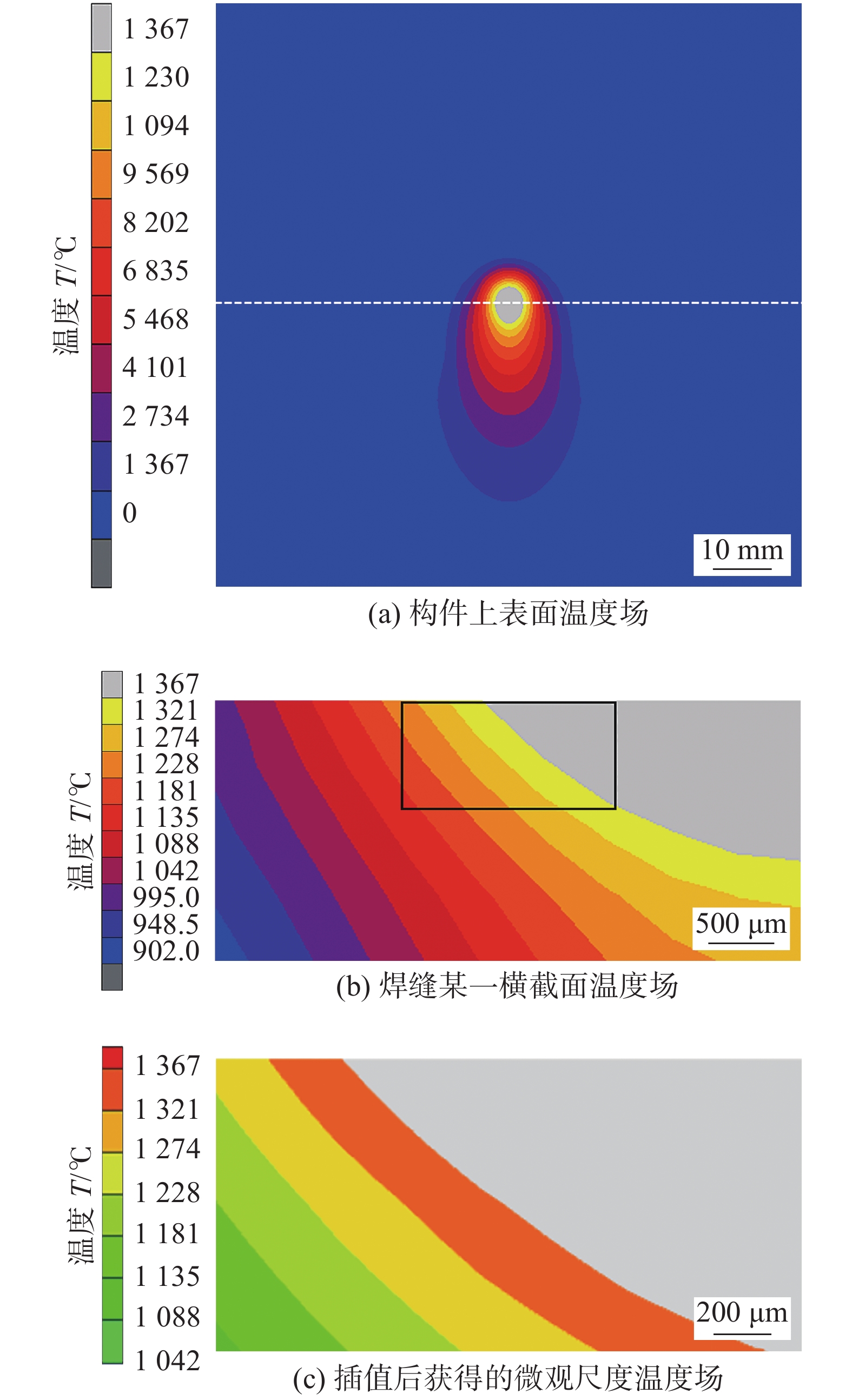

摘要: 基于枝晶生长动力学和晶粒长大理论,采用元胞自动机法(CA)建立了焊接熔池及热影响区的微观组织演变模型. 通过有限元模型计算了TIG焊接过程的温度场分布,并利用插值算法将热循环曲线应用于CA模型,计算了镍基合金TIG焊接熔池凝固过程枝晶生长及热影响区的晶粒长大. 结果表明,焊缝边缘的晶核主要以柱状晶的形式向焊缝中心生长,其最终形貌取决于半熔化母材晶粒上的联生结晶及不同取向枝晶间的竞争生长,焊缝中心为等轴晶组织. 焊接热影响区的晶粒长大使得熔池凝固形成的柱状晶组织粗大. 模拟结果与试验结果吻合较好.Abstract: Model for microstructure of molten pool and HAZ was developed based on the dendritic growth kinetics and the grain growth theory using the cellular automaton method.The temperature field during TIG welding process was calculated by the finite element model. And the thermal cycle curves were applied to the CA model to calculate the dendrite growth in the molten pool and grain growth in the heat-affected zone. The simulation results showed that the nuclei at the fusion boundary mainly grows in the form of columnar dendrite toward the center of the weld. The final morphology depends on the partially melted grains of base metal at the fusion boundary and competition growing between dendrite arrays with different orientation. The microstructure at the center of the molten pool was equiaxed dendrites. The grain growth in the heat-affected zone results in the columnar structure of the molten pool coarser. The simulation results agree well with the experimental results.

-

Keywords:

- cellular automata /

- molten pool /

- dendrite arrays /

- heat-affected zone /

- grain growth

-

-

表 1 微观组织模拟参数

Table 1 Parameters used in the Microscopic Simulation

液相线温度TL/K 液相线斜率mL 溶质分配系数k 液相扩散系数DL/(m2·s−1) 固相扩散系数DS/(m2·s−1) Gibbs Thomson系数Γ/(K·m) 初始溶质浓度C0(%) 1 640 −2.1 0.714 2.0 × 10−9 3.7 × 10−12 2.0 × 10−7 20 -

[1] Wei H L, Elmer J W, Debroy T. Origin of grain orientation during solidification of an aluminum alloy[J]. Acta Materialia, 2016, 115: 123 − 131. doi: 10.1016/j.actamat.2016.05.057

[2] Li X Q, Hao B H, Chen Y X, et al. The microscopic mechanical performance for nonuniform welded joint of nickel-based alloy with nanoindentation[J]. China Welding, 2019, 28(2): 29 − 34.

[3] Pavlyk V, Dilthey U. Simulation of weld solidification microstructure and its coupling to the macroscopic heat and fluid flow modelling[J]. Modelling and Simulation in Materials Science and Engineering, 2004, 12(1): 33 − 45. doi: 10.1088/0965-0393/12/1/S03

[4] Zhan X H, Dong Z B, Wei Y H, et al. Simulation of grain morphologies and competitive growth in weld pool of Ni-Cr alloy[J]. Journal of Crystal Growth, 2009, 311(23−24): 4778 − 4783. doi: 10.1016/j.jcrysgro.2009.09.008

[5] Han R H, Dong W C, Lu S P, et al. Modeling of morphological evolution of columnar dendritic grains in the molten pool of gas tungsten arc welding[J]. Computational Materials Science, 2014, 95: 351 − 361. doi: 10.1016/j.commatsci.2014.07.052

[6] 张敏, 徐蔼彦, 汪强, 等. Fe-C合金焊接熔池凝固过程CET转变的数值模拟[J]. 焊接学报, 2016, 37(2): 5 − 8. Zhang Min, Xu Aiyan, Wang Qiang, et al. Numerical simulation of CET transformation in the solidificationof Fe-C alloy weld pool[J]. Transactions of the China Welding Institution, 2016, 37(2): 5 − 8.

[7] 张敏, 周玉兰, 薛覃, 等. Ti-45Al合金焊接熔池凝固过程数值模拟[J]. 焊接学报, 2018, 39(3): 6 − 10. doi: 10.12073/j.hjxb.2018390058 Zhang Min, Zhou Yulan, Xue Qin, et al. Numerical simulation of solidification process of Ti-45Al alloy weld pool[J]. Transactions of the China Welding Institution, 2018, 39(3): 6 − 10. doi: 10.12073/j.hjxb.2018390058

[8] 宋奎晶. TA15钛合金TIG焊热影响区组织模拟及力学本构关系研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. [9] Rappaz M, Gandin Ch A, Desbiolles J L, et al. Prediction of grain structures in various solidification processes[J]. Metallurgical and Materials Transactions A, 1996, 27(3): 695 − 705. doi: 10.1007/BF02648956

[10] Gu C, Wei Y H, Liu R P, et al. Effect of temperature and fluid flow on dendrite growth during solidification of Al-3 Wt Pct Cu alloy by the two-dimensional cellular automaton method[J]. Metallurgical and Materials Transactions B, 2017, 48(6): 3388 − 3400. doi: 10.1007/s11663-017-1060-3

[11] He Y Z, Ding H L, Liu L F, et al. Computer simulation of 2D grain growth using a cellular automata model based on the lowest energy principle[J]. Materials Science & Engineering A, 2006, 429(1-2): 236 − 246.

[12] 金朝阳, 俞栋华, 吴欣桐. 热挤压态纯镁晶粒长大行为的元胞自动机模拟[J]. 塑性工程学报, 2016, 23(6): 216 − 222. Jin Zhaoyang, Yu Donghua, Wu Xintong. Simulation of grain growth behavior of hot-extruded pure magnesium by cellular automata[J]. Journal of Plasticity Engineering, 2016, 23(6): 216 − 222.

[13] 陈晶, 李少华, 颜飞雪, 等. JMatPro软件在GH3039真空扩散焊工艺研究中的应用[J]. 热加工工艺, 2018, 47(11): 232−235. Chen Jing, Li Shaohua, Yan Feixue, et al. Application of JMatPro software in research of GH3039 vacuum diffusion welding process[J].Hot Working Technology, 2018, 47(11): 232−235.

[14] Dong Z B, Song K J, Wang S J, et al. Solute redistribution with shear flow in molten pool of Ni-Cr alloy[J]. Journal of Materials Science & Technology, 2011, 27(2): 183 − 188.

-

期刊类型引用(1)

1. 吕志峰, 张金生, 王仕成, 赵欣, 李婷. 基于智能优化算法和有限元法的多线圈均匀磁场优化设计. 北京航空航天大学学报. 2019(05): 980-988 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: