Microstructure and properties of GTAW welded joint of 2195 Al-Li alloy in different forming states

-

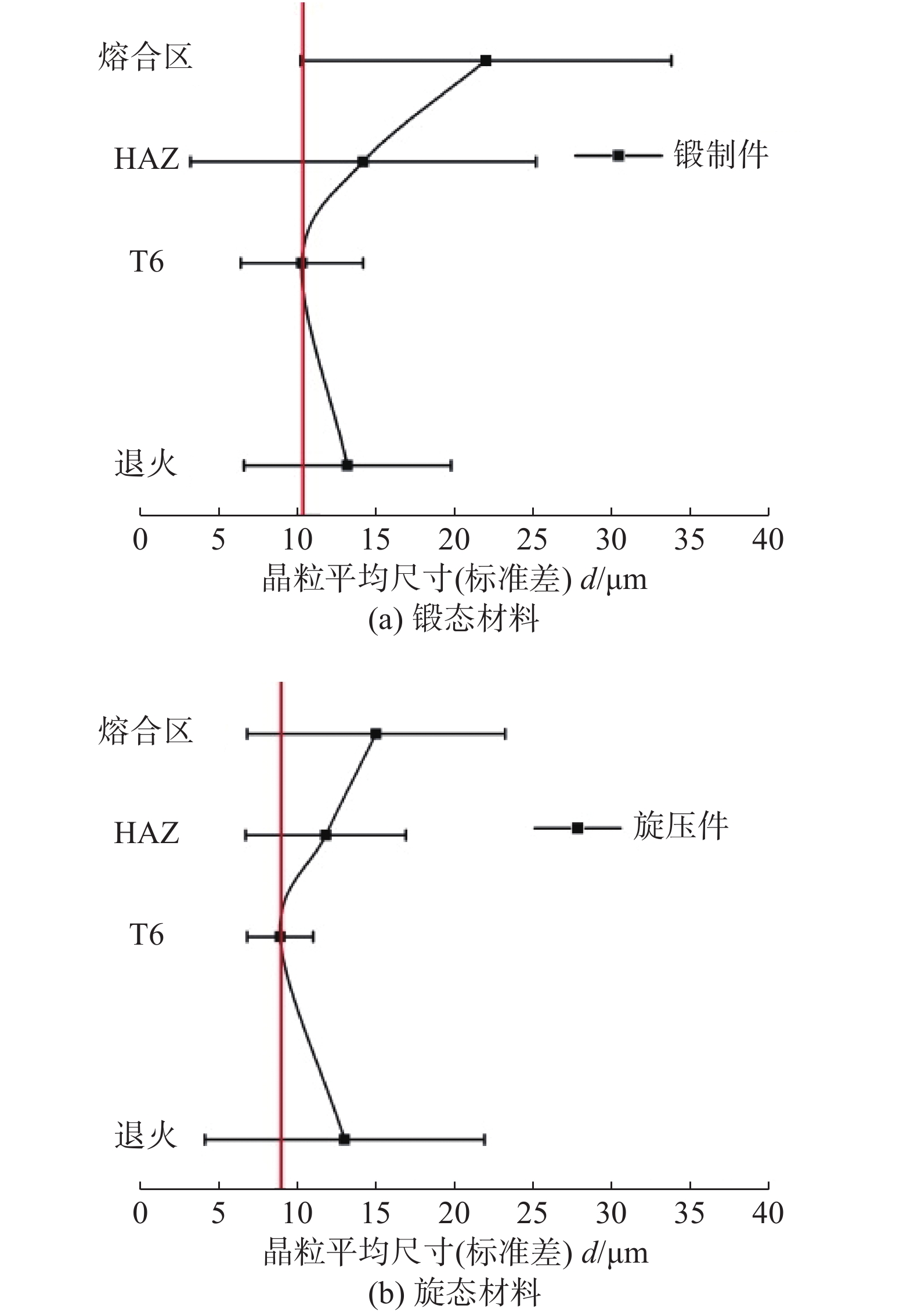

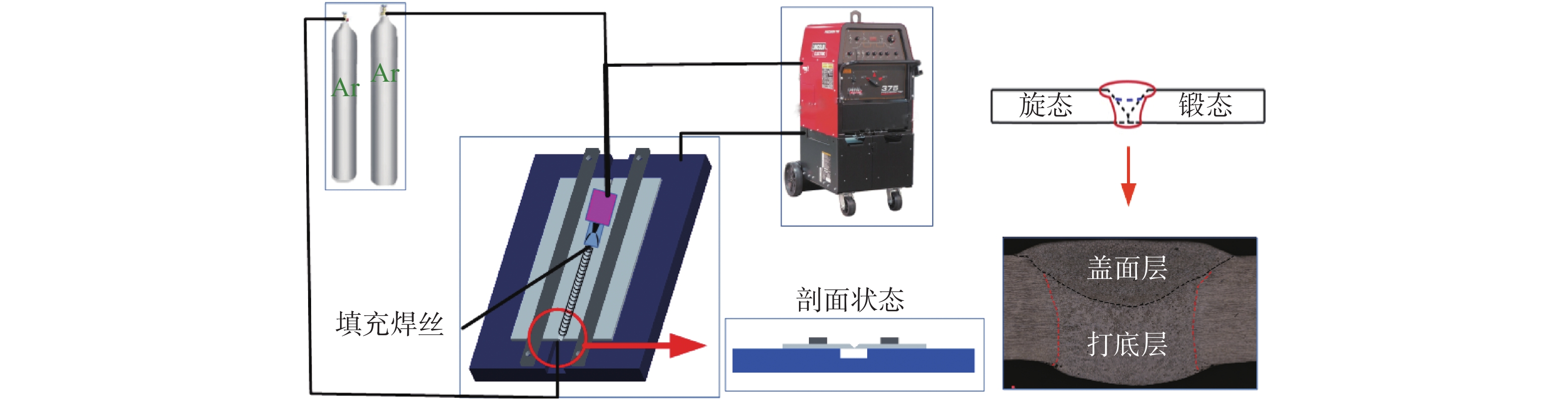

摘要: 采用喷射沉积2195铝锂合金旋态和锻态材料进行了GTAW对接焊,检测了接头抗拉强度和维氏硬度,观察了接头金相组织及断口形貌,对接头各区域进行了EBSD表征和微观特征量的统计分析,讨论了接头微观组织与力学性能的相关性. 结果表明,旋、锻态材料具有良好的GTAW工艺性,接头抗拉强度达到了各自母材的71%和68%,断后伸长率达到7.3%,拉伸断口呈现出韧性断裂特征. 接头焊缝区金属的小角度晶界比例较低,靠近旋侧的小角度晶界比例为6.4%,靠近锻侧的小角度晶界比例为7.8%;旋侧与锻侧的焊接热影响区及熔合区均趋于一种相似的微结构,母材、热影响区、熔合区及焊缝金属的平均晶粒尺寸依次处于10,10 ~ 15,15 ~ 23,20 ~ 25 μm的水平,具有较好的组织“连续性”,母材晶粒细小、成分均匀的特点在焊接过程中得到了保持,一定程度上展现了喷射沉积铝锂合金材料的应用优势.Abstract: GTAW butt welding was carried out using spray-deposited 2195 aluminum-lithium alloy spinning and forging materials. The tensile strength and Vickers hardness of the joint were measured, and the metallographic microstructure and fracture morphology of the joint were observed. The EBSD characterization and statistical analysis of micro characteristic quantity were carried out for each area of the joint. The correlation between microstructure and mechanical properties of the joint was discussed. The results show that the spinning and forging materials have good GTAW processability, the tensile strength of the joint reaches 71% and 68% of the respective base materials, the elongation reaches 7.3%, and the tensile fracture shows ductile fracture characteristics. The proportion of low angle grain boundary of the metal in the joint weld zone is relatively low. The proportion of low angle grain boundary close to the spin side is 6.4%, and the proportion of low angle grain boundary close to the forging side is 7.8%. The heat affected zone between the spin side and the forging side and the fusion zone tend to similar microstructure. The average grain size of the base material, heat affected zone, fusion zone and weld metal are in order of 10, 10 − 15, 15 − 23, 20 − 25 μm, with the better “continuity” of the structure. The fine grain size and uniform composition of the base material are maintained during the welding process, which to a certain extent shows the application advantages of spray-deposited aluminum-lithium alloy materials.

-

Keywords:

- spray deposited /

- 2195 aluminum lithium alloy /

- GTAW /

- microstructure /

- mechanical properties

-

-

表 1 SD2195铝锂合金主要化学成分(质量分数,%)

Table 1 Main chemical compositions of the SD2195 Al-Li alloy

Cu Mn Mg Ag Si Fe Zr Li Al 3.80 0.000 6 0.45 0.30 0.066 0.035 0.12 0.86 余量 表 2 焊丝的主要化学成分(质量分数,%)

Table 2 Main chemical compositions of welding wire

Cu Si Ti Zr Fe Mn Ag Al 6.44 0.28 0.35 0.26 0.080 0.001 1 0.35 余量 表 3 SD2195铝锂合金旋、锻态母材力学性能

Table 3 Mechanical properties of SD2195 Al-Li alloy in spinning and forged states

材料状态 抗拉强度Rm/MPa 屈服强度ReL/MPa 断后伸长率A(%) 锻制板-T6 495 422 9.5 旋压板-T6 490 437 6.5 表 4 SD2195铝锂合金不同成形状态母材微结构特征量的统计对比

Table 4 Statistics and comparison of microstructure features of SD2195 Al-Li alloy in different forming states

材料状态 再结晶晶粒比例δ1(%) 亚结构晶粒比例δ2(%) 变形晶粒比例δ3(%) 小角度晶界比例δ4(%) 平均晶粒尺寸(标准差)d/μm 锻制板-T6 16.5 7.1 76.4 30.1 10.3(3.9) 旋压板-T6 7.1 0.3 92.6 33.6 8.9(2.1) 轧板- T6(对比) 6.1 13.2 80.7 25.4 12.5(8.9) 表 5 旋-锻态接头微结构特征量统计

Table 5 Statistics of microstructural characteristics of spun-forged joint

材料状态/表征位置 再结晶晶粒比例δ1(%) 亚结构晶粒比例δ2(%) 变形晶粒比例δ3(%) 小角度晶界比例δ4(%) 平均晶粒尺寸(标准差)d/μm 旋侧-母材(HAZ) 23.9 5.2 60.9 22.3 11.8(6.8) WM(均值) 51.3 42.3 6.5 6.4 22.5(9.9) FZ(均值) 41.6 10.9 47.5 24.5 16.2(8.2) 锻侧-母材(HAZ) 18.9 9.4 71.7 27.5 15.4(9.4) WM(均值) 29.9 59.9 10.3 7.8 24.9(9.9) FZ(均值) 35.3 37.2 27.6 29.1 22.6(10.7) 表 6 旋-锻态接头力学性能及与母材的对比

Table 6 Mechanical properties of the spun-forged joint and comparison with base metal

接头/材料状态 抗拉强度Rm/MPa 抗拉强度均值 $\overline {{R_{\rm{m}}}} $ /MPa断后伸长率A(%) 断后伸长率均值 $\overline A $ (%)备注 旋-锻态接头 341 339 8.0 7.3 1号试样,断裂于锻侧HAZ 338 6.0 2号试样,断裂于锻侧熔合线 337 8.0 3号试样,断裂于旋侧HAZ 旋态母材(对比) 475 6.5 3个试样均值 锻态母材(对比) 495 9.5 3个试样均值 -

[1] Gupta R, Nayan N, Nagasireesha G, et al. Development and characterization of Al-Li alloys[J]. Materials Science and Engineering: A, 2006, 420(1): 228 − 234.

[2] Kostrivas A, Lippold J C. Weldability of Li-bearing aluminum alloys[J]. International Materials Reviews, 1999, 44(6): 217 − 237. doi: 10.1179/095066099101528289

[3] Fielding Paul S, Gorge J. Aluminum-lithium for aerospace[J]. Advanced Materials and Processes, 1996, 150(10): 2 − 24.

[4] Jiang Xunyan, Cheng Donghai, Chen Yiping, et al. The superplastic deformation of electron beam welded aluminum lithium alloy[J]. China Welding, 2018, 27(1): 41 − 45.

[5] 李杨. 分级时效工艺对2195铝锂合金拉伸性能的影响[D]. 哈尔滨: 哈尔滨工业大学, 2009. Li Yang. The effect of graded aging process on the tensile properties of 2195 Al-Li alloy[D]. Harbin: Harbin Institute of Technology, 2009.

[6] 马云龙, 杨子奇, 李劲风. 2195铝锂合金摩擦搅拌焊接头组织与腐蚀行为[J]. 焊接学报, 2019, 40(10): 142 − 147. Ma Yunlong, Yang Ziqi, Li Jinfeng. Microstructure and corrosion behavior of friction stir welded joints of 2195 Al-Li alloy[J]. Transactions of the China Welding Institution, 2019, 40(10): 142 − 147.

[7] 赵云鹏, 曾福明, 周志勇, 等. 新型铝合金的发展及其在密封舱结构上的工程应用[J]. 载人航天, 2016, 22(3): 302 − 307. doi: 10.3969/j.issn.1674-5825.2016.03.005 Zhao Yunpeng, Zeng Fuming, Zhou Zhiyong, et al. Development of new aluminum alloy and its engineering application in sealed cabin structure[J]. Manned Spaceflight, 2016, 22(3): 302 − 307. doi: 10.3969/j.issn.1674-5825.2016.03.005

[8] 陆正萍. 喷射成形超高强度铝合金搅拌摩擦焊接头组织性能研究[D]. 镇江: 江苏科技大学, 2015. Lu Zhengping. Research on microstructure and properties of spray formed ultra-high strength aluminum alloy friction stir welded joints[D]. Zhenjiang: Jiangsu University of Science and Technology, 2015.

[9] 罗传光, 李桓, 马飞, 等. 喷射成形2195铝锂合金封头旋压及焊接试验研究[J]. 天津大学学报, 2020, 53(8): 803 − 808. Luo Chuanguang, Li Huan, Ma Fei, et al. Spinning and welding test investigation of shell cover of spray-formed 2195 Al-Li alloy[J]. Journal of Tianjin University, 2020, 53(8): 803 − 808.

[10] Brooks R G, Moore C, Leatham A G, et al. The Osprey process[J]. Powder Metallurgy, 1977, 20(2): 100 − 102. doi: 10.1179/pom.1977.20.2.100

[11] Mathur P, Apelian D, Lawley A. Analysis of the spray deposition process[J]. Acta Metallurgica, 1989, 37(2): 429 − 443. doi: 10.1016/0001-6160(89)90227-7

[12] 于福胜. 运载火箭贮箱材料2195铝锂合金焊接性研究[D]. 天津: 天津大学, 2017. Yu Fusheng. Study on weldability of 2195 Al-Li Alloy for carrier rocket tank[D]. Tianjin: Tianjin University, 2017.

[13] Zhang Yuhui, Li Huan, Luo Chuanguang, et al. Effects of filler wires on the microstructure and mechanical properties of 2195-T6 Al-Li alloy spray formed by TIG welding[J]. Materials, 2019, 12(21): 3559. doi: 10.3390/ma12213559

[14] Zhai T, Wilkinson A J, Martin J W. A crystallographic mechanism for fatigue crack propagation through grain boundaries[J]. Acta Materialia, 2000, 48(20): 4917 − 4927.

[15] Jin Y J, Lu H, Yu C, et al. Study on grain boundary character and strain distribution of intergranular cracking in the CGHAZ of T23 steel[J]. Materials Characterization, 2013, 84(10): 216 − 224.

[16] Zhang Z F, Wang Z G. Comparison of fatigue cracking possibility along large- and low-angle grain boundaries[J]. Materials Science & Engineering A, 2000, 284(1): 285 − 291.

[17] Kamaya M, Fonseca J Q D, Li L M, et al. Local plastic strain measurement by EBSD[J]. Applied Mechanics and Materials, 2007, 7: 173 − 179.

[18] 彭大暑. 金属塑性加工原理[M]. 长沙: 中南大学出版社, 2004. Peng Dashu. Principles of metal plastic processing[M]. Changsha: Central South University Press, 2004.

-

期刊类型引用(3)

1. 张化平,仇未星,周建平,王翔,唐小强,周建桂. 基于电参数的GH4099短电弧铣削加工工艺研究. 制造技术与机床. 2024(05): 101-106 .  百度学术

百度学术

2. 康蕾,刘飞,陈韬. 1050A纯铝/TA15钛合金异种金属冷焊接头组织与性能. 焊接. 2024(12): 61-66 .  百度学术

百度学术

3. 王浩,吴欣,程耀永,毛唯. K480镍基高温合金钎焊接头组织与性能. 焊接. 2022(04): 37-42+47 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: