Effect of ultrasonic power on microstructure and properties of 2219-T351 aluminum alloy friction stir welding joint

-

摘要: 采用搅拌摩擦焊和不同功率的超声辅助搅拌摩擦焊对2219-T351铝合金进行焊接试验,测量焊接温度和焊接压力,对焊接接头的微观组织、显微硬度和力学性能进行分析,研究了加入不同超声功率后焊缝的组织性能和材料流动性. 结果表明,超声能降低焊接温度,随着超声功率增加减小的幅度越大. 加入了超声后,焊缝微观组织更加均匀,底部材料的流动情况得到改善,焊缝区有更多的强化相残留,焊接接头的显微硬度、抗拉强度及断后伸长率在加入超声后均有提高,在加入2.25 kW的超声功率时达到最高,最高拉伸强度为331 MPa,可达到母材的80%左右.Abstract: Aluminum alloy 2219-T351plates were welded by friction stir welding and ultrasonic assisted friction stir welding with different power. The welding temperature and welding pressure were investigated. Microstructure, microhardness and mechanical properties of welds under different ultrasonic powers were analyzed. The microstructure and material fluidity of the weld with different ultrasonic power were researched. Experimental results showed that Ultrasonic energy can reduce the welding temperature and welding force. With the action of ultrasound, the microstructure of the weld is more uniform, and the fluidity of the bottom material is improved. There is more residual reinforcement phase in the weld zone. The microhardness, tensile strength and elongation of the welded joints are all improved under ultrasonic. All the magnitudes reached the highest when adding 2.25 kW ultrasonic power. The highest tensile trength is 331 MPa, which can reach about 80% of the base metal.

-

Keywords:

- friction stir welding /

- ultrasonic /

- welding temperature /

- microstructure /

- mechanical properties

-

0. 序言

2219铝合金是一种热处理强化型变形铝合金,具有比强度高,低温与高温力学性能好,断裂韧度高,抗应力腐蚀性能好等特点,在航空航天以及军工装备等领域有着广泛的应用[1]. 在工业生产中焊接是一种重要的金属连接技术,然而2219铝合金的应用由于其较差的可焊性被极大的限制.

搅拌摩擦焊(FSW)作为一种固相相连的焊接技术已广泛应用于铝、镁、铜及其合金的焊接[2],因其固态焊接的特点可以有效的避免熔焊过程中产生的气孔、夹渣、疏松及大变形等缺陷,故非常适用于低熔点的轻合金. 但由于焊接过程中剧烈的热力耦合作用而导致焊缝区的强化相回溶和长大[3],这会使得焊缝区的力学性能低于母材区. 并且搅拌摩擦焊过程中焊缝上部的热源主要来自搅拌头轴间的摩擦产热,而下部则靠搅拌针摩擦产热以及上部的传热,这导致了焊缝上下部分热输入差距过大,而底部材料受热不足,塑性流动能力差则会在底部出现弱连接,极大的削弱了焊缝力学性能.

为了提高焊缝力学性能以及改善焊缝上下部材料流动不充分这一现象,超声作为辅助工具加入到了搅拌摩擦焊中. Witthauer等人[4]和Hung等人[5]研究超声振动可以降低金属材料变形的塑性屈服应力和流变应力,也可降低接触摩擦,Liu等人[6]和曹秒艳等人[7]研究发现超声振动可以强化材料的流动能力. 超声另一重要的作用是在液体或半固态介质中传播时具有空化和声流效应. Liu等人[8]将超声引入熔融态TiC/Al-12Si复合材料中,观察其微观结构发现空化和声流效应将第二相打破成碎片并使其弥散分布. 考虑到超声的这些效应,贺地求等人[9]将超声添加到搅拌摩擦焊中,提出了超声辅助搅拌摩擦焊(UAFSW)技术. 但加入超声能量的多少对焊接过程的影响是一个需要研究的问题,在此背景下,通过对比焊接试验,金相观察和力学试验,对超声影响焊缝性能的机制进行分析,并通过加入不同功率的超声分析超声功率的影响.

1. 试验方法

焊接试验材料采用一对经过蠕变时效的5 mm厚2219-T351铝合金轧制板材,焊件尺寸规格为500 mm × 75 mm,母材抗拉强度可达到416 MPa,屈服强度为330 MPa,断后伸长率为10.5%.图1展示了超声辅助搅拌摩擦焊试验系统,该系统是在传统搅拌摩擦焊系统上加装了超声波电源、超声波换能器、变幅杆、超声搅拌头等部分,超声振动装置与搅拌头连接为一体,将超声振动从轴向施加到搅拌头与工件上. 焊接搅拌头选用螺旋形搅拌头,搅拌头轴肩直径为12.5 mm,搅拌针直径为6 mm,长4.78 mm. 焊接前对焊件对接面、上下表面进行除氧化膜处理,将焊件装夹固定在工作台上,试验前进行了常规搅拌摩擦焊工艺参数探究,采用常规搅拌摩擦焊下较优的焊接工艺参数:搅拌头下压时进给速度为0.4 mm/s,总压深为4.9 mm,焊接转速和焊接速度分别选用1 100 r/min和100 mm/min,搅拌头倾角为3°. 焊接过程分为4段,每段焊接行程为100 mm,第一段进行常规搅拌摩擦焊,从第二段开始加入超声,三、四段改变超声功率(其中50%为1.5 kW,75%为2.25 kW,100%为3 kW),试验采用的超声装置的频率与振幅分别为20 000 Hz和26 μm.

在焊接过程中用Fluke Ti480红外热像仪全程测量焊接温度,用自主设计的测力装置测量焊接过程中的顶锻压力及前进阻力. 焊后用线切割在每段焊接的中部切出金相样及拉伸样. 用凯勒试剂(1.0%HF + 1.5%HCL + 2.5%HNO3 + 95%H2O)对抛光后的金相样进行腐蚀,使用超景深显微镜观察金相组织;用场发射扫描电镜(SEM)确定母材区二次相粒子及观察FSW和UAFSW焊核区二次相粒子的成分及分布;在数字式显微硬度计上进行显微硬度分析,载荷力与时间为500 N和15 s;在电子万能试验机上进行拉伸试验,拉伸速度为2 mm/min.

2. 试验结果和分析

2.1 焊接温度曲线及焊接作用力

搅拌摩擦焊过程中焊接温度对接头成形和性能起着至关重要的作用,焊接温度过高时材料过度软化会导致材料从轴肩边缘挤出,焊缝区材料缺少而形成孔洞或隧道型缺陷;而焊接温度过低会导致材料未能达到良好的塑性流动状态,从而产生缺陷.2219铝合金中沉淀强化相主要是亚稳定状态的θ″(Al2Cu)相,半共格状态的θ′(Al2Cu)相和足够细小的θ相[10],在搅拌摩擦焊中,由于大量的热输入,这些强化相粒子长大、溶解和转化为稳定的大颗粒θ相,失去了强化效果从而削弱焊缝强度,而降低焊接温度则可以减少强化相粒子的长大、溶解和转化.图2为焊接试验全程测温曲线,搅拌摩擦焊阶段在经历搅拌头下压的急剧升温后进入稳定焊接状态,焊接温度稳定在380 ℃左右,可以看到在加入了50%功率的超声后焊接温度有了明显的下降,由380 ℃下降到了350 ℃,随着超声功率的增加,温度下降的越发显著,每段大约有20 ~ 30 ℃的降幅. 超声能量可以降低金属材料变形的塑性屈服应力和流流变应力,增强材料的塑性流动能力,降低表面摩擦系数. 在焊接过程中热量的产生主要是靠搅拌头与材料间的摩擦,材料的塑性流动能力提高后搅拌头顶锻压力减小,搅拌头与材料间的摩擦力减小从而导致摩擦产热减少,随着超声功率的提高,超声能量的输入增强,摩擦产热减小的幅度越高.

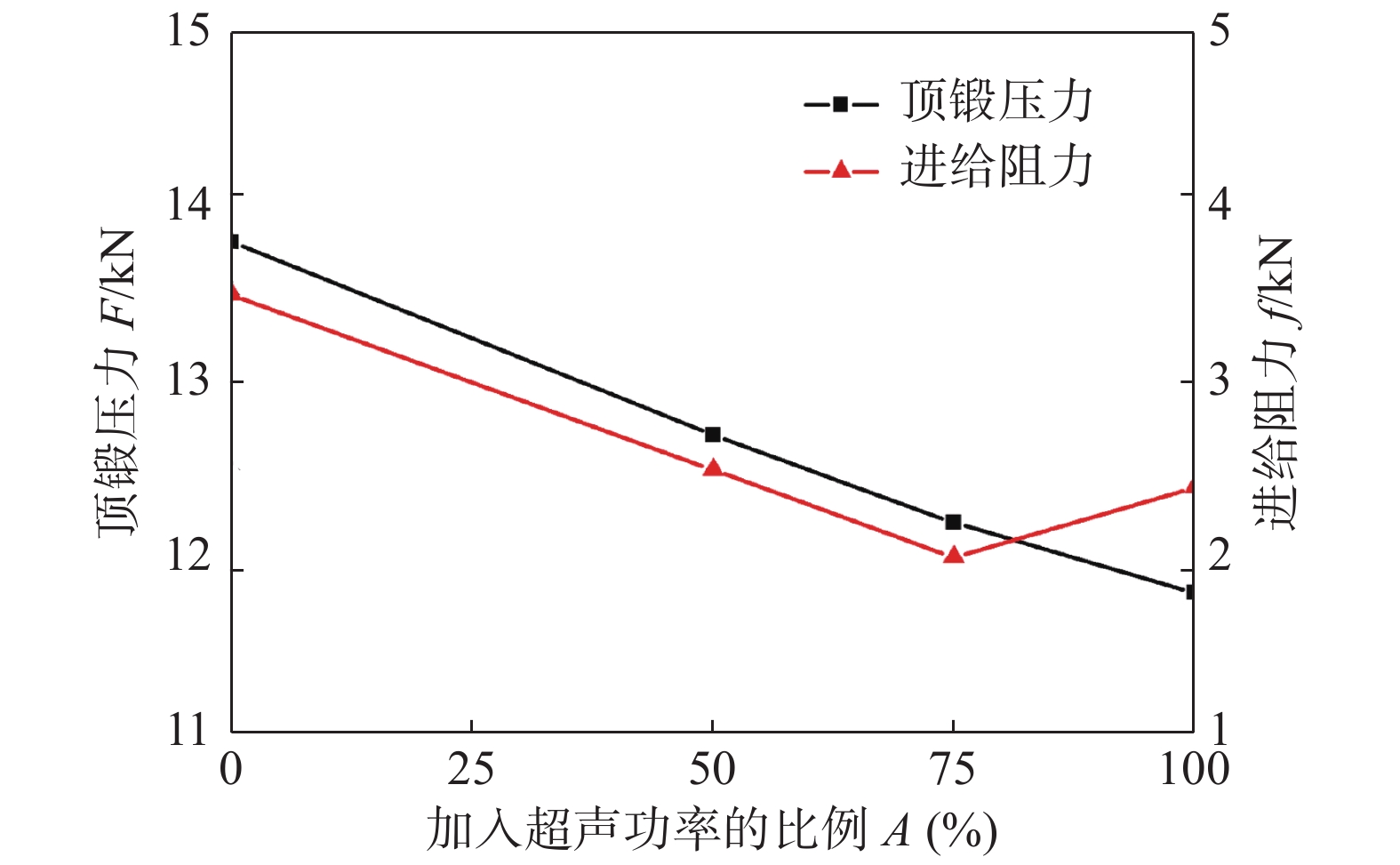

焊接过程中焊接作用力反映了搅拌头与工件的接触状态,姚喆赫研究发现了超声振动可以降低金属材料塑性变形时的压力载荷[11]. 图3为焊接稳定过程中作用力的变化,可以看到在不同参数下,顶锻压力在加入超声后顶锻压力有着明显的下降,由13.7 kN降低到了12.9 kN,随着超声功率的提升,顶锻压力持续下降,顶锻压力与材料的塑性流动能力有关,故而压力的减小反映了材料的塑性流动能力的增强,而摩擦力的减小也会导致摩擦产热的热输入减少,这与温度测量结果相符. 前进阻力在加入了超声后也有明显的下降,这是由于超声降低了材料塑性屈服应力和流变应力,但阻力在加入100%功率的超声时反而由1.9 kN提高到2.4 kN,这则是焊接温度下降过多导致前进阻力上升.

2.2 焊缝金相组织分析

图4为搅拌摩擦焊和不同超声功率下的焊缝金相组织全貌,焊缝接头的微观组织可划分为4个区域:焊核区(NZ),热力影响区(TMAZ),热影响区(HAZ)和母材区(BM). 观察图4a发现常规搅拌摩擦焊焊核区呈现了上下两个“洋葱环”,这是因为搅拌摩擦焊上层由轴肩与工件表面摩擦产热,而下层则是由搅拌针摩擦产热,这就导致了上下层热输入差异巨大,材料的塑性流动能力不同,搅拌针前进的过程中前进侧(AS)材料向返回侧(RS)挤压填补,塑性材料总是向阻力小的方向流动,从而形成了这种环形横截面,而搅拌摩擦焊过程中上下部材料塑性流动能力差异过大,所以形成了两个环形流场区域;由图4b ~ 4d所示,在超声搅拌摩擦焊过程中,由于超声波的轴向振动作用,增强了材料在厚度方向上的流动,使得材料在厚度方向分布的更加均匀,从而形成了一个完整均匀的“洋葱环”组织. 但在加入50%功率的超声时,靠前进侧上部出现了模糊的界线,这是由于加入超声能量不足导致,而在75%超声功率时则完全消除了分层现象,在100%的超声功率时靠前进侧的界线又出现了,这则是因为温度与压力较低,焊接质量下降.

传统搅拌摩擦焊由于搅拌针无法插入焊缝工件最底部,底部材料流动性能差,则可能会出现底部未焊透或弱连接,通常搅拌摩擦焊焊接接头最薄弱的区域出现在底部,在拉伸过程中裂纹源均出现在接头底面. 在加入超声后,超声增强厚度方向材料的流动能力这一特点能改善底部薄弱区域的性能.

图5为不同参数下焊核区的晶粒组织,在焊接后焊核区晶粒呈现为细小的等轴晶,这是由于焊核区的金属材料在搅拌头的剧烈机械搅拌和摩擦产热形成的热力耦合作用下发生了动态再结晶,从而形成了细小的等轴晶组织. 对比FSW和UAFSW焊核区晶粒可以发现在加入超声后,焊核区晶粒尺寸减小且更加均匀,在加入75%的超声功率时晶粒尺寸细化的最显著. 在搅拌摩擦焊中晶粒的再结晶程度主要和变形和热循环温度有关,加入超声后,材料的流变抗力减小,变形程度增加,使再结晶晶粒尺寸减小. 同时焊接温度下降,热输入减少,抑制了晶粒的粗化过程,并且研究表明超声的振动作用会破坏晶粒形核长大的过程,起到细化晶粒的作用. 但在加入100%超声功率时,晶粒尺寸并未继续减小,这是因为焊接温度和压力降低的幅度过大,金属材料的热力耦合作用较弱,动态再结晶过程不完全.

2.3 第二相粒子分析

研究表明2219铝合金基材中分布亚稳定状态的θ″(Al2Cu)相、半共格状态的θ′(Al2Cu)相以及非常细小θ相起着弥散强化的作用,而尺寸较大(5 ~ 20 μm)的θ相没有强化效果,在搅拌摩擦焊过程中,由于热力耦合作用这些强化相会转化为稳定的θ相并长大粗化,从而失去了强化效果.图6为母材和焊缝的二次相扫描结果,发现存在大量的尺寸在(5 ~ 15 μm)的粒子,对二次相粒子进行EDS分析,发现Al与Cu的成分比例约为2∶1,得出该粒子为稳定的θ(Al2Cu)相. 相较于焊缝,母材中的θ相分布较稀疏,且呈现出一定的方向,这是由于所用材料为轧制态. 经过搅拌摩擦焊后,焊缝区分布着大量密集的大颗粒θ相,Chen等人[12]的研究发现θ相粒子在300 ~ 400 ℃时会长大粗化,许晓嫦等人[13]研究了Al-Cu合金在强塑性变形过程中析出相的回溶过程,发现在强塑性变形过程中强化相θ″,θ′和θ相均会回溶到基体,所以经过搅拌摩擦焊剧烈的热力耦合作用后大量强化相粒子回溶到铝基体,还有部分强化相颗粒会长大为稳定的大颗粒θ相,故焊缝区力学性能较母材有所下降. 在加入了超声后,大颗粒的θ相明显减少,分布稀疏,在超声功率较大时数量较少,这是由于超声辅助焊接时焊接温度较搅拌摩擦焊下降了30 ~ 50 ℃,故而回溶的θ″,θ′和θ相减少,并且有θ相仍未长大,以细小的颗粒分布在基体中,保留着强化作用.

2.4 焊缝显微硬度测试

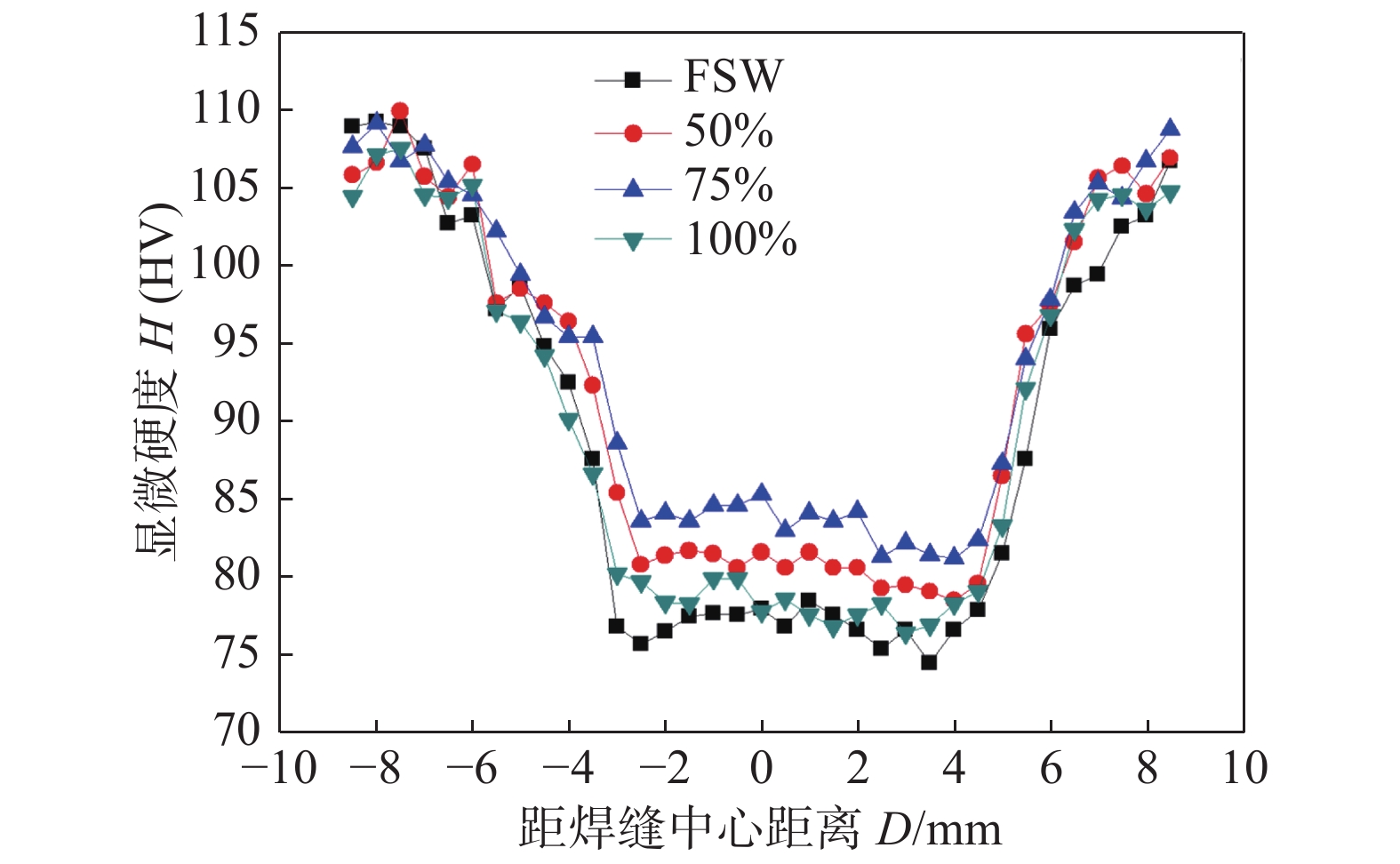

焊接接头的显微硬度是焊缝力学性能的重要指标,它反映金属材料抵抗局部变形的能力. 显微硬度试验在焊缝厚度方向的中心线处取点,每隔0.5 mm取一个点. 试验结果如图7所示,硬度曲线呈“U”形,搅拌摩擦焊焊缝区的硬度为77 HV(达到母材的71%),在加入50%功率的超声时显微硬度为82 HV,高于搅拌摩擦焊焊缝区硬度值;当调至75%超声功率时,硬度值到达最高值87 HV(为母材的81%);而超声功率为100%时,硬度反而有所下降,仅略高于搅拌摩擦焊焊缝硬度.

焊缝区强化相的回溶是其硬度低于母材的主要原因,在加入75%功率以下的超声后焊缝区硬度整体上都有所提高,超声对焊缝区硬度的提高主要是由于UAFSW焊缝区的晶粒更加细小均匀,以及较低的焊接温度而使部分强化相残留于焊缝区. 超声的空化效应会细化材料固化后的晶粒组织结构,改善金属的致密程度,缩短固化的起始及持续时间,这都有助于改善接头硬度[14]. 当加入的超声功率达到75%时,对焊缝的性能改善效果较好,而在将功率继续增大到100%时,较低的焊接压力及焊接温度导致未能达到最佳的焊接状态,故焊缝接头性能反而下降.

2.5 焊接接头力学性能

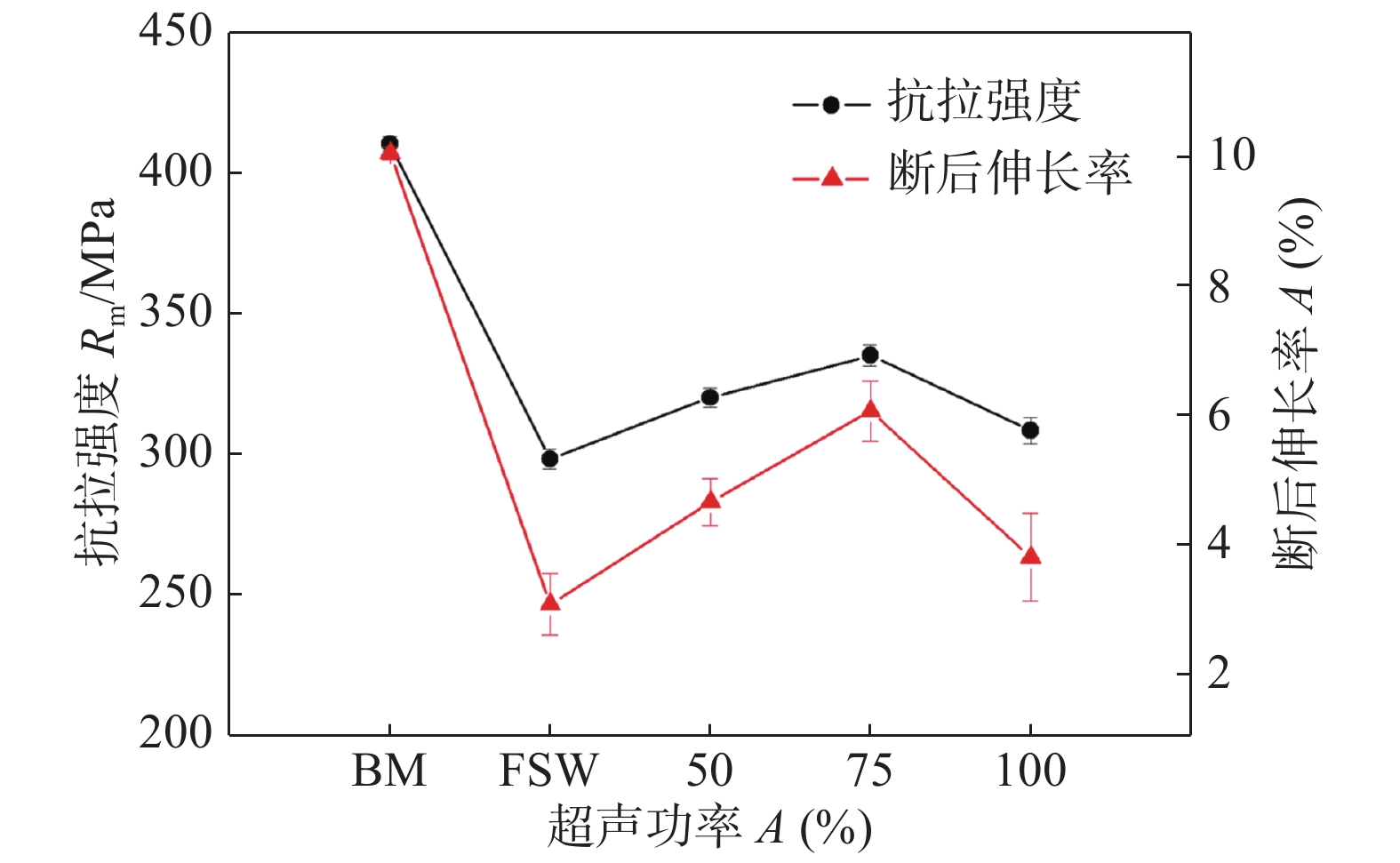

焊缝接头的抗拉强度及断后伸长率如图8所示,母材的抗拉强度与断后伸长率分别为416 MPa和10.5%,经过焊接后焊缝强度与断后伸长率均低于母材,传统搅拌摩擦焊焊缝强度为287 MPa(达到母材的69%),断后伸长率为3.4%. 在加入50%功率的超声时,抗拉强度与断后伸长率分别提高到了308 MPa和5.1%,在超声功率为75%时达到最高值,分别为331 MPa(为母材的80%)和6.3%,但在加入100%功率的超声时性能有所下降,强度与传统搅拌摩擦焊相当,断后伸长率略有提高.

2219铝合金中的第二相及其分布对其性能的影响十分强烈,在焊核区由于经历了复杂的热机过程,温度较高,故主要发生了沉淀相回溶,热影响区的沉淀相受热循环作用主要表现为长大,这均影响了焊缝性能. 而断后伸长率的降低则是因为拉伸过程中的变形一致性,母材在拉伸时整个拉伸样均参与了变形,而焊缝接头在拉伸时由于焊缝区性能较弱,故变形主要发生在焊缝区,这导致了断后伸长率的大幅下降. 在加入超声后,由上文分析焊缝中仍存留有部分强化相,以及超声改善了焊缝底部的材料流动,这都有助于提高焊缝强度,当超声降低焊接温度与改善材料塑性流动到达一个动态平衡时改善焊缝性能的效果最佳,当超声功率过大时会导致轴向力降低过多,而搅拌摩擦焊热输入主要由轴肩与材料摩擦产生,姚喆赫研究表明超声的热效应对金属加工过程中温度的影响较小[11],因此焊接温度会降低较大,反而削弱了超声的作用.

3. 结论

(1) UAFSW能降低焊接作用力和焊接温度,这对改变焊缝区第二相的尺寸和分布有很大影响. 由二次相分析可以看出FSW焊缝区大部分都是失去强化效果的大颗粒θ相,而在UAFSW焊缝区的大颗粒θ相要少且分布稀疏,这说明还有未长大的θ相粒子,这些粒子仍存在强化效果.

(2) FSW焊接接头的金相整体形貌为上下分层的双流场,而UAFSW焊接接头的金相组织全貌更加连贯,呈现出一个完整的流场,而焊接接头拉伸断裂的裂纹源均出现在最底部,故超声效应能改善焊缝底部的弱连接,提高了焊缝的力学性能. 相较于FSW焊核区晶粒组织,UAFSW焊核区晶粒组织更加细小,且分布更加均匀.

(3)输入的超声能量并非越高越好,而是需要一个合适的能量输入. 超声功率在75%以下时,UAFSW焊缝区力学性能相较FSW均有提高,在75%时达到最高值,显微硬度为87 HV(母材的81%),抗拉强度为331 MPa(母材的80%),断后伸长率为6.3%. 但在超声功率为100%时,超声的作用效应并不明显,这是由于焊接温度较低造成的.

-

-

[1] 杜波, 杨新岐, 孙转平,等. 2219-T87铝合金拉锻式摩擦塞补焊接头组织及性能[J]. 焊接学报, 2019, 40(2): 128 − 132. Du Bo, Yang Xinqi, Sun Zhuanping, et al. Microstructure and properties of 2219-T87 aluminum alloy friction pull plug welds[J]. Transactions of the China Welding Institution, 2019, 40(2): 128 − 132.

[2] 杨坤玉, 贺地求, 李东辉. 2519A铝合金超声辅助搅拌摩擦焊接试验分析[J]. 焊接学报, 2018, 39(6): 39 − 42. Yang Kunyu, He Diqiu, Li Donghui. Experimental analysis of 2519A aluminum alloy ultrasonic assisted friction stir welding[J]. Transactions of the China Welding Institution, 2018, 39(6): 39 − 42.

[3] Liu H J, Feng X L. Effect of post-processing heat treatment on microstructure and microhardness of water-submerged friction stir processed 2219-T6 aluminum alloy[J]. Materials and Design, 2013, 47(9): 101 − 105.

[4] Witthauer A T, Kim G Y, Faidley L E, et al. Effects of acoustic softening and hardening in high-frequency vibration-assisted punching of aluminum[J]. Materials and Manufacturing Processes, 2014, 29(10): 1184 − 1189. doi: 10.1080/10426914.2014.921704

[5] Hung J C, Hung C. The influence of ultrasonic-vibration on hot upsetting of aluminum alloy[J]. Ultrasonics, 2005, 43(8): 692 − 698. doi: 10.1016/j.ultras.2005.03.001

[6] Liu X C, Wu C S. Material flow in ultrasonic vibration enhanced friction stir welding[J]. Journal of Materials Processing Technology, 2015, 225: 32 − 44. doi: 10.1016/j.jmatprotec.2015.05.020

[7] 曹秒艳, 李建超, 杨卓云, 等. 超声振动对板材固体颗粒介质成形的影响[J]. 中国有色金属学报, 2016, 26(10): 2118 − 2127. Cao Miaoyan, Li Jianchao, Yang Zhuoyun, et al. Effect of ultrasonic vibration on solid granules medium forming of sheet metals[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(10): 2118 − 2127.

[8] Liu Z W, Rakita M, Han Q, et al. Microstructural evolution of reinforcements in the remelting in situ TiC/Al–12Si composites treated by ultrasonic vibration[J]. Materials Research Bulletin, 2011, 46(10): 1674 − 1678. doi: 10.1016/j.materresbull.2011.06.003

[9] 贺地求, 梁建章. 超声搅拌焊接方法及其装置: 中国, 200610004059.3[P]. 2006−01−26. [10] Li B, Shen Y. The investigation of abnormal particle-coarsening phenomena in friction stir repair weld of 2219-T6 aluminum alloy[J]. Materials and Design, 2011, 32(7): 3796 − 3802. doi: 10.1016/j.matdes.2011.03.029

[11] 姚喆赫. 超声能场在金属微/介观成形中的作用理论及试验研究[D]. 杭州: 浙江大学, 2016. [12] Chen S, Jiang X. Texture evolution and deformation mechanism in friction stir welding of 2219Al[J]. Materials Science and Engineering A, 2014, 612(9): 267 − 277.

[13] 许晓嫦, 刘志义, 党朋, 等. 研究强塑性变形过程中第二相回溶现象的现状及发展趋势[J]. 金属热处理, 2005, 30(4): 1 − 6. doi: 10.3969/j.issn.0254-6051.2005.04.001 Xu Xiaochang, Liu Zhiyi, Dang Peng, et al. Current situation and development of the research on re-dissolution of second phase during serve plastic deformation[J]. Transactions of Metal Heat Treatment, 2005, 30(4): 1 − 6. doi: 10.3969/j.issn.0254-6051.2005.04.001

[14] Ma H K, He D Q, Liu J S. Ultrasonically assisted friction stir welding of aluminium alloy 6061[J]. Science and Technology of Welding and Joining, 2015, 20(3): 216 − 221. doi: 10.1179/1362171814Y.0000000275

-

期刊类型引用(8)

1. 马付建,李锡伟,陈绍,付典颐,沙智华,张生芳. 6061铝合金超声辅助搅拌摩擦焊温度场分析. 焊接学报. 2024(08): 41-51 .  本站查看

本站查看

2. 赵耀邦,雷亚彤,程立宏,别亚星,历吴恺,徐爱杰,王建峰. 超声冲击调控2219铝合金搅拌摩擦焊接头残余应力. 上海航天(中英文). 2024(S2): 65-70 .  百度学术

百度学术

3. 邓越,崔雷,王东坡,邵震,赵衍华,张丽娜. 铝合金拉拔式摩擦塞补焊成形及其对界面结合行为的影响. 中国有色金属学报. 2023(09): 2825-2838 .  百度学术

百度学术

4. 侯俊良,周博芳,张红霞,李桃花,满武士,谢昊东. 汽车轻量化铝合金材料的搅拌摩擦焊研究现状. 电焊机. 2023(12): 86-94 .  百度学术

百度学术

5. 吴程浩,刘涛,高嵩,石磊,刘洪涛. 铝/钢异种金属的超声振动强化搅拌摩擦焊接工艺. 材料工程. 2022(01): 33-42 .  百度学术

百度学术

6. 李德福,王希靖,赵早龙,徐秋苹. 轴肩辅助加热6082铝合金摩擦塞补焊接头组织及力学性能. 焊接学报. 2022(01): 36-41+115 .  本站查看

本站查看

7. 温泉,李文亚,吴雪猛,任寿伟,赵静. 单静止上轴肩BT-FSW工艺过程及成形机理. 焊接学报. 2022(07): 88-96+118-119 .  本站查看

本站查看

8. 茅卫东,石铭霄,李盛良,李敬勇,陈书锦,陈九公. 机械振动辅助铝合金MIG焊接接头组织与性能研究. 电焊机. 2022(10): 9-14 .  百度学术

百度学术

其他类型引用(10)

下载:

下载: