Solidification crack sensitivity of GH2132 superalloy deposited metal

-

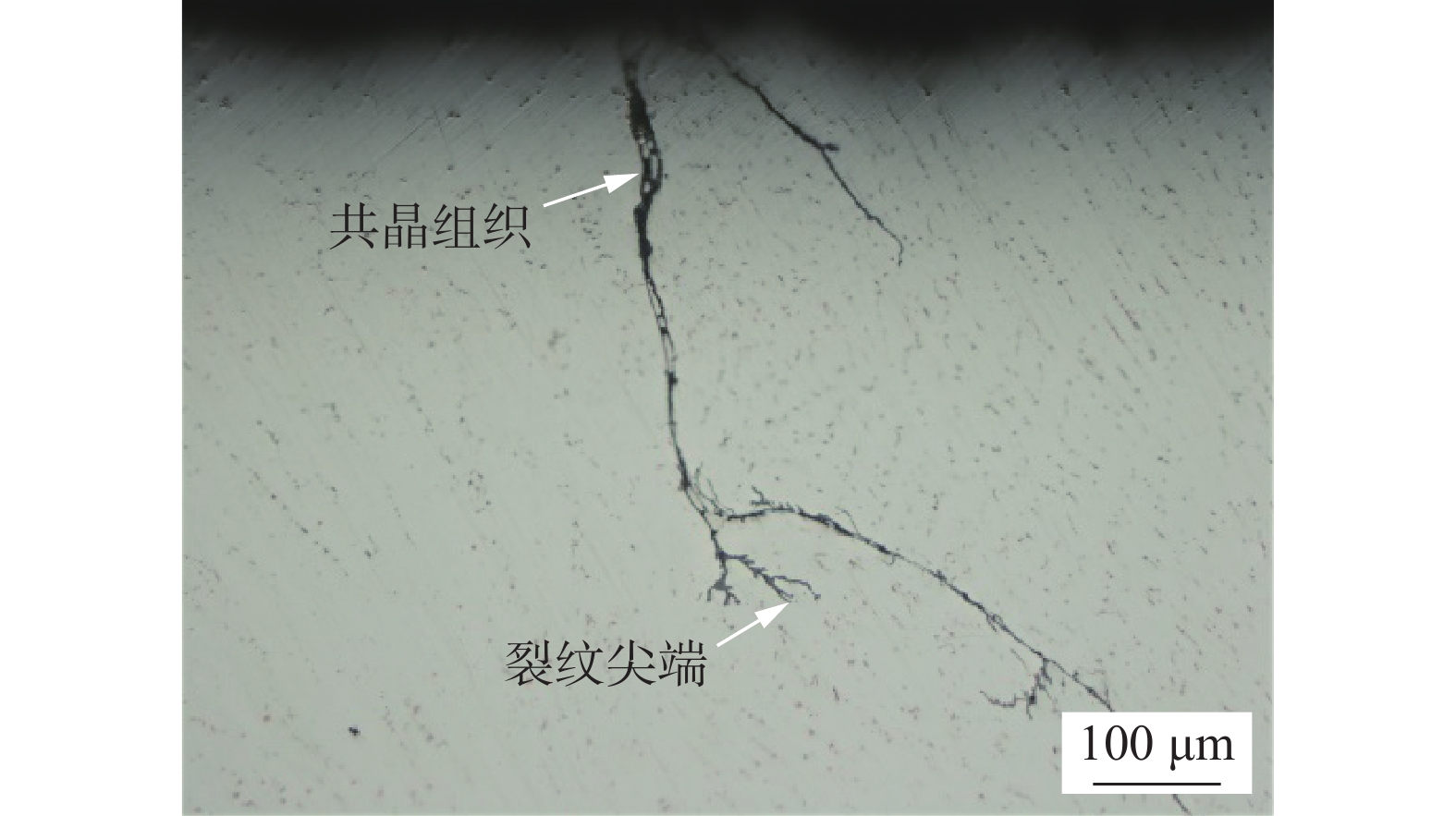

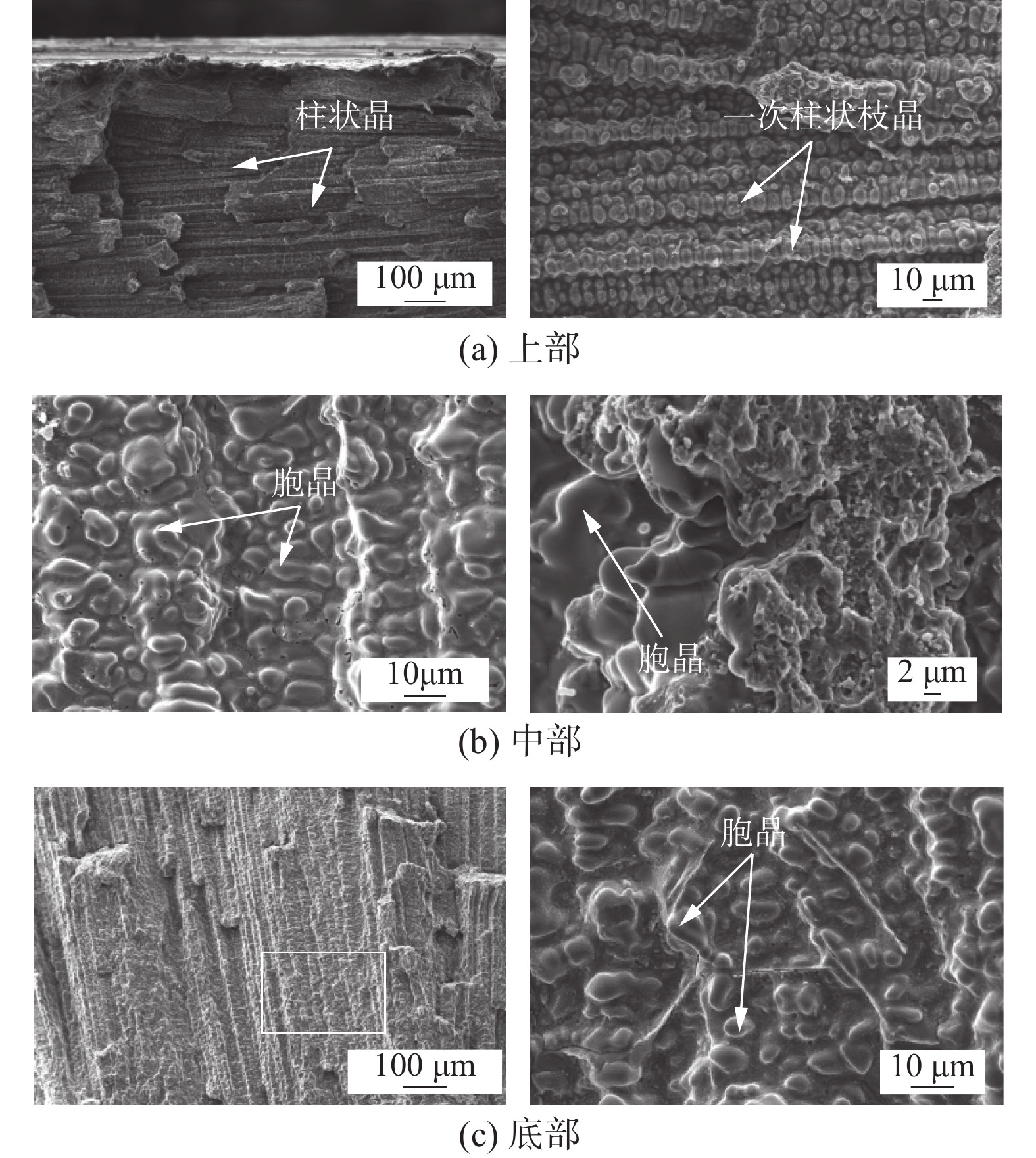

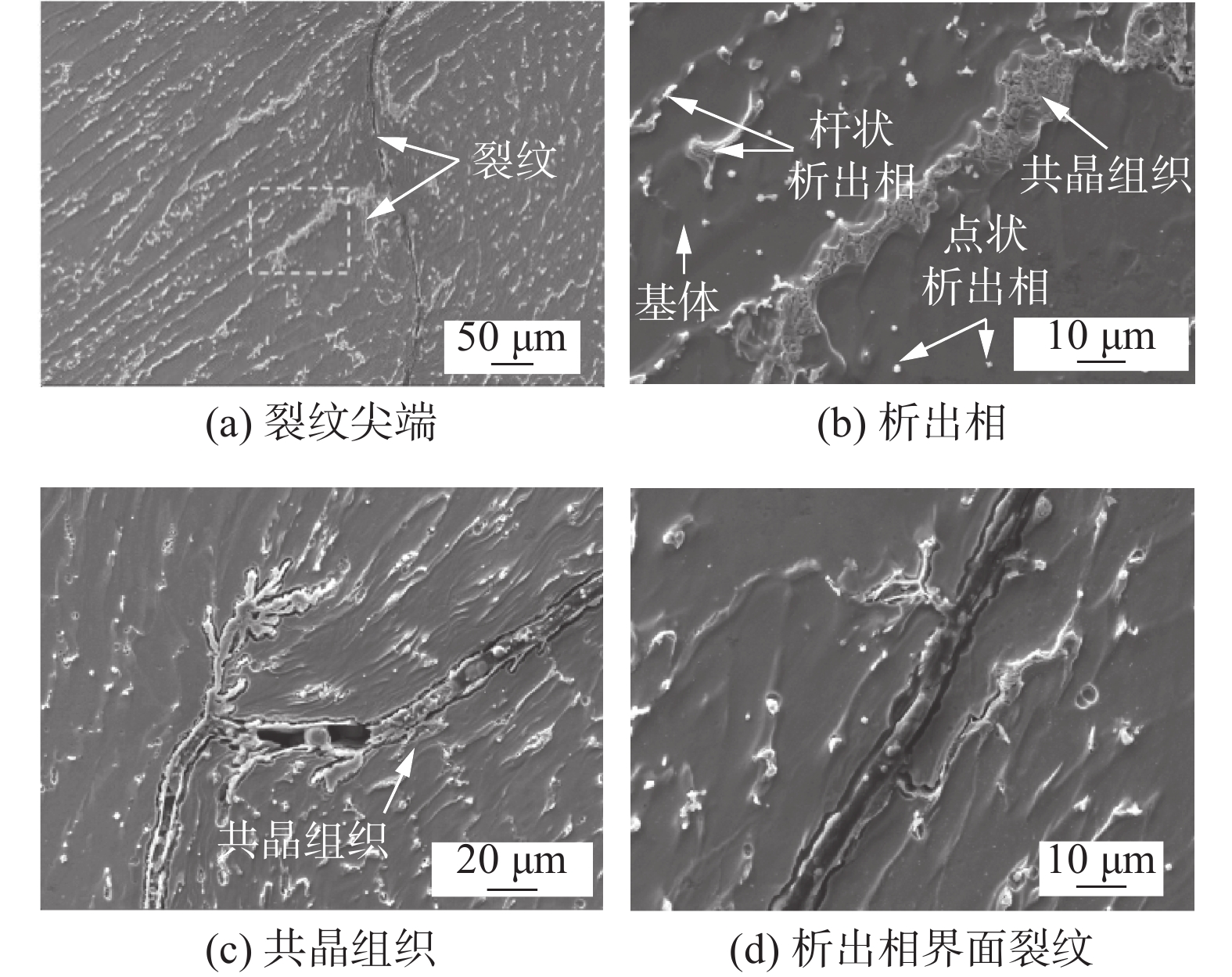

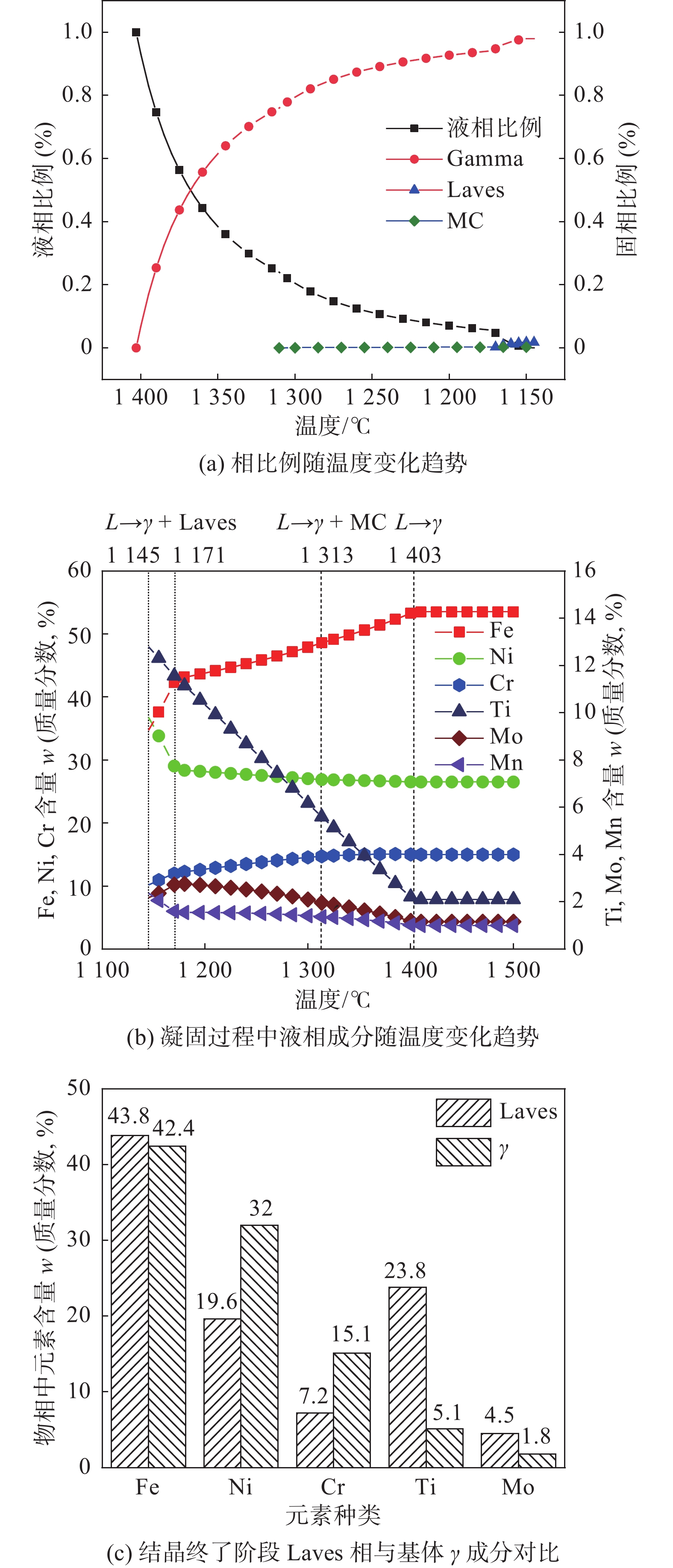

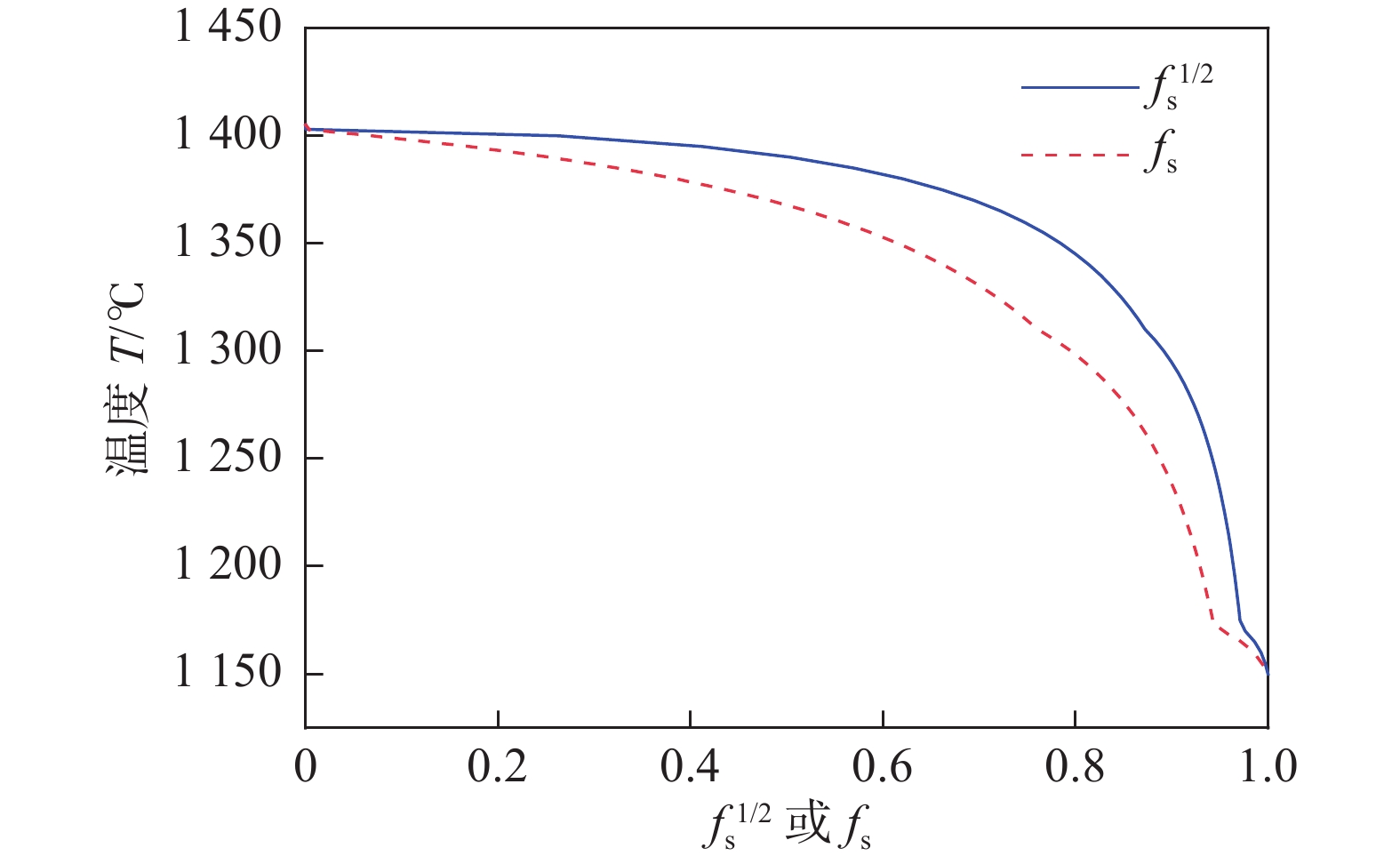

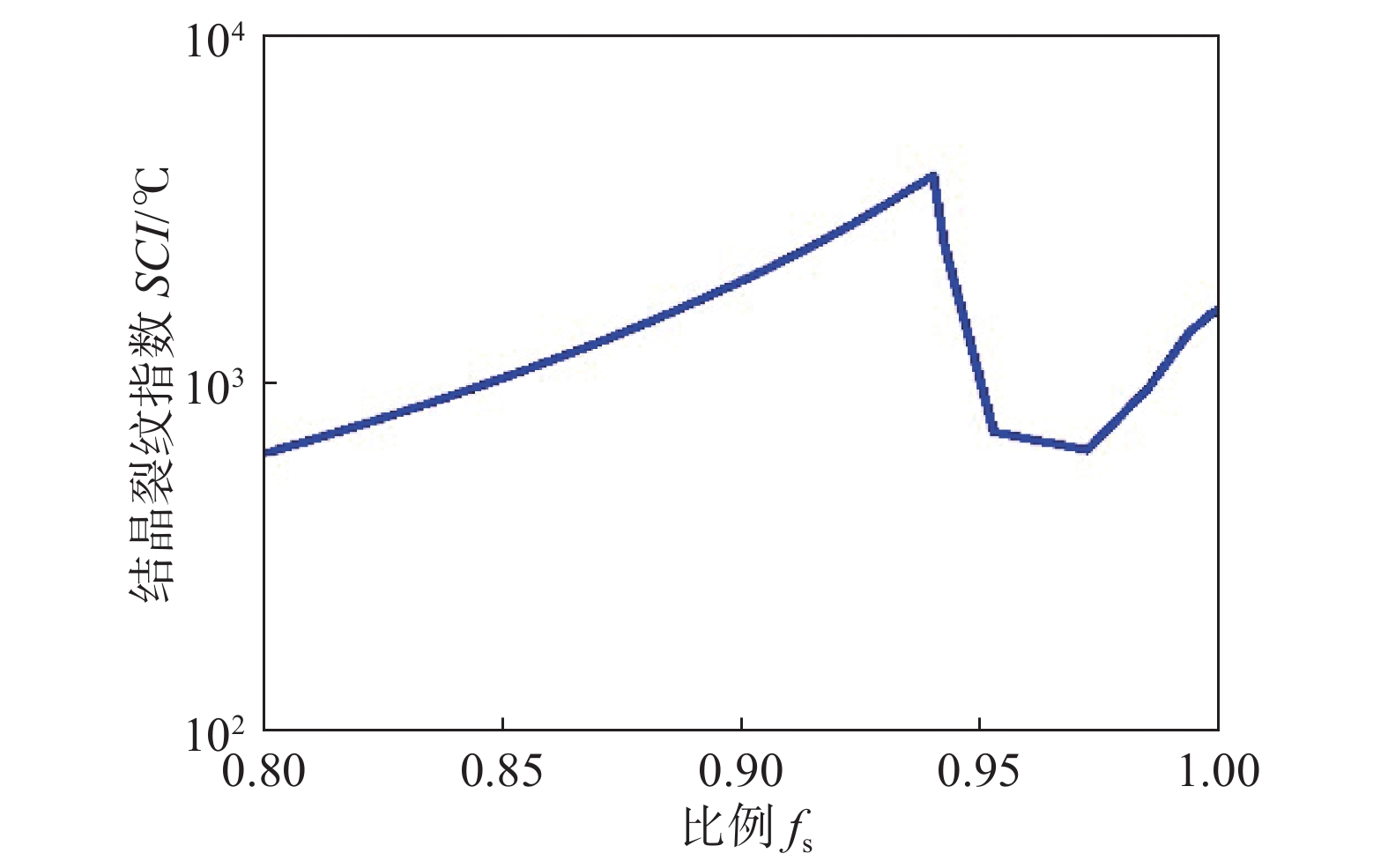

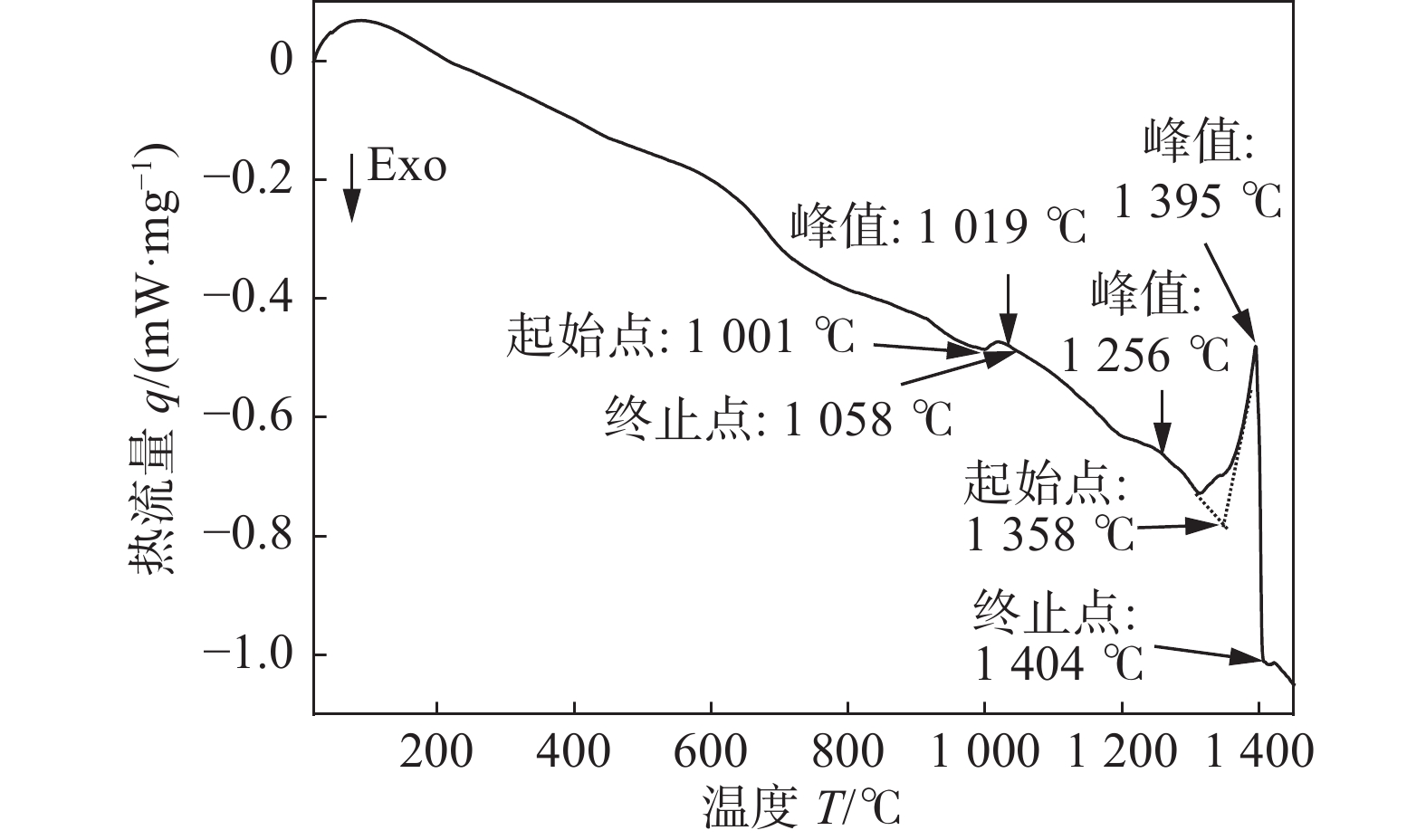

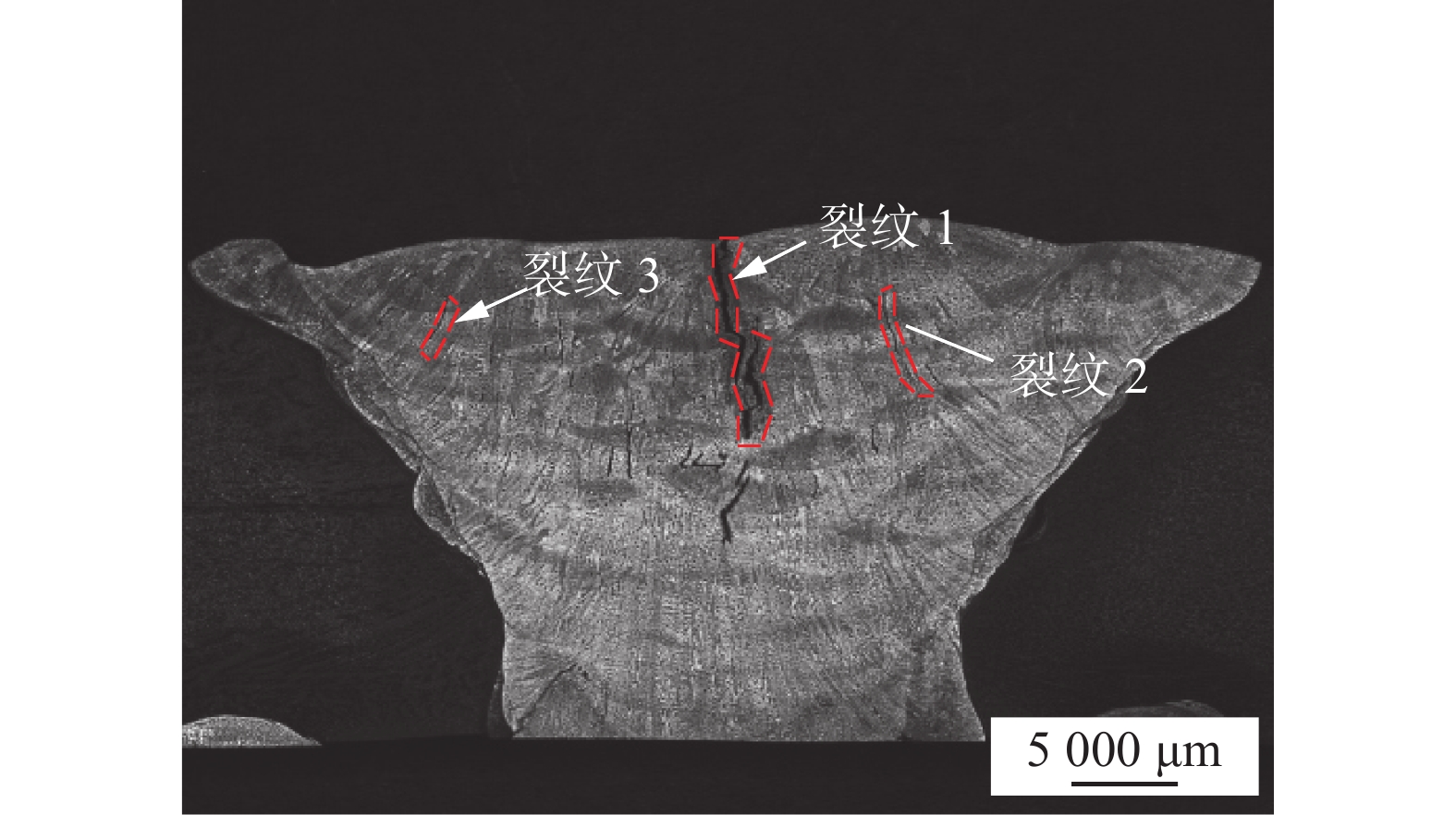

摘要: 针对GH2132高温合金熔敷金属热裂纹敏感性问题,通过采用试制焊丝、熔敷金属焊接试验、组织及断口分析、凝固计算等手段对熔敷金属组织、凝固行为、开裂机制等进行了研究. 结果表明,试验熔敷金属金相组织主要由柱状树枝晶γ相(NiCrFe固溶体)、枝晶间富Ti的Laves相(Cr,Fe,Ni)2 (Ti,Mo)、MC碳化物与共晶组织组成,凝固路径为L→L + γ→L + γ + MC→L + γ + MC + Laves→γ + MC + Laves,裂纹断口呈典型的鹅卵石共晶花样,整个断口形貌被呈自由表面的液膜所覆盖,属于发生在高温段的结晶裂纹. 结晶裂纹开裂机理为在凝固过程的终了阶段,发生了L→γ + Laves的低熔点共晶反应,在凝固收缩应力作用下,残余液相未及时补充而形成. Laves相的形成主要与凝固过程中Ti元素的偏析有关,理论计算结果表明,GH2132结晶裂纹指数(solidification cracking index, SCI)值为1944 ℃,(solidification temperature range, STR)为258 ℃,在结晶裂纹敏感性评价方面,相比STR,SCI指标能相对更为合理地实现结晶裂纹敏感性的量化评价,但仍存在考虑因素不全等问题.Abstract: Aiming at the problem of high sensitivity of hot crack in GH2132 superalloy welding, the microstructure, solidification behavior and cracking mechanism of GTAW deposited metal were studied by new developed welding wire, welding test of deposited metal, microstructural and fracture analysis, solidification calculation. The results show that the microstructure of the deposited metal was mainly composed of columnar dendrite γ phase (NiCrFe solid solution), Ti rich in Laves phase (Cr, Fe, Ni)2(Ti, Mo), MC carbides and eutectic structure in the interdendritic. The solidification mode of the new developing wire was L→L + γ→L + γ + MC→L + γ + MC + Laves→γ + MC + Laves. The fracture surface showed typical cobblestone eutectic pattern, and the whole fracture morphology was covered by liquid film with free surface, indicating that the crystal crack occurred in the high temperature section. The mechanism of solidification crack was L→γ + Laves eutectic reaction with low melting point occurs at the terminal stage of solidification process. Under the action of solidification shrinkage stress, the residual liquid phase was not replenished in time and formed. The formation of Laves phase was mainly related to the segregation of Ti element during solidification. The theoretical calculation results show that the SCI (Solidification Cracking Index) value of GH2132 was 1944 ℃, and the STR (Solidification Cracking Range) was 258 ℃. In the evaluation of crystal crack sensitivity, SCI index can achieve the quantitative evaluation of crystal crack sensitivity more reasonably than STR, but there are still some problems such as incomplete factors to be considered.

-

Keywords:

- superalloy /

- solidification crack /

- Laves phase

-

-

图 5 Scheil凝固计算结果

Figure 5. Solidification calculated results based on Scheil model. (a) Trend of phase proportion with temperature; (b) The composition of liquid phase changes with temperature during solidification; (c) The composition of Laves phase was compared with matrix γ at the end of crystallization

表 1 GTAW工艺参数

Table 1 GTAW parameters

焊接电流I/A 电弧电压U/V 焊接速度v1 /(mm∙min−1) 送丝速度v/(mm∙min−1) 保护气体 层温控制T/℃ 180 13.5 135 1100 99.99% Ar ≤100 表 2 试验用GH2132焊丝化学成分(质量分数,%)

Table 2 Compositions of experimental GH 2132 wire(wt. %)

C Cr Ni Mo Fe Ti 0.055 15.01 26.17 1.16 余量 2.09 S P Si Mn V Al 0.008 0.015 0.49 1.03 0.32 0.18 表 3 熔敷金属各典型相EDS分析结果(质量分数,%)

Table 3 EDS results of typical phases in deposited metal

分析 Ti Ni Cr Fe 基体 1.1±0.4 24.8±1.0 15.8±0.5 55.1±1.5 点状析出相 47.8±1.5 11.6±1.0 9.0±1.0 24.4±1.5 杆状析出相 20.8±1.5 26.1±1.5 6.6±0.4 45.6±2.3 液膜 12.6±2.3 28.2±0.5 13.9±2.4 41.7±3.2 共晶组织 18.8±0.8 32.1±0.9 7.9±0.2 30.3±1.3 表 4 基于凝固计算的不同高温合金SCI和STR对比[16]

Table 4 SCI and STR comparison for various alloy based upon prediction by Scheil solidification model

合金体系 结晶裂纹指数SCI/℃ 凝固温度区间STR/℃ fs = 0.8 ~ 0.9 fs = 0.9 ~ 0.99 fs = 0.8 ~ 0.99 Scheil凝固 GH2132 1249 2409 1944 258 CM247LC 875 15980 14109 392 IN718 1459 921 1261 264 IN738LC 787 6681 5711 286 -

[1] Ojo O A, Richards N L, Chaturvedi M C. Study of the fusion zone and heat-affected zone microstructures in tungsten inert gas-welded INCONEL 738LC superalloy[J]. Metallurgical and Materials Transactions A, 2006, 37(2): 421 − 433. doi: 10.1007/s11661-006-0013-2

[2] AckermannH. , Kosseva G T, Lucka K, et al. Oxidation behavior of selected wrought Ni-base high temperature alloy when used as flame tube material in modern blue flame oil burners[J]. Corrosion Science, 2007, 49(10): 3866 − 3879. doi: 10.1016/j.corsci.2007.05.021

[3] Huang Changming, Zou Bin, Guo Peng, et al. Sliding behavior and wear mechanism of iron and cobalt-based high-temperature alloys against WC and SiC balls[J]. Journal of Refractory Metals and Hard Materials, 2016, 59(9): 40 − 55.

[4] Bornassi S, Ghalandari M, Maghrebi S F. synchronous vibration measurements of a new upgraded heavy duty gas turbine MGT-70(3) by using tip-timing method[J]. Mechanics Research Communications, 2020, 104(3): 103484.

[5] Reed R C, Tao T, Warnken N. Alloys-By-Design: application to nickel-based single crystal superalloys[J]. Acta Materialia, 2009, 57(11): 5898 − 5913.

[6] Chen Y, Zhang K, Huang J, et al. Characterization of heat affected zone liquation cracking in laser additive manufacturing of Inconel 718[J]. Materials & Design, 2016, 90: 586 − 594.

[7] Chen K C, Chen T C, Shiue R K, et al. Liquation cracking in the heat-affected zone of IN738 superalloy weld[J]. Metals, 2018, 8(6): 387 − 399. doi: 10.3390/met8060387

[8] Taheri, M. Analysis of solidification and liquation cracks in the electron beam welding of IN738 superalloy[J]. Metallography, Microstructure, and Analysis, 2021, 10: 815 − 822. doi: 10.1007/s13632-021-00793-z

[9] 刘爱胜. GH2132合金材料平板堆焊层的组织性能[J]. 金属世界, 2022(1): 10 − 14. doi: 10.3969/j.issn.1000-6826.2022.01.0002 Liu Aisheng. Microstructure and properties of GH2132 alloy plate surfacing layer[J]. Metal World, 2022(1): 10 − 14. doi: 10.3969/j.issn.1000-6826.2022.01.0002

[10] 张秉刚, 彭飞, 王厚勤, 等. 沉淀强化镍基高温合金熔化焊液化裂纹研究进展[J]. 焊接, 2019(9): 26 − 31+66. Zhang Binggang, Peng Fei, Wang Houqin, et al. Research progress on liquation cracking of precipitation hardened nickel-based superallloys in fusion welding[J]. Welding & Joining, 2019(9): 26 − 31+66.

[11] Kou S. A criterion for cracking during solidification[J]. Acta Materialia, 2015, 88(4): 366 − 374.

[12] 王磊, 李赫, 黄勇, 等. 各向异性对焊接凝固裂纹影响规律的相场法模拟[J]. 焊接学报, 2021, 42(12): 83 − 86. doi: 10.12073/j.hjxb.20210309001 Wang Lei, Li He, Huang Yong, et al. Phase field investigation on solidification cracking susceptibility in the molten pool under different anisotropy[J]. Transactions of the China Welding Institution, 2021, 42(12): 83 − 86. doi: 10.12073/j.hjxb.20210309001

[13] Soysal T, Kou S. A simple test for assessing solidification cracking susceptibility and checking validity of susceptibility prediction[J]. Acta Materialia, 2018, 143(1): 181 − 197.

[14] 王俊, 李芳, 张跃龙, 等. 焊丝中Si元素含量对铝合金接头裂纹敏感性的影响规律及机理[J]. 焊接学报, 2020, 41(1): 55 − 60. Wang Jun, Li Fang, Zhang Yuelong, et al. Effect of Si content in welding wire on crack sensitivity of aluminum alloy joints and its mechanism[J]. Transactions of the China Welding Institution, 2020, 41(1): 55 − 60.

[15] 闫英杰, 张凯嘉, 王若蒙, 等. 稀释率对ENiCrFe-7焊材熔敷金属隔离层中凝固裂纹的影响机理[J]. 焊接学报, 2020, 41(7): 12 − 17. doi: 10.12073/j.hjxb.20200202001 Yan Yingjie, Zhang Kaijia, Wang Ruomeng, et al. Effect mechanism of dilution on solidification crack in ENiCrFe-7 buffering layer of deposited metal[J]. Transactions of the China Welding Institution, 2020, 41(7): 12 − 17. doi: 10.12073/j.hjxb.20200202001

[16] Yuanbo T. Tang, Chinnapat Panwisawas, et al. Alloys-by-design: Application to new superalloys for additive manufacturing[J]. Acta Materialia, 2021(202): 417 − 436.

[17] Wheeling, R. A., Lippold, J. C. Effect of composition on grain boundary wetting characteristics in Ni-30Cr weld metal[J]. Welding in the World, 2017, 61(03): 315 − 324.

[18] Jia Q, Rometsch P, Kürnsteiner P, et al. Selective laser melting of a high strength AlMnSc alloy: alloy design and strengthening mechanisms[J]. Acta Mater, 2019, 171(6): 108 − 118.

[19] 郑亮, 刘玉峰, 刘杨, 等. 高温合金差示扫描量热分析(DSC)的影响因素研究: 合金状态和升/降温速率[J]. 稀有金属材料与工程, 2019, 48(6): 1944 − 1953. Zheng Liang, Liu Yufeng, Liu Yang, et al. Influencing factors of differential scanning calorimetry (DSC) analysis of superalloy: alloy state and heating/cooling rate[J]. Rare Metal Materials and Engineering, 2019, 48(6): 1944 − 1953.

-

期刊类型引用(5)

1. 罗雨,高萌萌,许耀波,任飞燕,于俊杰,田文鹏,刘铂洋. 基于虚拟现实的立管横焊机器人辅助焊接工艺设计与实现. 机床与液压. 2024(13): 110-115+236 .  百度学术

百度学术

2. 陈昌荣,张子旺,江吉彬,练国富,汪草宏. 基于不确定推理的风电塔筒焊接工艺. 福建工程学院学报. 2023(03): 237-243 .  百度学术

百度学术

3. 高昶霖,宋燕利,左洪洲,章诚. 基于动态权重的自适应PSO-BP神经网络焊接缺陷成因诊断. 焊接学报. 2022(01): 98-106+119-120 .  本站查看

本站查看

4. 王巧玲,荣建,陈洪宇,魏艳红,荣佑珍,吴振勇. 航空用焊接数据库及专家系统平台的设计与开发. 电焊机. 2018(09): 16-20 .  百度学术

百度学术

5. 沈彦. 基于多目标决策法的电站锅炉焊接专家系统设计. 黑龙江大学自然科学学报. 2016(03): 303-307 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: