Vacuum brazing TC4 titanium alloy / 316L stainless steel with Ti43.76Zr12.50Cu37.49-xNi6.25Cox amorphous filler metals

-

摘要:

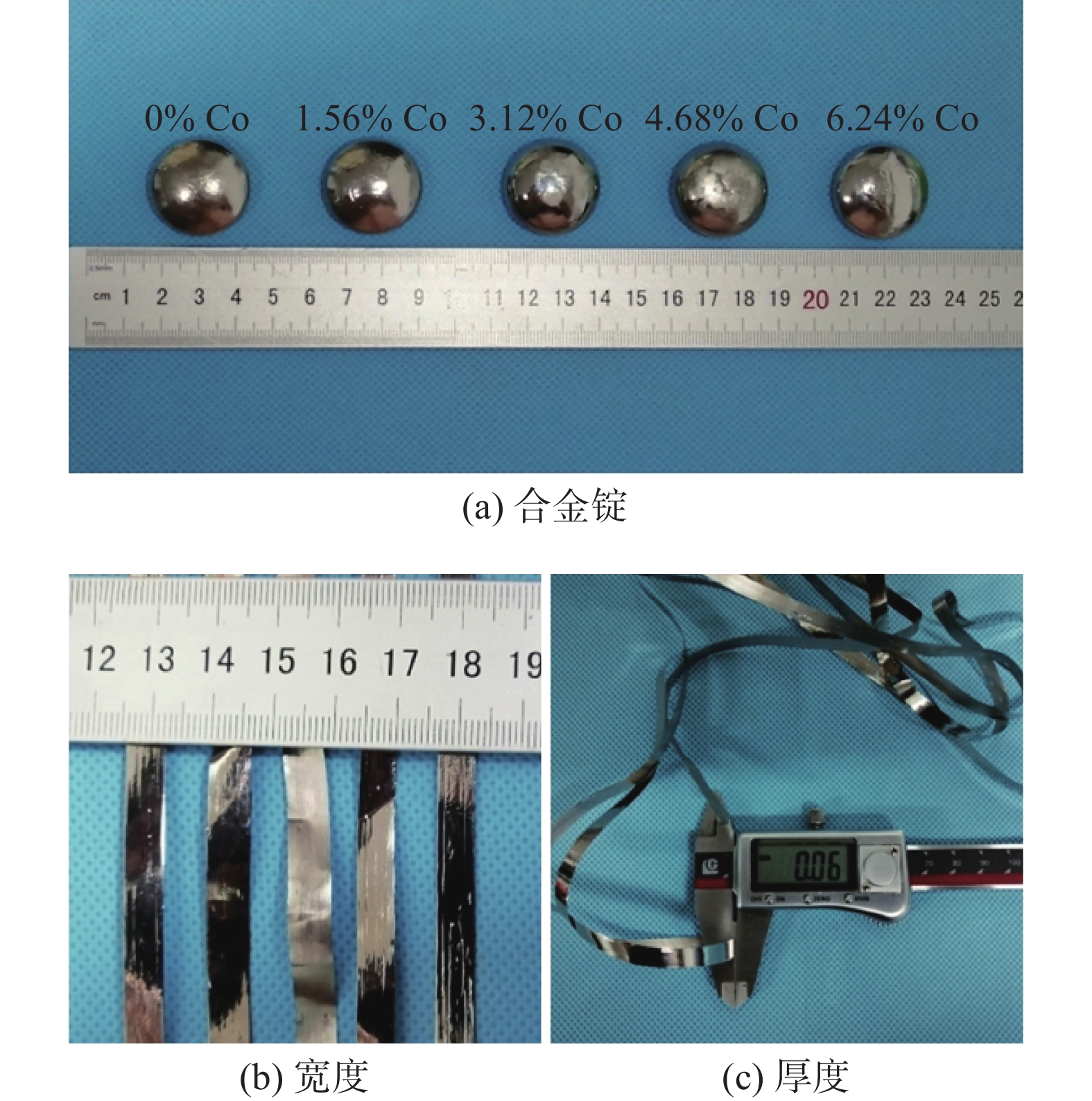

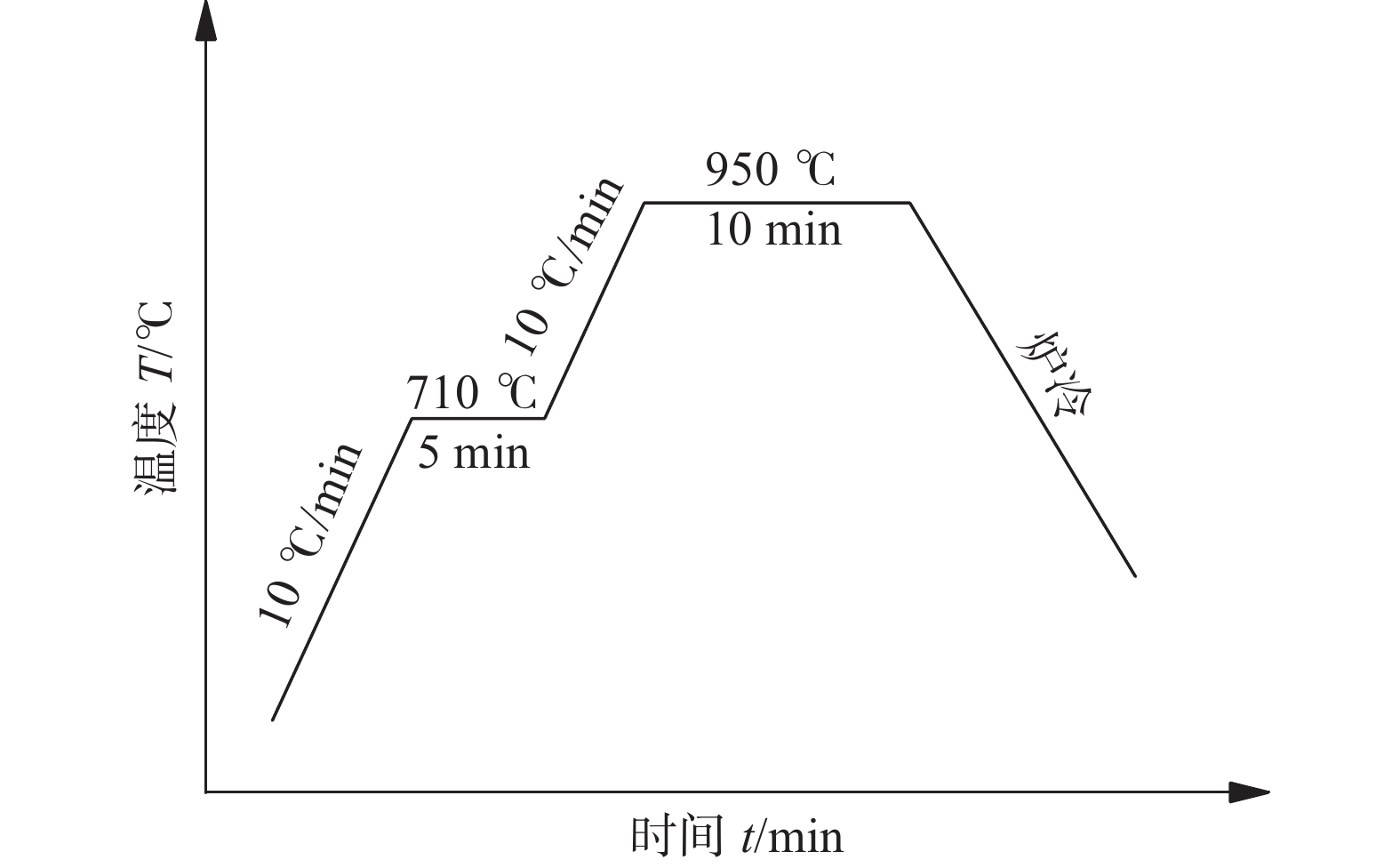

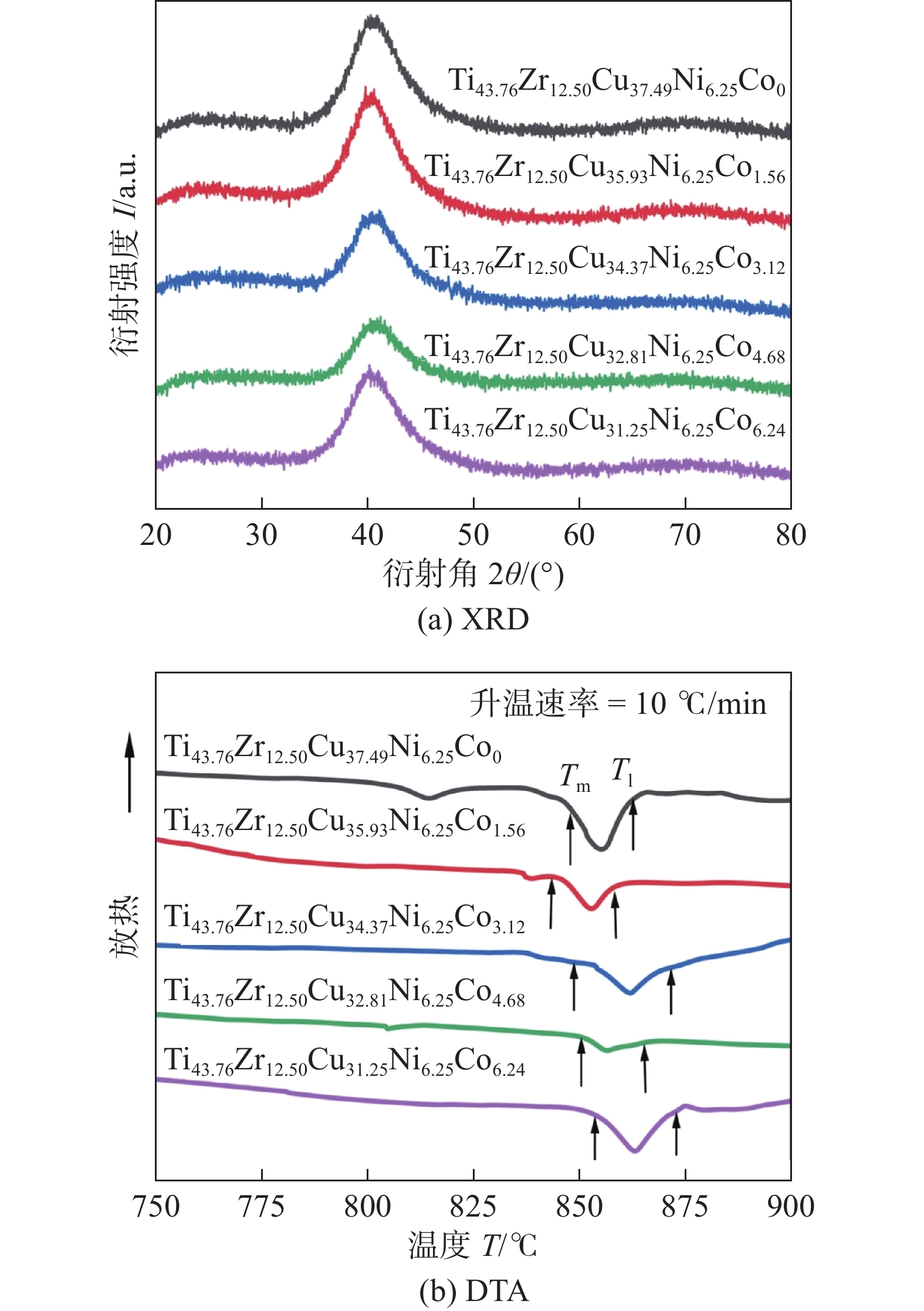

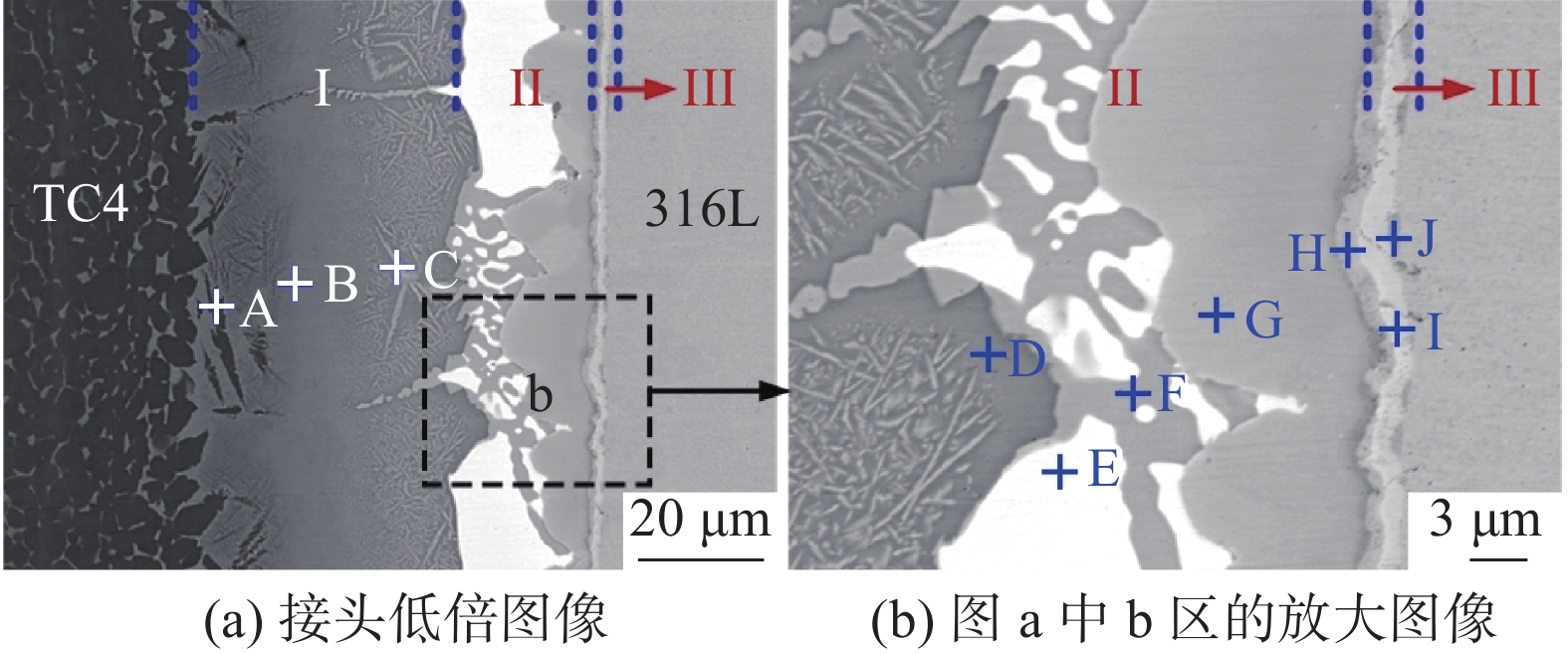

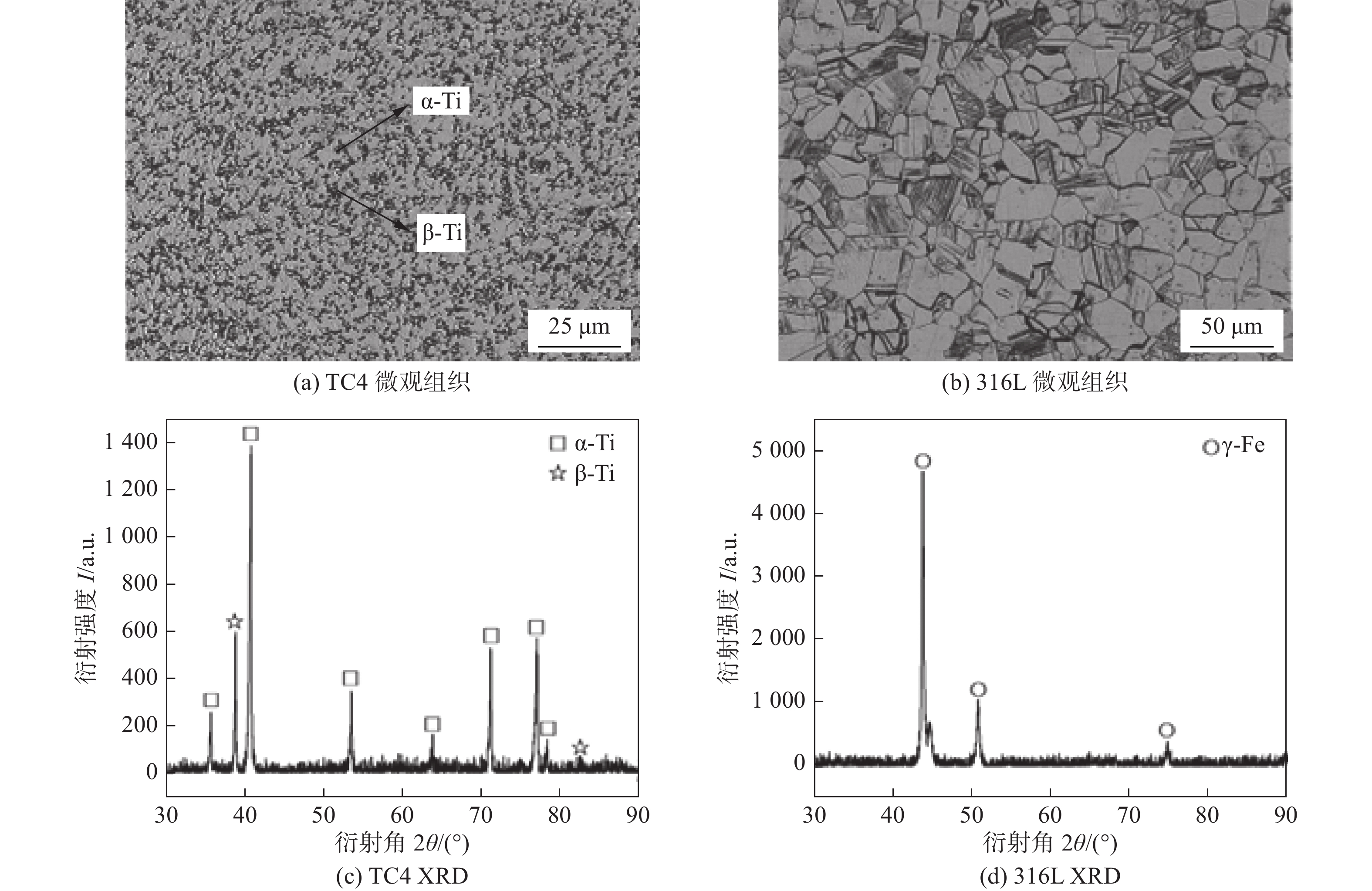

根据双团簇模型设计并制备了Ti-Zr-Cu-Ni-Co系非晶钎料,用于真空钎焊TC4钛合金和316L不锈钢,分析了钎料中Co元素含量对钎焊接头界面微观组织形貌、力学性能及断裂行为的影响规律.结果表明,钎焊接头可划分为TC4/扩散区(I区)/钎缝中心区(II区)/界面区(III区)/316L,界面典型微观组织结构为TC4/β-Ti + Ti2Cu/(Ti, Zr)2(Cu, Ni) + Ti2Cu + Ti2(Cu, Ni) + TiFe/(Fe, Cr)2Ti + α-(Fe, Cr) + τ + γ-(Fe, Ni) + σ/316L,随着Co元素含量的增加,接头剪切强度先升高后降低再升高,当Co元素含量为1.56%时达到最大310 MPa,不添加Co元素时,接头断裂于钎缝中心区(II区);当Co元素含量为1.56% ~ 6.24%时,接头断裂于靠近316L母材的界面区(III区)附近,断裂模式为典型的解理断裂.

-

关键词:

- 真空钎焊 /

- 非晶钎料 /

- 钛合金/不锈钢异种金属 /

- 微观组织 /

- 剪切强度

Abstract:Ti-Zr-Cu-Ni-Co amorphous filler metals were designed and prepared for vacuum brazing of TC4 titanium alloy to 316L stainless steel according to the dual-cluster model. The effect of Co content in filler metals on the microstructure, mechanical properties and fracture behavior of brazed joints was investigated. The results showed that the cross section of brazed joint could be divided into TC4/diffusion zone I/brazing seam center zone II/interface zone III/316L. The typical interfacial microstructure of the brazed joints was TC4/β-Ti + Ti2Cu/(Ti, Zr)2(Cu, Ni) + Ti2Cu + Ti2(Cu, Ni) + TiFe/(Fe, Cr)2Ti + α-(Fe, Cr) + τ + γ -(Fe, Ni) + σ/316L. The shear strength of brazed joints first increased, then decreased and then increased with the increase of Co content. The maximum shear strength of 310 MPa was obtained at 1.56% Co. When Co element was not added, brazed joints fractured in the center of the brazing seam (zone II). And when the Co content was 1.56 ~ 6.24%, brazed joints fractured near the interface zone (zone III) of 316L base metal. The fracture mode was typical cleavage fracture.

-

-

表 1 母材化学成分(质量分数,%)

Table 1 Chemical compositions of base metals

母材 Al V Cr Ni Mo Mn Fe Ti TC4 5.9 3.6 — — — — — 余量 316L — — 16.5 10.2 2.0 1.3 余量 — 表 2 钎料的固相线温度(Tm)和液相线温度(Tl)

Table 2 Solidus temperature and liquidus temperature of filler metals

钎料 固相线

温度

Tm/℃液相线

温度

Tl/℃熔化温度

区间

Tl ~ Tm/℃Ti43.76Zr12.50Cu37.49Ni6.25Co0 847 862 15 Ti43.76Zr12.50Cu35.93Ni6.25Co1.56 843 855 12 Ti43.76Zr12.50Cu34.37Ni6.25Co3.12 849 872 23 Ti43.76Zr12.50Cu32.81Ni6.25Co4.68 850 864 14 Ti43.76Zr12.50Cu31.25Ni6.25Co6.24 854 873 19 表 3 图6中标记位置的EPMA点元素分析结果(原子分数,%)

Table 3 EPMA analysis results of the marked locations in Fig. 6

点 Ti Cu Zr Ni Co Al V Fe Cr 可能相 A 85.6 0.8 0.3 0.1 — 11.3 1.6 0.2 — α-Ti B 75.8 4.6 0.6 1.4 0.3 7.2 5.8 3.9 0.6 β-Ti C 66.1 23.1 2.5 2.3 0.2 1.9 1.1 2.1 0.8 Ti2Cu D 72.6 7.0 2.8 1.4 0.3 4.5 2.7 6.2 2.5 β-Ti E 40.8 25.0 15.8 4.4 0.4 5.3 1.3 5.4 1.7 (Ti, Zr)2(Cu, Ni) F 63.0 27.9 3.7 2.6 0.2 0.8 0.4 1.3 0.2 Ti2Cu G 50.8 22.0 2.2 3.9 0.9 2.5 1.0 14.3 2.5 Ti2(Cu, Ni) + TiFe H 32.0 0.9 0.9 4.0 0.4 0.5 0.3 52.4 8.5 (Fe, Cr)2Ti I 3.9 0.6 — 3.4 0.3 0.1 0.8 59.1 31.8 α-(Fe, Cr) + τ J 1.0 0.3 — 9.3 0.5 — 0.1 70.8 18.0 γ-(Fe, Ni) + σ 表 4 图14中标记位置的EDS点元素分析结果(原子分数,%)

Table 4 EDS analysis results of the marked locations in Fig. 14

点 Ti Cu Zr Ni Co Al V Fe Cr 可能相 A 48.4 25.4 5.7 4.8 1.3 2.7 0.7 9.8 1.3 Ti2Cu B 53.8 25.2 11.0 2.8 0.2 3.2 0.4 2.9 0.6 (Ti, Zr)2(Cu, Ni) C 48.1 24.7 13.9 3.8 0.4 3.4 0.7 3.9 1.2 (Ti, Zr)2(Cu, Ni) D 30.8 0.7 2.1 3.4 0.6 1.1 0.4 50.5 10.5 TiFe2 E 48.5 21.7 3.2 3.8 1.3 3.7 0.7 14.9 2.4 Ti2(Cu, Ni) + TiFe F 48.3 23.6 3.5 5.2 1.2 2.3 — 13.9 2.0 Ti2(Cu, Ni) + TiFe G 58.1 12.1 10.2 3.4 0.8 6.5 1.9 5.6 1.6 (Ti, Zr)2(Cu, Ni) H 49.1 18.9 2.0 7.1 2.6 2.6 0.5 15.3 1.9 Ti2(Cu, Ni) + TiFe I 49.9 19.1 2.7 5.7 2.6 3.5 0.6 14.2 1.7 Ti-Cu-Fe J 11.5 0.4 0.7 2.9 0.3 0.7 0.6 57.0 26.0 FeCr K 38.2 5.6 1.3 5.4 1.5 1.6 0.3 36.9 9.3 TiFe L 47.9 19.4 3.0 6.0 2.4 2.9 0.3 16.0 2.2 Ti-Cu-Fe -

[1] 赵永庆, 葛鹏. 我国自主研发钛合金现状与进展[J]. 航空材料学报, 2014, 34(4): 51 − 61. Zhao Yongqing, Ge Peng. Current situation and development of new titanium alloys invented in China[J]. Journal of Aeronautical Materials, 2014, 34(4): 51 − 61.

[2] 宋庭丰, 蒋小松, 莫德锋, 等. 不锈钢和钛合金异种金属焊接研究进展[J]. 材料导报, 2015, 29(6): 81 − 87. Song Tingfeng, Jiang Xiaosong, Mo Defeng, et al. A survey on dissimilar welding of stainless steel and titanium alloy[J]. Materials Reports, 2015, 29(6): 81 − 87.

[3] 李鹏, 李京龙, 熊江涛, 等. 添加Ni + Nb中间层的钛合金与不锈钢扩散焊工艺研究[J]. 航空材料学报, 2011, 31(3): 46 − 51. Li Peng, Li Jinglong, Xiong Jiangtao, et al. Study on diffusion bonded titanium alloy to stainless steel with Ni + Nb interlayers[J]. Journal of Aeronautical Materials, 2011, 31(3): 46 − 51.

[4] 邓云华, 岳喜山, 李晓辉, 等. TC4钛合金/304不锈钢异种材料蜂窝结构钎焊工艺[J]. 焊接学报, 2019, 40(10): 148 − 155. Deng Yunhua, Yue Xishan, Li Xiaohui, et al. Brazing process of TC4 titanium/304 stainless steel dissimilar materials honeycomb sandwich structure[J]. Transactions of the China Welding Institution, 2019, 40(10): 148 − 155.

[5] 王廷, 张秉刚, 陈国庆, 等. 钛/钢异种金属焊接存在问题及研究现状[J]. 焊接, 2009(9): 29 − 33. Wang Ting, Zhang Binggang, Chen Guoqing, et al. Problems and research status of welding of dissimilar metals between titanium alloy and steel[J]. Welding & Joining, 2009(9): 29 − 33.

[6] Hao X H, Dong H G, Li S, et al. Lap joining of TC4 titanium alloy to 304 stainless steel with fillet weld by GTAW using copper-based filler wire[J]. Journal of Materials Processing Tech, 2018, 257: 88 − 100. doi: 10.1016/j.jmatprotec.2018.02.020

[7] Liu H, Cheng Z, Huang J H, et al. Feasibility study of different filler metals on MIG-TIG double-sided arc brazing of titanium alloy-stainless steel[J]. Journal of Manufacturing Processes, 2019, 47: 183 − 191. doi: 10.1016/j.jmapro.2019.09.029

[8] 王廷, 张秉刚, 张艳桥, 等. 采用不同结构Cu/V填充层的钛合金/不锈钢电子束焊接试验[J]. 焊接学报, 2014, 35(8): 71 − 74. Wang Ting, Zhang Binggang, Zhang Yanqiao, et al. Experimental research on electron beam welding of titanium alloy to stainless steel based on Cu/V filler metals with different shapes[J]. Transactions of the China Welding Institution, 2014, 35(8): 71 − 74.

[9] Tomashchuk I, Sallamand P, Belvavina N, et al. Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer[J]. Materials Science and Engineering:A, 2013, 585: 114 − 122. doi: 10.1016/j.msea.2013.07.050

[10] Zhang Y, Sun D Q, Gu X Y, et al. Nd/YAG pulsed laser welding of TC4 titanium alloy to 301L stainless steel via pure copper interlayer[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1-4): 953 − 961. doi: 10.1007/s00170-016-9453-z

[11] Fang Y J, Jiang X S, Song T F, et al. Pulsed laser welding of Ti-6Al-4V titanium alloy to AISI 316L stainless steel using Cu/Nb bilayer[J]. Materials Letters, 2019, 244: 163 − 166. doi: 10.1016/j.matlet.2019.02.075

[12] Balasubramanian M. Development of processing windows for diffusion bonding of Ti-6Al-4V titanium alloy and 304 stainless steel with silver as intermediate layer[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(9): 2932 − 2938. doi: 10.1016/S1003-6326(15)63919-X

[13] Li P, Li C, Dong H G, et al. Vacuum diffusion bonding of TC4 titanium alloy to 316L stainless steel with AlCoCrCuNi2 high-entropy alloy interlayer[J]. Journal of Alloys and Compounds, 2022, 909: 164698. doi: 10.1016/j.jallcom.2022.164698

[14] Li P, Dong H G, Xia Y Q, et al. Inhomogeneous interface structure and mechanical properties of rotary friction welded TC4 titanium alloy/316L stainless steel joints[J]. Journal of Manufacturing Processes, 2018, 33: 54 − 63. doi: 10.1016/j.jmapro.2018.05.001

[15] Liu H H, Aoki Y, Aoki Y, et al. Principle for obtaining high joint quality in dissimilar friction welding of Ti-6Al-4V alloy and SUS316L stainless steel[J]. Journal of Materials Science & Technology, 2020, 46: 211 − 224.

[16] Chu Q L, Zhang M, Li J H, et al. Experimental and numerical investigation of microstructure and mechanical behavior of titanium/steel interfaces prepared by explosive welding[J]. Materials Science and Engineering:A, 2017, 689: 323 − 331. doi: 10.1016/j.msea.2017.02.075

[17] Zhou Q, Liu R, Ran C, et al. Effect of microstructure on mechanical properties of titanium-steel explosive welding interface[J]. Materials Science and Engineering:A, 2022, 830: 142260. doi: 10.1016/j.msea.2021.142260

[18] Han K, Wang T, Chang S T, et al. Interface characteristics and mechanical property of titanium/steel joint by electron beam brazing with 72Ag-28Cu filler metal[J]. Journal of Manufacturing Processes, 2020, 59: 58 − 67. doi: 10.1016/j.jmapro.2020.09.049

[19] Xia Y Q, Dong H G, Li P, et al. Brazing TC4 titanium alloy/316L stainless steel joint with Ti50- xZr xCu39Ni11 amorphous filler metals[J]. Journal of Alloys and Compounds, 2020, 849: 156650. doi: 10.1016/j.jallcom.2020.156650

[20] Xia Y Q, Li P, Hao X H, et al. Interfacial microstructure and mechanical property of TC4 titanium alloy/316L stainless steel joint brazed with Ti-Zr-Cu-Ni-V amorphous filler metal[J]. Journal of Manufacturing Processes, 2018, 35: 382 − 395. doi: 10.1016/j.jmapro.2018.08.022

[21] 朱瑞, 李国选, 汪月勇, 等. TC4钛合金-316L不锈钢真空钎焊接头组织与性能研究[J]. 有色金属工程, 2021, 11(12): 8 − 14. doi: 10.3969/j.issn.2095-1744.2021.12.002 Zhu Rui, Li Guoxuan, Wang Yueyong, et al. An investigation on microstructure and mechanical properties of vacuum brazed TC4 titanium to 316L stainless steel[J]. Nonferrous Metals Engineering, 2021, 11(12): 8 − 14. doi: 10.3969/j.issn.2095-1744.2021.12.002

[22] Ma Y P, Dong D D, Dong C, et al. Composition formulas of binary eutectics[J]. Scientific Reports, 2015, 5: 14 − 18.

[23] Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element[J]. Materials Transactions, 2005, 46(12): 2817 − 2829. doi: 10.2320/matertrans.46.2817

[24] Akbarpour M R, Mirabad H M, Hemmati A, et al. Processing and microstructure of Ti-Cu binary alloys: A comprehensive review[J]. Progress in Materials Science, 2022: 100933.

[25] Turchanin M A, Velikanova T Y, Agraval P G, et al. Thermodynamic assessment of the Cu-Ti-Zr system. III. Cu-Ti-Zr System[J]. Powder Metallurgy and Metal Ceramics, 2007, 47: 586 − 606.

[26] Li X Q, Li L, Hu K, et al. Vacuum brazing of TiAl-based intermetallics with Ti-Zr-Cu-Ni-Co amorphous alloy as filler metal[J]. Intermetallics, 2015, 57: 7 − 16. doi: 10.1016/j.intermet.2014.09.010

[27] Raghavan V. Cu-Fe-Ti (Copper-Iron-Titanium)[J]. Journal of Phase Equilibria, 2002, 23(2): 172 − 174. doi: 10.1361/1054971023604152

[28] Xia Y Q, Dong H G, Zhang R Z, et al. Interfacial microstructure and shear strength of Ti6Al4V alloy/316 L stainless steel joint brazed with Ti33.3Zr16.7Cu50-xNix amorphous filler metals[J]. Materials & Design, 2020, 187: 108380.

[29] Zeng L J, Liu L B, Huang S X, et al. Experimental investigation of phase equilibria in the Ti-Fe-Cr ternary system[J]. Calphad, 2017, 58: 58 − 69. doi: 10.1016/j.calphad.2017.05.006

[30] Yen Y W, Su J W, Huang D P. Phase equilibria of the Fe-Cr-Ni ternary systems and interfacial reactions in Fe–Cr alloys with Ni substrate[J]. Journal of Alloys and Compounds, 2007, 457(1/2): 270 − 278.

[31] Cao X, Dong K W, Zhu R, et al. A high-strength vacuum brazed TC4/316L joint with a Ti-Zr-based amorphous ribbon as the filler metal[J]. Vacuum, 2021, 187: 110070.

-

期刊类型引用(0)

其他类型引用(9)

下载:

下载: