Mechanism of weld formation using double pulsed variable polarity plasma arc welding of high strength aluminum alloy

-

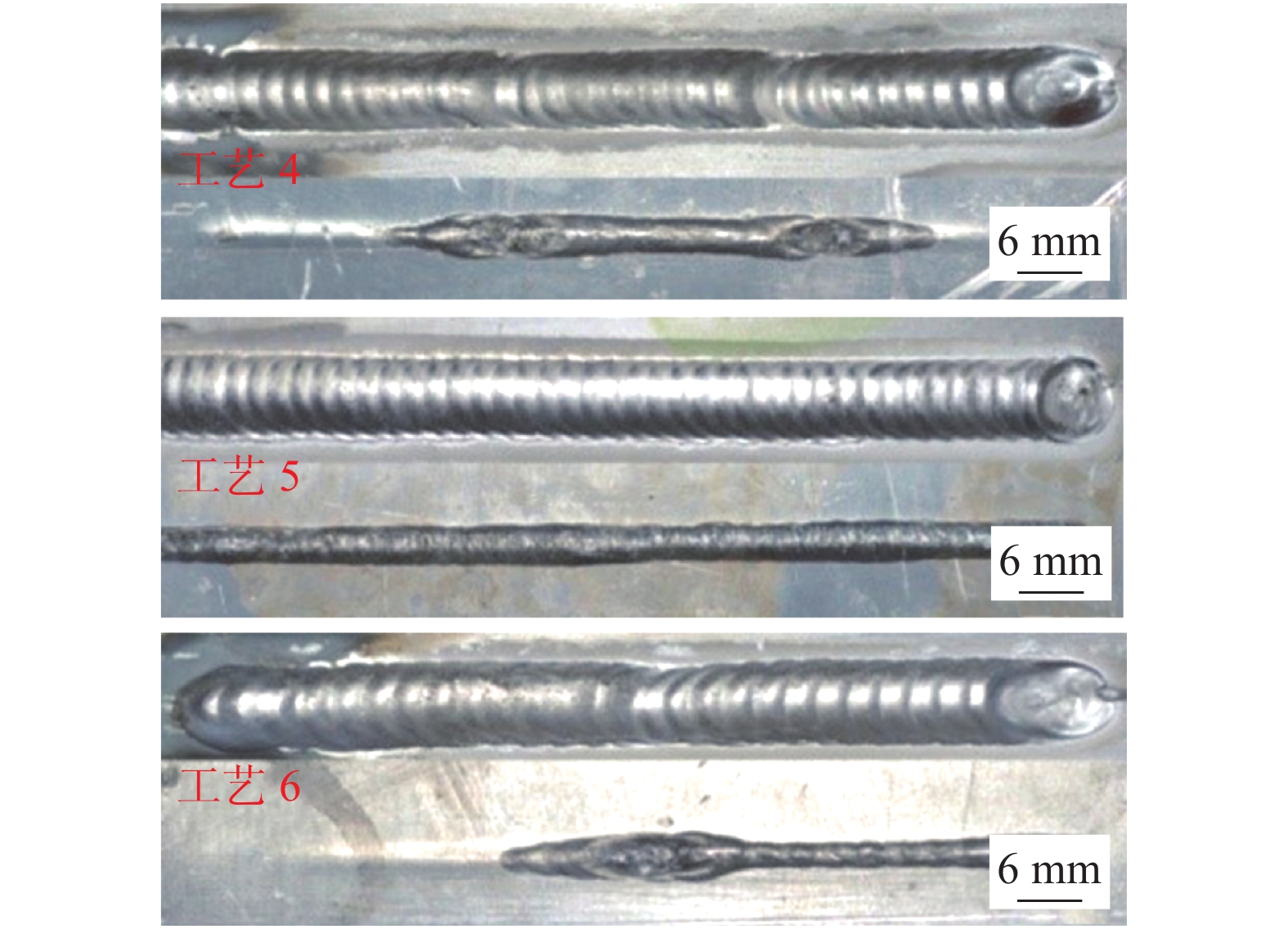

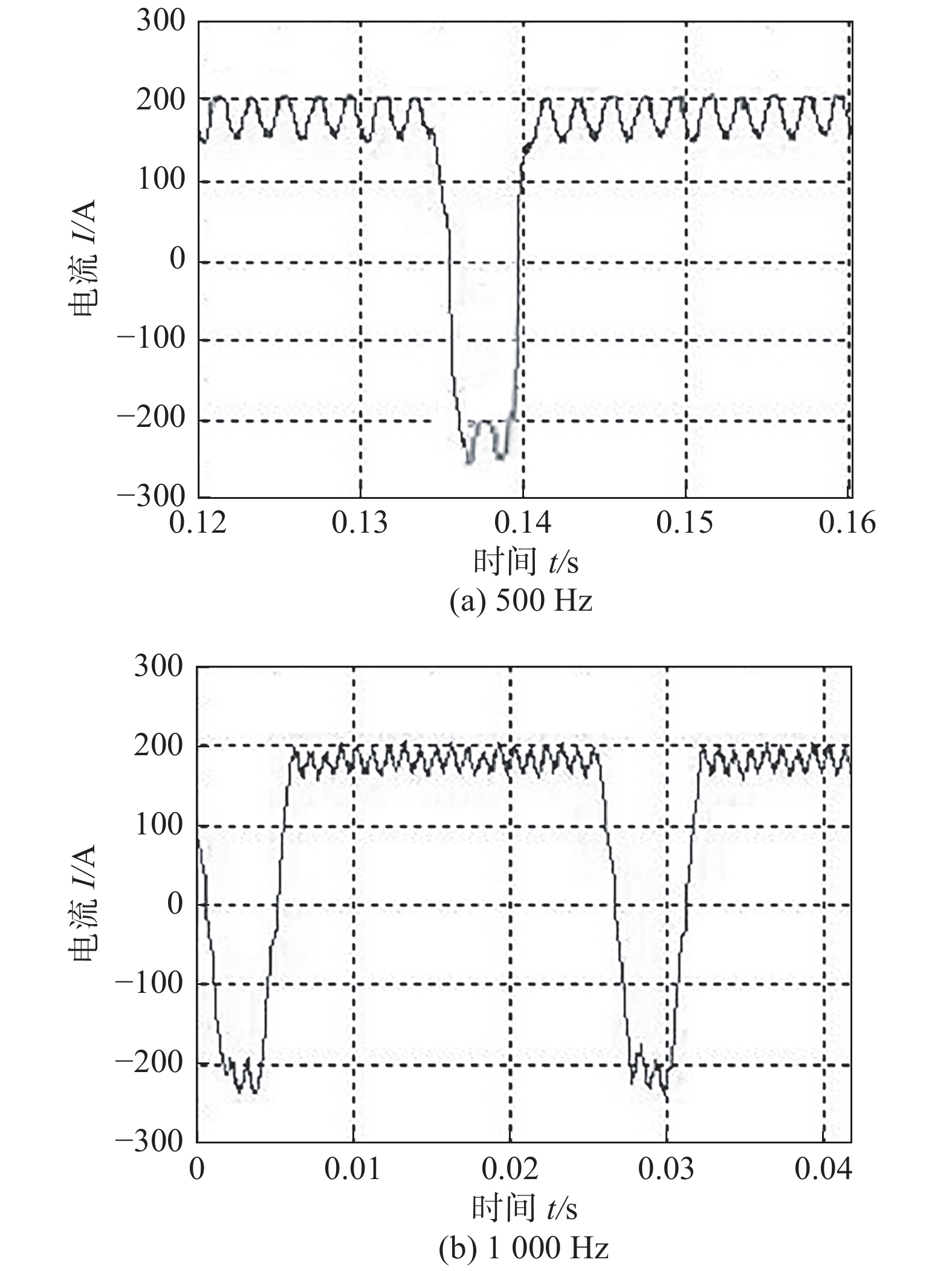

摘要: 建立双脉冲VPPA(variable polarity plasma arc)焊接系统,进行7A52高强铝合金双脉冲VPPA焊接工艺试验,研究低频脉冲调制叠加高频脉冲对VPPA焊接过程中焊缝成形和焊缝力学性能的影响. 结果表明,低频脉冲周期性振荡液态熔池,可获得表面饱满的鱼鳞纹焊缝;高频脉冲使电弧更为集中,有效地提高了电弧能量密度,穿透力加强;双脉冲耦合振荡加强了对熔池的搅动作用细化了铝合金焊缝晶粒. 焊接接头抗拉强度达到384.13 MPa,相比VPPA焊接接头强度提高了10.21%左右;焊接接头断面收缩率和断后伸长率均有一定程度的提高. 铝合金双脉冲VPPA焊接工艺提高了焊接接头力学性能.Abstract: By setting up a double pulse variable polarity plasma arc welding system, through process test of high strength aluminum alloy welding with double pulse VPPA (variable polarity plasma arc), weld formation and mechanical properties of welded joints of low frequency pulse modulation superposition high frequency pulse were studied. The results show that the low frequency pulse can obtain the fish scales weld by the periodic oscillating liquid molten pool. The high frequency pulse causes the arc more concentrated and improves effectively the energy density of the arc, thus enhance the arc force. Coupled oscillation of the double pulse strengthen the stirring of the molten pool, and refine the grain sizes of the aluminum alloy weld. The tensile strength of welded joints reaches 384.13 MPa, compared with VPPA welded joints, the strength is increased by about 10.21%. And the percentage reduction of area and percentage elongation of welded joints have been improved to a certain degree. The double pulse VPPA welding process improves the mechanical properties of the welded joints of the aluminum alloy.

-

Keywords:

- variable polarity waveform /

- pulse modulation /

- weld formation

-

0. 序言

在波导器件中为了保证微带电路板良好的接地性能,需要将其与铝合金壳体进行大面积装接. 传统的螺钉连接不能提供可靠、连续、一致性好的连接,并且还会严重影响微带电路板的电性能. 目前,工程上普遍采用胶接和低温钎焊的方式实现铝合金组件与微带电路板的大面积焊接[1]. 相较于胶接,采用低温钎焊的方法获得的接头强度校高,且接头的耐候性、导电性较好.

铝合金低温钎焊时,其表面存在致密氧化铝薄膜难以完全去除,导致钎料对铝合金的润湿性较差. 目前常利用电镀、化学镀或物理气相沉积等方法在铝合金表面制备Ni,Cu,Ag等金属层以改善铝合金表面的润湿性从而实现铝合金与其它母材的低温钎焊连接[2-4],但是上述方法存在成本高、污染严重[5]、膜基结合力不足[3]等问题.

近年来,表面工程技术发展迅速,为实现铝合金表面金属层的制备提供了新的策略. 李文亚等人[6]和聂海杰等人[7]使用冷喷涂技术在合金基板表面制备了金属涂层,进而实现了异质材料的钎焊连接. 然而,冷喷涂设备昂贵,且喷涂时较大的冲击力不适用于薄板构件,实际应用中具有一定的局限性. 值得重视的是,高速电弧喷涂技术因其安全、高效、经济性显著等特点[8-10],在铝合金表面耐磨、耐腐蚀涂层的制备中被广泛应用,其中多用到Fe,C,Ni,Al,Mg,Mo等元素[11-13],而使用电弧喷涂技术在铝合金表面制备用于低温钎焊的Ag基涂层却鲜有报道.

基于上述研究背景,使用电弧喷涂技术在铝合金表面制备了Ag合金涂层. 鉴于纯Ag的强度较低、Ag与Al之间的反应活性较差,而Ni与Al之间的冶金反应活性强,因此考虑选用Ag-Ni合金作为低温钎焊改性涂层材料,Ni-Al合金作为打底层材料. 在铝合金基板上制备Ag-Ni单一涂层和Ni-Al/Ag-Ni复合涂层,对比研究了两种结构涂层的显微形貌、界面结合特性及钎焊性能,并分析了涂层及钎焊接头在拉、剪载荷下的失效机制. 该工艺对波导器件中微带电路板与铝合金壳体间的大面积钎焊连接具有重要的理论指导及工程借鉴价值.

1. 试验方法

使用厚度为5 mm的5A06铝合金作为基板材料.电弧喷涂丝材使用Ni-5%Al(简称Ni-5Al)和Ag-15%Ni(简称Ag-15Ni)合金丝,直径均为2 mm. 选用T2紫铜和Sn-37Pb共晶钎料作为涂层钎焊试验的母材和钎料.

涂层制备前先对基板进行预处理. 使用线切割机将5 mm厚的5A06铝合金基板裁制出直径5和25 mm两种尺寸的试件,随后将试件放入无水乙醇中超声清洗5 min,吹干后进行喷砂粗化以净化表面并增大涂层与基板结合面积. 将粗化后的试件预热至80 ℃,随后使用武汉理工大学自研的高速电弧喷涂机制备涂层. 预热完成后,使用武汉理工大学自研的高速电弧喷涂机制备涂层. 喷涂参数如表1所示,其中电压确保正常引弧,电流确定送丝速度[14],再结合喷枪移动速度和喷枪口到工件距离来控制所需涂层的质量及厚度. 电弧喷涂中使用的压缩气体为纯N2,以尽量避免涂层的氧化. 所制备的Ag-15Ni单一涂层和Ni-5Al/Ag-15Ni复合涂层厚度均为80 μm.

表 1 涂层的制备参数Table 1. Preparation parameters of the coatings涂层类型 电弧喷涂

丝材喷涂电压

U/V喷涂电流

I/A喷枪移动速度

v/(m·min−1)喷枪口到工件

距离S/cm气体压力

P/MPa气源

类型Ag-15Ni单一涂层 Ag-15Ni 34 280 10 15 0.6 纯N2 Ni-5Al/Ag-15Ni

复合涂层Ni-5Al 34 150 10 18 0.6 纯N2 Ag-15Ni 34 280 12 15 0.6 纯N2 试验中使用Sn-37Pb焊膏将带有涂层的铝合金试件与T2紫铜试件进行低温钎焊连接,试件直径均为5 mm. 钎焊试验在深圳科晶GSL-1100X型真空管式炉内进行,试件上方依靠螺栓提供1 250 N的正压力. 钎焊时以5 ℃/min的速度升温至130 ℃保温30 min,再以3 ℃/min的速度升温至220 ℃保温8 min,随后随炉冷却,待炉温降至100 ℃时取出样件完成钎焊工艺.

采用JSM-7500F型扫描电子显微镜(scanning electron microscope, SEM)和JXA-8230型电子探针显微分析仪(electron probe micro analyzer, EPMA)观察涂层和钎焊接头的横截面显微结构,并使用INCA X-Act型能谱仪(energy dispersive spectroscopy, EDS)和D8 Advance型X射线衍射分析仪(X-ray diffraction, XRD)进行物相分析. 参照GB/T 8642—2002《热喷涂 抗拉结合强度的测定》,利用E-7高温结构胶将带有涂层的铝合金试件的正、反两面分别与不锈钢柱粘接在一起,并使用REGER-100型万能试验机测试涂层的结合强度,试件直径均为25 mm;按照GB/T 11363—2008《钎焊接头强度试验方法》使用WCW-100型万能试验机测试涂层钎焊接头的抗剪强度. 所有强度测试中,夹具双向拉伸速率均为1 mm/min,测试结果均取3个样品的平均值.

2. 试验结果与分析

2.1 涂层的形貌及组成成分

图1为Ag-15Ni涂层的宏观及微观形貌. 从图1a可以看出,Ag-15Ni涂层表面一致性高,存在一定的粗糙度,有利于熔融钎料在涂层表面的润湿铺展.从图1b可以看出,涂层整体均匀致密、无明显分层现象,主要由白色相、少量球状和条状的浅灰色相以及少量孔隙组成. 表2为图1b中Ag-15Ni涂层标记区域的能谱结果. 涂层中浅灰色相为富Ni相(点1),白色相为富Ag相(点2). 因为Ag与Ni具有极差的固溶度,Ag-Ni合金相难以发现. 从图2的XRD结果同样证明,Ag-15Ni涂层的成分主要是Ni,Ag单质,未检测到其它合金相及氧化物. 图3为图1b中Ag-15Ni涂层与基板界面处元素线扫描结果,界面处未发现O元素含量的波动,可知该处没有裂纹和夹杂,界面结合良好;界面处未发现Ni,Ag元素含量的梯度变化,说明未发生元素扩散现象.

表 2 Ag-15Ni涂层内局部位置的元素含量(原子分数, %)Table 2. Elemental compositions in local positions inside the Ag-15Ni coating layer测试点 Ni Al Ag O 1 97.36 — 2.64 — 2 7.27 ― 92.73 ― 低温钎焊时因Ag与Sn之间的反应速度快,银层易被完全消耗引起反润湿现象并造成界面剥离. 此外,实际应用中因Ag与Al的电位相差较大,在恶劣环境中易于界面处发生电化学腐蚀失效[15]. 因此,有必要添加过渡涂层来避免上述问题. 考虑到Ni/Al之间界面能较低、易形成冶金结合,且Ni-Al合金涂层对铝基底的附着力好[16],故选用了Ni-5Al合金作为过渡涂层.

图4为Ni-5Al涂层的宏观及微观形貌. 从图4a可以看出,涂层表面一致性高,存在一定的粗糙度,有利于Ag-15Ni涂层在其表面的涂敷,使涂层和基板结合更为紧密. 从图4b可看出,微观上Ni-5Al涂层结构致密、组分单一,主要由白色相和少量深灰色相组成. 表3为图4b中Ni-5Al涂层标记区域的能谱分析结果. 涂层中的深灰色相(点1)包含Al,Ni,O 3种元素,白色相为富Ni相(点2). 图5为上述Ni-5Al涂层的XRD结果. 涂层主要由Ni,Al单质组成,未检测出其它化合物. 在电弧喷涂过程中,Ni-5Al丝材端部被快速加热至熔化,部分铝会从镍固溶体中析出. 活泼的铝与熔融的镍易在空气中发生反应,可能生成Al2O3,NiO以及Ni-Al金属间化合物. 由于在喷涂过程中使用的压缩气为N2,较低的氧含量以及合金中较低的铝含量使得生成的化合物含量显著减少. Ni-5Al涂层的XRD分析图谱中未检测到化合物的衍射峰.

表 3 Ni-5Al涂层内部局部位置的元素含量(原子分数, %)Table 3. Elemental compositions in local positions inside the Ni-5Al coating layer测试点 Ni Al Ag O 1 13.59 56.28 ― 30.13 2 88.31 11.69 ― ― 图6为图4b中Ni-5Al涂层与铝基板界面处的元素线扫描结果. 从图6可以看出,界面处未发现O元素含量的明显波动,说明涂层与基体结合紧密,界面没有裂纹和夹杂形成. 此外,界面处的Ni,Al元素含量存在一定的梯度变化,这意味着Ni-5Al涂层与铝基板间发生了元素扩散.

Wang等人[17]在6061-T6铝合金表面制备了Ni-5%Al/Ni-20%Al(质量分数)复合涂层,在厚度约为200 μm的Ni-5Al打底层中检测到NiAl和Al2O3相,这两种相的生成均会释放大量的热. 因此当熔融液滴颗粒到达铝基板表面时热量损失减少,基板与涂层之间发生了微冶金结合. 在Wang等人[18]的另一研究中,通过对Ni-5%Al/Ni-20%Al(质量分数)复合涂层进行不同程度的热处理,实现了Ni-5%Al(质量分数)打底层与铝基板间界面冶金反应层的生长,有效增强了涂层与基板的结合强度(达到了55.6 MPa). 因此,研究中制备的Ni-5Al涂层内深灰色相的存在以及涂层与基板界面处元素的梯度变化可以说明,Ni-5Al涂层与铝基板间存在局部冶金结合.

图7为Ni-5Al/Ag-15Ni复合涂层的截面显微形貌.从图7可以看出,引入Ni-5Al打底层后依然可以获得高质量涂层. 复合涂层整体厚度均匀、致密度高,涂层与涂层、涂层与基板间均实现了紧密结合. 为了探究涂层的结合情况,试验中对Ni-5Al/Ag-15Ni涂层内部的元素含量进行了分析,结果如表4所示.Ag-15Ni涂层中靠近Ni-5Al/Ag-15Ni界面的部位(点1)相比中间部位(点2)具有更高的Ni元素含量. 图8为图7b中Ni-5Al涂层与Ag-15Ni涂层界面处的线扫描结果. 两种涂层界面处Ni,Ag元素含量均存在明显的梯度变化,且未发现O元素含量的波动. 这说明界面处没有裂纹和夹杂存在,两种涂层结合紧密,发生了元素扩散.

表 4 Ni-5Al/Ag-15Ni复合涂层内部局部位置的元素含量 (原子分数, %)Table 4. Elemental compositions in local positions inside the Ni-5Al/Ag-15Ni composite coating layer测试点 Ni Al Ag O 1 21.85 ― 78.15 ― 2 8.80 ― 91.20 ― 2.2 涂层的结合强度及结合机制

Ag-15Ni单一涂层和Ni-5Al/Ag-15Ni复合涂层在涂层与基板、涂层与涂层的界面处没有发现裂纹等缺陷,具有良好的结合效果. 在实际应用中,结合强度是涂层质量的一个重要评价指标. 为了验证涂层的可靠性,使用粘接拉伸法进行了涂层结合强度测试,结果如图9所示. 从图9可以看出,Ni-5Al/Ag-15Ni复合涂层的结合强度为42 MPa,而Ag-15Ni单一涂层的结合强度为40 MPa,前者具有较佳的结合性能. 为了探究两种涂层结合强度出现差异的原因,试验中分别观察了涂层/基体界面以及涂层拉伸断口的显微形貌.

图10为不同涂层界面处SEM形貌.图11为涂层拉伸断口形貌. 图10a为Ag-15Ni涂层与铝基板界面处SEM图. 从图10a可知,界面结合紧密,界线清晰,未发现明显的扩散层. 从图11a可知,Ag-15Ni单一涂层拉伸断裂时发生涂层的大面积脱落,仅在铝基板边缘出现局部残留. 这说明Ag-15Ni涂层与铝基板之间没有发生冶金结合,连接方式为单一的机械咬合. 图10b和图10c分别为Ni-5Al涂层与铝基板、Ni-5Al过渡层与Ag-15Ni涂层界面处的SEM图. 从图10b和图10c可知,涂层与基体、涂层与涂层之间均实现了良好的界面结合,且界面附近存在明暗梯度变化;特别地,在图10c所示的Ni-5Al过渡层与Ag-15Ni涂层界面处可以明显观察到一层浅灰色的扩散层,说明了界面处元素扩散现象的发生. 从图11b可知,复合涂层拉伸断裂时表现为Ag-15Ni涂层的脱落. 与Ag-15Ni单一涂层不同的是,复合涂层中脱落的Ag-15Ni涂层是不完整、非连续的,断裂时伴随少量Ni-5Al过渡层的剥离.这种剥离方式说明复合涂层中Ni-5Al过渡层与铝基板、Ni-5Al过渡层与Ag-15Ni涂层之间局部存在因冶金结合而导致的粘连现象. 因此,复合涂层的连接方式为机械咬合伴随局部冶金结合,这也是其结合强度比Ag-15Ni单一涂层更高的原因.

2.3 涂层的低温钎焊行为

试验中使用Sn-37Pb焊膏将两种涂层与T2紫铜间进行了低温钎焊连接,接头的截面形貌如图12所示. 由图12可知,两种涂层与T2紫铜间的钎焊效果良好,接头中无明显裂纹与孔洞发现. 表5为图12中不同涂层钎焊接头内标记区域的能谱结果. 结合能谱结果及已有研究可知[19],在Ag-15Ni涂层与Sn-37Pb钎料界面处(点1和点3),以及在Ag-15Ni涂层内部均发现了Ag3Sn相的生成(点4). T2紫铜中的Cu元素已扩散至Ag-15Ni涂层内部,并在其中形成了(Cu, Ni)6Sn5相(点2). 特别地,在Ag-15Ni涂层中形成了一些白色区域(点5),通过对其进行EDS分析发现,这些区域为Sn-Pb过共晶合金. 上述结果表明,Ag-15Ni涂层特殊的显微结构以及Ag-Sn之间较强的反应活性,使得熔融Sn-37Pb钎料能与Ag-15Ni涂层充分反应并渗入其间,展现出了优良的焊接性.

表 5 不同涂层钎焊接头中局部位置的元素含量(原子分数,%)Table 5. Elemental compositions in local positions inside the soldered joints with different coating layer测试点 Ni Cu Ag Sn Pb 主要物相 1 ― ― 66.02 31.57 2.41 Ag3Sn 2 6.99 41.66 ― 44.74 6.61 (Cu,Ni)6Sn5 3 ― ― 76.16 23.84 ― Ag3Sn 4 ― ― 73.55 26.45 ― Ag3Sn 5 ― ― ― 37.57 62.43 Sn-Pb过共晶 为了对比两种涂层与T2紫铜钎焊接头的连接性能,分别测试了两种钎焊接头的抗剪强度,结果如图13所示. 从图13可知,Ag-15Ni单一涂层钎焊接头的抗剪强度为26 MPa,而Ni-5Al/Ag-15Ni复合涂层钎焊接头的抗剪强度为31 MPa,后者较前者高出5 MPa. 图14为两种涂层与T2紫铜钎焊接头的断口截面形貌. 由于涂层与Sn-37Pb钎料界面处存在大量Ag3Sn脆性相,所以两种钎焊接头的失效位置均主要发生在Ag-15Ni涂层与Sn-37Pb钎料的界面处,并伴随局部Ag-15Ni涂层与基材界面(图14a)或打底层界面(图14b)的撕裂剥离. 虽然两种接头的失效方式相似,但是抗剪强度却有一定差异,其原因可能与熔融Sn-37Pb钎料渗入Ag-15Ni涂层中改变了涂层的应力状态有关.

在电弧喷涂过程中,熔融金属颗粒快速冲击异质基材表面并迅速凝固必然会在涂层中产生较大的内应力. 低温钎焊时,熔融Sn-37Pb钎料与Ag-15Ni涂层间的充分反应会改变Ag-15Ni涂层中的应力状态. 对于Ag-15Ni单一涂层而言,其与铝基板的连接方式为机械咬合,当涂层内部的应力状态发生变化时,涂层与基材间的结合力会有所弱化,甚至出现反润湿现象,从而降低钎焊接头的剪切能力;而对于复合涂层而言,Ag-15Ni涂层与Ni-5Al过渡层间形成了局部冶金结合,并且熔融Sn基钎料在Ni合金表面具有一定的润湿性. 因此,Sn-37Pb钎料与Ag-15Ni涂层间的充分反应不会过度影响涂层与基材间的界面结合强度,最终体现在Ni-5Al/Ag-15Ni复合涂层钎焊接头相比Ag-15Ni单一涂层钎焊接头具有更高的抗剪强度.

3. 结论

(1) 使用电弧喷涂技术可以有效解决铝合金壳体与微带电路板之间大面积低温钎焊连接中存在的铝合金表面润湿性差的问题. 在5A06铝合金表面所制备的Ag-15Ni单一涂层和Ni-5Al/Ag-15Ni复合涂层厚度均为80 μm,两种涂层致密、均匀,与基材间实现了紧密结合.

(2) Ag-15Ni单一涂层与铝基板间的连接方式为机械咬合,平均结合强度为40 MPa;复合涂层中Ni-5Al过渡层与铝基板、Ag-15Ni涂层间的连接方式为机械咬合伴随局部微冶金结合,平均结合强度为42 MPa. Ni-5Al过渡层的添加使复合涂层获得了更加优异的抗拉能力.

(3) 使用Sn-37Pb钎料实现了两种涂层与T2紫铜间的低温钎焊连接. Ag-15Ni单一涂层钎焊接头的抗剪强度为26 MPa,而Ni-5Al/Ag-15Ni复合涂层钎焊接头的抗剪强度为31 MPa,强度的差异归因于钎料与Ag-15Ni涂层间的充分反应改变了涂层与基材间的应力状态.

-

表 1 双脉冲VPPA焊接参数

Table 1 Welding process parameters of pulse VPPA

编号 正极性平均电流Iz /A 反极性平均电流If /A 高频脉冲频率fg /Hz 低频冲频率fd /Hz 脉冲占空比D ( %) 工艺1 200 245 500 0.5 50 工艺2 200 245 500 2 50 工艺3 200 245 500 1 50 工艺4 200 245 250 1 50 工艺5 200 245 500 1 50 工艺6 200 245 1000 1 50 表 2 脉冲VPPA焊接接头力学性能

Table 2 Welding joint mechanical properties of pulse VPPA

试件编号 抗拉强度Rm / MPa 断后伸长率A(%) 断面收缩率Z(%) 脉冲1 387.06 8.83 15.37 脉冲2 384.72 7.73 13.42 脉冲3 380.61 7.33 16.13 平均值 384.13 7.96 14.97 典型1 338.42 3.83 14.02 典型2 332.33 4.67 13.89 典型3 331.38 3.95 13.21 平均值 334.04 4.15 13.71 -

[1] Tomsic M, Barhorst S. Keyhole plasma arc welding of aluminum with variable polarity power[J]. Welding Journal, 1984, 63(2): 25 − 32.

[2] Nunes A C, Bayless E O, Jones C S, et al. Variable polarity plasma arc welding on the space shuttle external tank[J]. Welding Journal, 1984, 63(9): 27 − 35.

[3] 励克勤, 沈江红, 谢峰, 等. 变极性等离子弧焊接系统的研制[J]. 宇航材料工艺, 2002, 32(6): 39 − 42. doi: 10.3969/j.issn.1007-2330.2002.06.010 Li Keqin, Shen Jianghong, Xie Feng, et al. Development of variable polarity plasma arc welding equipment[J]. Aerospace Materials & Technology, 2002, 32(6): 39 − 42. doi: 10.3969/j.issn.1007-2330.2002.06.010

[4] Wang S C, Lefebvre F, Yan J L, et al. VPPA welds of Al-2024 alloys: analysis and modelling of local microstructure and strength[J]. Materials Science and Engineering: A, 2006, 431(1): 123 − 136.

[5] Fuerschbach P W. Cathodic cleaning and heat input in variable polarity plasma arc welding of aluminum[J]. Welding Journal, 1998, 77(2): 76 − 85.

[6] 韩永全, 陈树君, 殷树言, 等. 大厚度铝合金变极性等离子弧穿孔立焊技术[J]. 机械工程学报, 2006, 42(9): 144 − 148. doi: 10.3321/j.issn:0577-6686.2006.09.025 Han Yongquan, Chen Shujun, Yin Shuyan, et al. Variable polarity plasma arc welding process for thick aluminum alloy[J]. Chinese Journal of Mechanical Engineering, 2006, 42(9): 144 − 148. doi: 10.3321/j.issn:0577-6686.2006.09.025

[7] 李国伟, 陈芙蓉, 韩永全, 等. 高强铝合金脉冲变极性等离子弧焊接头组织与性能[J]. 焊接学报, 2016, 37(11): 27 − 30. Li Guowei, Chen Furong, Han Yongquan, et al. Microstructure and mechanical properties of pulse VPPA welded high-strength aluminum alloy joints[J]. Transactions of the China Welding Institution, 2016, 37(11): 27 − 30.

[8] 李玉龙, 从保强, 齐铂金, 等. 不同脉冲频率条件下2219-T87高强铝合金焊缝成形行为[J]. 焊接学报, 2013, 34(12): 67 − 70. Li Yulong, Cong Baoqiang, Qi Bojin, et al. Weld appearance of 2219-T87 high strength aluminum alloy at different pulse frequency[J]. Transactions of the China Welding Institution, 2013, 34(12): 67 − 70.

[9] Praveen P, Yarlagadda P K D V, Kang M J. Advancements in pulse gas metal arc welding[J]. Journal of Materials Processing Technology, 2005, 164(20): 1113 − 1119.

[10] 邱灵, 杨春利, 林三宝, 等. 高频脉冲变极性焊接工艺性能研究[J]. 焊接, 2007(7): 35 − 38. doi: 10.3969/j.issn.1001-1382.2007.07.013 Qiu Ling, Yang Chunli, Lin Sanbao, et al. Technology properties of variable polarity arc welding with high frequency pulsed current[J]. Welding & Joining, 2007(7): 35 − 38. doi: 10.3969/j.issn.1001-1382.2007.07.013

[11] 春兰, 韩永全, 陈芙蓉, 等. 铝合金脉冲变极性等离子弧焊接工艺[J]. 焊接学报, 2016, 37(1): 29 − 32. Chun Lan, Han Yongquan, Chen Furong, et al. Pulse variable polarity plasma arc welding technology of aluminum alloy[J]. Transactions of the China Welding Institution, 2016, 37(1): 29 − 32.

-

期刊类型引用(5)

1. 李岩,刘琪,李艳彪,张艳峰,田孟良,吴志生. 薄壁GH3536尾喷管组焊变形控制工艺优化仿真. 稀有金属材料与工程. 2023(08): 2775-2782 .  百度学术

百度学术

2. 王来臻,段瑞彬,李宝健,龙斌,王克宽,白云龙. 薄板焊接变形感应热矫正线圈方案选择. 石油工程建设. 2022(02): 53-60 .  百度学术

百度学术

3. 刘文杰,邢彦锋. Q345NQR2耐候钢薄板CMT焊接变形分析. 电焊机. 2020(01): 51-56+126 .  百度学术

百度学术

4. 董曼淑,刘龙,董志波. 重型复杂结构件过渡槽焊接变形工艺研究. 机械制造文摘(焊接分册). 2020(02): 34-39 .  百度学术

百度学术

5. 许谦,胡广旭,董志波,许红祥,方洪渊. QTT天线轨道重力弯矩下多层多道焊角变形预测. 焊接学报. 2020(08): 10-13+97-98 .  本站查看

本站查看

其他类型引用(4)

下载:

下载: